Deactivator and preparation method thereof

A metal passivator and metal technology, applied in chemical instruments and methods, catalyst protection, physical/chemical process catalysts, etc., can solve the problems of low passivation efficiency and failure to use normally, achieve stable product quality, reduce hydrogen The effect of low yield and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A metal deactivator, comprising the following raw materials in mass percentage: 18% of metal oxide, 27% of oxidizing agent, 20% of organic amine, and 35% of solvent; wherein, the metal oxide is antimony trioxide; The oxidizing agent is hydrogen peroxide with a concentration of 30% by mass; the organic amine is triethanolamine; and the solvent is deionized water.

[0026] Described metal deactivator is prepared according to the following method:

[0027] After mixing the organic amine and the solvent, add the metal oxide, raise the temperature to 90°C within 2 hours, then start to drop the oxidant at a rate of 250 kg / hour to make the oxidant and the metal oxide react, and control the reaction temperature at 90°C. At ~120°C, antimony trioxide is converted into pentavalent antimony under the action of hydrogen peroxide, and mixed with triethanolamine and water at the same time, and samples are taken to observe whether the powder is completely dissolved; after the reaction,...

Embodiment 2

[0032] The metal passivator prepared in Example 1 was applied to the No. 1 Refinery of Lanzhou Refinery and Chemical General Plant, and compared with the use effect of the LMP-3 passivator produced by Luoyang Petrochemical Engineering Company.

[0033] Table 2 Properties of raw oil

[0034] Densitykg / cm 3

886.8 Family Composition %(m) Distillation range °C alkanes 57.7 HK 155 Aromatics 29.7 10% 324 colloid 12.6 50% 452 Heavy metal mg / kg 70% 529 Ni 3.96 Carbon residue%(m) 3.77 V 1.80 Pb 0.44

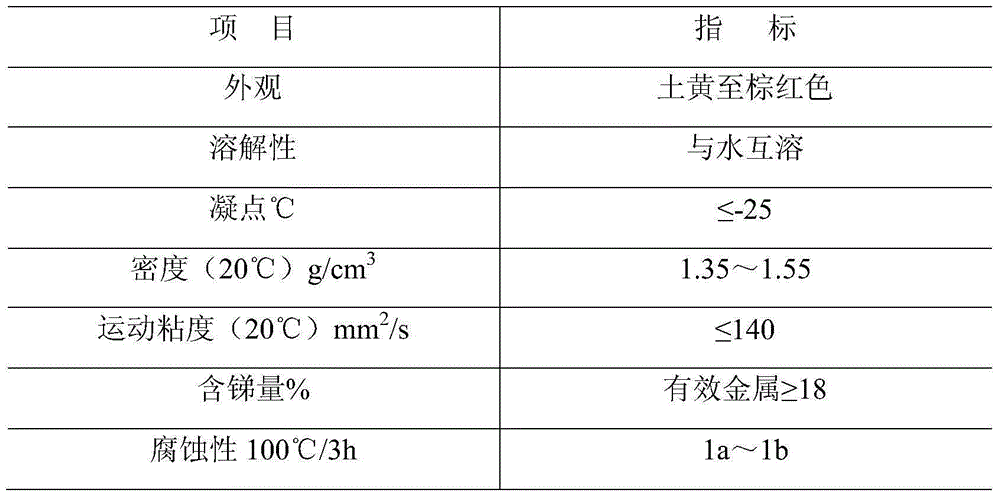

[0035] The LMP-3 type passivator after table 3 is used and the nature of embodiment 1 metal passivator

[0036]

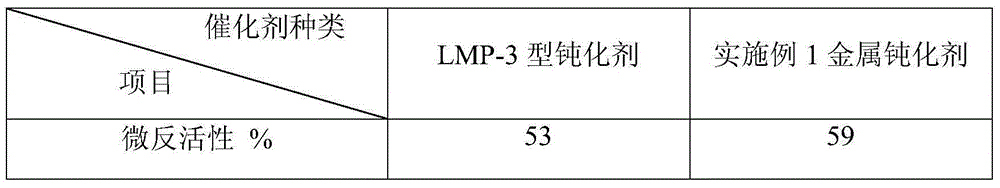

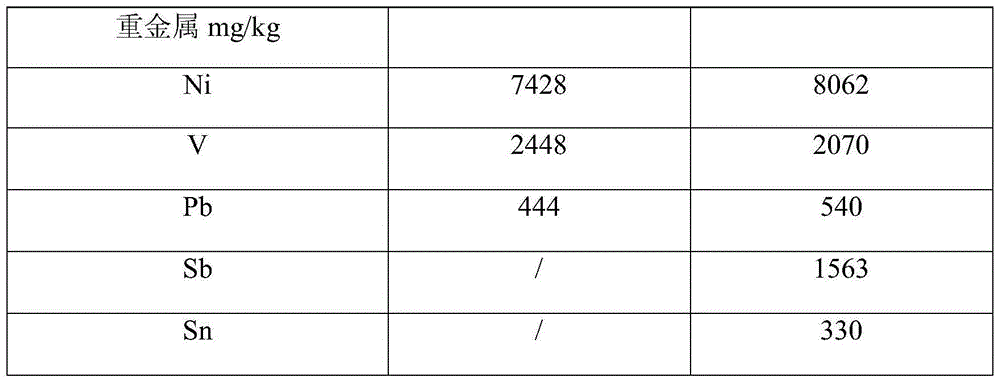

[0037]

[0038] Table 4 uses the production statistics after LMP-3 type passivator and embodiment 1 metal passivator

[0039]

[0040] From catalyst analysis (table 3) and production statistics (table 4), it can be seen that under substantially consistent operating conditions, compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com