Aqueous nano hollow glass bead heat-preservation thermal-insulating coating and preparation method thereof

A hollow glass microbead and glass microbead technology, which is used in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problem of unsatisfactory heat insulation performance, tensile performance, bacteriostatic and fungistatic performance. and other problems, to achieve the effect of short surface drying time, low thermal conductivity, and prevention of mold growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

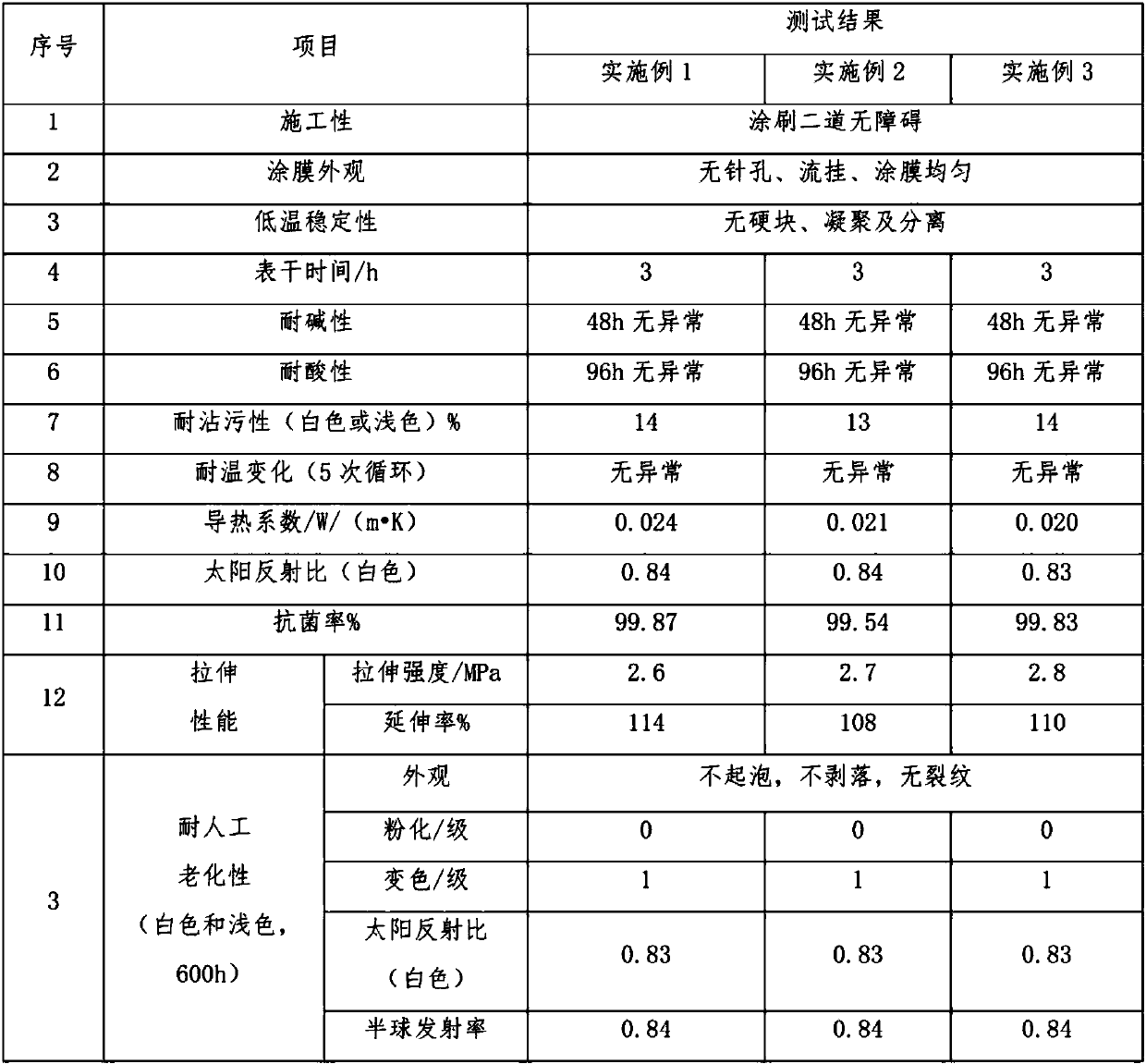

Examples

Embodiment 1

[0025] A water-based nano-hollow glass bead thermal insulation coating, which is composed of the following components in parts by weight: 20 parts of deionized water, 0.8 parts of hydroxyethyl cellulose, 45 parts of pure acrylic emulsion, 0.6 parts of 5040 sodium salt dispersant, moistening 0.2 parts of wet agent, 15 parts of nano-titanium dioxide, 5 parts of carbon calcium filler, 0.2 parts of AMP-95 multifunctional additive, 5 parts of alcohol ester twelve film-forming additives, 1.5 parts of ethylene glycol antifreeze, and 0.3 parts of fungicide 0.2 parts, antifungal agent 0.2 parts, 681F defoamer 0.2 parts, thickener 0.5 parts, hollow glass microspheres 20 parts.

[0026] Among them, the hydroxyethyl cellulose is HBR250 hydroxyethyl cellulose produced by Aqualon Company; the pure acrylic emulsion is RS9699 pure acrylic emulsion produced by Bardford; the wetting agent is PE100 wetting agent; calcium carbonate pigment The filler is 850 mesh superfine calcium carbonate pigmen...

Embodiment 2

[0032] A water-based nano-hollow glass bead thermal insulation coating, which consists of the following components in parts by weight: 10.5 parts of deionized water, 1 part of hydroxyethyl cellulose, 40 parts of pure acrylic emulsion, 0.8 parts of 5040 sodium salt dispersant, 0.3 parts of wet agent, 20 parts of nano-titanium dioxide, 10 parts of carbon calcium filler, 0.15 parts of AMP-95 multifunctional additive, 8 parts of alcohol ester twelve film-forming aids, 2 parts of ethylene glycol antifreeze, 0.2 parts of fungicide 0.3 parts of antifungal agent, 0.4 parts of 681F defoamer, 1.2 parts of thickener, and 25 parts of hollow glass microspheres.

[0033] Among them, the hydroxyethyl cellulose is HBR250 hydroxyethyl cellulose produced by Aqualon Company; the pure acrylic emulsion is RS9699 pure acrylic emulsion produced by Bardford; the wetting agent is PE100 wetting agent; calcium carbonate pigment The filler is 850 mesh ultra-fine calcium carbonate pigment filler; the fung...

Embodiment 3

[0035]A water-based nano-hollow glass bead thermal insulation coating, consisting of the following components in parts by weight: 15 parts of deionized water, 0.9 part of hydroxyethyl cellulose, 43 parts of pure acrylic emulsion, 0.7 part of 5040 sodium salt dispersant, 0.25 parts of wet agent, 18 parts of nano-titanium dioxide, 8 parts of carbon calcium filler, 0.18 parts of AMP-95 multifunctional additive, 6.5 parts of alcohol ester twelve film-forming aid, 1.7 parts of ethylene glycol antifreeze, and 0.25 parts of fungicide 0.25 parts of antifungal agent, 0.3 parts of 681F defoamer, 0.8 parts of thickener, and 22 parts of hollow glass microspheres.

[0036] Among them, the hydroxyethyl cellulose is HBR250 hydroxyethyl cellulose produced by Aqualon Company; the pure acrylic emulsion is RS9699 pure acrylic emulsion produced by Bardford; the wetting agent is PE100 wetting agent; calcium carbonate pigment The filler is 850 mesh superfine calcium carbonate pigment filler; the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com