High temperature resistant coating and preparation method thereof

A technology for high temperature resistant coatings and raw materials, which is applied in the field of coatings to achieve the effects of good high temperature resistance and corrosion resistance, long anti-corrosion time and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

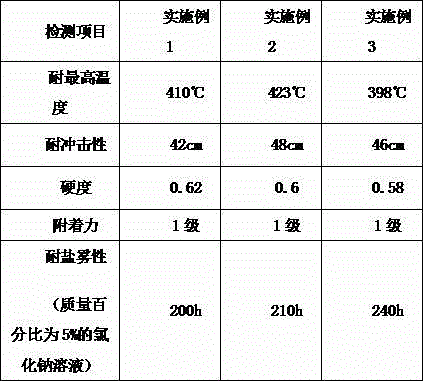

Examples

Embodiment 1

[0042] This example provides a method for preparing a high-temperature-resistant coating. The high-temperature-resistant coating is composed of two components, A and B, wherein component A and component B are the following raw materials in parts by mass: component A: acrylic resin : 65 parts, bisphenol A epoxy resin: 42 parts, castor oil: 20 parts, mica powder: 18 parts, benzyl silicone resin: 12 parts, silicone resin: 20 parts, defoamer: 2 parts, solvent : 45 parts; B component: anti-rust additive: 2 parts, leveling agent: 10 parts, catalyst: 2 parts, pigment: 8 parts, surfactant: 11 parts; the mica powder in A component is purified The mica powder, the purification method of mica powder concrete operation is as follows:

[0043] Dehydrate the organic solvent with 13X molecular sieve for 5 days for later use;

[0044] Add mica powder, organic solvent and catalyst capture agent into a 320mm three-neck flask, stir at room temperature for 40min, then let it stand for 1h, th...

Embodiment 2

[0051] This example provides a method for preparing a high-temperature-resistant coating. The high-temperature-resistant coating is composed of two components, A and B, wherein component A and component B are the following raw materials in parts by mass: component A: acrylic resin : 68 parts, bisphenol A epoxy resin: 45 parts, castor oil: 25 parts, mica powder: 24 parts, benzyl silicone resin: 16 parts, silicone resin: 25 parts, defoamer: 4 parts, solvent Component: 50 parts; B component: anti-rust additive: 4 parts, leveling agent: 12 parts, catalyst: 5 parts, pigment: 12 parts, surfactant: 13 parts; the mica powder in component A is purified The mica powder, the purification method of mica powder concrete operation is as follows:

[0052] Dehydrate the organic solvent with 13X molecular sieve for 6 days for later use;

[0053] Add mica powder, organic solvent and catalyst capture agent into a 320mm three-necked flask, stir at room temperature for 45min, then let stand f...

Embodiment 3

[0060] This example provides a method for preparing a high-temperature-resistant coating. The high-temperature-resistant coating is composed of two components, A and B, wherein component A and component B are the following raw materials in parts by mass: component A: acrylic resin : 67 parts, bisphenol A epoxy resin: 44 parts, castor oil: 24 parts, mica powder: 22 parts, benzyl silicone resin: 15 parts, silicone resin: 24 parts, defoamer: 3 parts, solvent : 48 parts; B component: anti-rust additive: 3 parts, leveling agent: 11 parts, catalyst: 4 parts, pigment: 10 parts, surfactant: 12 parts; the mica powder in A component is purified The mica powder, the purification method of mica powder concrete operation is as follows:

[0061] Dehydrate the organic solvent with 13X molecular sieve for 7 days for later use;

[0062] Add mica powder, organic solvent and catalyst capture agent into a 320mm three-necked flask, stir at room temperature for 50min, then let stand for 3h, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com