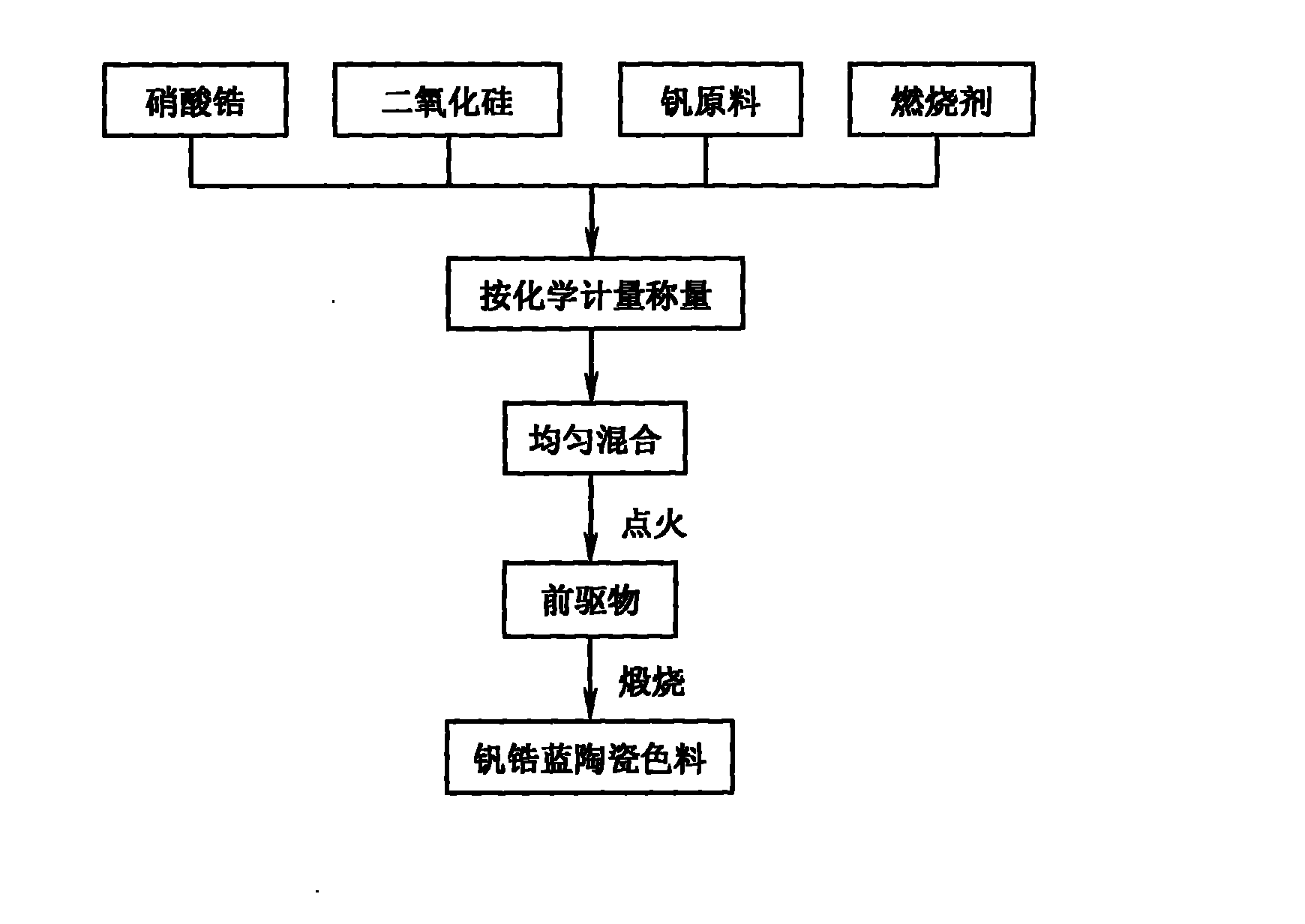

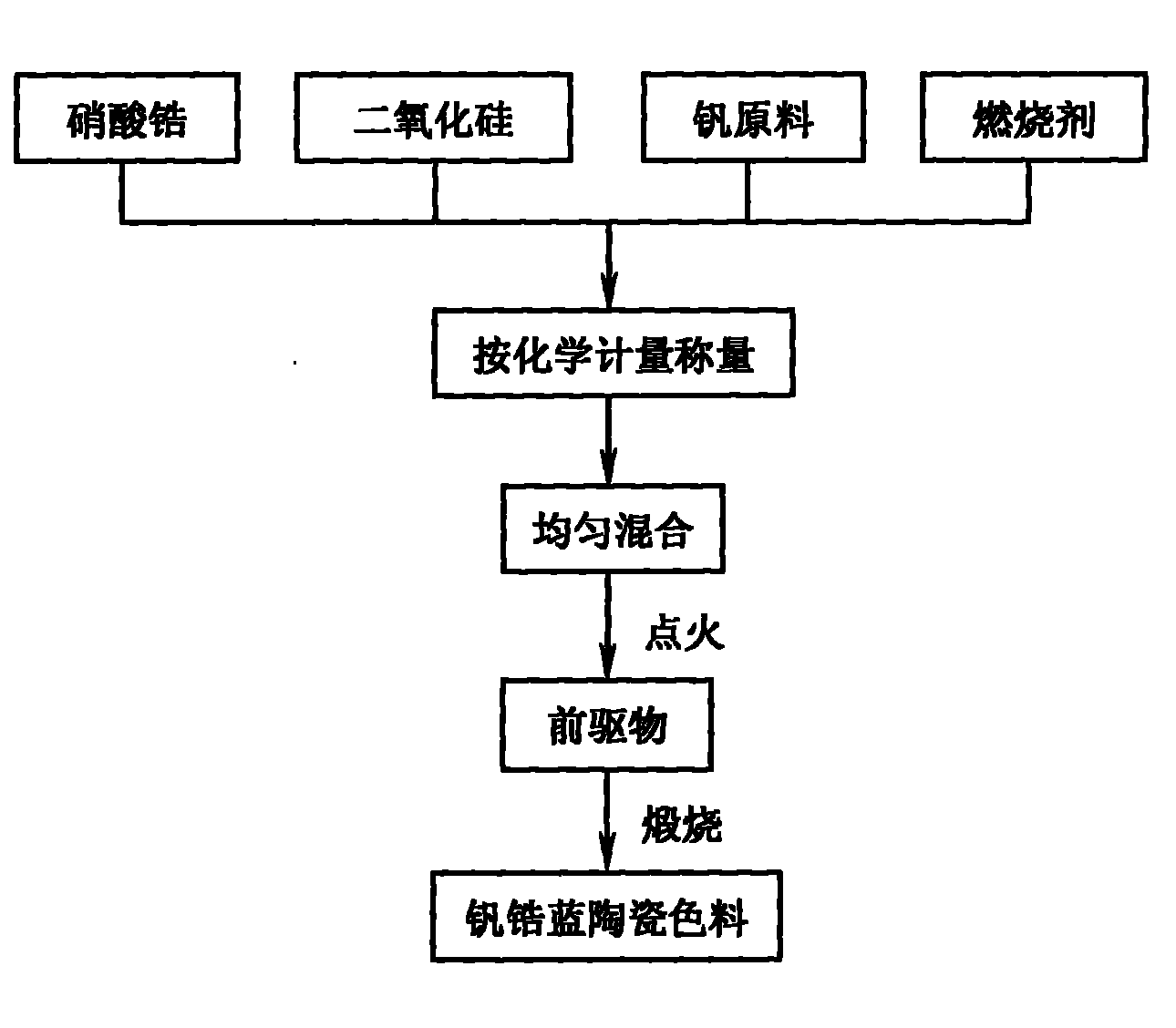

Method for preparing zircon-vanadium blue ceramic pigment

A technology of ceramic pigment and vanadium-zirconium blue, which is applied in the field of preparation of vanadium-zirconium blue ceramic pigment, can solve the problems of high price of pigment, cumbersome operation steps, lengthy process, etc., and achieve simple production process, simple operation and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 38.32 grams of zirconium nitrate, 6.01 grams of silicon dioxide and 21.69 grams of ammonium acetate were uniformly mixed, and then 2.35 grams of ammonium metavanadate were added and stirred uniformly to obtain a uniform mixture; 0.46 grams of sodium fluoride and 0.46 grams of Sodium fluorosilicate, fully grind to get a uniform mixture, put the mixture into a combustion vessel; put the mixture together with the vessel into a furnace at 550 ° C, a low-temperature combustion reaction occurs instantly, turn off the power, take out the vessel and cool it in the air After cooling, the vanadium-zirconium blue ceramic color material precursor is obtained; the precursor is calcined at 800° C. for 30 minutes, and the vanadium-zirconium blue ceramic color material with a particle size of less than 1 μm can be obtained.

Embodiment 2

[0015] 16.00 g of zirconium nitrate, 4.35 g of silicon dioxide, 5.60 g of urea and 5.60 g of citric acid were uniformly mixed, then 0.55 g of ammonium metavanadate and 0.50 g of vanadium pentoxide were added, and evenly stirred and mixed to obtain a uniform mixture. Add 0.15 grams of sodium fluoride and 0.15 grams of sodium chloride to the mixture, grind it thoroughly to obtain a uniform mixture, put the mixture into a combustion vessel; put the mixture into a furnace at 450°C together with the vessel, and a low temperature will occur instantly Combustion reaction, turn off the power, take out the vessel and cool it in the air, and obtain the vanadium-zirconium blue ceramic colorant precursor after cooling; calcinate the precursor at 900°C for 50 minutes to obtain the vanadium-zirconium blue ceramic colorant.

Embodiment 3

[0017] 38.32 grams of zirconium nitrate, 6.01 grams of superfine silicon dioxide, 11.80 grams of ammonium acetate and 12.60 grams of citric acid were uniformly mixed, and then 1.44 grams of vanadium pentoxide was added, and uniformly stirred and mixed to obtain a uniform mixture. Add 0.46 gram of sodium chloride and 0.46 gram of sodium fluorosilicate to the mixture, grind it thoroughly to obtain a uniform mixture, put the mixture into a combustion vessel; put the mixture into a furnace at 350°C together with the vessel, and A low-temperature combustion reaction occurs, the power is turned off, the vessel is taken out and cooled in the air, and the vanadium-zirconium blue ceramic colorant precursor is obtained after cooling; the precursor is calcined at 1000° C. for 20 minutes to obtain the vanadium-zirconium blue ceramic colorant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com