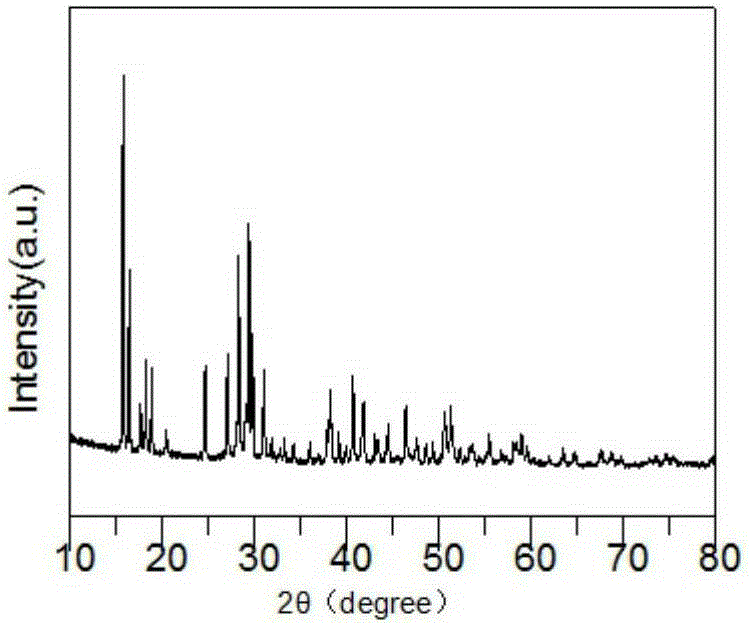

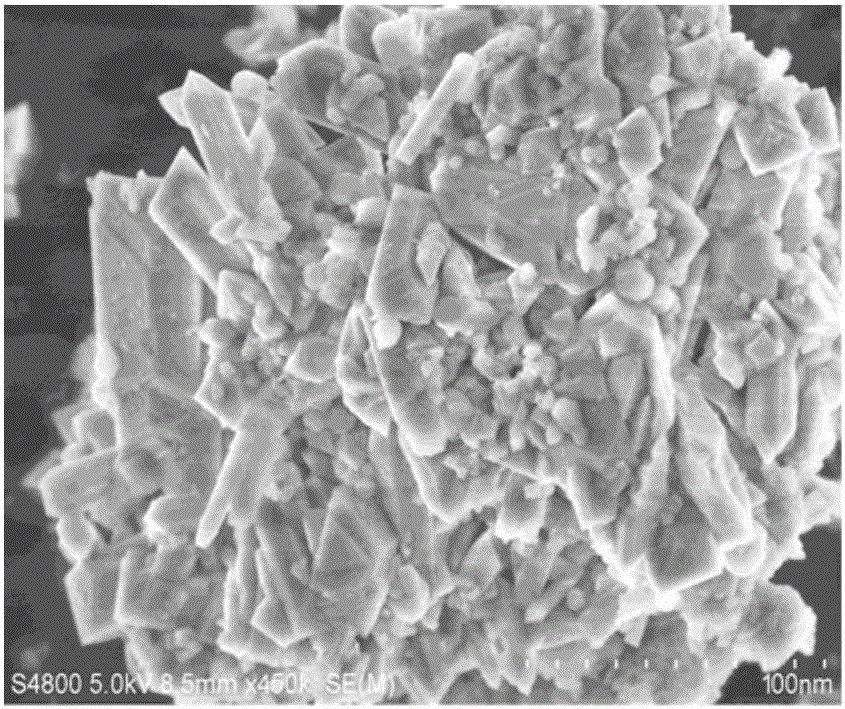

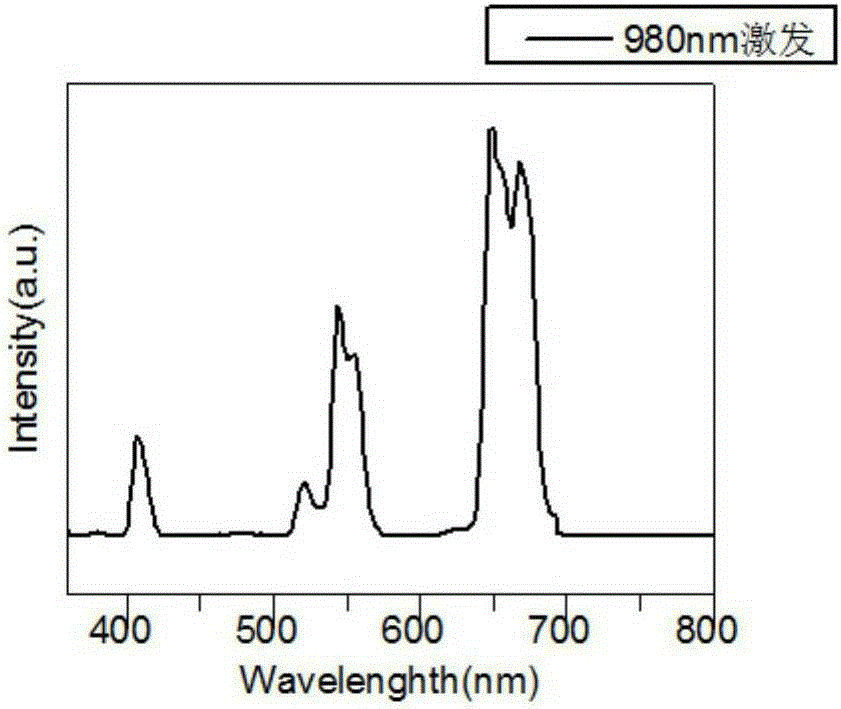

A preparation method of rare earth-doped yttrium potassium fluoride upconversion luminescent nanomaterial

A yttrium-potassium fluoride, rare earth doping technology, applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems of high pollution, high energy consumption, low yield and the like, achieve enhanced luminescence performance, overcome the preparation process, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing yttrium potassium fluoride up-conversion luminescent nanomaterials by thermal injection, the specific steps are as follows:

[0036] 1) Weigh 0.4mol of yttrium oxide (Y 2 o 3 ) and 4mol of potassium bifluoride (KHF 2 ) into a 50ml three-necked flask containing oleic acid / oleylamine solvent system, the reaction was carried out under a closed system, and after a period of vacuuming at normal temperature, the vacuum valve was closed, and then argon gas was passed into the reactor, and the reaction was carried out at 20°C / The temperature was raised to 160° C. at a heating rate of 1 min, and kept at a stirring rate of 1000 rpm / min for 30 minutes. Wherein the volume ratio of oleic acid / oleylamine is 2:1, and the amount of total solvent is 15ml;

[0037] 2) Weigh 0.2mol of ytterbium fluoride (YbF 3 ) and 0.02mol of erbium fluoride (ErF 3 ) into a 50ml three-necked flask containing oleic acid / oleylamine solvent system, the reaction was carried out u...

Embodiment 2

[0042] A method for preparing yttrium potassium fluoride up-conversion luminescent nanomaterials by thermal injection, the specific steps are as follows:

[0043] 1) Weigh 0.4mol of yttrium oxide (Y 2 o 3 ), 4mol of potassium acetate (C 2 h 3 KO 2 ) and 4mol of ammonium bifluoride (NH 4 .HF 2 ) into a 50ml three-necked flask containing oleic acid / oleylamine solvent system, the reaction was carried out under a closed system, and after a period of vacuuming at normal temperature, the vacuum valve was closed, and then argon gas was passed into the reactor, and the reaction was carried out at 20°C / The temperature was raised to 160° C. at a heating rate of 1 min, and kept at a stirring rate of 1000 rpm / min for 30 minutes. Wherein the volume ratio of oleic acid / oleylamine is 2:1, and the amount of total solvent is 15ml;

[0044] 2) Weigh 0.2mol of ytterbium fluoride (YbF 3 ) and 0.02mol of erbium fluoride (ErF 3 ) into a 50ml three-necked flask containing oleic acid / oleyla...

Embodiment 3

[0049] A method for preparing yttrium potassium fluoride up-conversion luminescent nanomaterials by thermal injection, the specific steps are as follows:

[0050] 1) Weigh 0.4mol of yttrium oxide (Y 2 o 3 ), 4mol of potassium hydrogen fluoride (KHF 2 ) into a 50ml three-necked flask containing oleic acid / oleylamine solvent system, the reaction is carried out under a closed system, and after vacuuming for a period of time at normal temperature, the vacuum valve is closed, and then argon gas is passed into the reactor, with 10 to 20 Temperature rise rate of °C / min Raise the temperature to 160 °C and keep the temperature for 30 minutes at a stirring rate of 1000 rpm / min. Wherein the volume ratio of oleic acid / oleylamine is 2:1, and the amount of total solvent is 15ml;

[0051] 2) Weigh 0.4mol of ytterbium fluoride (YbF 3 ) and 0.04mol of erbium fluoride (ErF 3 ) into a 50ml three-necked flask containing oleic acid / oleylamine solvent system, the reaction was carried out under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com