Low-refractive-index infrared optical coating material and preparing method thereof

A technology of infrared optics and low refractive index, applied in sputtering coating, metal material coating process, ion implantation coating, etc. Reduce and solve film cracks and ensure stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

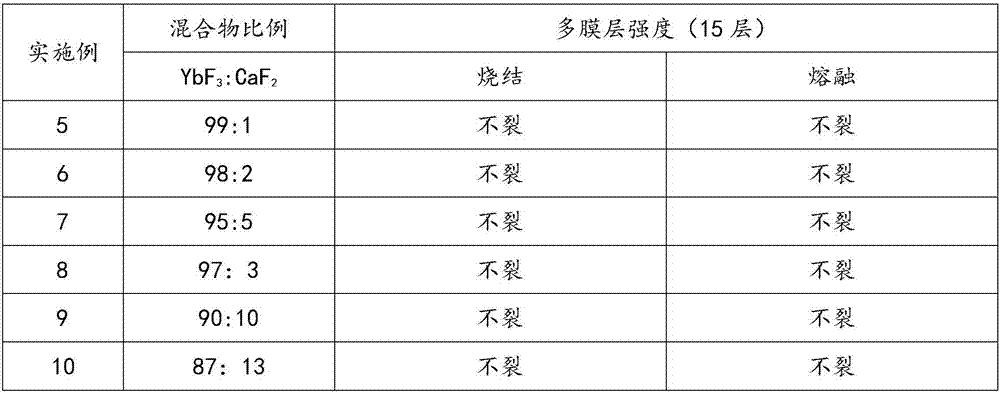

Examples

Embodiment 1

[0017] A low-refractive-index infrared optical coating material is composed of two fluorides, ytterbium fluoride and calcium fluoride.

[0018] The weight ratio of infrared optical coating materials is:

[0019] Ytterbium fluoride: 85, calcium fluoride: 0.5.

[0020] A method for preparing a low-refractive-index infrared optical coating material, comprising the following steps;

[0021] Proportioning step; according to the weight ratio of infrared optical coating materials:

[0022] Ytterbium fluoride: 85, calcium fluoride: 0.5, prepare materials according to weight ratio,

[0023] Sintering step: sintering the mixture of ytterbium fluoride and calcium fluoride obtained after proportioning, the sintering temperature is 700°C, and the obtained sintered mixture can be particles or flakes of different sizes.

Embodiment 2

[0025] A low-refractive-index infrared optical coating material is composed of two fluorides, ytterbium fluoride and calcium fluoride.

[0026] The weight ratio of infrared optical coating materials is:

[0027] Ytterbium fluoride: 89, calcium fluoride: 12.

[0028] A method for preparing a low-refractive-index infrared optical coating material, comprising the following steps;

[0029] Proportioning step; according to the weight ratio of infrared optical coating materials:

[0030] Ytterbium fluoride: 89, calcium fluoride: 12, prepare materials according to weight ratio,

[0031] Sintering step: sintering the mixture of ytterbium fluoride and calcium fluoride obtained after proportioning, the sintering temperature is 1250°C, and the obtained sintered mixture can be particles or flakes of different sizes.

Embodiment 3

[0033] A low-refractive-index infrared optical coating material is composed of two fluorides, ytterbium fluoride and calcium fluoride.

[0034] The weight ratio of infrared optical coating materials is:

[0035] Ytterbium fluoride: 99.5, calcium fluoride: 15.

[0036] A method for preparing a low-refractive-index infrared optical coating material, comprising the following steps;

[0037] Proportioning step; according to the weight ratio of infrared optical coating materials:

[0038] Ytterbium fluoride: 99.5, calcium fluoride: 15, prepare materials according to weight ratio,

[0039] Sintering step: sintering the mixture of ytterbium fluoride and calcium fluoride obtained after proportioning, the sintering temperature is 1000°C, the obtained sintered mixture can be particles or sheets of different sizes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com