Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Meet the development application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

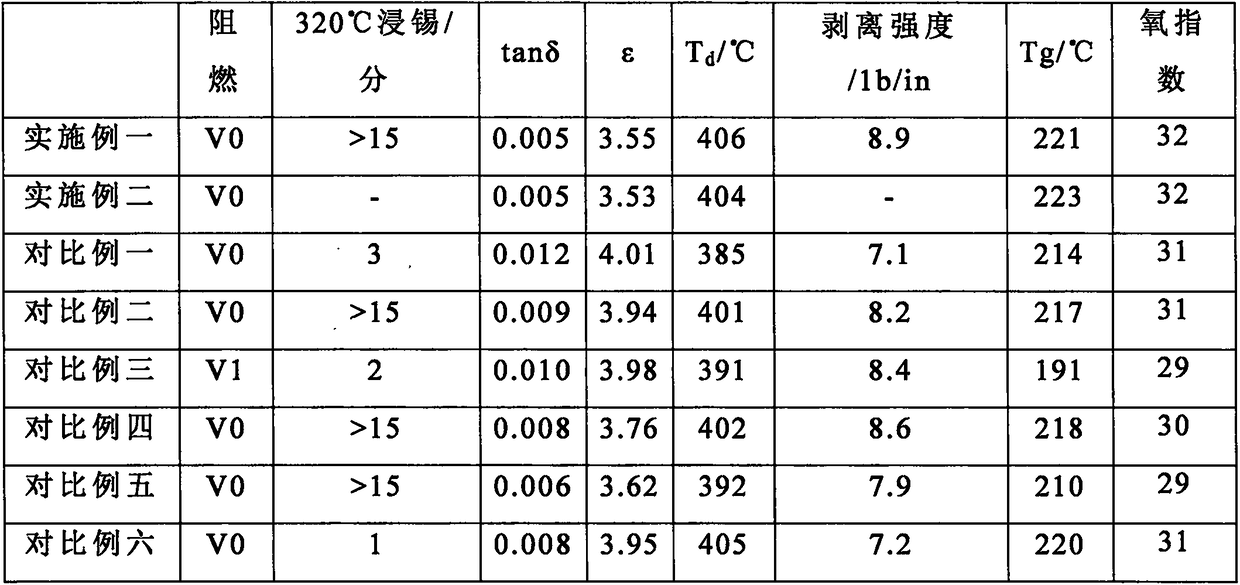

Flame-resistant and heat-resistant copper clad laminate preparation method

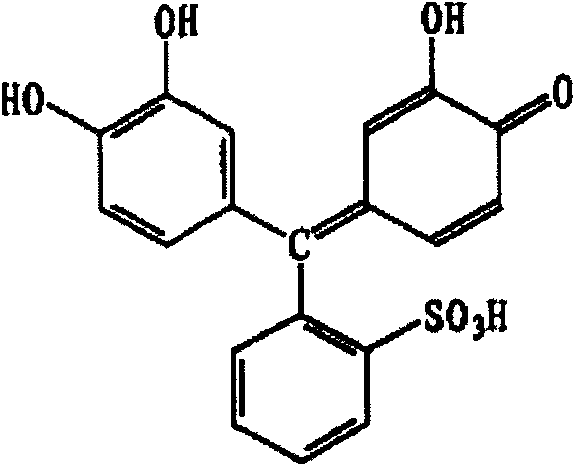

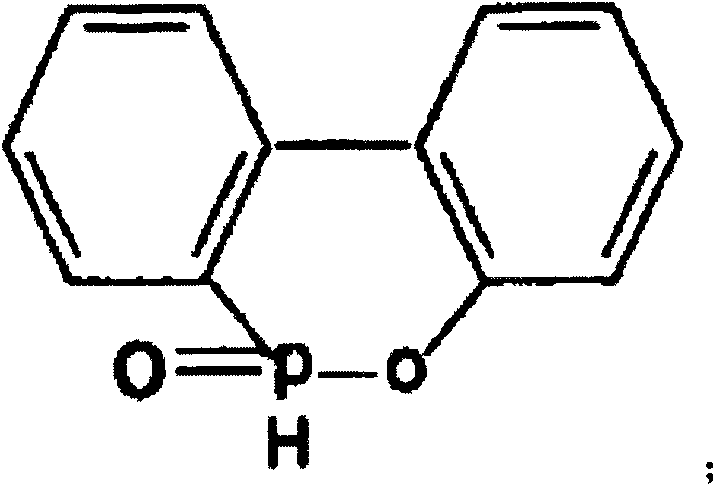

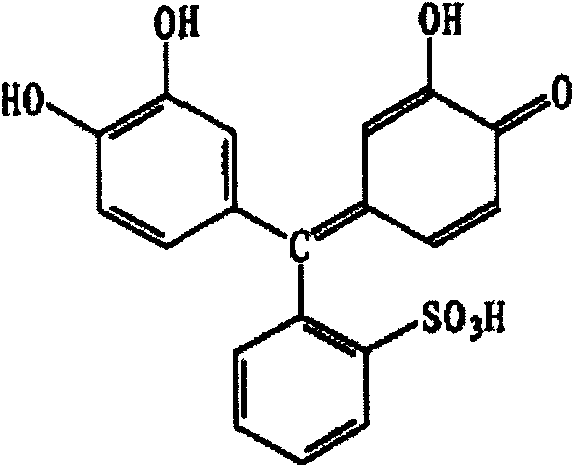

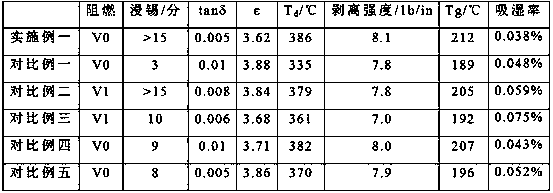

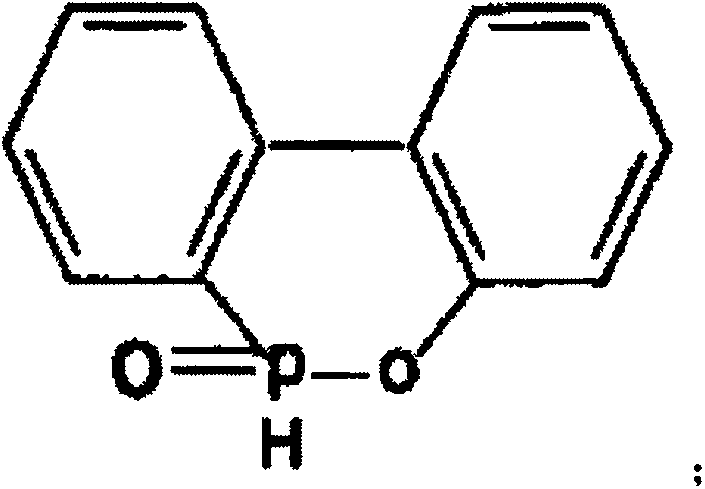

InactiveCN105172297AReasonable compositionUniform dispersionSynthetic resin layered productsLaminationMetal foilDimethyl phosphonate

The present invention relates to a flame-resistant and heat-resistant copper clad laminate preparation method, which comprises: adopting nanometer silica foam, dodecyl benzenesulfonic acid, bismuth nitrate pentahydrate, methyl trichlorosilane and polyoxyethylene sorbitan monooleate as a raw materials to obtain a filler; adopting DOPO, a bisphenol A cyanate ester monomer, a phenol compound, a m-nitrobenzene sulfonic acid pyridine salt, 2,3-epoxy cyclopentyl cyclopentyl ether and dimethyl phosphonate as raw materials to obtain a resin prepolymer; adding the filler to o-phthalic acid diglycidyl este to obtain an active filler; mixing the resin prepolymer and an indole compound, and then adding the active filler and isomeric undecanol polyoxyethylene ether phosphate potassium salt to obtain a composite system; and carrying out hot pressing molding on the composite system, a reinforced material and metal foil to obtain the flame-resistant and heat-resistant copper clad laminate, wherein the flame-resistant and heat-resistant copper clad laminate has characteristics of excellent flame retardant property and excellent heat resistance, and meets the development applications of the flame-resistant and heat-resistant copper clad laminate.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

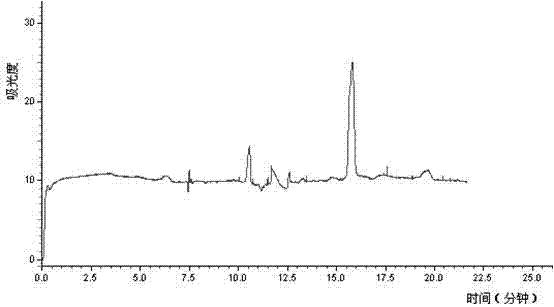

Conjugated linoleic acid isomer biological enrichment method

ActiveCN104404092AReduce inhibitionIncrease enrichment levelMicroorganism based processesFermentationLactic acid bacteriumCellulose

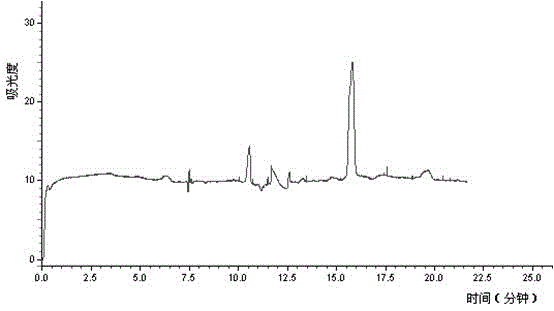

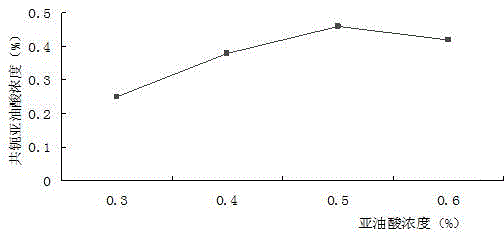

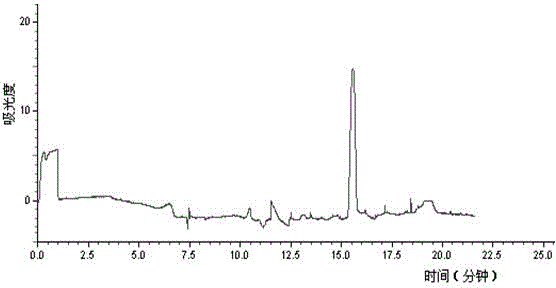

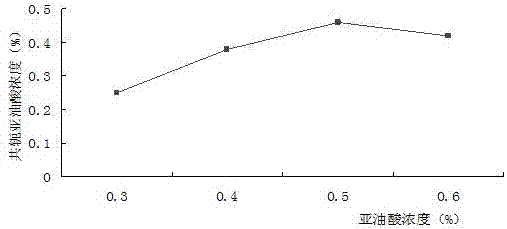

A conjugated linoleic acid isomer biological enrichment method includes preparation of a biological enrichment culture medium, preparation of production strains, conjugated linoleic acid isomer biological enrichment and other steps, and c9,t11-conjugated linoleic acid (CLA) isomers can be obtained. The c9,t11-conjugated linoleic acid (CLA) isomer content is greater than 0.45% by mass, substrate conversion rate is more than 90%, the c9,t11-conjugated linoleic acid (CLA) isomer content in products is increased significantly, by biological enrichment culture, not only an anti-cancer function product rich in the c9,t11-conjugated linoleic acid (CLA) isomer can be obtained, proteins and celluloses in defatted soybean also can be decomposed into polypeptides and soluble dietary fiber and other health care function active factors, the health care function of the products is significantly enhanced, and the application range of the product is further broadened.

Owner:NANCHANG UNIV

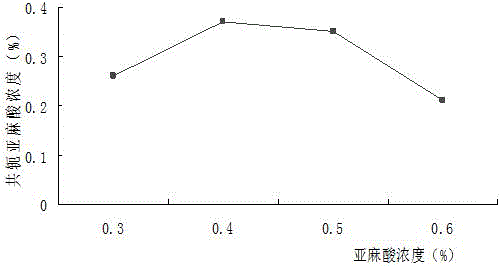

Biological enrichment method of conjugated linolenic acid isomer

ActiveCN104480150AReduce inhibitionIncrease enrichment levelMicroorganism based processesFermentationCelluloseEnrichment methods

The invention relates to a biological enrichment method of a conjugated linolenic acid isomer. The biological enrichment method comprises biological enrichment culture medium preparation, production strain preparation, biological enrichment of the conjugated linolenic acid isomer, and other steps to obtain the c9,t11,c15-conjugated linolenic acid isomer. According to the present invention, the c9,t11,c15-conjugated linolenic acid isomer mass content in the obtained product is more than 0.36%, and the substrate conversion rate is more than 90%; and with the biological enrichment culture, the c9,t11,c15-conjugated linolenic acid isomer-rich anti-cancer function product is obtained, proteins and cellulose in defatted soybean can be decomposed into polypeptides, soluble dietary fibers and other active factors having health functions through lactic acid bacteria, and the health function of the product is significantly enhanced so as to further broaden the application range of the product.

Owner:NANCHANG UNIV

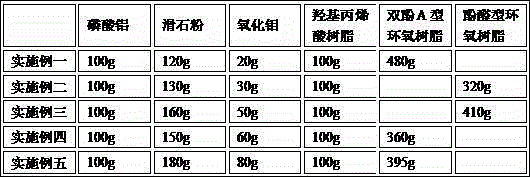

Preparation method for flame-retardant heat-resistant antenna radome base material

The invention relates to a preparation method for a flame-retardant heat-resistant antenna radome base material. The preparation method comprises the following steps: preparing a filler with the average grain size of 180 nanometers by taking nano silicon dioxide foam, dodecylbenzene sulfonic acid, bismuth nitrate pentahydrate and methyl trichlorosilane as raw materials; preparing a resin prepolymer by taking DOPO, a bisphenol A cyanate ester monomer, a phenolic compound, 1,3,5-triglycidyl -S-triazinetrione, bisphenol A epoxy resin and diaminodiphenyl ether as raw materials; mixing the resin prepolymer with maleic anhydride; then sequentially adding poly(methylsilsesquioxane) and the filler; then adding isomeric undecanol polyoxyethylene ether phosphate potassium salt and glass beads to obtain a composite system; then injecting the composite system into a die coated with a release agent, carrying out mold pressing under a vacuum condition, and finally turning off a power supply and naturally cooling; and releasing the die to obtain the flame-retardant heat-resistant antenna radome base material. The flame-retardant heat-resistant antenna radome base material has excellent flame retardance and heat resistance, and the development application of the flame-retardant heat-resistant antenna radome base material is satisfied.

Owner:苏州凯欧曼新材料科技有限公司

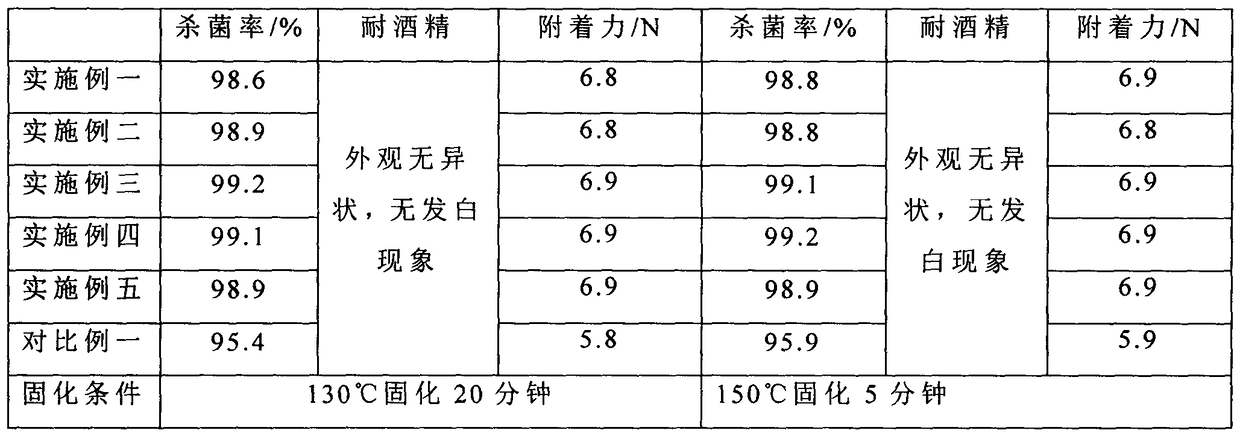

Preparation method for anti-microbial cotton material

InactiveCN105178012AReasonable compositionImprove antibacterial propertiesFibre treatmentYtterbium fluoridePolymer science

The invention relates to a preparation method for an anti-microbial cotton material. Cotton fibers are placed in a finishing liquid comprising amino-terminated hyperbranched polymers, micromolecule functional agents, ytterbium fluoride and nano-titanium dioxide, dipping treatment is carried out, and anti-microbial cotton fibers are obtained. The cotton fibers finished through the method has good hand feeling, air permeability and fastness to washing and has strong anti-microbial endurance. Treatment is convenient, the method is simple, and operation is easy.

Owner:SUZHOU KEMIAO NEW MATERIAL

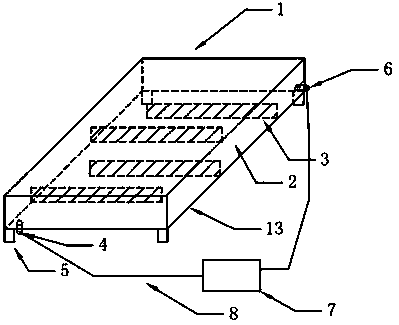

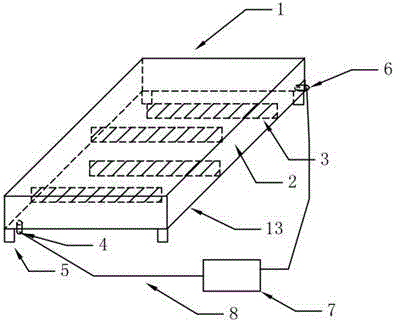

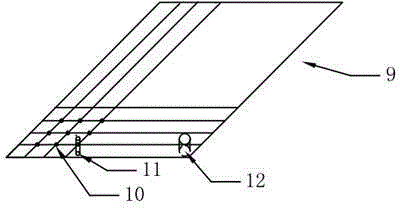

Circular combined type plant root collecting device

InactiveCN103843601APromote growthMeet the development applicationAgriculture gas emission reductionCultivating equipmentsPlant rootsEngineering

The invention discloses a circular combined type plant root collecting device, comprising a collecting groove, crossbeam support pieces, a planting plate, planting holes, a hose and a kneading pump, wherein the collecting groove is composed of cross block plates, longitudinal plates and a base plate, wherein the cross block plates are in parallel and positioned at two ends, the longitudinal plates are in parallel and positioned at two sides, the base plate is positioned at the bottom of the collecting groove, and thus forming a rectangular frame of the collecting rove; one corner of the base plate is provided with a liquid outlet pipe; the longitudinal plate in the diagonal line of the liquid outlet pipe is provided with a liquid inlet pipe; the four corners of the lower surface of the base plate are provided with stand bars; the crossbeam support piece is arranged in parallel with the cross block plates, and the length of the e crossbeam support piece is smaller than these of the cross block plates; two adjacent crossbeam support pieces are respectively connected with the longitudinal plates at two sides in a staggering manner; the bottoms of the crossbeam support pieces are connected with the base plate; the planting plate is placed on the crossbeam support pieces, the length of the planting plate is accordant with the internal size of the collecting groove; the planting plate is provided with a plurality of planting hole along the transverse and longitudinal directions; one corner of the planting plate is provided with a liquid adding pipe; planting pipes are arranged in the planting holes; the kneading pump, the liquid outlet pipe and the liquid inlet pipe are connected by the hose.

Owner:JIANGSU UNIV

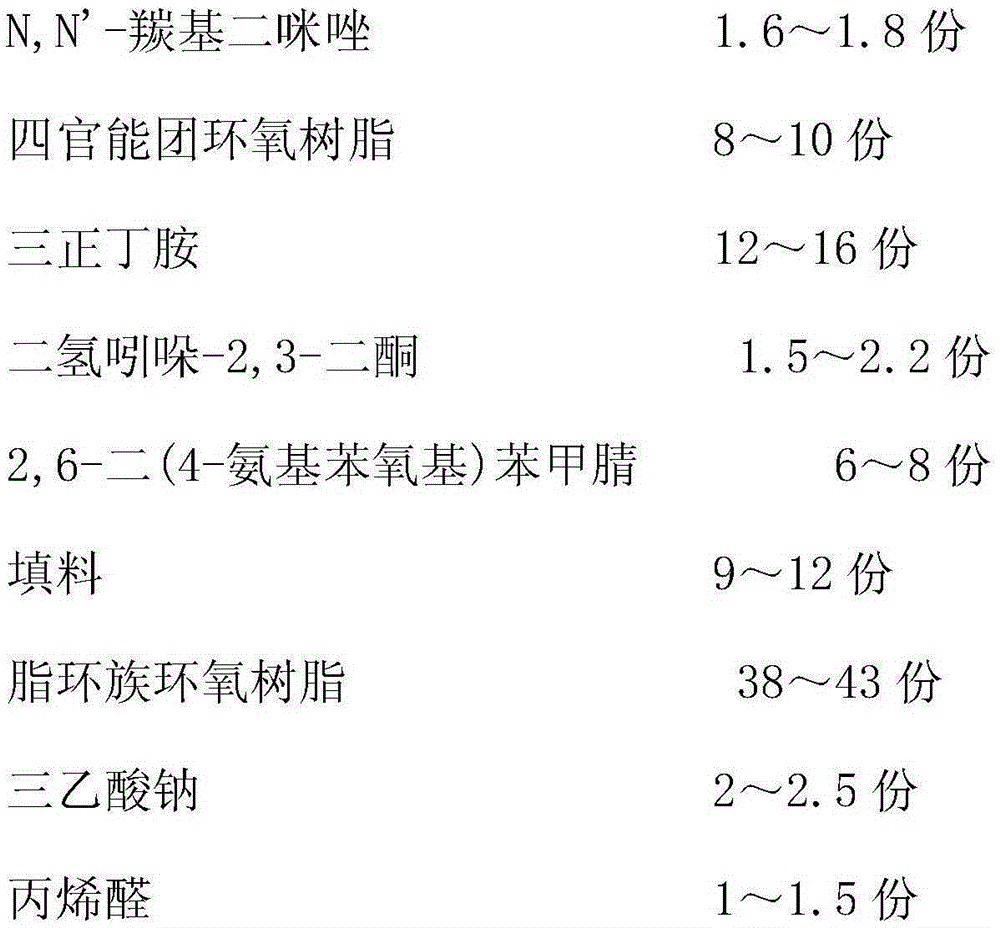

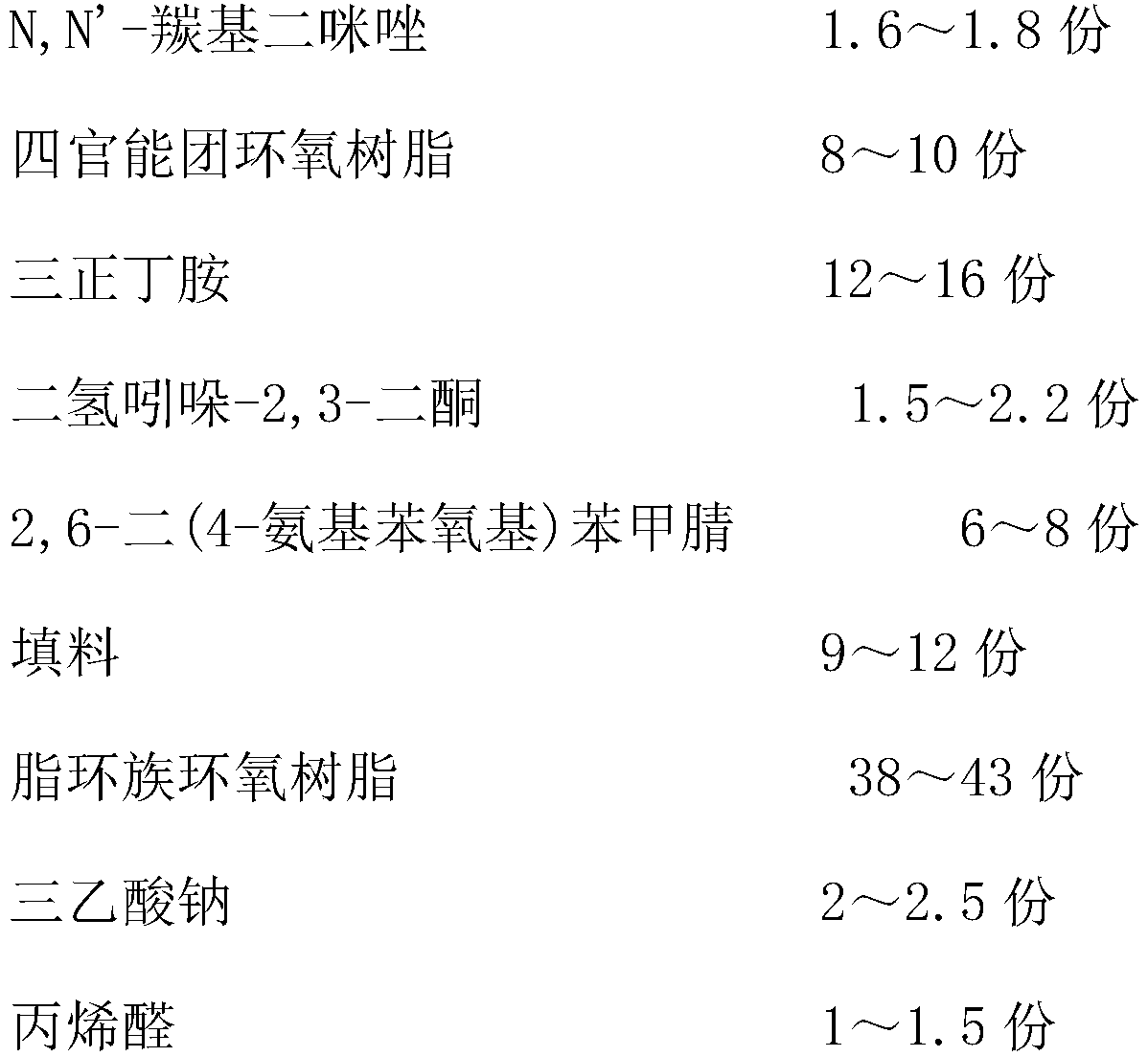

Heat-conducting electronic material composition

The invention relates to a heat-conducting electronic material composition which is obtained by mixing N,N'-carbonyldimidazole, tetra-functional epoxy resin, tri-n-butylamine, indoline-2,3-diketone, 2,6-di(4-aminophenoxy) cyanobenzene, a filler, cycloaliphatic epoxide resin, sodium triacetate and acraldehyde. Raw materials in a preparation method disclosed by the invention are wide in source, and the preparation process is simple and controllable, only needs normal operation and is easy to realize industrialization, therefore, the prepared heat-conducting electronic material composition has good heat conductivity and mechanical properties, and development applications of the heat-conducting electronic material composition can be met.

Owner:WUJIANG XINTA FORWARD HARDWARE FACTORY

A kind of bioconcentration method of conjugated linoleic acid isomers

ActiveCN104404092BReduce inhibitionIncrease enrichment levelMicroorganism based processesFermentationLactic acid bacteriumCellulose

A conjugated linoleic acid isomer biological enrichment method includes preparation of a biological enrichment culture medium, preparation of production strains, conjugated linoleic acid isomer biological enrichment and other steps, and c9,t11-conjugated linoleic acid (CLA) isomers can be obtained. The c9,t11-conjugated linoleic acid (CLA) isomer content is greater than 0.45% by mass, substrate conversion rate is more than 90%, the c9,t11-conjugated linoleic acid (CLA) isomer content in products is increased significantly, by biological enrichment culture, not only an anti-cancer function product rich in the c9,t11-conjugated linoleic acid (CLA) isomer can be obtained, proteins and celluloses in defatted soybean also can be decomposed into polypeptides and soluble dietary fiber and other health care function active factors, the health care function of the products is significantly enhanced, and the application range of the product is further broadened.

Owner:NANCHANG UNIV

Novel flame-retardant composite solid material

InactiveCN104893654AReasonable compositionImprove mechanical propertiesNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceHeat resistance

The invention relates to a novel flame-retardant composite solid material which is reasonable in composition and high in compatibility among components; therefore, the prepared novel flame-retardant composite solid material is better in mechanical property, adhesive property and heat resistance, especially excellent in flame retardation, and can meet demands in development and application of novel flame-retardant composite solid material; a preparation method disclosed by the invention is wide in raw material sources, simple and controllable in preparation process; only normal operations are required, and industrialization can be achieved easily.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

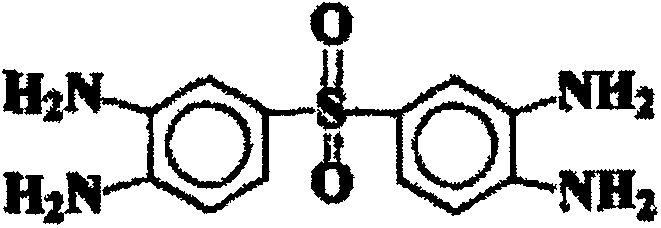

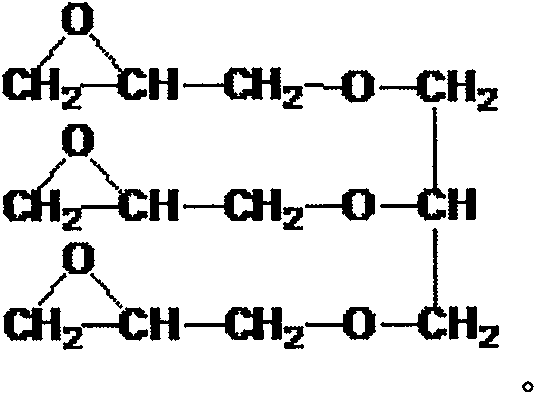

Preparation method of high frequency electronic medium material

InactiveCN108047715AMeet the development applicationImprove mechanical propertiesAcrylonitrileCyanate compound

The invention relates to a preparation method of a high frequency electronic medium material, which is prepared by hot pressing of a reinforcement material coated with a glue solution. The preparationmethod of the glue solution includes: dispersing triphenylchlorosilane in deionized water, then adding diethyl magnesium and 2-ethyl-1-hexanotitanium, and then adding polyoxyethylene sorbitan monostearate to obtain filler; adding the filler into phthalic diglycidyl ester to obtain active filler; mixing cyclopentadienyl iron tricarbonyl and a cyanate monomer, then adding an amino compound, aliphatic glycidyl ether and diallyl phthalate, and performing cooling to obtain a resin prepolymer; then adding the resin prepolymer into butanone and conducting stirring; adding the active filler and acrylonitrile; then adding PMA and diallyl diphenyl ether, and further performing stirring to obtain the glue solution. The high frequency electronic medium material prepared by the method provided by theinvention has the characteristics of excellent mechanical properties and heat resistance, and meets the development and application of high frequency electronic medium materials.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

Electronic material and preparation method thereof

InactiveCN108327363ADoes not affect the curing processHigh densitySynthetic resin layered productsLaminationHeat resistanceMetal foil

The invention relates to an electronic material and a preparation method thereof. The preparation method comprises the following steps: mesoporous silica is modified firstly, then epoxy with monofunctional groups and epoxy with bifunctional groups are prepared, and a glue solution is obtained by mixing; the glue solution, a reinforcing material and metal foil are subjected to hot-press molding, and the electronic material can be obtained. The electronic material has the excellent flame retardance and heat resistance, and requirements for development and application of the electronic material are met.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

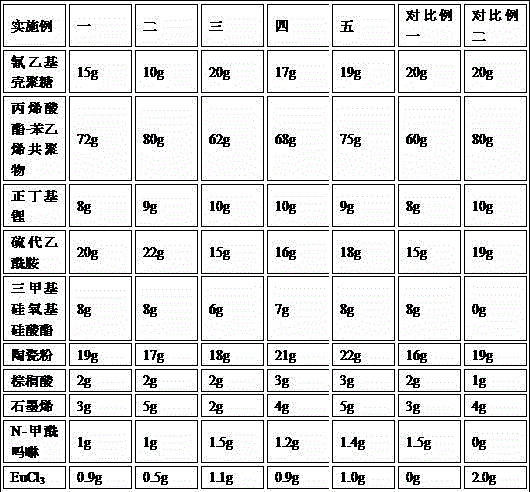

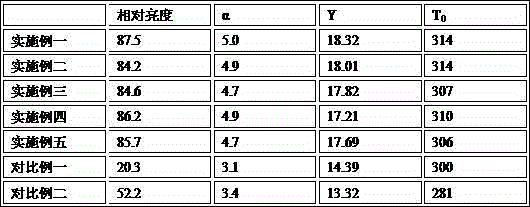

Novel luminescent composite material

InactiveCN104962021AReasonable compositionImprove mechanical propertiesLuminescent compositionsMeth-Morpholine

The invention relates to a novel luminescent composite material. EuCl3 and trimethylsilanolate silicate ester are mixed for 2 hours to obtain a mixture; thioacetamide and ceramic powder are sequentially added into the mixture; the materials are stirred for 4 hours; then, palmitic acid and n-butyllithium are added; the materials are stirred for 2 hours at 80 DEG C; next, cyanoethyl chitosan and grapheme are added, and are stirred for 1 hour at 120 DEG C; finally, acrylic ester- styrol copolymers and N-formyl morpholine are added; the materials are stirred for 4 hours at 130 DEG C to obtain luminescent compounds; then, the luminescent components are added into a mold and is subjected to molding pressing to obtain the novel luminescent composite material. A preparing method disclosed by the invention has the advantages that the raw material resources are wide, the preparing process is simple and controllable, only conventional operation is needed, and the industrialization is easily realized.

Owner:SUZHOU KEMIAO NEW MATERIAL

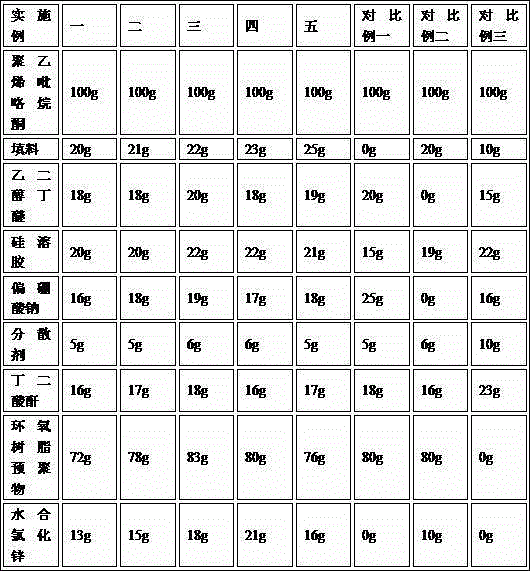

Preparation method of novel composite solid gum

ActiveCN105038662AGood bondGood responsivenessNon-macromolecular adhesive additivesN-vinyl-pyrrolidone polymer adhesivesPrepolymerChemistry

The invention relates to a preparation method of a novel composite solid gum. The preparation method comprises the following steps: mixing a filling material, ethylene glycol monobutyl ether, and silica sol for one hour to obtain a mixture; then adding sodium metaborate, a dispersant, and succinic anhydride into the mixture in sequence, stirring for 0.5 hour, then adding epoxy resin prepolymer, stirring for 3 hours at a temperature of 140 DEG C; finally adding polyvinylpyrrolidone and zinc chloride hydrate, stirring for 8 hours at a temperature of 60 DEG C to obtain a compound; then filling the compound into a mould, and cold-pressing the compound to obtain the composite solid gum. The disclosed preparation method has the advantages that the raw material resources are wide, the preparation process is simple and controllable, only normal operation is needed, and the preparation method can be easily applied to industrialization.

Owner:佛山市顺德区领锋新材料有限公司

Fold-resistant composite material

The invention relates to a fold-resistant composite material. Cobalt phthalocyanine, stearic acid and polyether diol are evenly mixed to be reacted at the temperature of 85 DEG C for two hours to obtain a mixture; 1,3-bis(isocyanatomethyl)-cyclohexan, thioacetamide, bisphenol A dianhydride and polyoxyethylene rosin ester are sequentially added into the mixture to be stirred at the temperature of 110 DEG C for four hours, then phenylcyclohexane and hydroxylamine potassium are added to be stirred at the temperature of 120 DEG C for one hour; at last, polyimide resin, phenoxy resin and tetrazole are added to be stirred at the temperature of 120 DEG C for half an hour, and accordingly a fold-resistant prefabricated object is obtained; then the fold-resistant prefabricated object is placed in a mold, and the fold-resistant composite material is obtained through hot pressing. The fold-resistant composite material has excellent mechanical property and heat resistance, and the application and development requirements of the fold-resistant composite material can be met.

Owner:SUZHOU KEMIAO NEW MATERIAL

Mold-proof semisolid composite system

The invention relates to a mold-proof semisolid composite system. The mold-proof semisolid composite system is prepared by using active filler, polydimethylsiloxane, trimethylsiloxysilicate, sodium lauryl sulfate, sodium alga acid, astaxanthin, diethyl phosphite, acrylic resin prepolymer and 1,3-propylene glycol. The mold-proof semisolid composite system disclosed by the invention has the advantages that the components are reasonable, the compatibility between the components is good, the prepared mold-proof semisolid composite system has good oxidation resistance and adhesive performance and especially has excellent mold-proof performance and heat-resistant performance, and the demands of the development and application of the mold-proof semisolid composite system are satisfied.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

Low-dielectric-loss casting body

The invention relates to a low-dielectric-loss casting body which is prepared by the following steps: preparing a resin-base composite system from a bismaleimide resin monomer, maleic anhydride, octamethylcyclotetrasiloxane, pentaerythritol tetraacrylate, a phenoxy oxygen resin, isomerized tridecyl alcohol polyethenoxy ether, a polycaprolactam resin, a filler and ethylene glycol; and adding the resin-base composite system into a mold, and carrying out hot pressing to obtain the low-dielectric-loss casting body. The low-dielectric-loss casting body has excellent mechanical properties and heat resistance, and satisfies the development and application of the low-dielectric-loss casting body.

Owner:苏州凯欧曼新材料科技有限公司

A kind of method for preparing composite solid glue

ActiveCN105038662BImprove antioxidant capacityGood adhesionNon-macromolecular adhesive additivesN-vinyl-pyrrolidone polymer adhesivesEpoxyPolyvinylpyrrolidone

The invention relates to a preparation method of a novel composite solid gum. The preparation method comprises the following steps: mixing a filling material, ethylene glycol monobutyl ether, and silica sol for one hour to obtain a mixture; then adding sodium metaborate, a dispersant, and succinic anhydride into the mixture in sequence, stirring for 0.5 hour, then adding epoxy resin prepolymer, stirring for 3 hours at a temperature of 140 DEG C; finally adding polyvinylpyrrolidone and zinc chloride hydrate, stirring for 8 hours at a temperature of 60 DEG C to obtain a compound; then filling the compound into a mould, and cold-pressing the compound to obtain the composite solid gum. The disclosed preparation method has the advantages that the raw material resources are wide, the preparation process is simple and controllable, only normal operation is needed, and the preparation method can be easily applied to industrialization.

Owner:佛山市顺德区领锋新材料有限公司

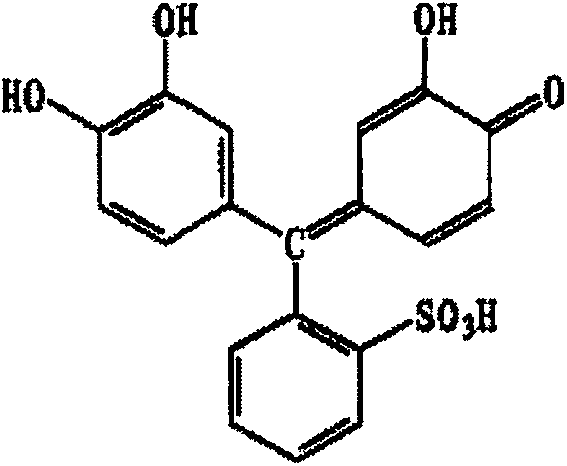

High dielectric property copper-clad board glue and preparation method thereof

InactiveCN108587063AImprove heat resistanceGuaranteed StrengthSynthetic resin layered productsElectrical equipmentDielectricCopper

The invention relates to high dielectric property copper-clad board glue and a preparation method thereof. The preparation method comprises adding methyl butynol into diglycidyl phthalate, stirring the mixture at 75 DEG C for 5 minutes, then adding 1, 8-octanedithiol and N, N-dicyclohexylcarbodiimide into the mixture, stirring the mixture for 5 minutes, then adding a modified silica system and nano-hollow alumina into the mixture, stirring the mixture for 15 minutes, finally, adding a modified epoxy system into the mixture, stirring the mixture at 125 DEG C for 2 hours, adding a butanone / PMA mixed solution into the mixture to obtain glue, dipping a 1080 glass cloth into the glue to obtain a prepreg, heating to dry the prepreg and preparing the modified epoxy resin-based copper clad board.The modified epoxy resin-based copper clad board has excellent dielectric properties and heat resistance and meets the development and application requirements of the modified epoxy resin-based copper-clad board.

Owner:苏州巨峰新材料科技有限公司

An electronic heat-resistant composite material

ActiveCN105273347BImprove mechanical propertiesMeet the development applicationMorpholineSodium iodide

The invention relates to an electronic heat-resisting composite material. A nitrogen compound and ceramic powder are mixed for 2 h, and then N-formyl morpholine and sodium iodide are added and mixed for 1.5 h to obtain a mixture; an amine compound and a diisoamyl dicyclopentadiene oxide are added into the mixture in sequence to be stirred at the temperature of 95 DEG C for 2 h; then an acrylate-styrene copolymer is added to be stirred at the temperature of 120 DEG C for 1 h; then, 2,6-bi(4-aminophenoxy)benzonitrile is added to be stirred at the temperature of 180 DEG C for 2 min to obtain a compound; the compound is placed into a mold, and mold pressing is performed to obtain an electronic heat-resisting composite material. The preparation method is wide in raw material source, the preparation process is simple and controllable, only conventional operation is needed, and industrialization is facilitated.

Owner:WUJIANG XINTA FORWARD HARDWARE FACTORY

Circulation combined root exudate collection device

InactiveCN103843601BPromote growthMeet the development applicationWithdrawing sample devicesAgriculture gas emission reductionPlant rootsDiagonal

The invention discloses a circular combined type plant root collecting device, comprising a collecting groove, crossbeam support pieces, a planting plate, planting holes, a hose and a kneading pump, wherein the collecting groove is composed of cross block plates, longitudinal plates and a base plate, wherein the cross block plates are in parallel and positioned at two ends, the longitudinal plates are in parallel and positioned at two sides, the base plate is positioned at the bottom of the collecting groove, and thus forming a rectangular frame of the collecting rove; one corner of the base plate is provided with a liquid outlet pipe; the longitudinal plate in the diagonal line of the liquid outlet pipe is provided with a liquid inlet pipe; the four corners of the lower surface of the base plate are provided with stand bars; the crossbeam support piece is arranged in parallel with the cross block plates, and the length of the e crossbeam support piece is smaller than these of the cross block plates; two adjacent crossbeam support pieces are respectively connected with the longitudinal plates at two sides in a staggering manner; the bottoms of the crossbeam support pieces are connected with the base plate; the planting plate is placed on the crossbeam support pieces, the length of the planting plate is accordant with the internal size of the collecting groove; the planting plate is provided with a plurality of planting hole along the transverse and longitudinal directions; one corner of the planting plate is provided with a liquid adding pipe; planting pipes are arranged in the planting holes; the kneading pump, the liquid outlet pipe and the liquid inlet pipe are connected by the hose.

Owner:JIANGSU UNIV

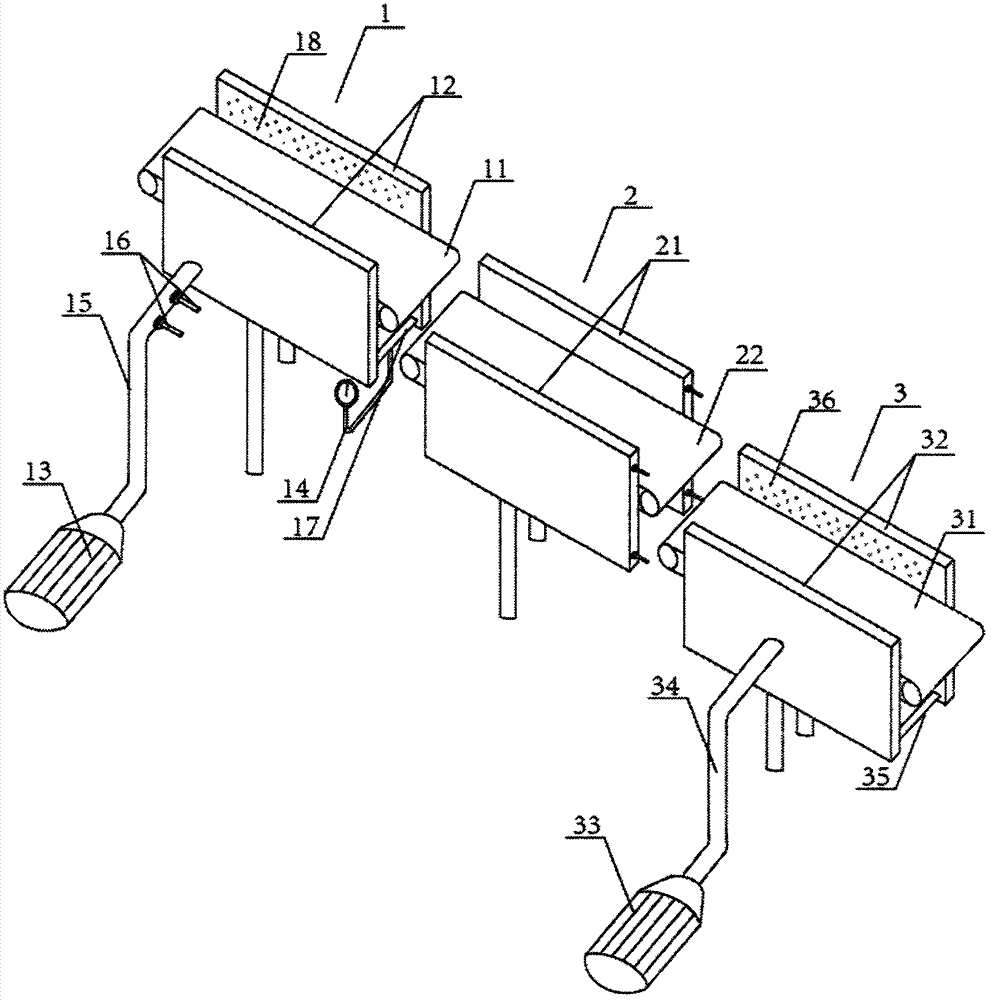

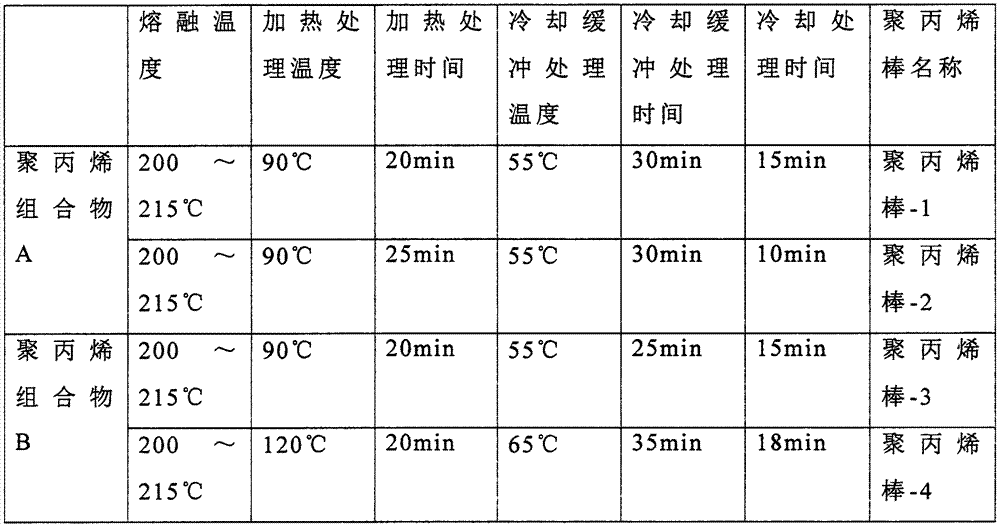

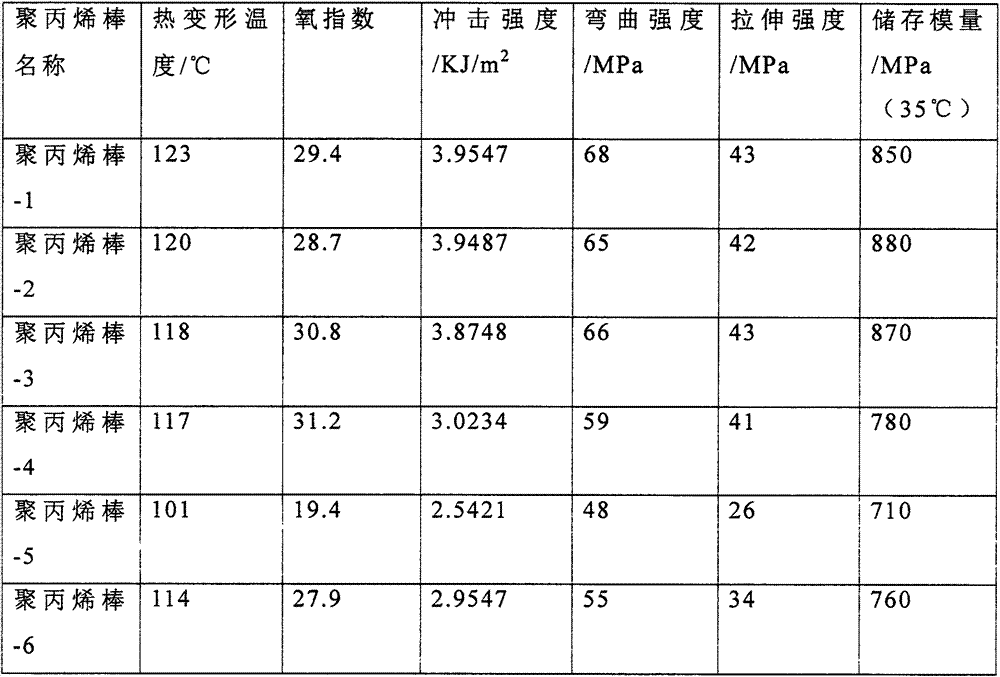

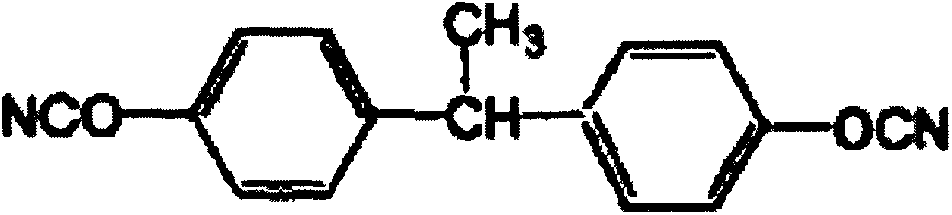

Preparation method of polypropylene rod and post-processing equipment used in the method

The invention relates to a preparation method of a polypropylene rod and post-processing equipment for the preparation method. A polypropylene composition is subjected to extrusion molding by extrusion equipment, cut by cutting equipment and subjected to post-processing by the post-processing equipment to obtain the polypropylene rod; polypropylene of which the molecular weight is 3000 to 4000, thiocyano-1-(2-aminophenyl) ethanone, a flame retardant filler, an auxiliary filler and a melting index regulator are mixed to obtain the polypropylene composition; three independent devices, namely a heating device, a cooling buffer device and a cooling device, are arranged in sequence to form the post-processing equipment. The preparation method disclosed by the invention is wide in raw material source and simple and controllable in preparation process, only requires normal operation of the post-processing equipment, and further realizes continuous production of rod forming, cutting and post-processing for the first time, thereby being liable to industrialization.

Owner:江苏多淇医疗设备有限公司

A thermally conductive electronic material composition

ActiveCN105400134BImprove thermal conductivityImprove mechanical propertiesHeat conductingMechanical property

The invention relates to a heat-conducting electronic material composition which is obtained by mixing N,N'-carbonyldimidazole, tetra-functional epoxy resin, tri-n-butylamine, indoline-2,3-diketone, 2,6-di(4-aminophenoxy) cyanobenzene, a filler, cycloaliphatic epoxide resin, sodium triacetate and acraldehyde. Raw materials in a preparation method disclosed by the invention are wide in source, and the preparation process is simple and controllable, only needs normal operation and is easy to realize industrialization, therefore, the prepared heat-conducting electronic material composition has good heat conductivity and mechanical properties, and development applications of the heat-conducting electronic material composition can be met.

Owner:WUJIANG XINTA FORWARD HARDWARE FACTORY

High-frequency electronic medium material

The invention relates to a high-frequency electronic medium material. The material is manufactured in the mode that a reinforcing material is coated with glue and then hot-pressed. The glue preparation method includes the steps that triphenylsilyl chloride is dispersed in deionized water, then diethyl magnesium and 2-ethyl-1-hexanol titanium are added, then sorbitan monooleate ethoxylate is added, and filler is obtained; the filler is added into phthalic diglycidyl ester, and active filler is obtained; cyclopentadienyl iron tricarbonyl and a cyanate ester monomer are mixed, then an amino compound, aliphatic glycidol ether and diallyl phthalate are sequentially added, and resin prepolymer is obtained after cooling; then, the resin prepolymer is added into butanone and stirred; the active filler and acrylonitrile are added; PMA and diallyl diphenyl ether are added and continuously stirred to obtain a glue solution. The prepared high-frequency electronic medium material has excellent mechanical properties and heat resistance, and the requirements of development and application of the high-frequency electronic medium material are met.

Owner:NANJING ANERTAI COMM SCI & TECH

Modified epoxy resin-based copper clad laminate and preparation method thereof

InactiveCN107722562AHigh densityReduce filler reactivityElectrical equipmentFlat articlesEpoxyHeat resistance

The invention relates to a modified epoxy resin-based copper clad laminate and a preparation method thereof. The preparation method comprises: adding a modified silica foam system into a bifunctionalepoxy system, stirring for 30 min at a temperature of 120 DEG C, adding a monofunctional epoxy system and hollow nanometer alumina at a temperature of 95-105 DEG C, and stirring for 20 min to obtain aglue solution; and carrying out hot pressing molding on the glue solution, a reinforcing material and metal foil to obtain a modified epoxy resin-based copper clad laminate, wherein the obtained modified epoxy resin-based copper clad laminate has excellent flame retardancy and excellent heat resistance, such that the development and application of modified epoxy resin-based copper clad laminatescan be met.

Owner:苏州巨峰新材料科技有限公司

A preparation method of composite hard sheet for tropical blister packaging

ActiveCN106696427BExcellent low temperature curingMeet the development applicationLamination ancillary operationsLayered product treatmentPolyesterPolymer science

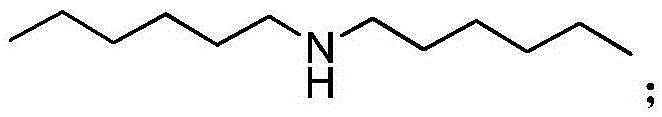

The invention relates to a preparation method of a composite hard sheet for tropical bubble cap package. The preparation method comprises the specific steps that a mixture of titanium dioxide, ytterbium fluoride and zirconia is calcined after being ball-milled to obtain a filler; dihexylamine and the filler are mixed, and then N-formyl morpholine, diethyl phosphonate and benzimidazole are mixed; diisoprene bicyclo oxide, polyamide and ethoxylated trimethylolpropane triacrylate are sequentially added into the mixture, and stirring is performed at the temperature of 170 DEG C for 5 minutes to obtain a compound; the compound is added to an extruder; then, a polyester film with the surface subjected to corona treatment is prepared into a composite polyester film through the extruder; the composite polyester film and an aluminum foil are subjected to hot-pressing compounding to obtain an aluminum plastic material; then the aluminum plastic material is prepared into the composite hard sheet for tropical bubble cap package through the extruder. The raw materials adopted in the preparation method are wide in source, the preparation process is simple and controllable, only conventional operation is needed, and industrialization is easy.

Owner:JIANGSU ZHENMEI PACKAGING TECH

Semi-curing sheet for high dielectric property copper clad laminate and preparation method thereof

The invention relates to a semi-curing sheet for high dielectric property copper clad laminate and preparation method thereof. The method includes the following steps of: adding methyl butynol2-methylbutyraldehyde into diglycidyl phthalate, stirring at 75 DEG C for 5 minutes, then adding 1, 8-octanedithiol, N, N-dicyclohexylcarbodiimide and stirring for 5 minutes, then adding modified silicon dioxide system, nano hollow alumina and stirring for 15 minutes, finally adding modified epoxy system, stirring at 125 DEG C for 2 hours to obtain the glue solution; adjusting the solid content of the glue solution to be 65% by using butanone / PMA mixture, then dipping the reinforced material 1080 glass cloth into the glue solution to obtain the prepreg. The prepreg is heated and dried to obtain thesemi-curing sheet for the high dielectric property copper clad laminate. The modified epoxy resin-based copper clad laminate is prepared, has excellent dielectric property and heat resistance, and meets the development and application of the modified epoxy resin-based copper clad plate.

Owner:苏州巨峰新材料科技有限公司

Preparation method of heat-resistant composite magnetic material

InactiveCN105261437AHigh strengthImprove heat resistanceOrganic/organic-metallic materials magnetismInductances/transformers/magnets manufacturePhosphateMonomer

The invention relates to a preparation method of a heat-resistant composite magnetic material. The method comprises the following steps: mixing a phenolic compound with a bisphenol A cyanate ester monomer, and adding endo-methylene tetrahydro-biphenyl dimethylbenzene anhydride, pentaerythritol tetraacrylate and bisphenol A epoxy resin to obtain a resin prepolymer; mixing the resin prepolymer with methylene bis(dialkylthiocarbamate), a modified magnetic filler and a heterogeneous undecanol polyoxyethylene ether phosphate kalium salt to obtain a composite system; injecting the composite system into a mold coated with a release agent, and carrying out mold pressing in a vacuum condition; and finally turning off a power supply, naturally cooling the product and demolding the product to obtain the heat-resistant composite magnetic material. The heat-resistant composite magnetic material has excellent flame retardant property and heat resistance, and meets development and application of the heat-resistant composite magnetic material.

Owner:苏州凯欧曼新材料科技有限公司

Electronic heat-resisting composite material

The invention relates to an electronic heat-resisting composite material. A nitrogen compound and ceramic powder are mixed for 2 h, and then N-formyl morpholine and sodium iodide are added and mixed for 1.5 h to obtain a mixture; an amine compound and a diisoamyl dicyclopentadiene oxide are added into the mixture in sequence to be stirred at the temperature of 95 DEG C for 2 h; then an acrylate-styrene copolymer is added to be stirred at the temperature of 120 DEG C for 1 h; then, 2,6-bi(4-aminophenoxy)benzonitrile is added to be stirred at the temperature of 180 DEG C for 2 min to obtain a compound; the compound is placed into a mold, and mold pressing is performed to obtain an electronic heat-resisting composite material. The preparation method is wide in raw material source, the preparation process is simple and controllable, only conventional operation is needed, and industrialization is facilitated.

Owner:WUJIANG XINTA FORWARD HARDWARE FACTORY

Polypropylene-based polymer material

The invention relates to a polypropylene-based polymer material, which is prepared through the steps of mixing nickel nitrate, magnesium nitrate and carclazyte evenly and then sintering in a muffle furnace at 1050 DEG C for 2h to obtain a solid; crushing the solid, and filtering through an 800-mesh sieve, wherein screen underflow is taken as a composite filler; melting and mixing polypropylene with the molecular weight of 13,000-16,000, phenoxyacetic acid, the composite filler, acrylic ester and benzoguanamine to prepare a polypropylene composition; and carrying out extrusion molding on the polypropylene composition through extrusion equipment and treating at 80 DEG C for 10min to prepare the polypropylene-based polymer material. The raw materials in the preparation method are readily available, the preparation process is simple and controllable, only normal operation is needed by post-treatment equipment and industrialization is easy to implement.

Owner:安徽省鸿鑫生物科技有限公司

Filler used for flame-retardant heat-resistant copper-clad laminate and preparation method of filler

InactiveCN107973934AReasonable compositionUniform dispersionSynthetic resin layered productsLaminationMethyltrichlorosilaneCopper

The invention relates to a filler used for a flame-retardant heat-resistant copper-clad laminate and a preparation method of the filler. The method comprises the following steps: taking nano silicon dioxide foam, dodecylbenzene sulfonic acid, bismuth nitrate pentahydrate, methyl trichlorosilane, polyoxyethylene sorbitan monooleate as raw materials to obtain the filler. According to the filler provided by the invention, the filler is used for preparing the flame-retardant heat-resistant copper-clad laminate, and the filler has excellent flame-retardant performance and heat-resistant performance, and satisfies the development and application of the flame-retardant heat-resistant copper-clad laminate.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com