A thermally conductive electronic material composition

A technology of electronic materials and compositions, which is applied in the field of thermally conductive electronic material compositions, can solve problems such as poor compatibility and decreased mechanical properties of materials, and achieve good compatibility, meet the needs of development and application, and increase the number of microcrack points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

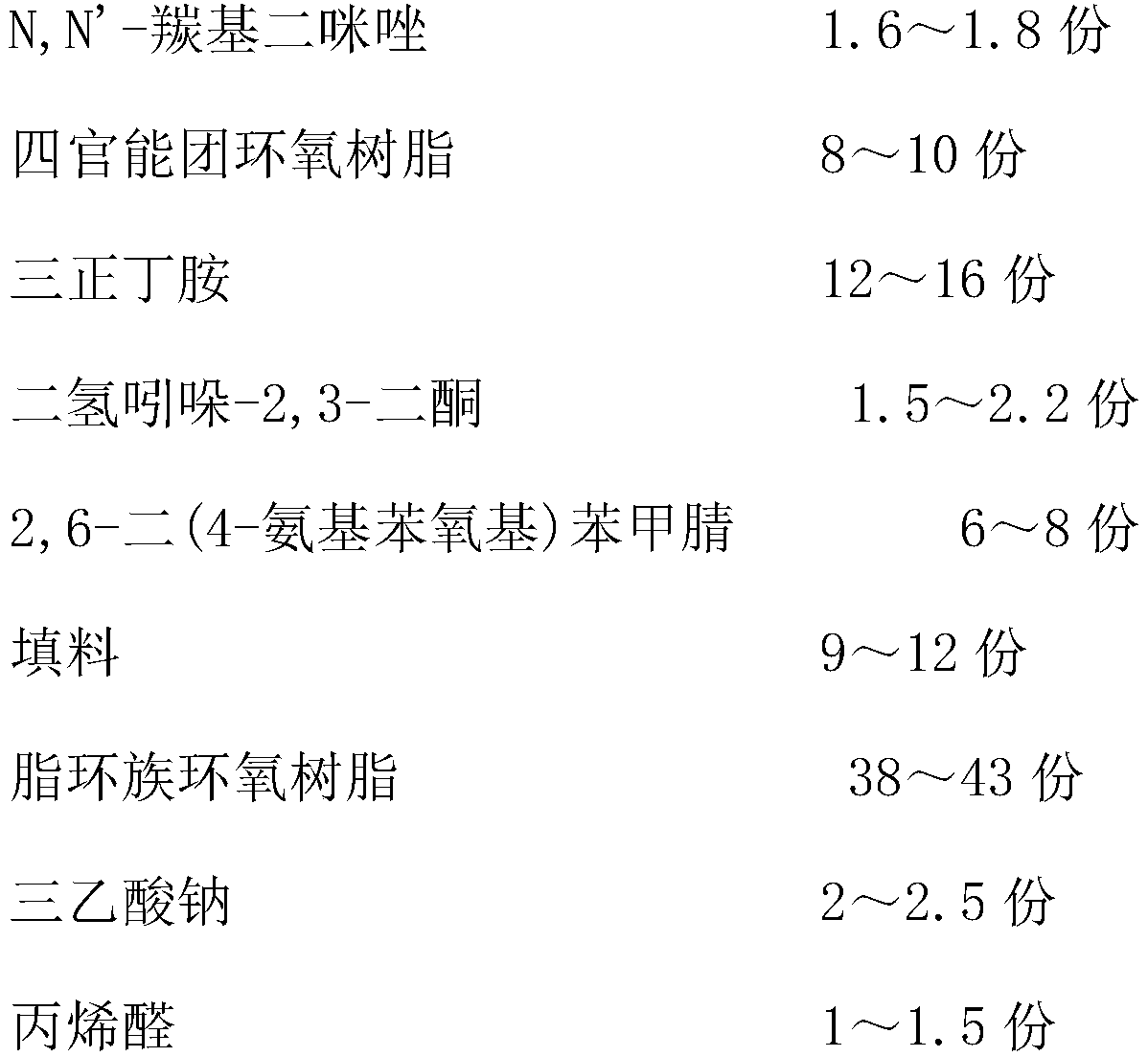

[0018] According to the composition in Table 1, sodium triacetate was dissolved in ether to prepare sodium triacetate ether solution; N,N'-carbonyldiimidazole was added to ethanol to prepare N,N'-carbonyldiimidazole ethanol solution; alicyclic epoxy Mix the resin with acrolein, then add tri-n-butylamine, and stir at 100°C for 30 minutes; then add indoline-2,3-dione, and continue stirring for 30 minutes; Stir for 30 minutes; then add filler and continue stirring for 1 hour; finally add 2,6-bis(4-aminophenoxy)benzonitrile; adjust the temperature to 90°C and stir for 45 minutes; adjust the temperature to 50°C and add in sequence Sodium triacetate ether solution and N,N'-carbonyldiimidazole ethanol solution are stirred evenly, and the solvent is removed by rotary evaporation to obtain a thermally conductive electronic material composition.

[0019] Table 1 Composition of each raw material / g

[0020] Example

[0021] First, 1Kg of graphite powder, 300g of ytterbium fluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com