Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Strong interface interaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible high-strength MXene-based electromagnetic shielding composite film and preparation method thereof

ActiveCN111809439AImprove conductivityImprove shielding effectSynthetic cellulose/non-cellulose material pulp/paperPaper-making machinesComposite filmNanofiber

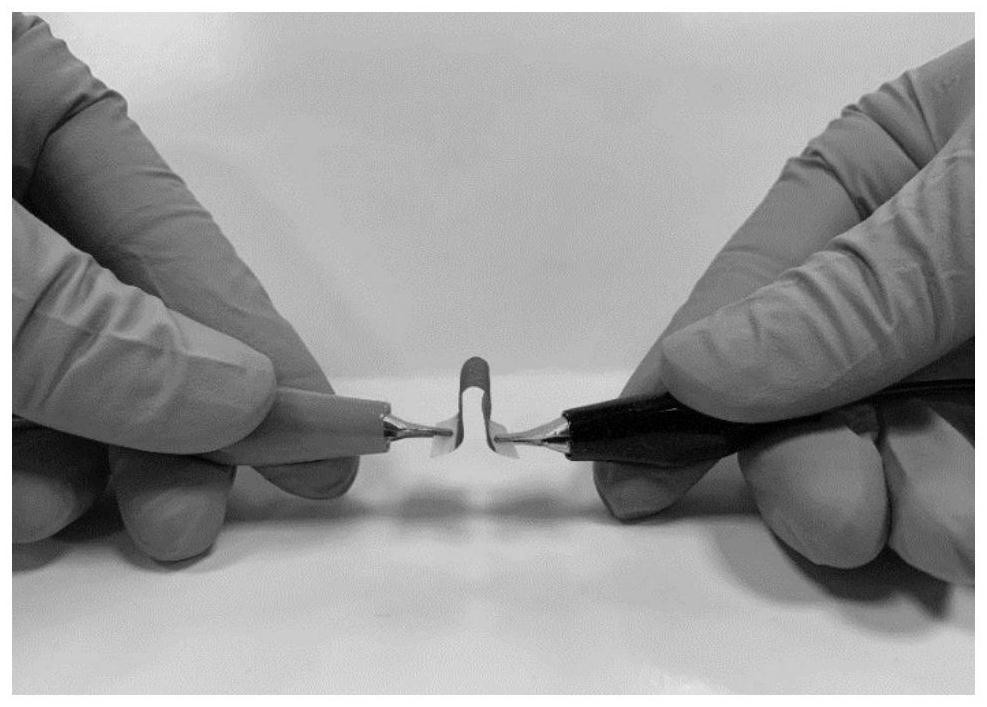

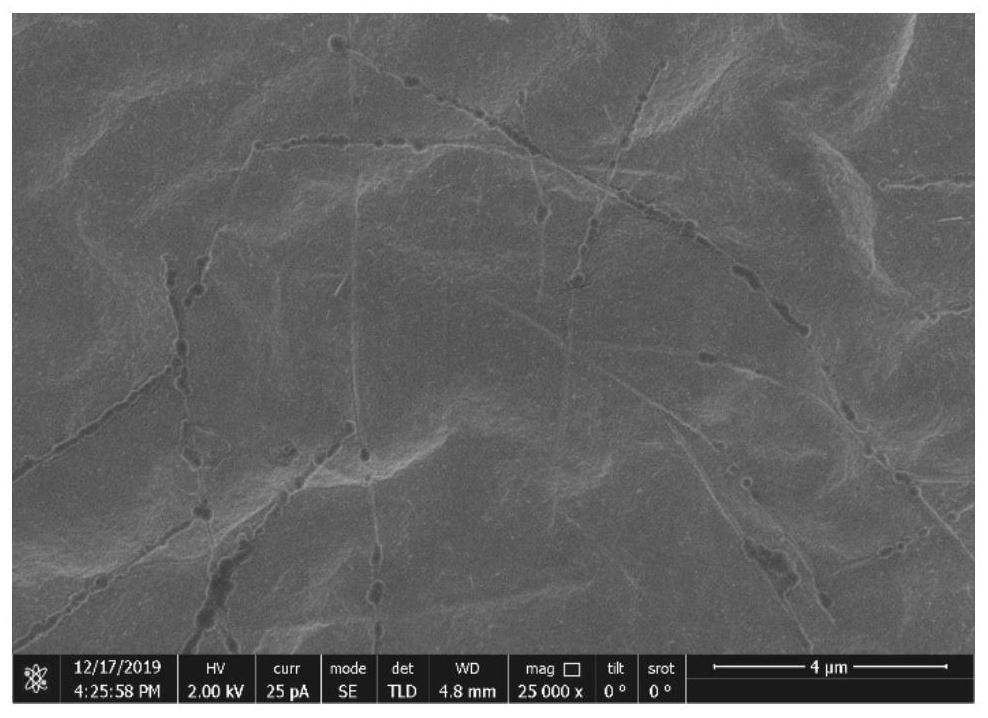

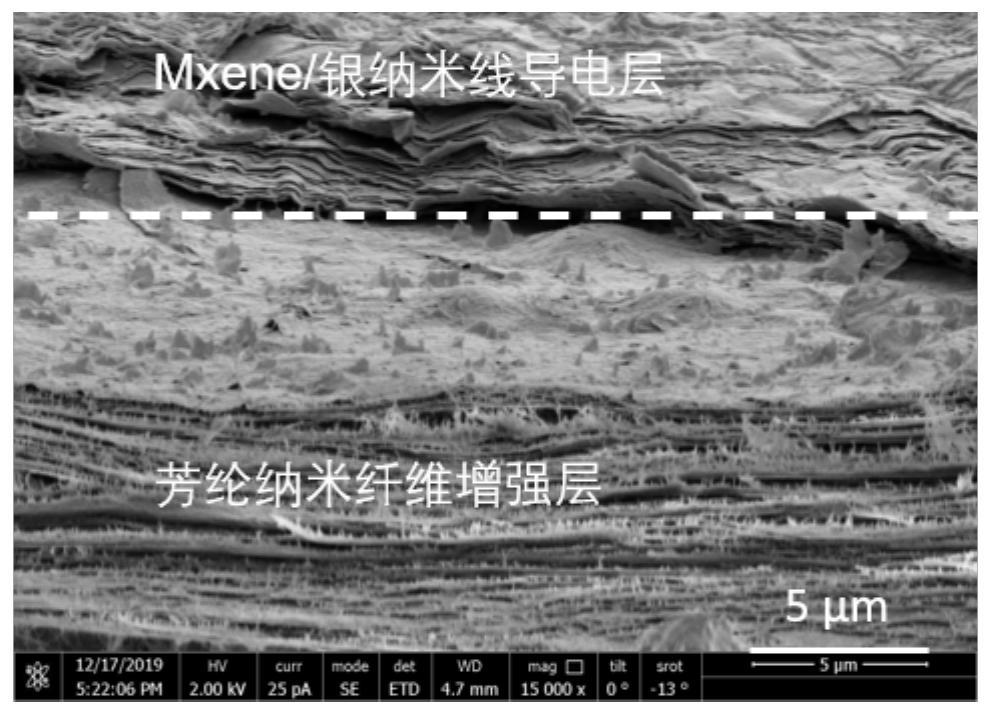

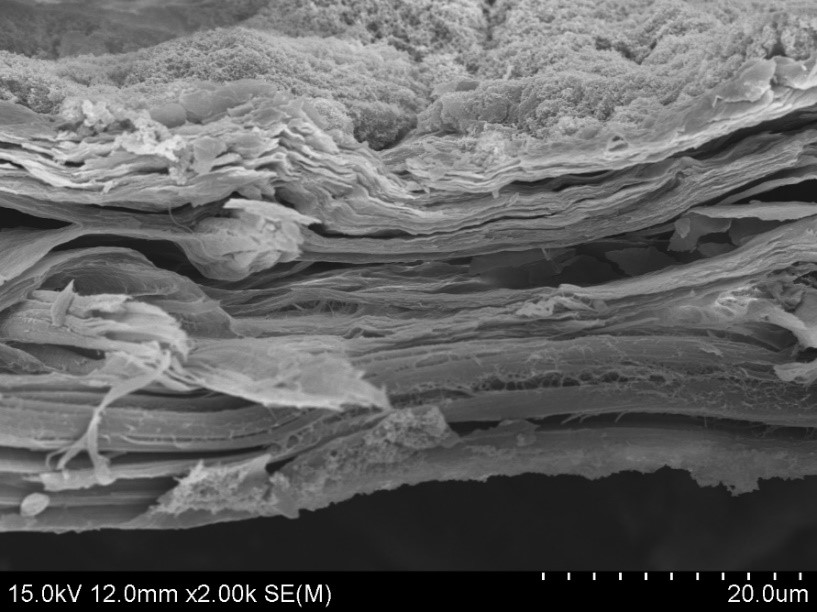

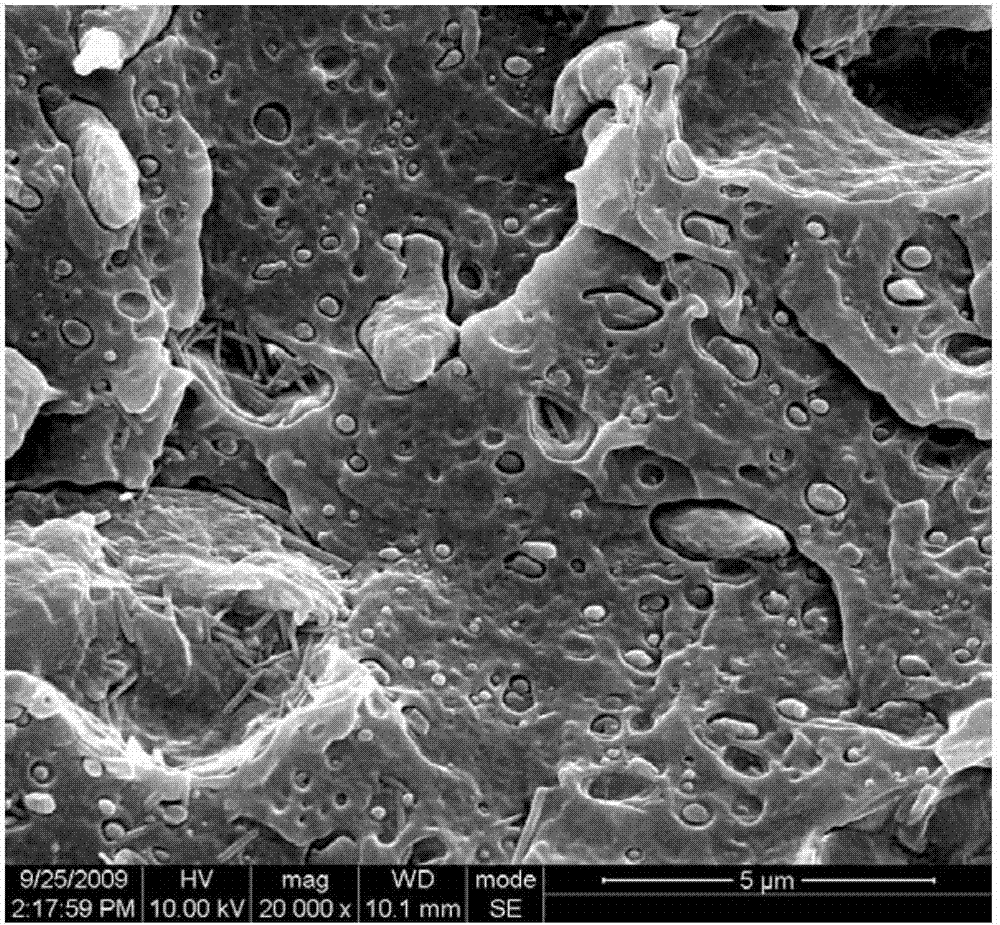

The invention discloses a flexible high-strength MXene-based electromagnetic shielding composite film, which comprises a conductive layer Ti3C2Tx MXene / silver nanowire and a polymer enhancement layeraramid nanofiber, and is characterized in that the mass fraction of the Ti3C2Tx MXene / silver nanowire conductive layer is 10-80%; the mass ratio of the Ti3C2Tx MXene to silver nanowire is (10: 0.5)-(10: 1.5). The invention further discloses a preparation method of the flexible high-strength MXene-based electromagnetic shielding composite film. The composite film prepared by the invention has excellent flexibility and mechanical properties, good conductivity and broadband high electromagnetic shielding effectiveness, and can meet the application in the fields of aerospace, military engineering,artificial intelligence and flexible wearable electronic equipment.

Owner:SHAANXI UNIV OF SCI & TECH

Transparent hydrophobic wear-resistant coating and preparation method thereof

ActiveCN107603415AWith transparencyControllable hydrophobicityLiquid surface applicatorsEpoxy resin coatingsEpoxyOrganic solvent

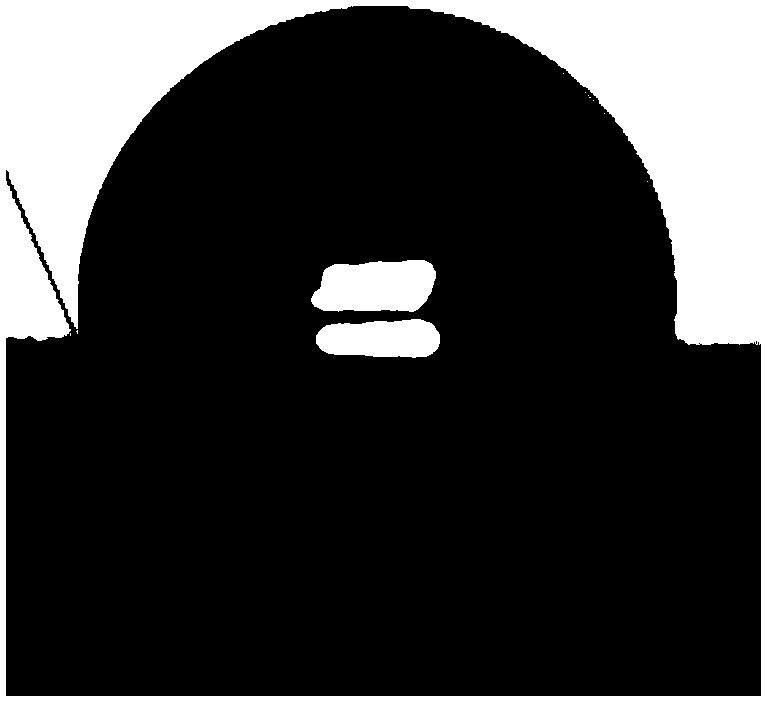

The invention relates to a transparent hydrophobic wear-resistant coating and a preparation method thereof. The transparent hydrophobic wear-resistant coating comprises an epoxy resin layer and a low-surface-energy fluorine-containing layer which are arranged in sequence from top to bottom. The preparation method comprises the following steps: (1) blending epoxy resin and a curing agent into an organic solvent, carrying out ultrasonic treatment to obtain a coating solution, wherein the total content of the epoxy resin and the curing agent is 0.001-5wt%; adopting a dip-coating method for a substrate material, uniformly adhering the coating solution to the surface of the substrate material, and taking out and curing to obtain the epoxy resin layer; and (2) preparing the low-surface-energy fluorine-containing layer, namely coating the epoxy resin layer with the fluorine-containing solution, and drying to obtain the transparent hydrophobic wear-resistant coating. The transparent hydrophobic wear-resistant coating is equivalent to glass in transparency, the surface contact angle is 102 degrees or above, the hydrophobicity of the coating is controllable, and the transparent hydrophobic wear-resistant coating has excellent mechanical strength and bonding property and is convenient for large-scale industrial production.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

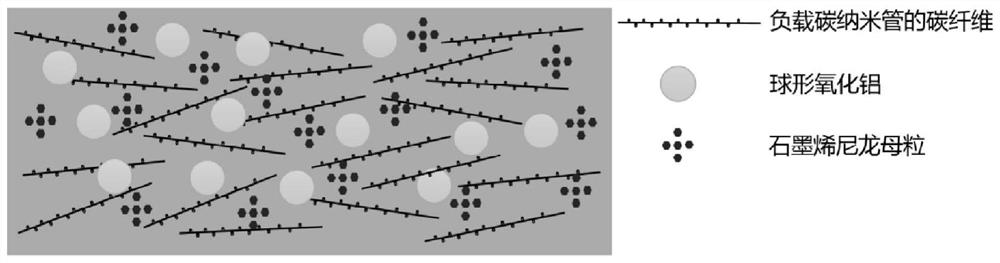

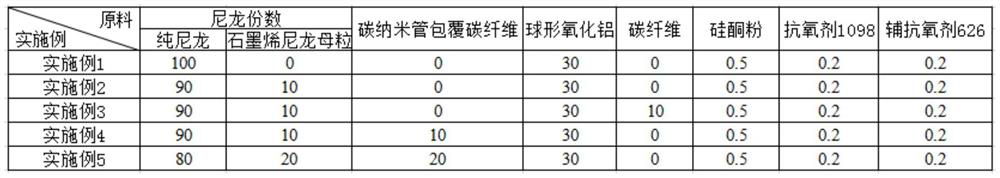

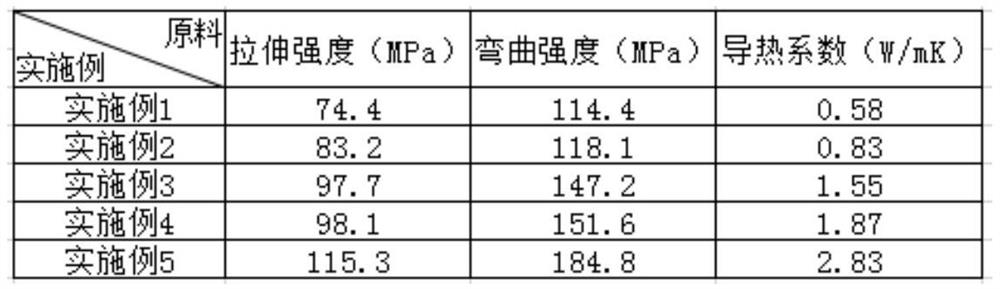

High-strength high-thermal-conductivity nylon composite material and preparation method thereof

ActiveCN113150541AImprove thermal conductivityGood dispersionHeat-exchange elementsFiberCarbon fibers

The invention provides a high-strength high-thermal-conductivity nylon composite material and a preparation method thereof. The nylon composite material is prepared from the following raw materials in parts by weight: 100 parts of nylon resin, 5-30 parts of carbon fibers, 10-30 parts of thermal conductive filler, 0.1-5 parts of a dispersing agent and 0.1-5 parts of an antioxidant, the nylon resin is composed of 5-30% of graphene nylon master batch and 70-95% of pure nylon resin; and carbon nanotubes are grafted on the surfaces of the carbon fibers. According to the invention, high-thermal-conductivity fillers such as graphene and carbon nanotubes are pretreated and then subjected to melt blending, so that the fillers are well dispersed and a thermal conduction path can be constructed at a low content, the thermal conductivity of the composite material is remarkably improved, and the carbon fibers are added into the matrix, so that the overall mechanical property of the material is improved, the dimensional stability is improved, and the water absorption rate of the nylon is reduced.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing environmentally-friendly plastic wood

InactiveCN101954663ASmooth infusionKeep the colorPressure impregnationPolymer scienceCompressive strength

The invention provides a method for preparing environmentally-friendly plastic wood and relates to a method for preparing plastic wood. The method solves the problems of high monomer volatility and low monomer conversion rate in the conventional preparation method of the plastic wood. The method comprises the following steps of: I, mixing an organic monomer, an initiator and a polymerization promoter uniformly to obtain impregnation liquid; II, adding wood and the impregnation liquid into a reaction tank and vacuumizing the reaction tank; III, performing pressurization by introducing air; IV, wrapping the wood with aluminium foil, placing the wood at normal temperature and under normal pressure, and then heating the wood to obtain the environmentally-friendly plastic wood. The environmentally-friendly plastic wood prepared by the method has the advantages of high monomer conversion rate of 75 to 88 percent, no volatility and no peculiar smell during later application, compressive strength parallel to grain of 90 to 120 MPa, swelling-resistant rate of 40 to 52 percent after being soaked continuously for 200 hours, high size stability, weight loss rate of 7 to 14 percent after being subjected to fungal erosion for 12 weeks and high corrosion resistance. The environmentally-friendly plastic wood can serve as building and interior decoration materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

Hyaluronic acid/polyacrylonitrile compound film, method for preparing same and application thereof

ActiveCN101785975AImprove hydrophilic abilityStrong interfacial interactionSemi-permeable membranesSolubilityPervaporation

The invention relates to a hyaluronic acid / polyacrylonitrile compound film, a method for preparing the same and application thereof. The compound film is prepared by using hyaluronic acid, glutaraldehyde and a polyacrylonitrile basal film as raw materials, wherein the mass ratio of the glutaraldehyd to the hyaluronic acid is 1-10:1, and the thickness ratio of the polyacrylonitrile basal film to the hyaluronic acid layer is 135-400:1. Particularly, the preparation method comprises the following steps of: coating acid casting solution of the glutaraldehyde-containing hyaluronic acid on the polyacrylonitrile basal film which is treated by water, alkali and acid in sequence, drying, and heating the polyacrylonitrile basal film for 0.5 to 3 hours. The preparation method has the advantages of simple method, mild conditions and low cost; and the hyaluronic acid separation layer is high in hydrophilicity, and simultaneously due to the bonding characteristics, the hyaluronic acid separation layer is closely combined with a support layer, so that the prepared hyaluronic acid / polyacrylonitrile compound film is high in stability and separation property, and can be widely applied to the film realizing the separation based on a solubility diffusion mechanism such as pervaporation.

Owner:南通诚恩机械有限公司

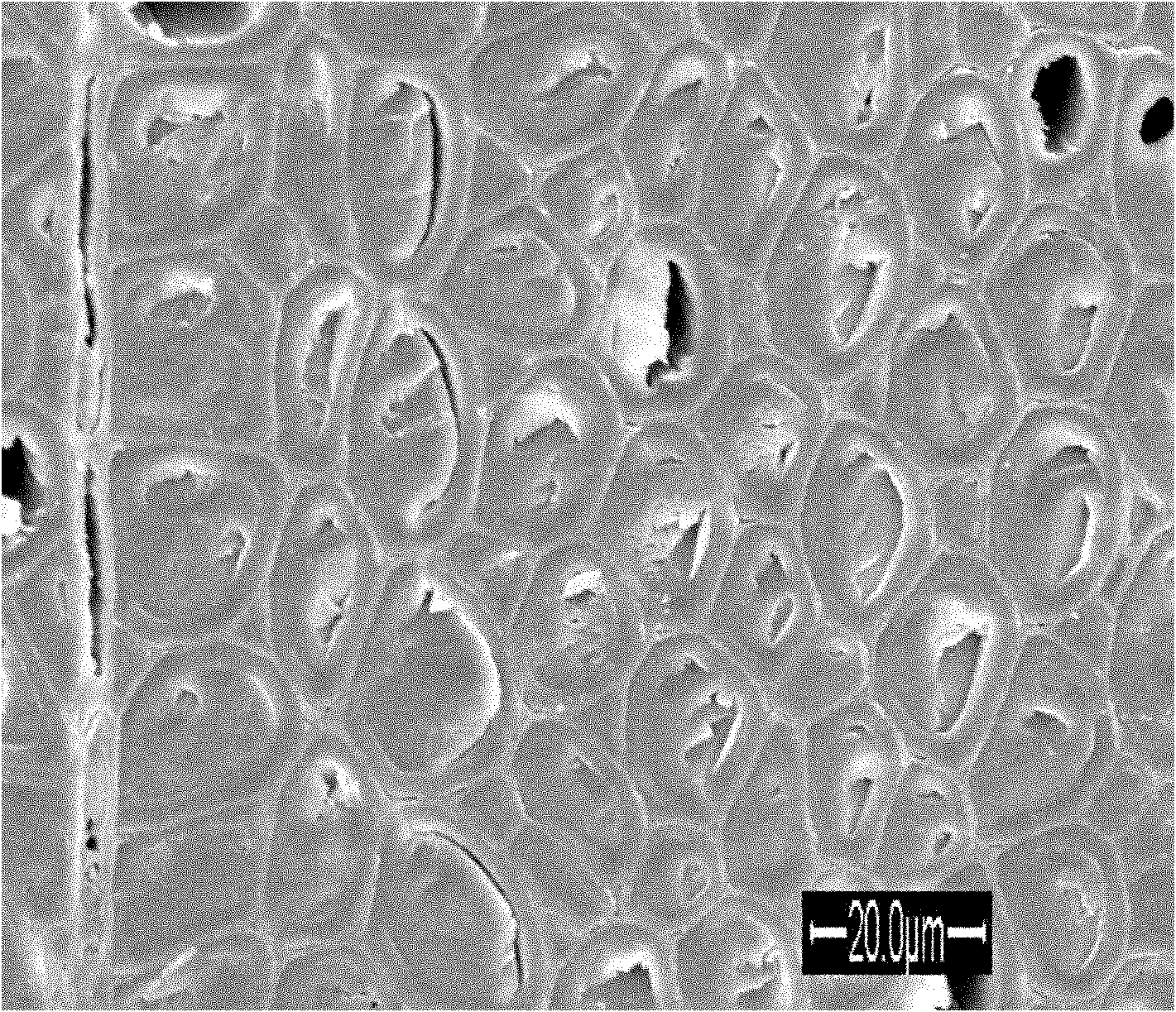

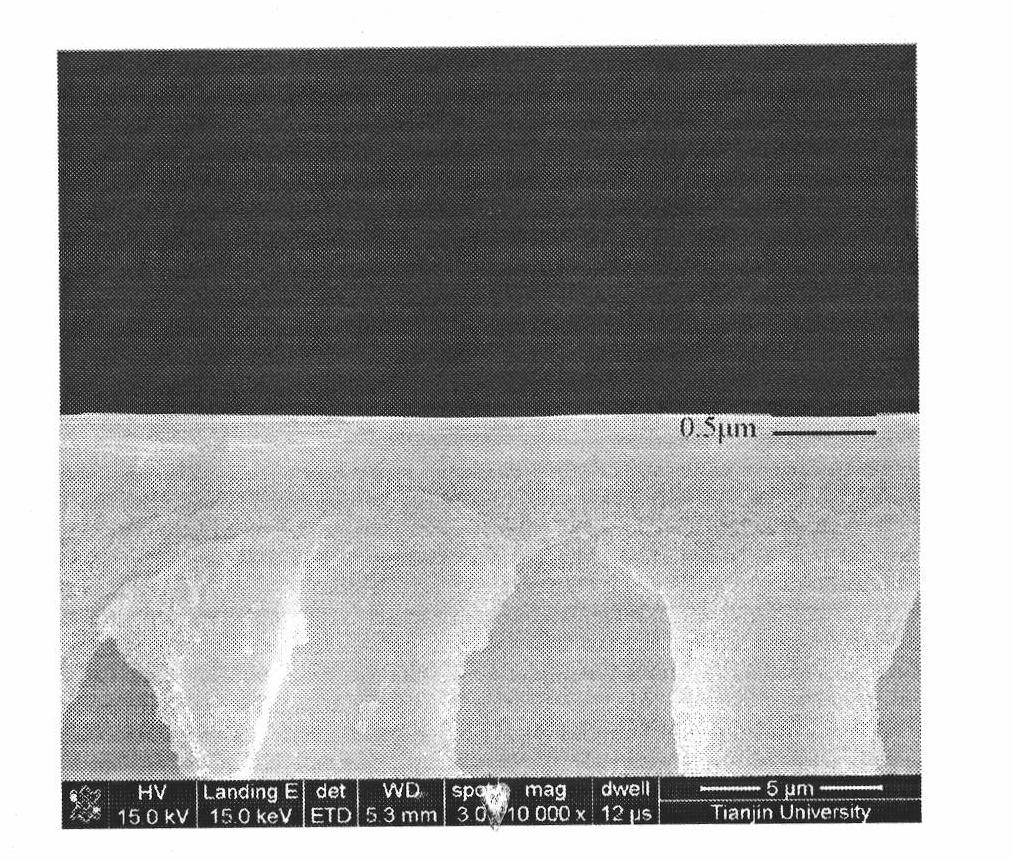

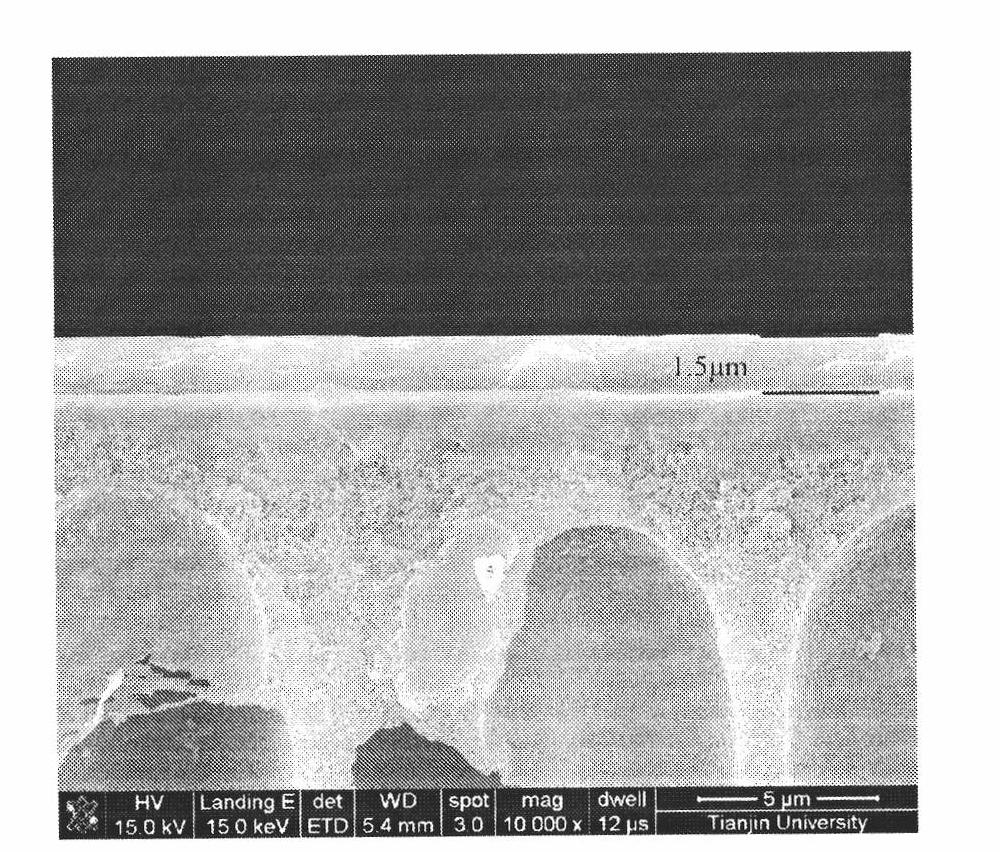

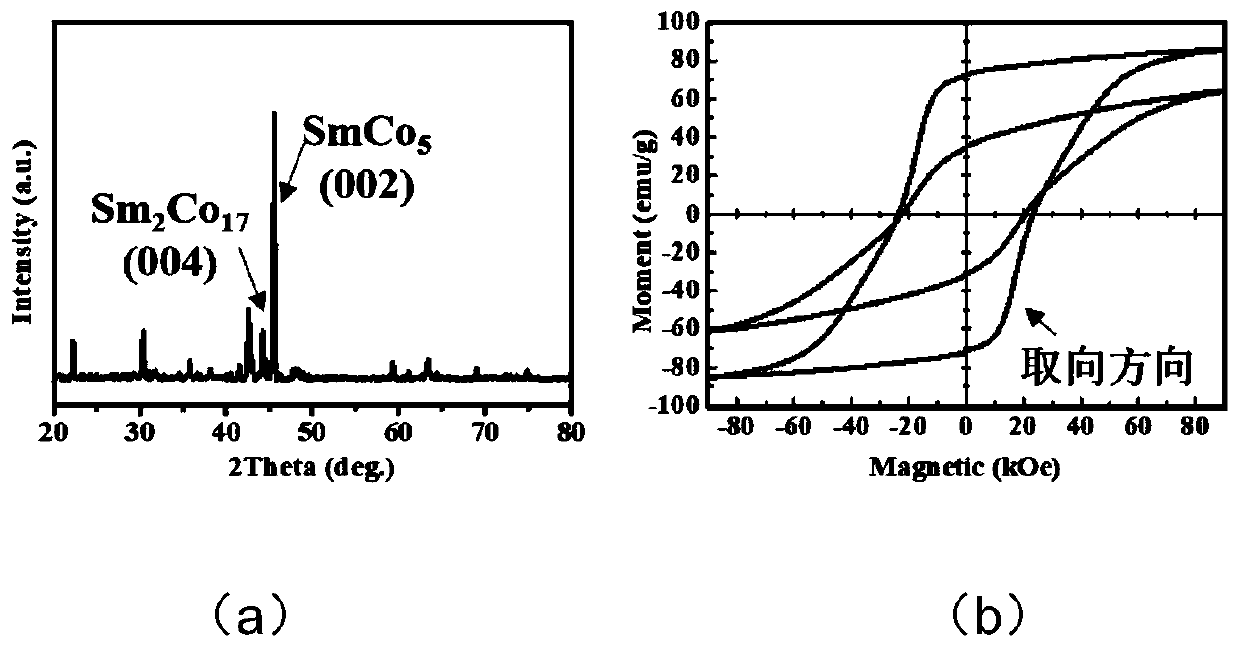

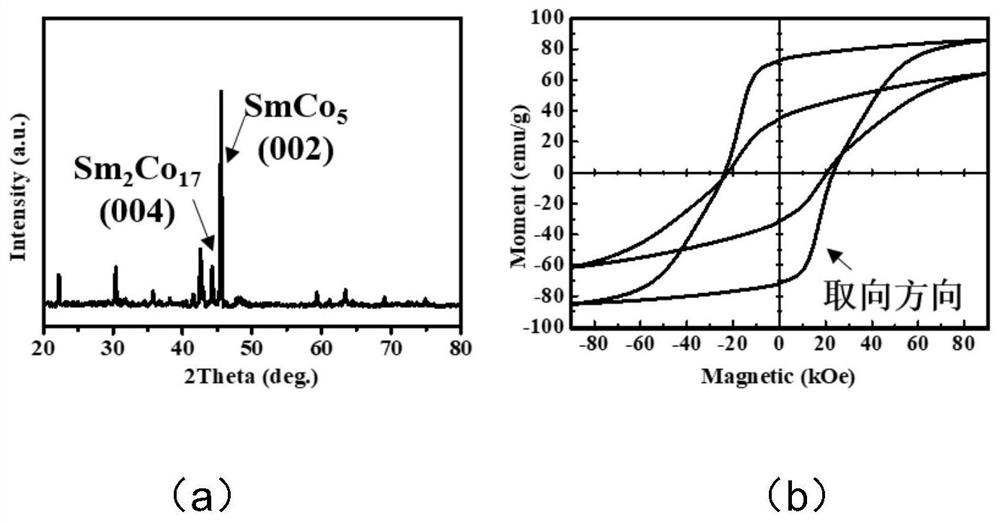

Method for preparing SmCo5/Sm2Co17 core-shell dual-phase composite magnetic nanoparticles in situ

ActiveCN109867310AHigh energy productStrong interface interactionMaterial nanotechnologyCobalt compoundsCouplingMagnetite Nanoparticles

The invention discloses a method for preparing SmCo5 / Sm2Co17 core-shell dual-phase composite magnetic nanoparticles in situ, which comprises the following steps: adding CaCl2 to prepare SmCoCa-OH andthen preparing the SmCo5 / Sm2Co17 core-shell composite magnetic nanoparticles by calcium thermal reduction reaction. The two phases are distributed in one particle in the form of core-shell structure.The two phases have strong exchange coupling and the material has high magnetic energy product.

Owner:BEIHANG UNIV +1

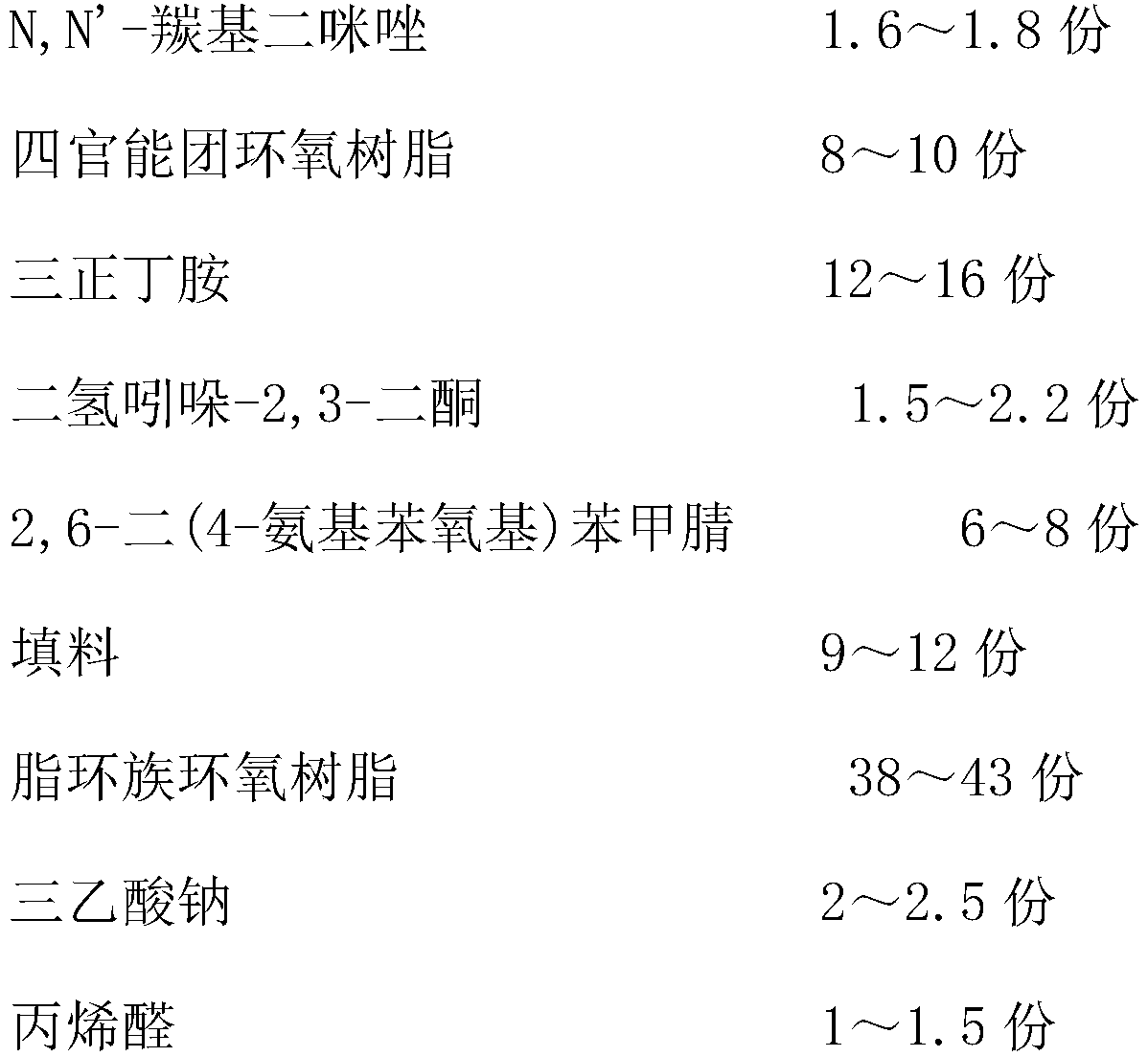

Heat-conducting electronic material composition

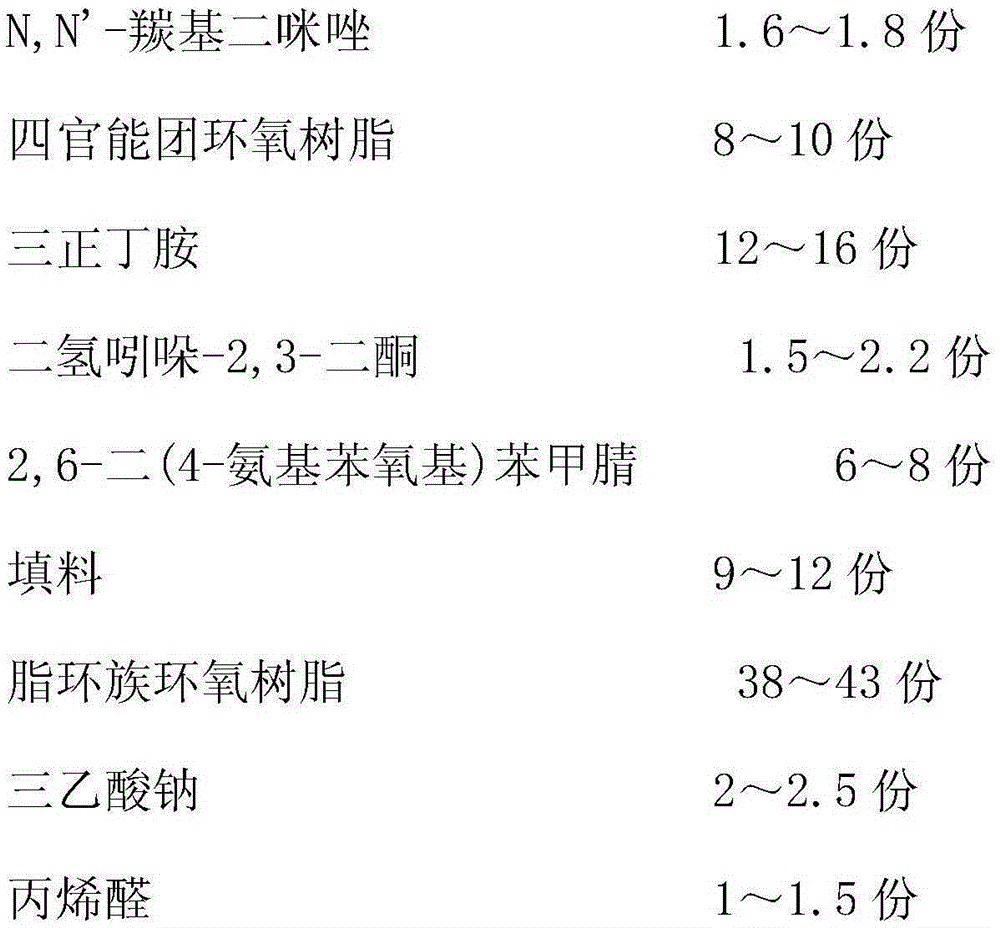

The invention relates to a heat-conducting electronic material composition which is obtained by mixing N,N'-carbonyldimidazole, tetra-functional epoxy resin, tri-n-butylamine, indoline-2,3-diketone, 2,6-di(4-aminophenoxy) cyanobenzene, a filler, cycloaliphatic epoxide resin, sodium triacetate and acraldehyde. Raw materials in a preparation method disclosed by the invention are wide in source, and the preparation process is simple and controllable, only needs normal operation and is easy to realize industrialization, therefore, the prepared heat-conducting electronic material composition has good heat conductivity and mechanical properties, and development applications of the heat-conducting electronic material composition can be met.

Owner:WUJIANG XINTA FORWARD HARDWARE FACTORY

Nylon 12 composite material for MJR3D printing and preparation method thereof

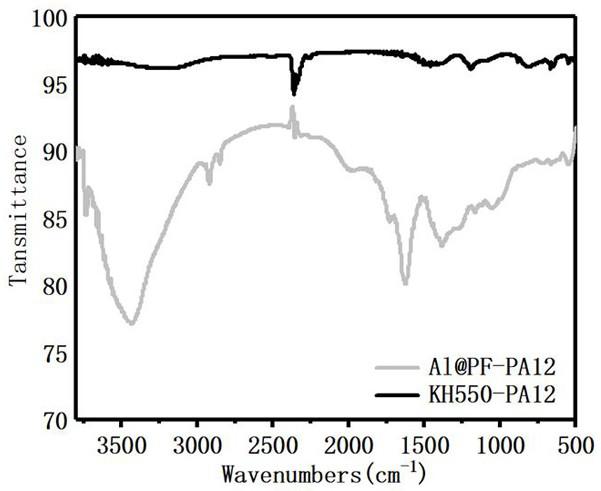

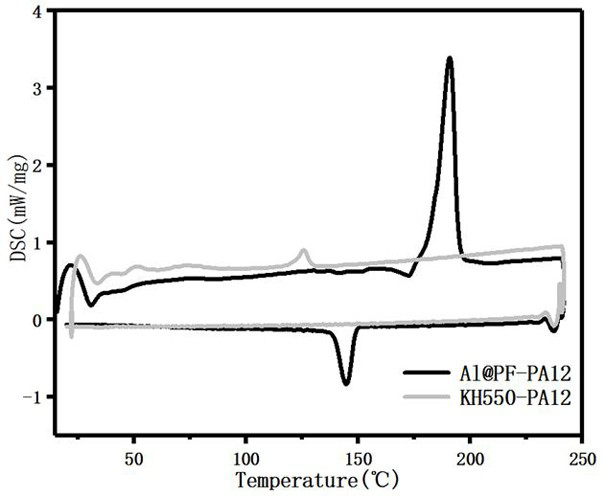

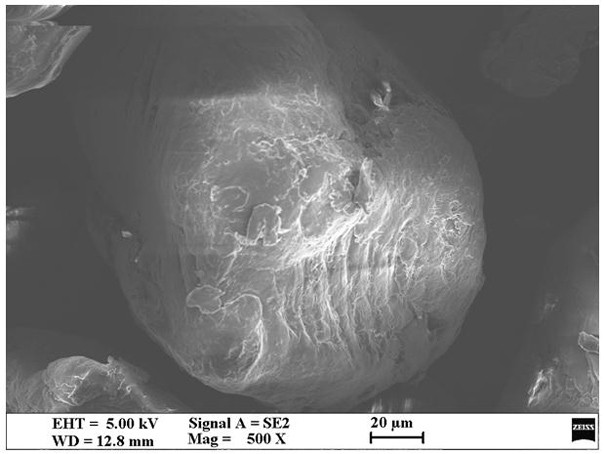

ActiveCN114276675AStrong and Flexible AdhesionStrong adhesionAdditive manufacturing apparatusPolymer scienceNylon 12

The invention discloses a nylon 12 composite material for MJR3D printing and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing Ni-activated PA12 powder; then carrying out chemical modification on polydopamine by using perfluorodecanethiol, and carrying out one-step surface fluorination on the nano aluminum particles to prepare a nano colloid Al (at) PF; and finally, the nano colloid Al (at) PF is activated through Ni, chemical adhesion is carried out on the surface of the PA12 powder, and the nylon 12 composite material for the MJR3D printing technology is successfully prepared. The PF (perfluorodecanethiol modified polydopamine) has excellent adhesive force and high fluoride content, so that the reaction component n-Al and the nylon 12 powder have good interfacial interaction, and the PF has great application prospects in the MJR3D printing process.

Owner:FUZHOU UNIV

Preparation method of high-performance nylon nanocomposite

The invention discloses a preparation method of a high-performance nylon nanocomposite. The method comprises the steps as follows: self-made nano SiO2 is used as filler, firstly, the nano SiO2 spheresurface is grafted with a polyamino acid molecular chain with chemical structure characteristics similar to nylon through macromolecular design, and the dual network structure function of a particle physical network and a grafting molecular chain and matrix molecular chain entanglement network is expected to be played, so that uniform dispersion of nanoparticles in a polymer matrix and the good interface interaction between the nanoparticles and the matrix material are realized. Then, macromolecular modified SiO2 is added to nylon for melt blending, and a novel high-performance nylon nanocomposite with wide application prospects is developed.

Owner:QINGDAO UNIV OF SCI & TECH

LED-lamp forsterite-nylon heat-conduction composite material and preparing method thereof

InactiveCN106189212AGood chemical stabilityImprove thermal conductivityHeat-exchange elementsFiberCarbon fibers

The invention discloses an LED-lamp forsterite-nylon heat-conduction composite material. The LED-lamp forsterite-nylon heat-conduction composite material is prepared from, by weight, 200 parts of nylon6, 40-50 parts of nylon66, 20-30 parts of forsterite, 20-30 parts of carbon fibers, 50-60 parts of acetone, 80-100 parts of nitric acid of 60% to 70%, 3-4 parts of tetraethyl orthosilicate, 3-4 parts of maleic anhydride, 15-20 parts of toluene-2,4-diisocyanate, 20-25 parts of (methyl) hydroxy propyl acrylate, 0.4-1 part of catalyst, 0.4-2 parts of polymerization inhibitor, 3-5 parts of sodium lignin sulfonate, 3-4 parts of potassium hydrogen tartrate, 150-170 parts of tetrahydrofuran, 80-100 parts of methylbenzene and a proper amount of deionized water. The nylon heat-conduction composite material is compact in structure, fast in heat transmission and heat dissipation, good in mechanical performance and durable in use, high-strength LED lamps can be effectively protected, and the service life of the lamps can be prolonged.

Owner:TONGLING RIXING ELECTRONICS

Multifunctional durable film with hierarchical structure and preparation method

The invention discloses a multifunctional durable thin film with a hierarchical structure and a preparation method, the multifunctional durable thin film comprises a bionic lotus leaf super-hydrophobic layer polydimethylsiloxane / silicon dioxide (PDMS / SiO2), a conductive layer MXene and an enhancement layer nano aramid fiber, the thickness of the hydrophobic layer is 3-10 [mu] m, the thickness of the conductive layer is 3-50 [mu] m, the thickness of the enhancement layer is 10-50 [mu] m, and the thickness of the enhancement layer is 10-50 [mu] m. All the functional layers are firmly connected through hydrogen bond interaction, and meanwhile the coupling enhancement effect is achieved through the performance of the functional layers. Multi-level structural design is achieved through vacuum filtration, hot press molding and spraying curing processes, and the prepared composite film has good flexibility and mechanical strength, efficient electromagnetic shielding performance, excellent super-hydrophobic self-cleaning performance and excellent weather resistance and high-temperature resistance; the method is suitable for application in the fields of military, electronic equipment and aerospace in severe environments.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

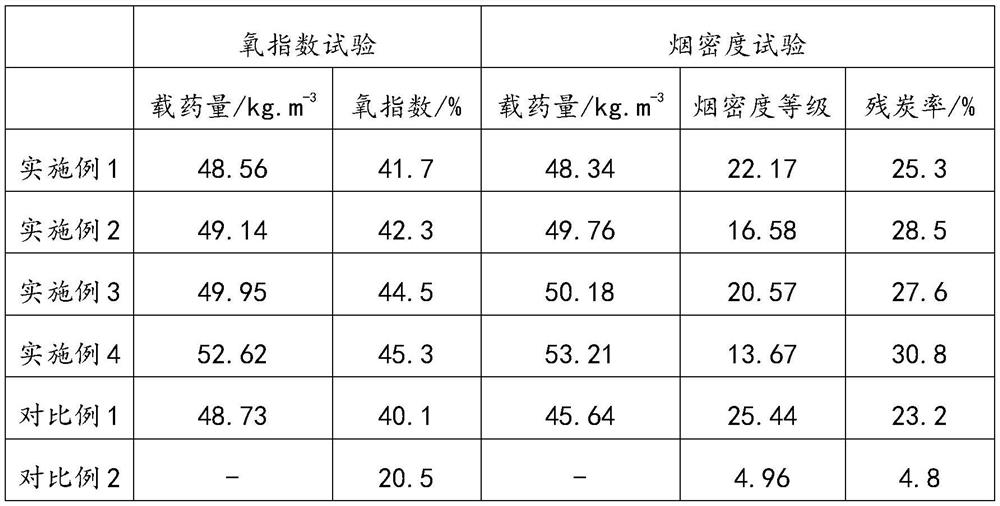

Flame-retardant reinforced wood and preparation method thereof

ActiveCN112157765AImprove mechanical propertiesGood durabilityWood treatment detailsPressure impregnationComposite materialActive agent

The invention discloses flame-retardant reinforced wood and a preparation method thereof, and relates to the technical field of wood chemical modification. The invention discloses flame-retardant reinforced wood which is prepared by the following steps: soaking wood in a wood modifier, carrying out vacuum impregnation treatment under the condition of vacuum pressurization, controlling the vacuum degree to be -0.3 to 0.8 MPa, the pressure to be 0.5-1.5 MPa and the vacuum impregnation time to be 1.5-3 hours to obtain vacuum impregnated wood, and drying the vacuum impregnated wood. The wood modifier is prepared from the following raw materials: a triazole compound, hydroxyethyl methylacrylate, a catalyst n-butyllithium, ammonium dihydrogen phosphate, a nonionic surfactant, silicon dioxide powder, a silane coupling agent, a flame retardant, polyethylene glycol and water. The flame-retardant reinforced wood provided by the invention has excellent hardness, bending strength, impact toughness, dimensional stability and flame retardancy, and also has waterproofness and loss resistance, so that the service life of the modified wood is prolonged.

Owner:桃江县鑫龙阳光木业胶板厂(普通合伙)

Wood modifier and preparation method thereof

ActiveCN112223464ABiologically activeImprove mechanical propertiesWood impregnation detailsPolymer science(Hydroxyethyl)methacrylate

The invention discloses a wood modifier and a preparation method thereof, and relates to the technical field of wood chemical modification. The wood modifier disclosed by the invention is prepared from the following raw materials in parts by weight: 5-10 parts of a triazole compound, 10-20 parts of hydroxyethyl methacrylate, 0.5-0.8 part of a catalyst, 10-20 parts of ammonium dihydrogen phosphate,20-40 parts of a nonionic surfactant, 45-90 parts of polyethylene glycol and 300-800 parts of water. The invention further discloses a preparation method of the wood modifier. The wood modifier provided by the invention can stabilize the size of wood treated by the modifier, has excellent hardness, bending strength, impact toughness and loss resistance, also has waterproofness and flame retardance, and prolongs the service life of the modified wood. The raw materials of the modifier are non-toxic and environment-friendly and are pollution-free to human bodies and the environment, and the application range of modified wood is widened.

Owner:桃江县鑫龙阳光木业胶板厂(普通合伙)

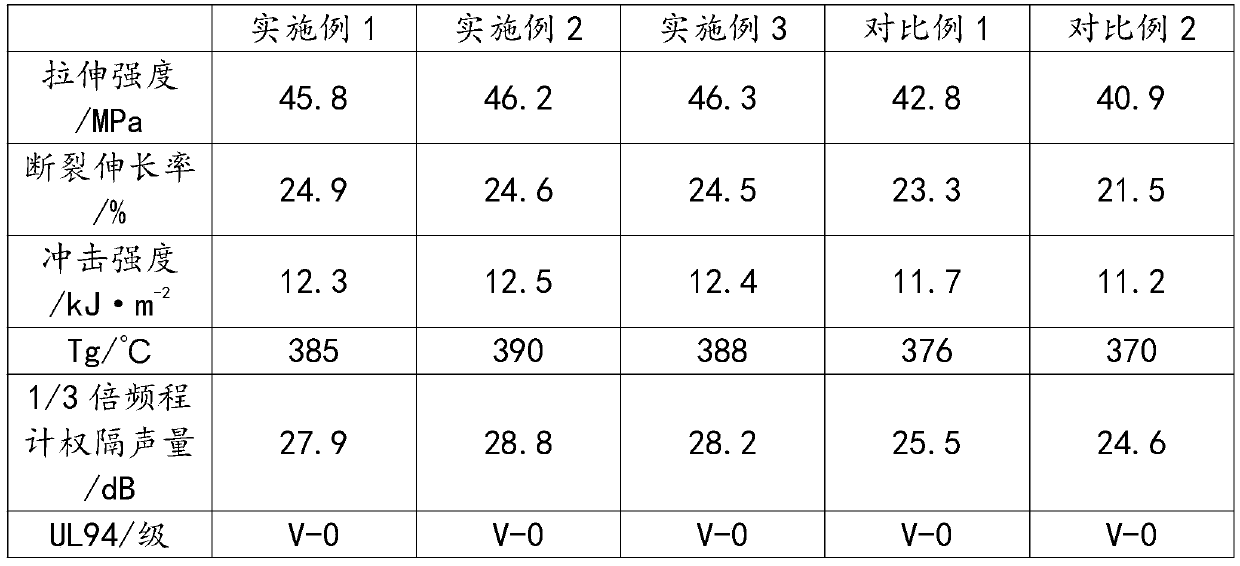

Sound insulation and noise reduction composite waved plate tile and production process thereof

InactiveCN111169127AImprove flame retardant performanceImprove insulation performanceLamination ancillary operationsSynthetic resin layered productsPolymer scienceUltraviolet lights

The invention discloses a sound insulation and noise reduction composite waved plate tile which is of a two-layer composite structure and comprises a PC layer and a sound absorption layer. The PC layer is prepared from the following raw materials in parts by weight: 60 to 70 parts of PC resin, 15 to 20 parts of polyacrylonitrile-butadiene-styrene copolymer, 0.8 to 1 part of an ultraviolet light absorber, 2 to 3 parts of a composite filler and 0.5 to 0.7 part of a compound flame retardant; thesound absorption layer is made of a polyurethane rigid foam material blended with modified expanded graphite; the invention further discloses a production process of the sound insulation and noise reduction composite waved plate tile. According to the sound insulation and noise reduction composite waved plate tile, the PC layer is prepared by takingPC resin as a polymer matrix, ABS copolymer is adopted for blending modification, the compound flame retardant and the composite filler are used as auxiliary materials, and the PC layer has good heat insulation, mechanical and sound insulation properties; the sound absorption layer has excellent sound-absorbing and sound-insulating effects and flame-retardant performance; the obtained sound insulation and noise reduction composite waved plate tile has good sound insulation, noise reduction and flame retardant properties, and is a high-performanceroof material product.

Owner:界首市丰杨塑业有限公司

Biomass granular fuel and preparation method thereof

InactiveCN112111311AReduce porosityImprove molding rateBiofuelsSolid fuelsProcess engineeringEnvironmental engineering

The invention discloses a biomass granular fuel and a preparation method thereof, and relates to the field of development and utilization of waste biomass resources. The biomass granular fuel disclosed by the invention is prepared by the following steps: drying and crushing a biomass raw material to obtain powder, adding the lignin-based binder and the additive into the powder, uniformly stirringby virtue of a stirrer, mechanically compressing, granulating and cooling, thereby obtaining the biomass granular fuel. The lignin-based binder is obtained by adding a polyacrylic acid / urea polymer into a suspension containing lignin particles, adjusting the pH value, stirring, filtering, drying and crushing. According to the biomass granular fuel provided by the invention, by adding the lignin-based binder, the forming rate of the biomass granular fuel is increased, the biomass granular fuel is not easy to break in the transportation process, the combustion speed is stable, slag bonding is not liable to generate in the combustion process, the combustion efficiency is improved, the service life of a combustion device is prolonged, and the environmental pollution is reduced.

Owner:桃江县新辉生物质颗粒有限公司

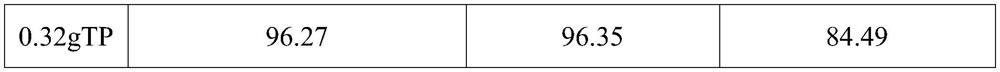

Biodegradable antibacterial film and preparation method thereof

PendingCN114656738AHigh crystallinityImproves water resistance and strengthCellulosePolyvinyl alcohol

The invention discloses a biodegradable antibacterial film and a preparation method thereof, and belongs to the field of biodegradable antibacterial film preparation, polyvinyl alcohol, nano cellulose crystal and tea polyphenol are used as main film preparation materials, glycerol is used as a plasticizing modifier, glutaraldehyde is used as a cross-linking agent, and the biodegradable antibacterial film is prepared by a one-step method. The biodegradable antibacterial film is prepared by adopting a solution tape casting method. The prepared film has good mechanical properties, water resistance, light transmittance, moisturizing performance, antibacterial performance and full-biodegradation performance, and solves the problems that antibacterial films on the market are slow in degradation rate and cannot be completely degraded, and the problems that environmental pollution is caused in the degradation process of synthetic antibacterial agents and the like.

Owner:SHAANXI UNIV OF SCI & TECH

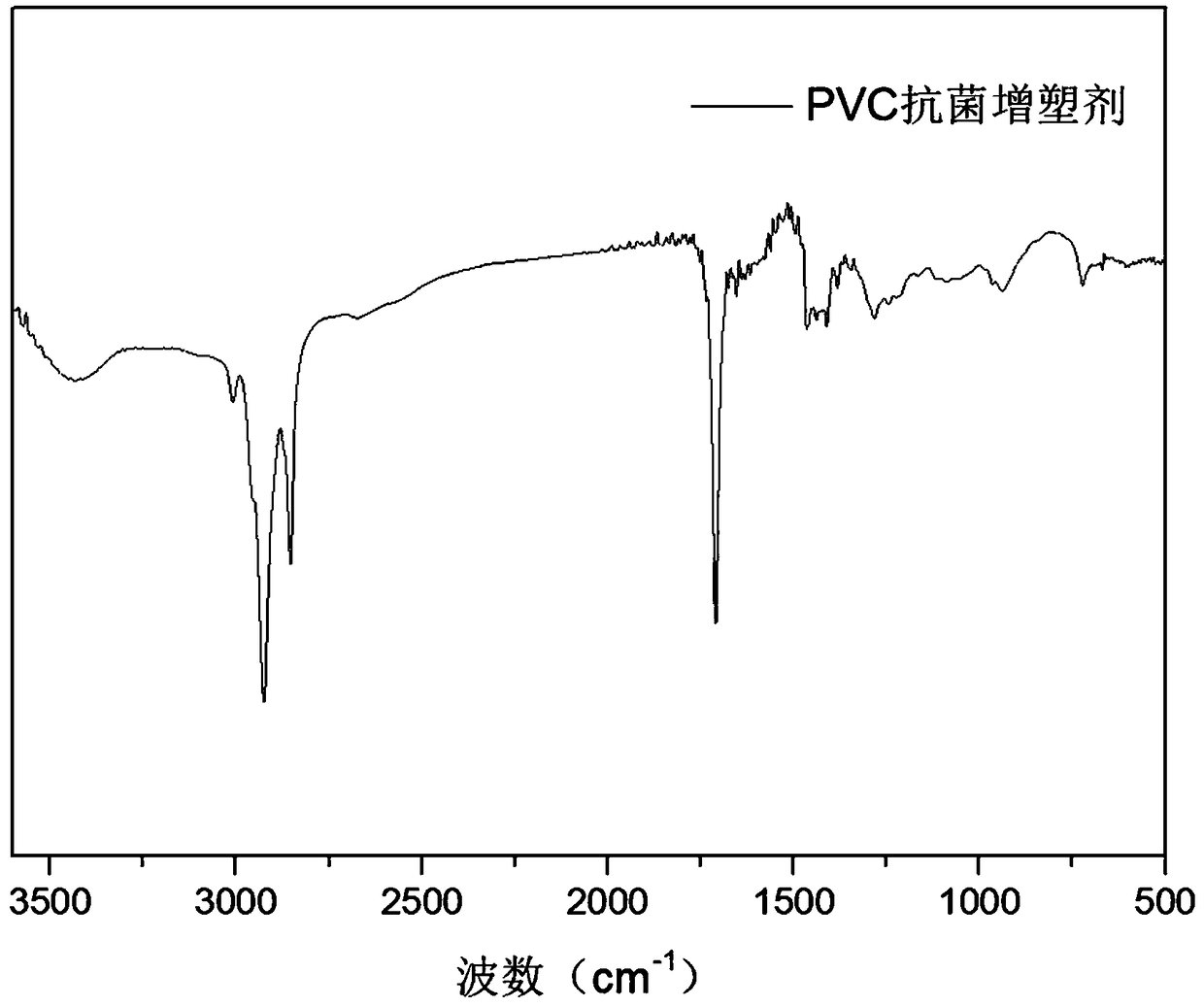

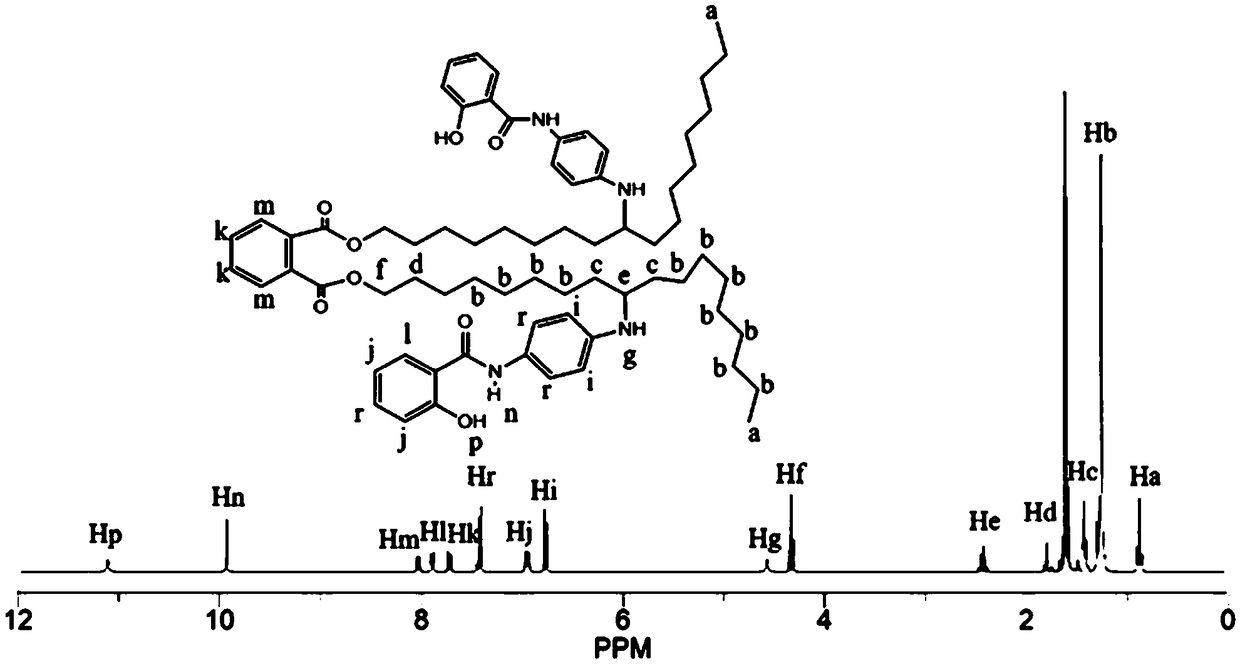

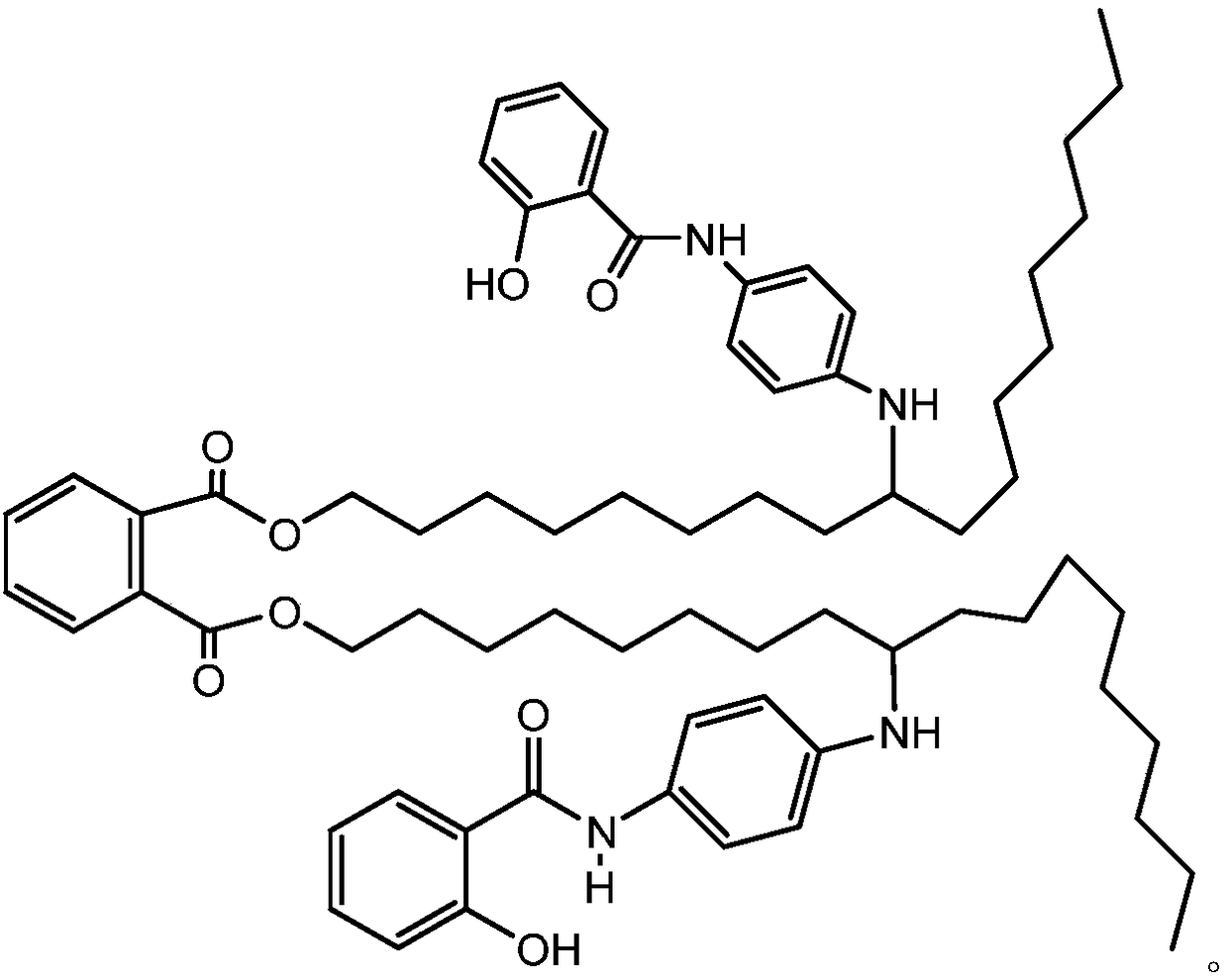

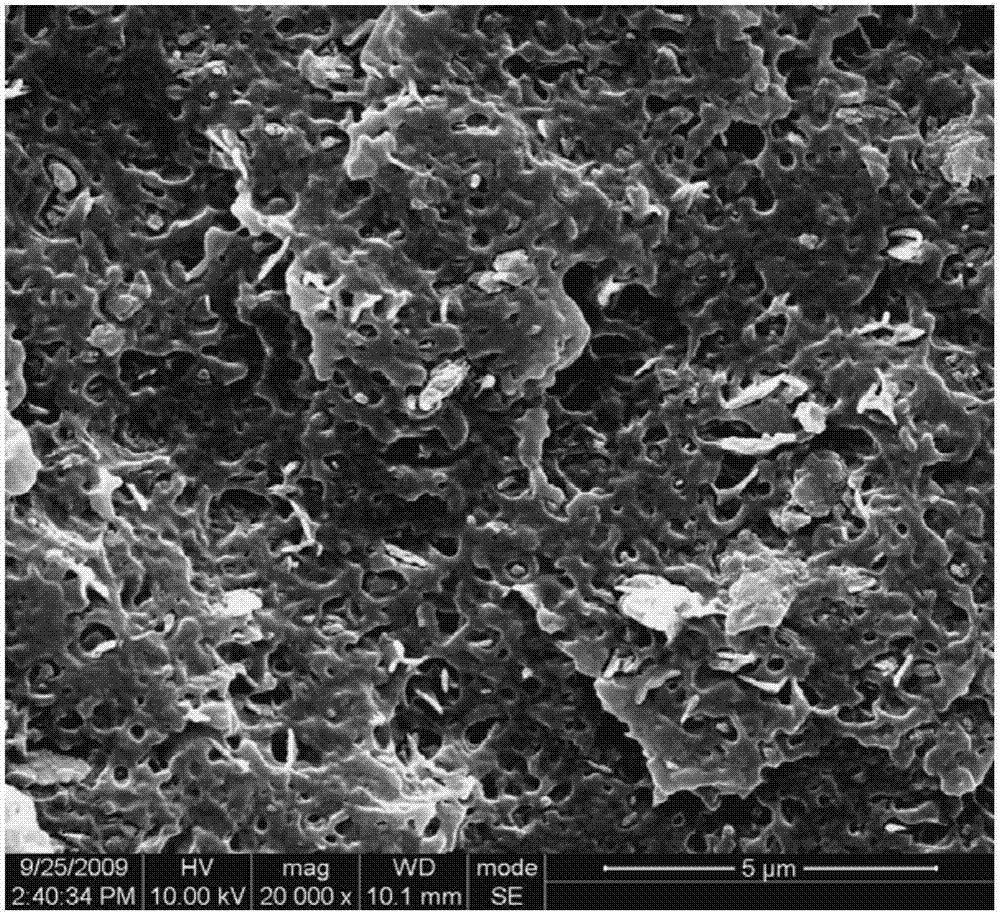

High-antibacterial and wear-resisting PVC (Polyvinyl Chloride) resin material and preparation method thereof

InactiveCN108864618AGood plasticizing effectStrong antibacterial effectChemistryAntibacterial effect

The invention relates to the technical field of high molecular materials and relates to a high-antibacterial and wear-resisting PVC (Polyvinyl Chloride) resin material and a preparation method thereof. The high-antibacterial and wear-resisting PVC resin material is prepared from the following components in parts by weight: 100 parts of PVC resin, 10 to 40 parts of an antibacterial plasticizer, 8 to 12 parts of a stabilizer, 1 to 3 parts of a lubricant, 5 to 8 parts of an antioxidant, 3 to 5 parts of an anti-impact modifying agent, 5 to 20 parts of filler and 1 to 3 parts of an additive. According to the high-antibacterial and wear-resisting PVC resin material and the preparation method thereof, an antibacterial functional auxiliary agent and a plasticizing-promoting auxiliary agent are integrated, have a good plasticizing effect and a relatively strong antibacterial effect, and are matched with other components to have a mutual synergistic effect, so that the PVC material has a good antibacterial effect and good mechanical properties and weather-resisting performance; the application field and application field of PVC are greatly improved; furthermore, the preparation method provided by the invention is simple, preparation technological conditions are easy to control and the preparation efficiency is high; the raw material price and the production energy consumption are relatively low, so that the preparation method is suitable for large-scale production.

Owner:界首市海钰塑化有限公司

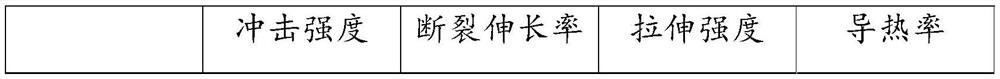

A kind of polyvinyl chloride toughened reinforced masterbatch and its preparation method and application

The invention discloses a polyvinyl chloride toughened and reinforced masterbatch, which is made of the following raw materials in weight percentage: 5%-40% of thermoplastic elastomer, 5%-40% of modified kaolin, and 0%-20% of processing aid , and the balance is polyvinyl chloride. The invention also discloses the preparation method and application of the master batch. The polyvinyl chloride toughened and reinforced masterbatch of the present invention adopts polyurethane thermoplastic elastomer as raw material, combined with modified kaolin, there is good interfacial interaction between modified kaolin, polyurethane thermoplastic elastomer and matrix resin, and can effectively transfer stress, thereby Significantly improve the impact strength and tensile properties of polyvinyl chloride, add the masterbatch to polyvinyl chloride, and process it to prepare high-strength and high-toughness polyvinyl chloride nanocomposites, and the tensile strength of the prepared polyvinyl chloride nanocomposites Up to 53.1MPa or more, the elongation at break is over 220%, and the notched impact strength is over 12.3kJ / m2.

Owner:XIAN UNIV OF SCI & TECH

Flexible high-strength mxene-based electromagnetic shielding composite film and preparation method thereof

ActiveCN111809439BImprove conductivityImprove shielding effectSynthetic cellulose/non-cellulose material pulp/paperPaper-making machinesComposite filmNanofiber

The invention discloses a flexible high-strength MXene-based electromagnetic shielding composite film, comprising a conductive layer Ti 3 C 2 T x MXene / silver nanowires and aramid nanofibers with polymer reinforcement, Ti 3 C 2 T x The mass fraction of MXene / silver nanowire conductive layer is 10-80%; Ti 3 C 2 T x The mass ratio of MXene to silver nanowires is 10:0.5˜10:1.5. The invention also discloses a method for preparing a flexible and high-strength MXene-based electromagnetic shielding composite film. The composite film prepared by the invention has excellent flexibility and mechanical properties, good electrical conductivity and broadband high electromagnetic shielding efficiency, and can meet the requirements of aerospace, aerospace, Applications in military engineering, artificial intelligence, and flexible wearable electronics.

Owner:SHAANXI UNIV OF SCI & TECH

Novel environment-friendly functional polypropylene and preparation method thereof

The invention relates to novel environment-friendly functional polypropylene, which is characterized by being prepared from the following raw materials in percentage by weight: 94.50 to 99.89 percent of polypropylene, 0.01 to 0.50 percent of organic peroxide and 0.10 to 5.00 percent of o-diallyl bisphenol A diglycidyl ether. The invention also provides a preparation method of the novel environment-friendly functional polypropylene. The novel environment-friendly functional polypropylene not only has excellent interface interaction with the inorganic filler, the organic additive and the polar polymer material, but also has extremely low total migration volume and VOC (volatile organic compound) value, so that the novel environment-friendly functional polypropylene has high performance and high safety at the same time.

Owner:SHANTOU SAMMA PLASTIC IND CO LTD

A kind of transparent hydrophobic wear-resistant coating and preparation method thereof

ActiveCN107603415BWith transparencyControllable hydrophobicityLiquid surface applicatorsEpoxy resin coatingsPolymer scienceOrganosolv

A transparent hydrophobic wear-resistant coating and a preparation method therefor. The transparent hydrophobic wear-resistant coating is composed of an epoxy resin layer and a low-surface-energy fluorine-containing layer which are arranged in sequence from top to bottom. The preparation method therefor comprises: (1) blending epoxy resin and a curing agent into an organic solvent, and carrying out ultrasonic treatment to obtain a coating solution, the total content of the epoxy resin and the curing agent being 0.001-5wt%; by adopting a dip-coating method for a substrate material, uniformly adhering the coating solution to the surface of the substrate material, and taking out and curing to obtain the epoxy resin layer; and (2) preparing the low-surface-energy fluorine-containing layer: coating the epoxy resin layer with the fluorine-containing solution, and drying to obtain the transparent hydrophobic wear-resistant coating. The coating is equivalent to glass in transparency, the surface contact angle is 102° or above, and the hydrophobicity of the coating is controllable; the coating has excellent mechanical strength and bonding property and is convenient for large-scale industrial production.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

A kind of high strength and high thermal conductivity nylon composite material and preparation method thereof

Owner:ZHEJIANG UNIV OF TECH

Cyanate resin raw material composition, cyanate resin, and cyanate resin metal composite material and preparation method thereof

ActiveCN108264763BImprove bindingStrong interface interactionSynthetic resin layered productsLaminationPolymer scienceMetallic materials

The invention discloses a cyanate resin raw material composition and cyanate resin and a cyanate resin metal composite material and a preparation method thereof. The cyanate resin raw material composition comprises, based on 100 parts by weight, 40-89.5 parts by weight of cyanate monomer material, 10-50 parts by weight of short glass fiber, 0.01-0.1 part by weight of catalyst, and 0.2-10 parts byweight of liquid promoter, wherein the short glass fiber contains a boron element, and on the basis of 100 parts by weight of the short glass fiber, the content of the boron element is 15 parts by weight or above based on B2O3. The use of the cyanate resin raw material composition is beneficial for increasing the bonding force between a resin material and a metal material in the resin metal composite material.

Owner:BYD CO LTD

A thermally conductive electronic material composition

ActiveCN105400134BImprove thermal conductivityImprove mechanical propertiesHeat conductingMechanical property

The invention relates to a heat-conducting electronic material composition which is obtained by mixing N,N'-carbonyldimidazole, tetra-functional epoxy resin, tri-n-butylamine, indoline-2,3-diketone, 2,6-di(4-aminophenoxy) cyanobenzene, a filler, cycloaliphatic epoxide resin, sodium triacetate and acraldehyde. Raw materials in a preparation method disclosed by the invention are wide in source, and the preparation process is simple and controllable, only needs normal operation and is easy to realize industrialization, therefore, the prepared heat-conducting electronic material composition has good heat conductivity and mechanical properties, and development applications of the heat-conducting electronic material composition can be met.

Owner:WUJIANG XINTA FORWARD HARDWARE FACTORY

Method for preparing environmentally-friendly plastic wood

InactiveCN101954663BSmooth infusionKeep the colorPressure impregnationPolymer scienceCompressive strength

The invention provides a method for preparing environmentally-friendly plastic wood and relates to a method for preparing plastic wood. The method solves the problems of high monomer volatility and low monomer conversion rate in the conventional preparation method of the plastic wood. The method comprises the following steps of: I, mixing an organic monomer, an initiator and a polymerization promoter uniformly to obtain impregnation liquid; II, adding wood and the impregnation liquid into a reaction tank and vacuumizing the reaction tank; III, performing pressurization by introducing air; IV,wrapping the wood with aluminium foil, placing the wood at normal temperature and under normal pressure, and then heating the wood to obtain the environmentally-friendly plastic wood. The environmentally-friendly plastic wood prepared by the method has the advantages of high monomer conversion rate of 75 to 88 percent, no volatility and no peculiar smell during later application, compressive strength parallel to grain of 90 to 120 MPa, swelling-resistant rate of 40 to 52 percent after being soaked continuously for 200 hours, high size stability, weight loss rate of 7 to 14 percent after beingsubjected to fungal erosion for 12 weeks and high corrosion resistance. The environmentally-friendly plastic wood can serve as building and interior decoration materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

FPGA development module based traffic signal control demonstration box

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

An in situ preparation of smco 5 /sm 2 co 17 Method for core-shell structure two-phase composite magnetic nanoparticles

ActiveCN109867310BHigh energy productStrong interface interactionMaterial nanotechnologyCobalt compoundsPhysical chemistryMagnetite Nanoparticles

The invention discloses a method for preparing SmCo5 / Sm2Co17 core-shell dual-phase composite magnetic nanoparticles in situ, which comprises the following steps: adding CaCl2 to prepare SmCoCa-OH andthen preparing the SmCo5 / Sm2Co17 core-shell composite magnetic nanoparticles by calcium thermal reduction reaction. The two phases are distributed in one particle in the form of core-shell structure.The two phases have strong exchange coupling and the material has high magnetic energy product.

Owner:BEIHANG UNIV +1

Titanium dioxide-polyamide thermal conductive composite material for LED lamps and preparation method of material

The invention provides a titanium dioxide-polyamide thermal conductive composite material for LED lamps. The composite material is prepared from, by weight, 6-200 parts of polyamide, 40-50 parts of polyamide 66, 20-30 parts of rutile type titanium dioxide, 20-30 parts of carbon fibers, 50-60 parts of acetone, 80-100 parts of 60%-70% nitric acid, 3-4 parts of nonylphenol polyoxyethylene ether, 3-4 parts of lauric acid, 15-20 parts of methylbenzene-2,4-diisocyanate, 20-25 parts of 2-hydroxypropyl methacrylate, 0.4-1 part of catalyst, 0.4-2 parts of polymerization inhibitor, 3-5 parts of ethoxyquin, 3-4 parts of disodium stannous citrate, 150-170 parts of tetrahydrofuran, 80-100 parts of methylbenzene and an appropriate amount of deionized water. The polyamide thermal conductive composite material is compact in structure, rapid in heat transfer and heat dissipation, good in mechanical property, durable in use and capable of effectively protecting high-strength LED lamps and greatly prolonging the service life of the lamps.

Owner:BENGBU GAOHUA ELECTRONICS

A kind of preparation method of high toughness, high strength carbon nanotube/epoxy resin composite material

The invention discloses a preparation method of a high-toughness and high-strength carbon nanotube / epoxy resin composite material, which belongs to the field of polymer composite materials. The method is to use block copolymer-epoxy-terminated polyether polysiloxane as a dispersant for carbon nanotubes, and to coat the surface of epoxy-terminated polyether polysiloxane to make carbon nanotubes The tubes are uniformly dispersed in the epoxy resin, at the same time, the organosilicon and polyether flexible chain structure in its block structure and the carbon nanotubes synergistically toughen the epoxy resin to prepare a high toughness, high strength carbon nanotube / epoxy resin composite material. The preparation process of the invention has no organic solvent, is green and environment-friendly, has simple operation and moderate conditions, can be applied to epoxy resins of conventional grades on the market, and meets the needs of large-scale production. The high toughness, high strength and excellent comprehensive performance of the carbon nanotube / epoxy resin composite material make it have great market application value in the fields of machinery industry, building materials, electronic appliances, aerospace and the like.

Owner:FUZHOU UNIV +1

A kind of preparation method of high-performance nylon nanocomposite material

The invention discloses a preparation method of a high-performance nylon nanocomposite material, which comprises the following steps: using self-made nano silicon dioxide as a filler, first designing a nano-SiO 2 The polyamino acid molecular chains with similar chemical structure characteristics to nylon are grafted on the surface of the ball, and it is expected to play the dual network structure of the particle physical network and the entanglement network of the grafted molecular chains and the matrix molecular chains at the same time, so as to realize the nanoparticle in the polymer matrix. Uniform dispersion in the medium and good interfacial interaction between nanoparticles and matrix materials. Then the macromolecularly modified SiO 2 Add it to nylon for melt blending, so as to develop a new type of high-performance nylon nanocomposite material with wide application prospects.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com