High-strength high-thermal-conductivity nylon composite material and preparation method thereof

A nylon composite material and high thermal conductivity technology, which is applied in the field of high-strength and high thermal conductivity nylon composite materials and its preparation, can solve the problems of difficult dispersion of melt blending, small particle size of graphene and carbon nanotubes, and easy agglomeration, etc., to achieve improved Mechanical properties and thermal stability, strong interfacial interaction, and the effect of reducing interfacial thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

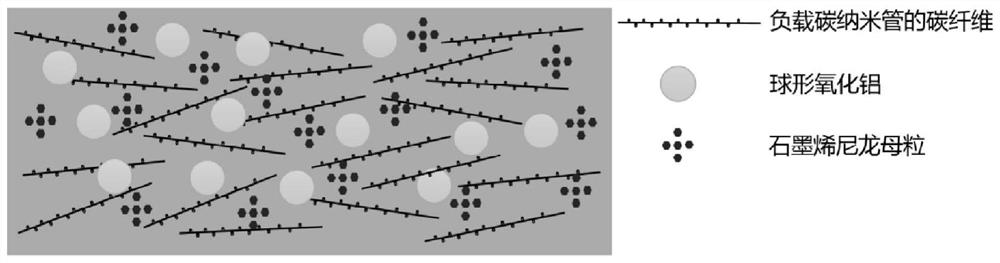

Image

Examples

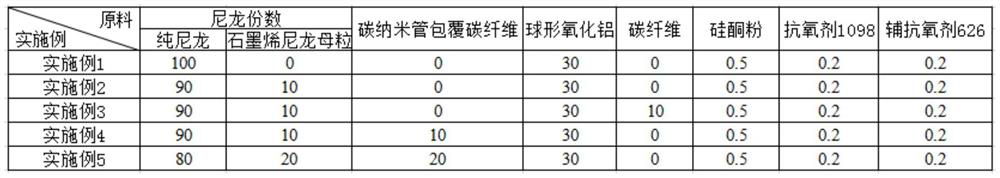

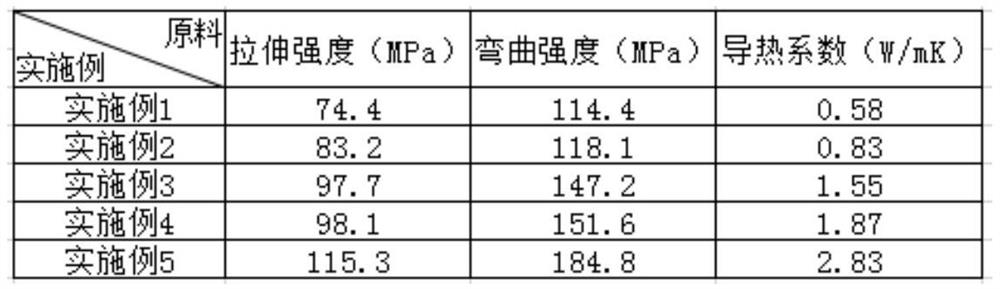

Embodiment 1

[0047] 1.5kg of nylon 66, 450g of spherical alumina, 7.5g of silicone powder, 3g of antioxidant 1098, and 3g of antioxidant 626 were vacuum-dried at 85°C for 12 hours, granulated by twin-screw extrusion, and then injection-molded into mechanical splines and wafers.

[0048] The temperature of each zone of the extruder: Zone 1: 260°C, Zone 2: 265°C, Zone 3: 270°C, Zone 4: 275°C, Zone 5: 280°C, Zone 6: 280°C, Zone 7: 275°C, Zone 8 : 270°C, District 9: 270°C, District 10: 275°C. The specific performance is shown in Table 2.

Embodiment 2

[0050] 1.35kg of nylon 66, 150g of graphene nylon 6 masterbatch, 450g of spherical alumina, 7.5g of silicone powder, 3g of antioxidant 1098, and 3g of antioxidant 626 were vacuum-dried at 85°C for 12 hours, and produced by twin-screw extrusion. Granules, and then injection molding mechanical splines and discs.

[0051] The temperature of each zone of the extruder: Zone 1: 260°C, Zone 2: 265°C, Zone 3: 270°C, Zone 4: 275°C, Zone 5: 280°C, Zone 6: 280°C, Zone 7: 275°C, Zone 8 : 270°C, District 9: 270°C, District 10: 275°C. The specific performance is shown in Table 2.

Embodiment 3

[0053] 1.35kg of nylon 66, 150g of graphene nylon 6 masterbatch, 450g of spherical alumina, 150g of carbon fiber, 7.5g of silicone powder, 3g of antioxidant 1098, and 3g of antioxidant 626 were vacuum-dried at 85°C for 12h, passed through a twin-screw Extrusion granulation, and then injection molding mechanical splines and discs.

[0054] The temperature of each zone of the extruder: Zone 1: 260°C, Zone 2: 265°C, Zone 3: 270°C, Zone 4: 275°C, Zone 5: 280°C, Zone 6: 280°C, Zone 7: 275°C, Zone 8 : 270°C, District 9: 270°C, District 10: 275°C. The specific performance is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com