Biodegradable antibacterial film and preparation method thereof

A biodegradable and film technology, applied in the field of biodegradable antibacterial film and its preparation, can solve the problems of great harm to the human body and the environment, poor crack resistance, and inability to completely degrade naturally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of a biodegradable antibacterial film, comprising the following steps:

[0026] Step 1: Preparation of PVA / CNC blend solution: Weigh 5g of PVA and add it to 100ml of deionized water. The stirring speed of the water bath at 95°C is 900rpm, and stirring and swelling for 1h to obtain a PVA aqueous solution with a concentration of 5% (m / v); continue stirring and cooling To room temperature, add the CNC suspension with a mass fraction of 1 to 7% to the PVA mother solution, drop 1 to 2 ml of a 2.5% mass fraction of glutaraldehyde aqueous solution and 1 ml of glycerol, and stir and disperse at 700 rpm for 1 hour to obtain a PVA / CNC blend solution. .

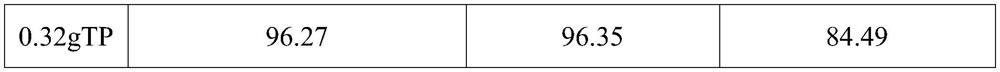

[0027] Step 2: Preparation of PVA / CNC / antibacterial agent composite film: add 0.08-0.4 g of tea polyphenol powder to the solution described in step 1, stir and disperse at room temperature for 30 minutes, and stir and disperse at a stirring speed of 700 rpm for 30 minutes to prepare a casting liquid , stand ...

Embodiment 1

[0032] Example 1: Agricultural mulch film

[0033] Step 1: Preparation of polyvinyl alcohol PVA solution: Weigh 5 g of polyvinyl alcohol PVA and add it to 100 ml of deionized water. The stirring speed of the water bath at 95 ° C is 700 rpm, stirring and swelling for 1 h, and stirring is continued to cool to room temperature to obtain a concentration of 5% (m / v) An aqueous solution of polyvinyl alcohol PVA.

[0034] Step 2: Preparation of polyvinyl alcohol PVA / nanocellulose crystal CNC blend: 3.43 g of the nanocellulose crystal CNC suspension with a mass fraction of 7 wt% was added to the polyvinyl alcohol PVA mother solution, and 1 ml of 2.5% mass fraction was added dropwise. The aqueous solution of glutaraldehyde and 1 ml of glycerol were stirred and dispersed at 700 rpm for 30 min to obtain a polyvinyl alcohol PVA / nanocellulose crystal CNC blended solution.

[0035] Step 3: Preparation of polyvinyl alcohol PVA / nanocellulose crystal CNC / tea polyphenol TP composite film: add...

Embodiment 2

[0037] Example 2: Antibacterial Packaging Film

[0038] Step 1: Preparation of polyvinyl alcohol PVA solution: Weigh 5 g of polyvinyl alcohol PVA and add it to 100 ml of deionized water. The stirring speed of the water bath at 95 ° C is 700 rpm, stirring and swelling for 1 h, and stirring is continued to cool to room temperature to obtain a concentration of 5% (m / v) An aqueous solution of polyvinyl alcohol PVA.

[0039] Step 2: Preparation of polyvinyl alcohol PVA / nanocellulose crystal CNC blend: 1.1 g of the nanocellulose crystal CNC suspension with a mass fraction of 7 wt% was added to the polyvinyl alcohol PVA mother solution, and 2 ml of 2.5% mass fraction was added dropwise. The aqueous solution of glutaraldehyde and 1 ml of glycerol were stirred and dispersed at 700 rpm for 30 min to obtain a polyvinyl alcohol PVA / nanocellulose crystal CNC blended solution.

[0040] Step 3: Preparation of polyvinyl alcohol PVA / nanocellulose crystal CNC / tea polyphenol TP composite film:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com