High-antibacterial and wear-resisting PVC (Polyvinyl Chloride) resin material and preparation method thereof

A technology of PVC resin and antioxidant, which is applied in the field of high antibacterial and wear-resistant PVC resin materials and its preparation, can solve the problems of limiting the application range of PVC, PVC does not have antibacterial properties, and health hazards, and achieves a significant synergistic antibacterial effect, Good antibacterial effect and guaranteed mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

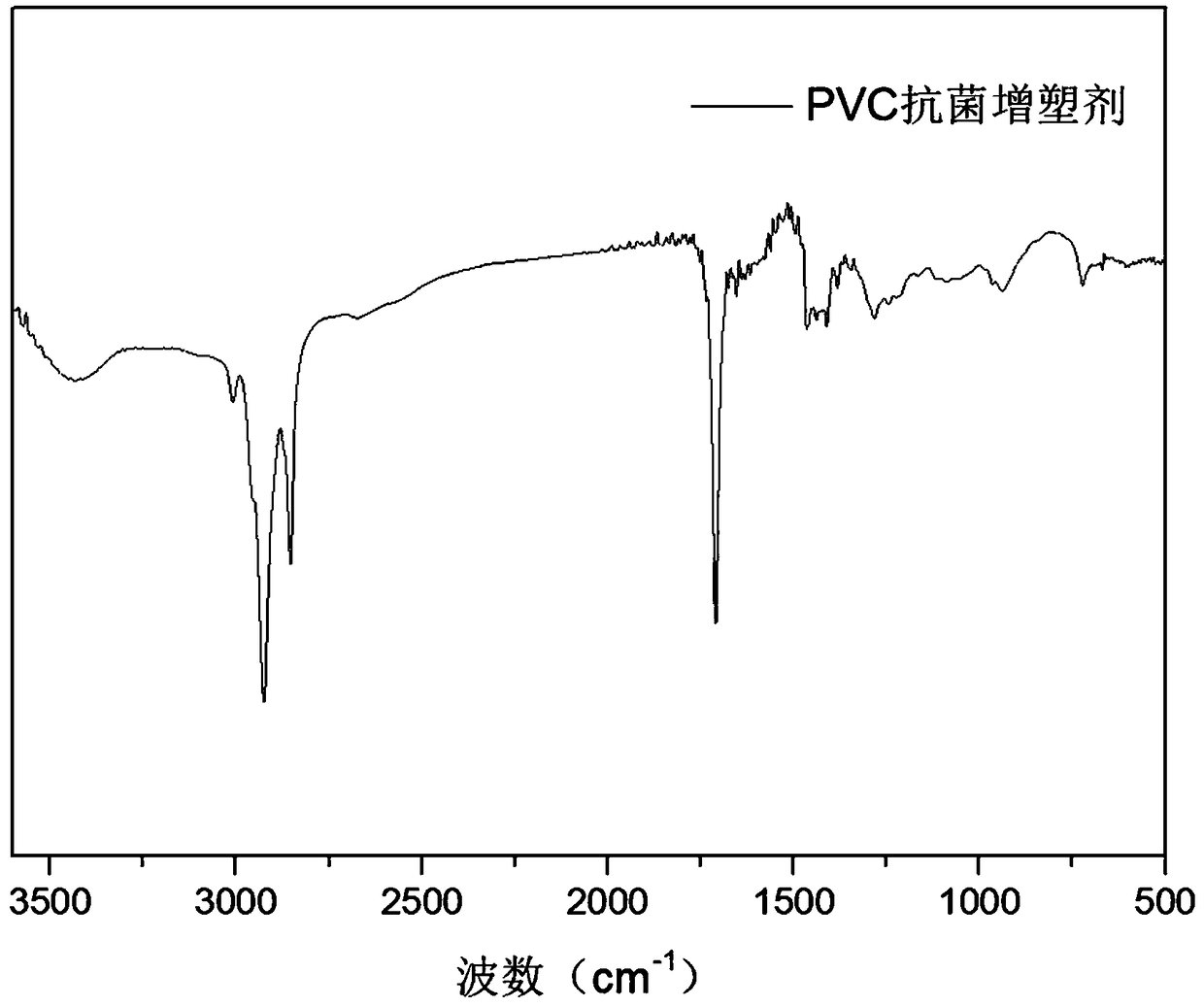

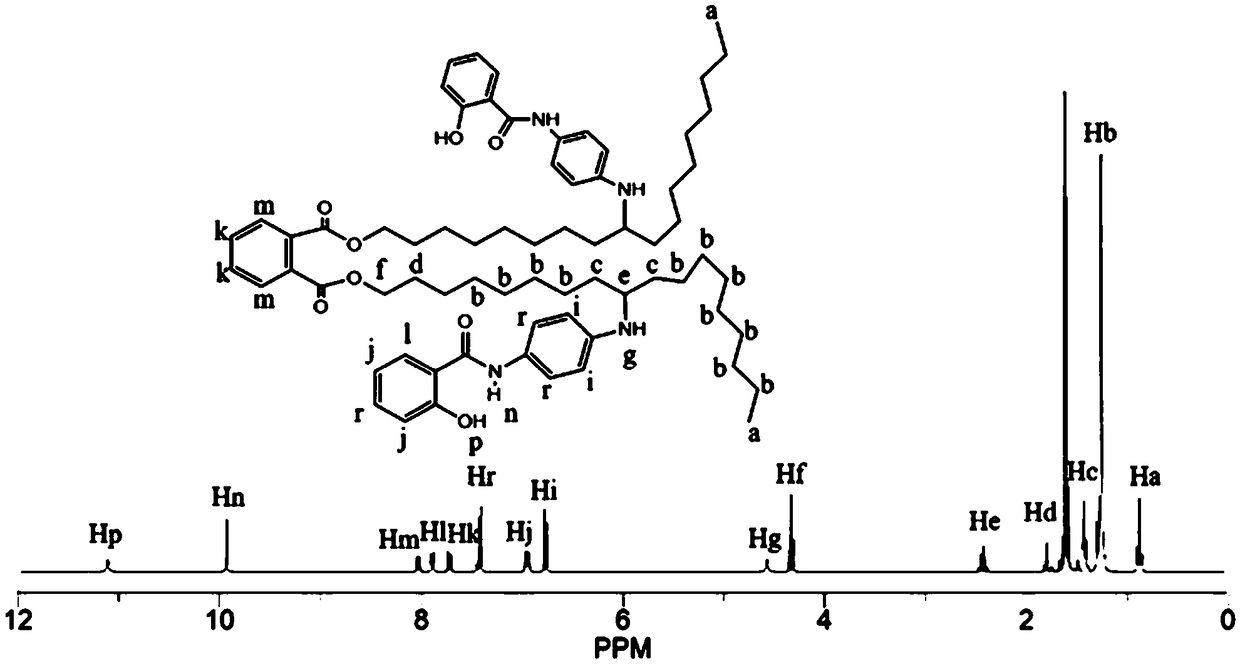

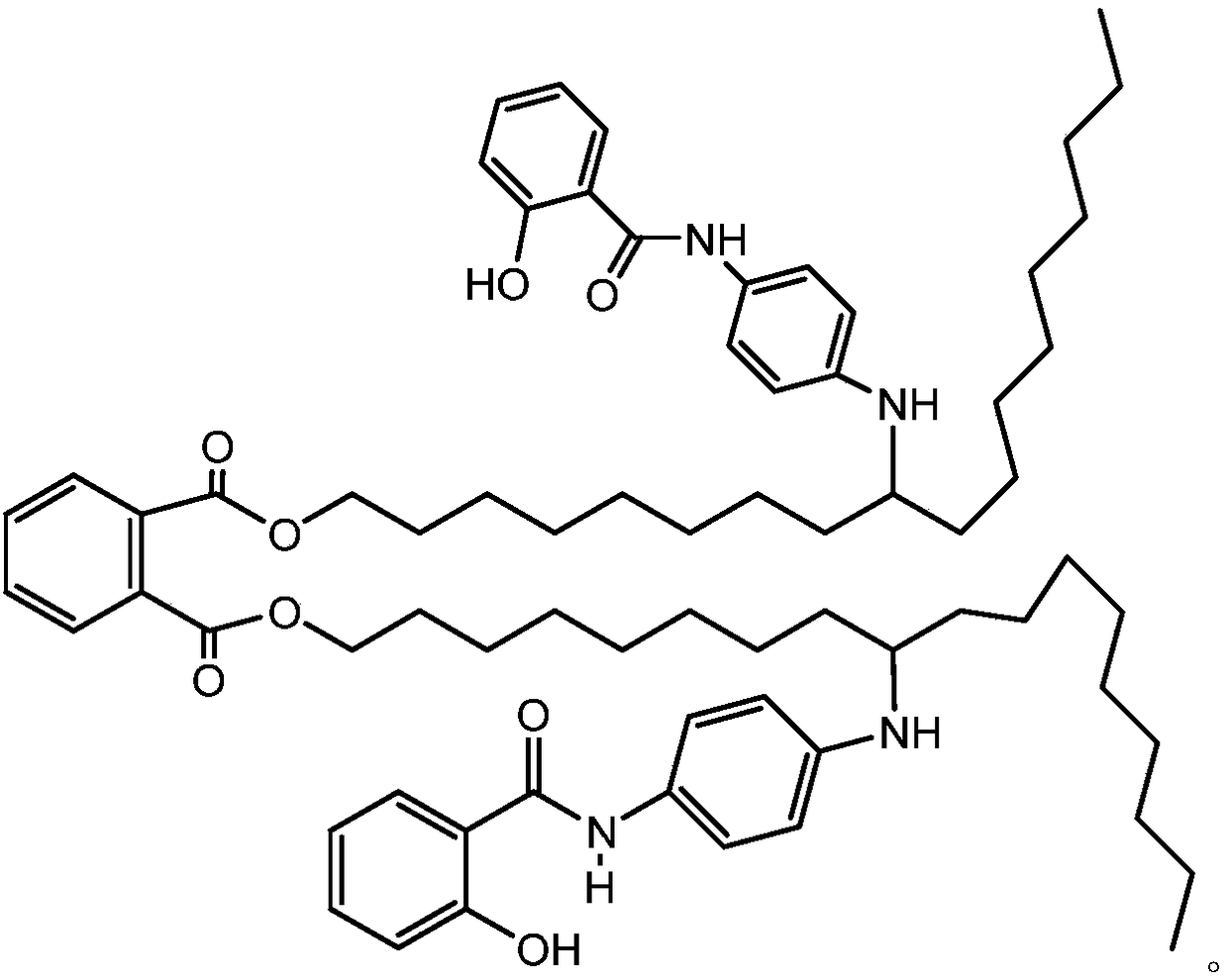

Method used

Image

Examples

Embodiment 1

[0038] A high antibacterial and wear-resistant PVC resin material is composed of the following components by weight:

[0039] 100 parts of PVC resin, 30 parts of antibacterial plasticizer, 10 parts of calcium zinc stabilizer, 3 parts of lubricant compounded by stearic acid and glycerol monostearate in a ratio of 2:1, antioxidant 1076 and antioxidant 5 parts of anti-oxidant, 5 parts of ACR resin, 15 parts of modified calcium carbonate with a particle size of 5 μm, and 2 parts of borax compounded by the quality of DLTDP at a ratio of 3:1.

[0040]The above-mentioned PVC resin is a low-polymerization PVC resin containing 30% by weight with an average polymerization degree of 600 and a particle size of 60 μm, and 35% by weight of a medium-polymerization PVC resin with an average polymerization degree of 1300 and a particle size of 40 μm. 35% by weight of a high degree of polymerization PVC resin with an average degree of polymerization of 2200 and a particle size of 20 μm, based o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com