Wood modifier and preparation method thereof

A modifier and wood technology, applied in the direction of impregnated wood, wood impregnation, wood processing equipment, etc., can solve the problems of poor anti-loss ability, large VOC release, and influence on mutual effect, so as to increase impact resistance toughness and strength, increase The effect of interfacial adhesion and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

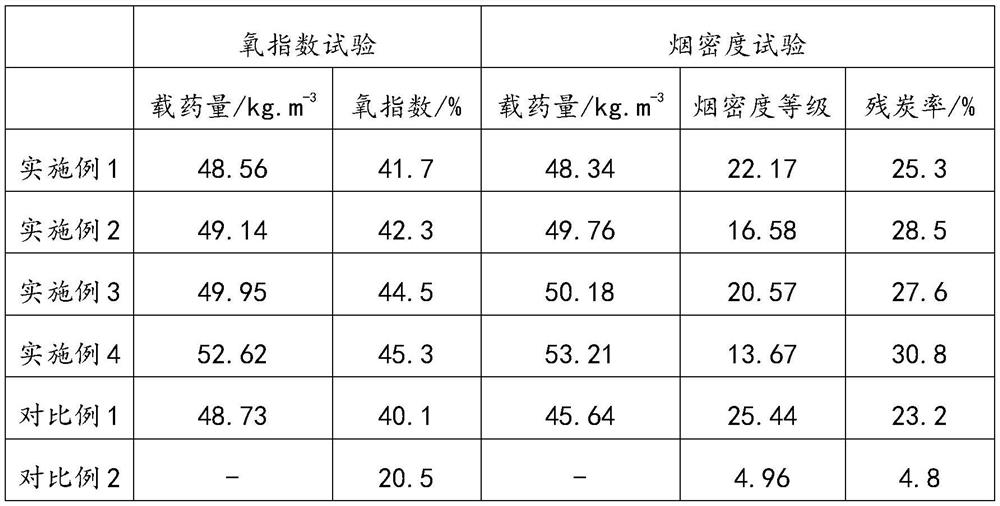

Examples

Embodiment 1

[0031] A kind of wood modifier, is made up of the raw material of following parts by weight: 5 parts of triazole compound, 20 parts of hydroxyethyl methacrylate, 0.8 part of catalyst, 20 parts of ammonium dihydrogen phosphate, 20 parts of nonionic surfactant , 90 parts of Polyethylene Glycol and 800 parts of water, its preparation method comprises the following concrete steps:

[0032] (1) Divide polyethylene glycol into three equal parts and add in two times;

[0033] (2) Add the triazole compound, hydroxyethyl methacrylate and the first part of polyethylene glycol into the reaction kettle, stir evenly, add the catalyst, stir and react at room temperature for 0.5-1h, and then add ammonium dihydrogen phosphate , heat up to 50°C, and stir at a rate of 200-320r / min for 2-3h at this temperature;

[0034] (3) Add sodium hydroxide to the reaction kettle, adjust the pH value to 7-8, then add non-ionic surfactant and two parts of polyethylene glycol, heat up to 60-80°C, at a rate of...

Embodiment 2

[0038]A kind of wood modifier, is made up of the raw material of following parts by weight: 10 parts of triazole compound, 10 parts of hydroxyethyl methacrylate, 0.5 part of catalyst, 10 parts of ammonium dihydrogen phosphate, 40 parts of nonionic surfactant , 45 parts of polyethylene glycol and 300 parts of water, its preparation method is the same as in Example 1, and the specific steps are with reference to Example 1.

[0039] In this example, the triazole compounds are 5 parts of 5-methyl-3-octyl-1,2,4-triazole, 5 parts of 3-butyl-1,2,4-triazole, and the catalyst is positive Butyl lithium, nonionic surfactant is sucrose ester, polyethylene glycol is PEG-600.

Embodiment 3

[0041] A kind of wood modifier, is made up of the raw material of following parts by weight: 6 parts of triazole compound, 18 parts of hydroxyethyl methacrylate, 0.6 part of catalyst, 15 parts of ammonium dihydrogen phosphate, 30 parts of nonionic surfactant , 60 parts of polyethylene glycol and 500 parts of water, the preparation method is the same as in Example 1, and the specific steps are with reference to Example 1.

[0042] In this example, the triazole compound is 3,5-diisopropyl-1,2,4-triazole, the catalyst is n-butyllithium, the nonionic surfactant is sorbitan ester, polyethylene glycol The alcohols are 20 parts PEG-200 and 40 parts PEG-400.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com