Preparation method of heat-resistant composite magnetic material

A magnetic material and heat-resistant technology, which is applied to the magnetism of organic materials/organic magnetic materials, manufacturing of inductors/transformers/magnets, electrical components, etc., can solve problems such as ignoring heat resistance, achieve good curing effect, and improve overall performance , High heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 A method for preparing a heat-resistant composite magnetic material, comprising the following steps:

[0022] (1) Disperse 300g of nano-silica foam in deionized water, then add 100g of dodecylbenzenesulfonic acid and 400g of bismuth nitrate pentahydrate; then hydrothermally react at 150°C for 10 hours; then filter the reaction solution to obtain a solid powder; then mix the solid powder with 1Kg ferric oxide, and ball mill for 1 hour to obtain the mixture; use phthalate as binder, press the mixture into tablets; then calcined at 850°C for 3 hours; then in a nitrogen atmosphere sintering at 1250°C for 5 hours, and after natural cooling, crush the obtained solid to obtain a filler with a particle size of 1.8 to 2.5 microns;

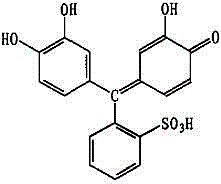

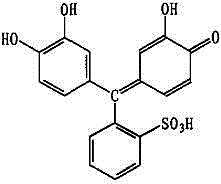

[0023] (2) Mix 5g of phenolic compound and 100g of bisphenol A cyanate monomer, stir at 90°C for 20 minutes, add 2g of methylene tetrahydrobiphenyl dicarboxylic anhydride, and continue stirring for 10 minutes; then add 19g of pentaerythr...

Embodiment 2

[0025] Embodiment 2 A method for preparing a heat-resistant composite magnetic material, comprising the following steps:

[0026] (1) Disperse 300g of nano-silica foam in deionized water, then add 100g of dodecylbenzenesulfonic acid and 400g of bismuth nitrate pentahydrate; then hydrothermally react at 150°C for 10 hours; then filter the reaction solution to obtain a solid powder; then mix the solid powder with 1Kg ferric oxide, and ball mill for 1 hour to obtain the mixture; use phthalate as binder, press the mixture into tablets; then calcined at 850°C for 3 hours; then in a nitrogen atmosphere sintering at 1250°C for 5 hours, and after natural cooling, crush the obtained solid to obtain a filler with a particle size of 1.8 to 2.5 microns;

[0027] (2) Mix 5g of phenolic compound and 100g of bisphenol A cyanate monomer, stir at 90°C for 20 minutes, add 3g of methylenetetrahydrobiphenyl dicarboxylic anhydride, and continue stirring for 10 minutes; then add 19g of pentaerythri...

Embodiment 3

[0029] Embodiment 3 A method for preparing a heat-resistant composite magnetic material, comprising the following steps:

[0030] (1) Disperse 300g of nano-silica foam in deionized water, then add 100g of dodecylbenzenesulfonic acid and 400g of bismuth nitrate pentahydrate; then hydrothermally react at 150°C for 10 hours; then filter the reaction solution to obtain a solid powder; then mix the solid powder with 1Kg ferric oxide, and ball mill for 1 hour to obtain the mixture; use phthalate as binder, press the mixture into tablets; then calcined at 850°C for 3 hours; then in a nitrogen atmosphere sintering at 1250°C for 5 hours, and after natural cooling, crush the obtained solid to obtain a filler with a particle size of 1.8 to 2.5 microns;

[0031] (2) Mix 8g of phenolic compound and 100g of bisphenol A cyanate monomer, stir at 90°C for 20 minutes, add 2g of methylenetetrahydrobiphenyl dicarboxylic anhydride, and continue stirring for 10 minutes; then add 19g of pentaerythri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com