Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Strong surface binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

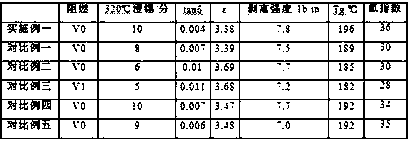

Flame-resistant and heat-resistant copper clad laminate preparation method

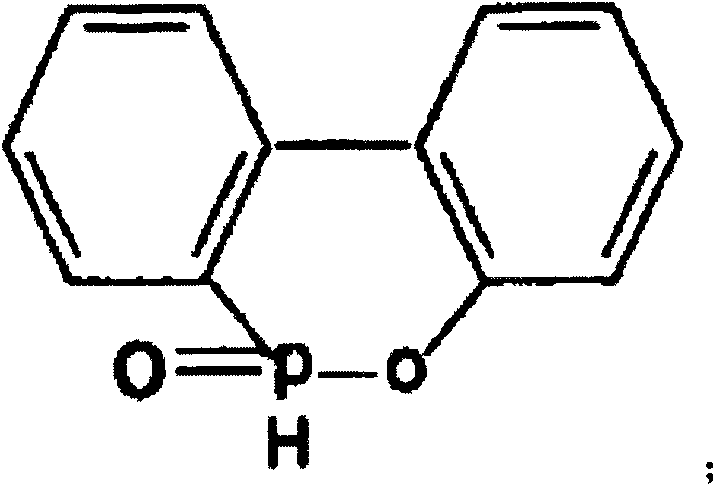

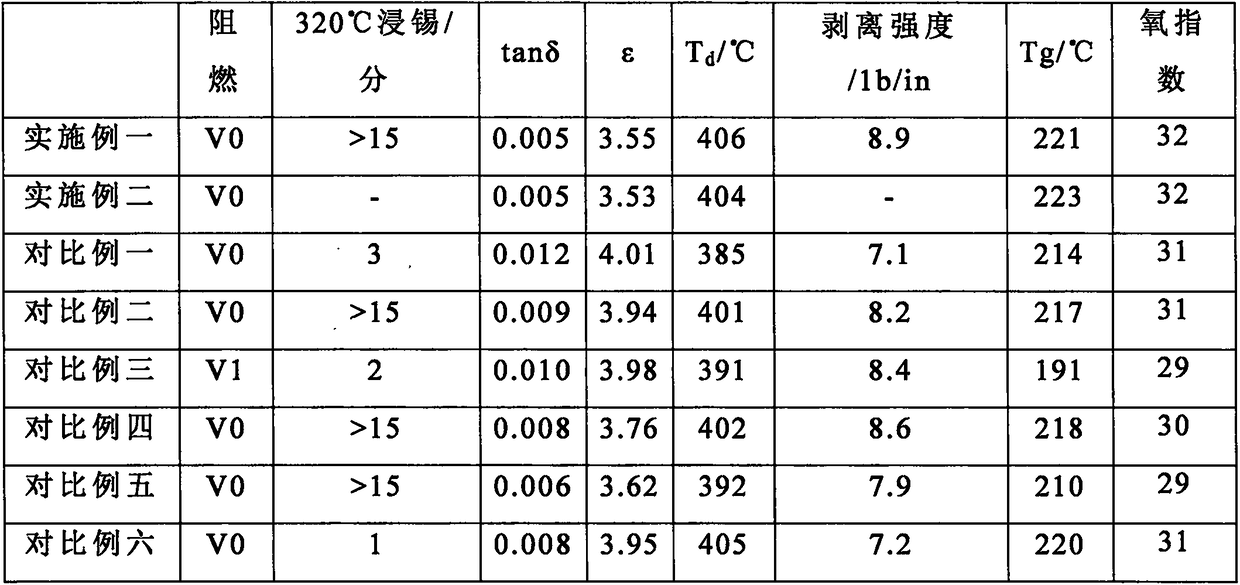

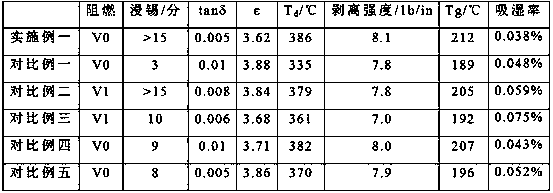

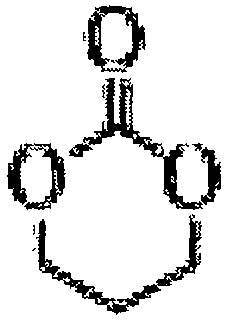

InactiveCN105172297AReasonable compositionUniform dispersionSynthetic resin layered productsLaminationMetal foilDimethyl phosphonate

The present invention relates to a flame-resistant and heat-resistant copper clad laminate preparation method, which comprises: adopting nanometer silica foam, dodecyl benzenesulfonic acid, bismuth nitrate pentahydrate, methyl trichlorosilane and polyoxyethylene sorbitan monooleate as a raw materials to obtain a filler; adopting DOPO, a bisphenol A cyanate ester monomer, a phenol compound, a m-nitrobenzene sulfonic acid pyridine salt, 2,3-epoxy cyclopentyl cyclopentyl ether and dimethyl phosphonate as raw materials to obtain a resin prepolymer; adding the filler to o-phthalic acid diglycidyl este to obtain an active filler; mixing the resin prepolymer and an indole compound, and then adding the active filler and isomeric undecanol polyoxyethylene ether phosphate potassium salt to obtain a composite system; and carrying out hot pressing molding on the composite system, a reinforced material and metal foil to obtain the flame-resistant and heat-resistant copper clad laminate, wherein the flame-resistant and heat-resistant copper clad laminate has characteristics of excellent flame retardant property and excellent heat resistance, and meets the development applications of the flame-resistant and heat-resistant copper clad laminate.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

Method for restraining cracking furnace pipe from coking

ActiveCN103421531AThe method is simpleSimple technologyThermal non-catalytic crackingCoke ratePre treatment

The invention provides a method for restraining a cracking furnace pipe from coking. The method comprises the following steps: pre-treating the inner surface of the cracking furnace pipe before a coking restraining coating of the inner surface of the cracking furnace pipe is coated; coating a coking resistant coating on the inner surface of the cracking furnace pipe; adding a coking inhibitor into cracking raw materials. According to the invention, the coke formation is reduced through the recombination of the coking resistant technology, so that the hydrocarbon high-temperature cracking coking rate is greatly reduced, and the use cycle of hydrocarbon cracking equipment is prolonged.

Owner:内蒙古冠泰环保科技有限公司

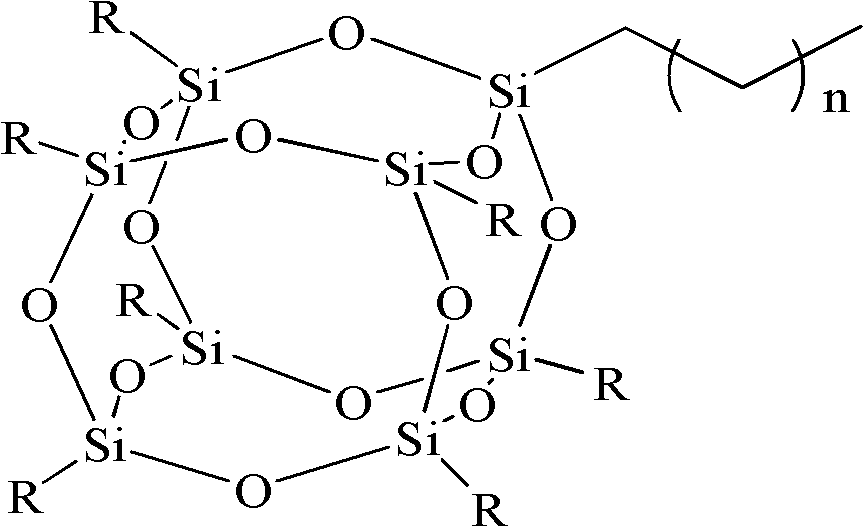

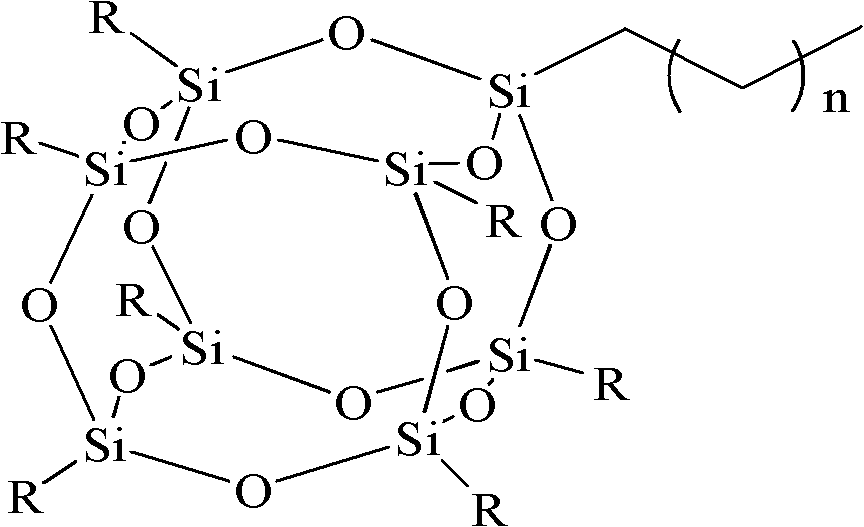

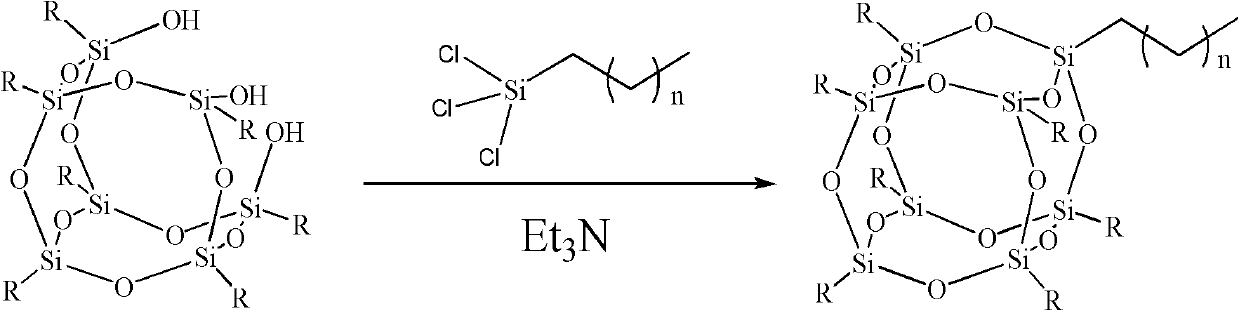

POSS (polyhedral oligomeric silsesquioxanes) modified high barrier three-layer co-extrusion packaging film and preparation method thereof

ActiveCN102019738AHigh barrierImprove barrier propertiesFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a POSS (polyhedral oligomeric silsesquioxanes) modified high barrier three-layer co-extrusion packaging film and a preparation method thereof, relating to a packaging film. The invention provides a polyhedral oligomeric silsesquioxanes modified high barrier three-layer co-extrusion packaging film with better barrier property, mechanical property, heat resistance and transparency and a preparation method thereof. The film comprises an outer layer, an intermediate layer and an inner layer, wherein the outer layer of the film comprises the components of low-density polyethylene, linear low-density polyethylene and a polyhedral oligomeric silsesquioxanes modifier, the intermediate layer of the film comprises the components of ethylene-vinyl alcohol copolymer and compatibilizing resins, and the inner layer of the film comprises the components of LDPE, LLDPE and an opening agent. Firstly, the polyhedral oligomeric silsesquioxanes modifier is prepared, then the outer layer film master batch containing the polyhedral oligomeric silsesquioxanes modifier is prepared, and finally the polyhedral oligomeric silsesquioxanes modified high barrier three-layer co-extrusion packaging film is prepared.

Owner:XIAMEN UNIV +1

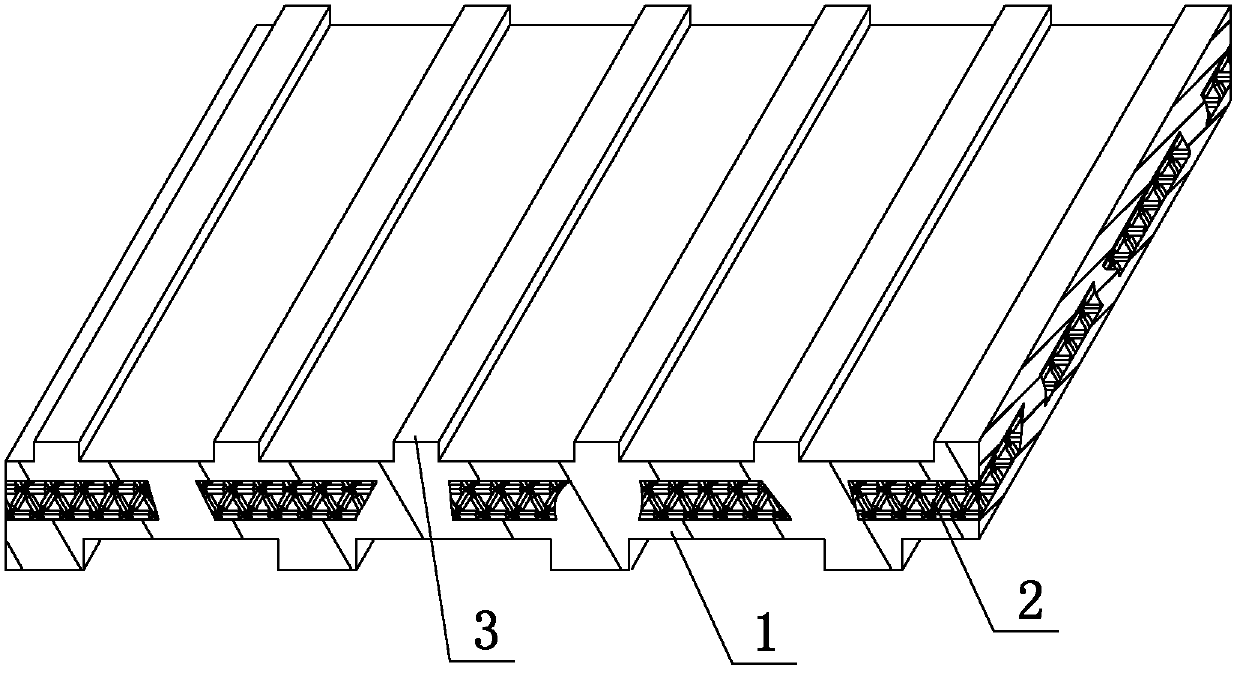

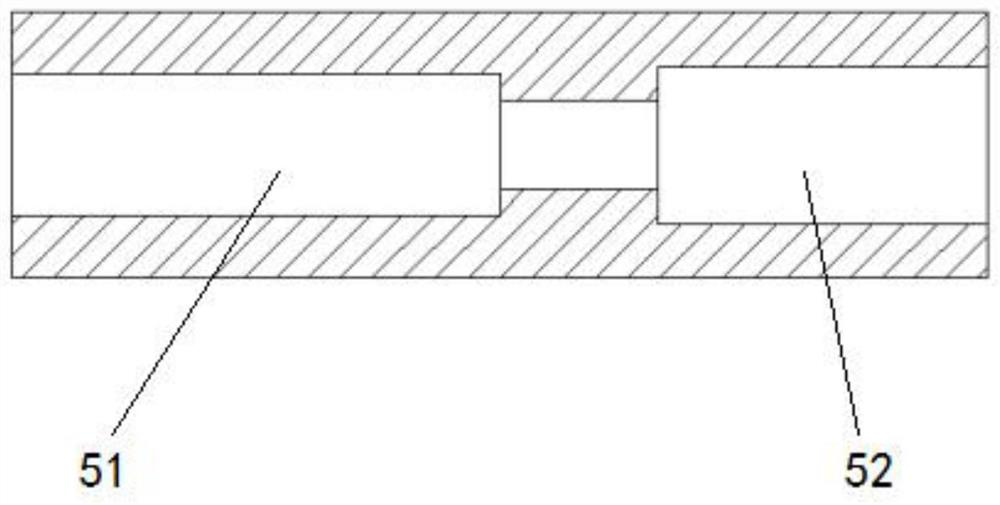

Forming method of thermoplastic continuous fiber-reinforced composite material piece

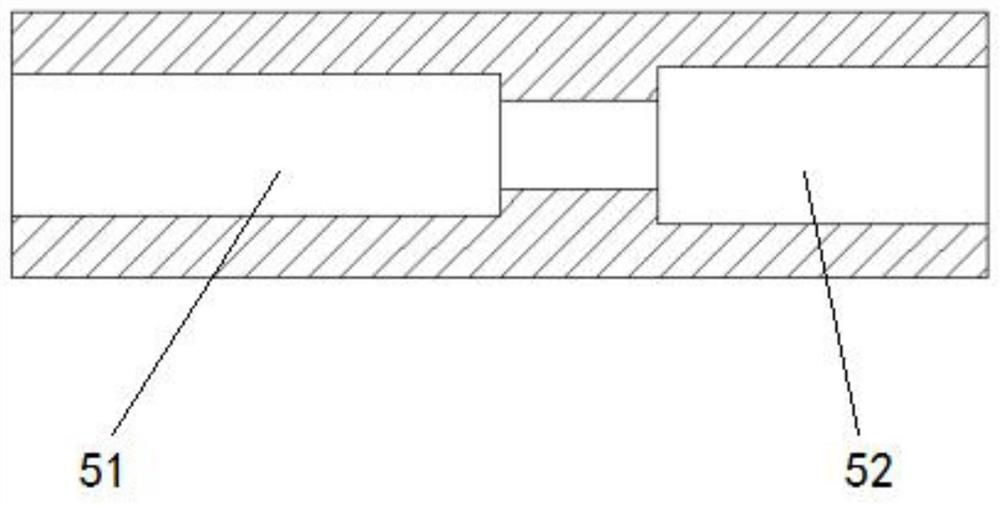

ActiveCN110757722AStrong Surface Replication AbilityStrong surface bindingCoatingsFiber-reinforced compositeInjection moulding

The invention discloses a forming method of a thermoplastic continuous fiber-reinforced composite material piece. The forming method comprises the steps that (1) thermoplastic continuous fiber prepregtape is subjected to overlaying and mould pressing, and an organic composite plate is obtained; (2) the organic composite plate obtained in the step (1) is subjected to two-dimensional cutting, and a2D organic plate is obtained; (3) the 2D organic plate obtained in the step (2) is heated, softened and then moved into a forming mould; and (4) mould assembling and micro-foam injection molding areconducted, and after cooling and mould opening, the thermoplastic continuous fiber-reinforced composite material piece is obtained. According to the forming method, the thermoplastic continuous fibercomposite material and the micro-foam injection molding material are combined, integrated forming is achieved through mould pressing-injection moulding, materials, moulds and the forming technique arecooperated, and the prepared composite material piece is smooth and even in surface, free of reduction and low in warping angle and is suitable for subsequent spraying and coating. The product rigidity is high, the weight is low, and the piece is suitable for preparation of television and computer shells as well as automobile accessory light-weight outer parts.

Owner:中广核俊尔(浙江)新材料有限公司 +1

Preparation method for flame-retardant heat-resistant antenna radome base material

The invention relates to a preparation method for a flame-retardant heat-resistant antenna radome base material. The preparation method comprises the following steps: preparing a filler with the average grain size of 180 nanometers by taking nano silicon dioxide foam, dodecylbenzene sulfonic acid, bismuth nitrate pentahydrate and methyl trichlorosilane as raw materials; preparing a resin prepolymer by taking DOPO, a bisphenol A cyanate ester monomer, a phenolic compound, 1,3,5-triglycidyl -S-triazinetrione, bisphenol A epoxy resin and diaminodiphenyl ether as raw materials; mixing the resin prepolymer with maleic anhydride; then sequentially adding poly(methylsilsesquioxane) and the filler; then adding isomeric undecanol polyoxyethylene ether phosphate potassium salt and glass beads to obtain a composite system; then injecting the composite system into a die coated with a release agent, carrying out mold pressing under a vacuum condition, and finally turning off a power supply and naturally cooling; and releasing the die to obtain the flame-retardant heat-resistant antenna radome base material. The flame-retardant heat-resistant antenna radome base material has excellent flame retardance and heat resistance, and the development application of the flame-retardant heat-resistant antenna radome base material is satisfied.

Owner:苏州凯欧曼新材料科技有限公司

High-toughness wear-resisting cable material

PendingCN110041661ALarge poresImprove mechanical propertiesPlastic/resin/waxes insulatorsCastor oilActive ingredient

The invention discloses a high-toughness wear-resisting cable material and belongs to the technical field of wires and cables. According to the invention, biogas slurry is firstly treated and then shrimp shells are treated in the manner of mixed fermentation, so that chitin is differentiated and degraded, active ingredients can be generated, cross-linking action can be enhanced and overall wear-resisting property can be promoted; aramid fiber pulp has a fluff structure, has an ultra-large contact area with a resin component and is capable of promoting interaction of inner components of the system, improving shock resistance, promoting toughness, increasing degree of orientation, increasing surface roughness, promoting compatibility thereof with a modified resin component and jointly promoting toughness and wearing resistance; due to the addition of castor oil, vibration strength of covalent bonds in the resin component can be reduced, tensile strength can be effectively promoted, and the castor oil and the compound modified resin component can be combined into an interwound firm three-dimensional network so as to promote the inner mechanical properties. The high-toughness wear-resisting cable material is capable of solving the problems of inferior wear-resisting property, low tensile strength, low toughness and inconvenience in processing of the present common cable material.

Owner:北京中科惠景储能材料科技有限公司

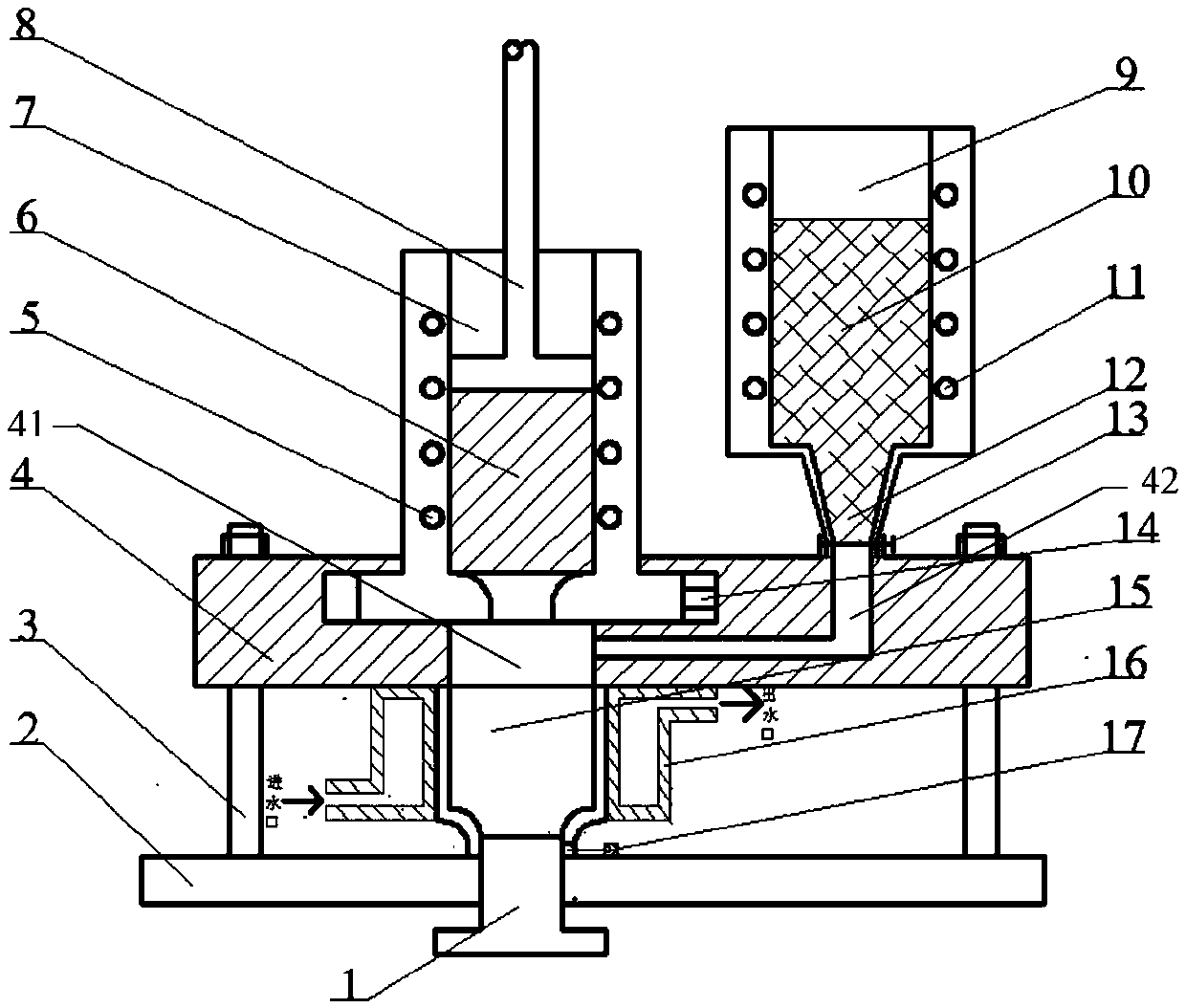

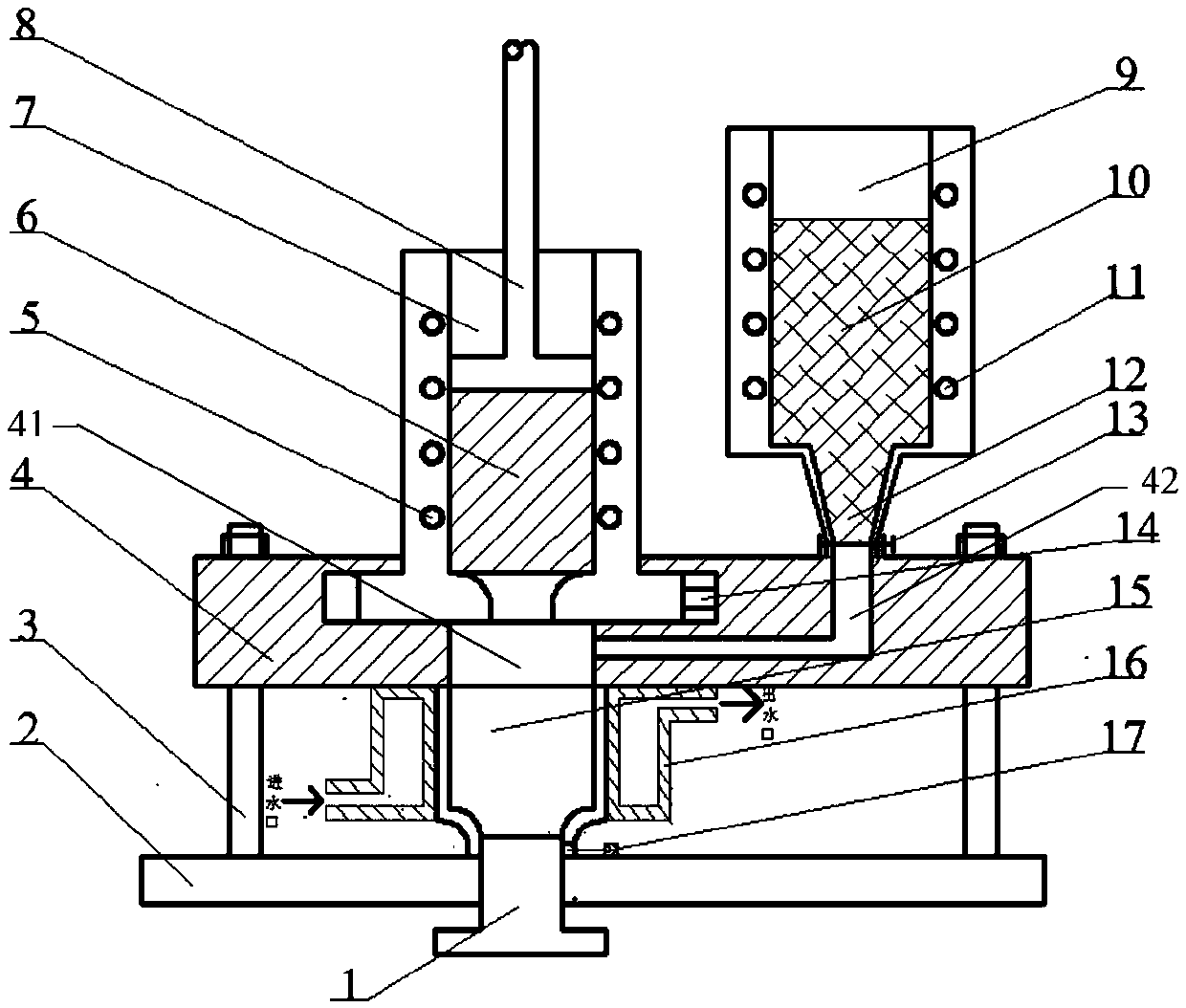

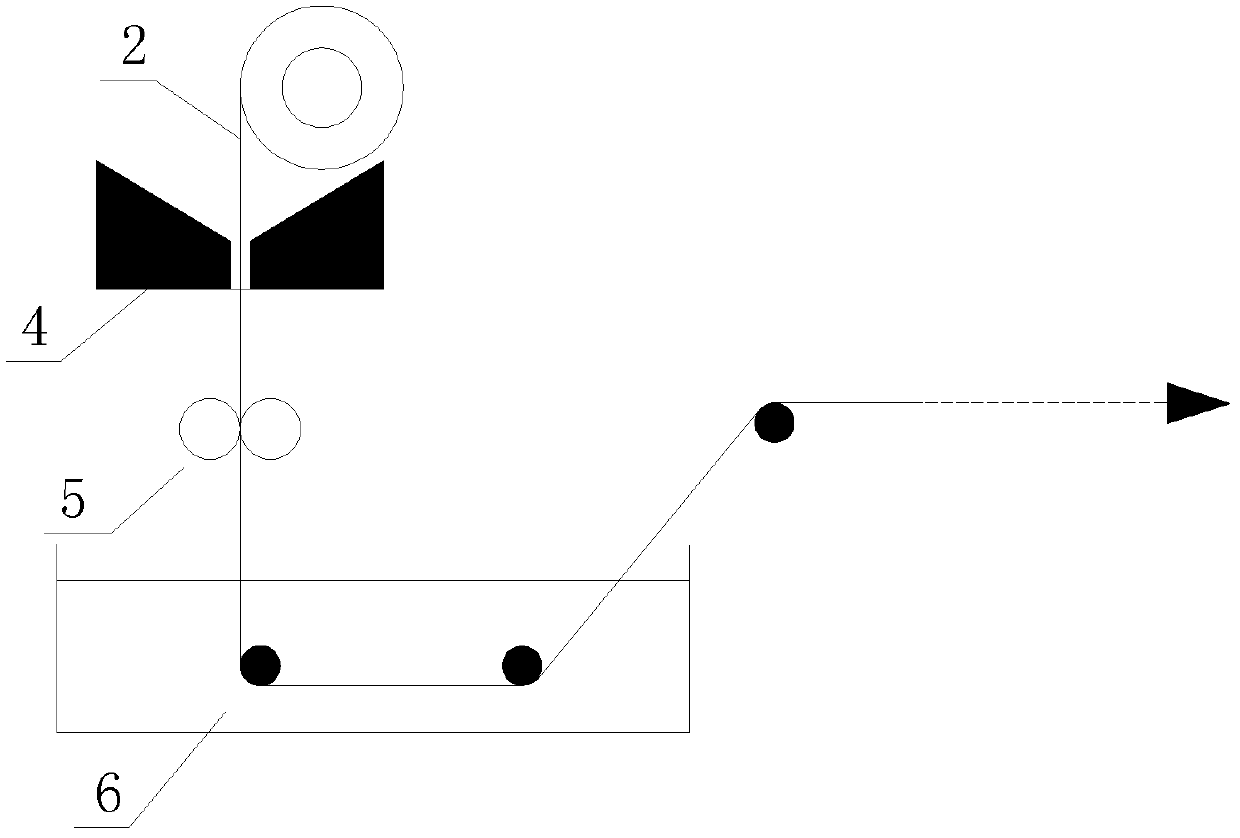

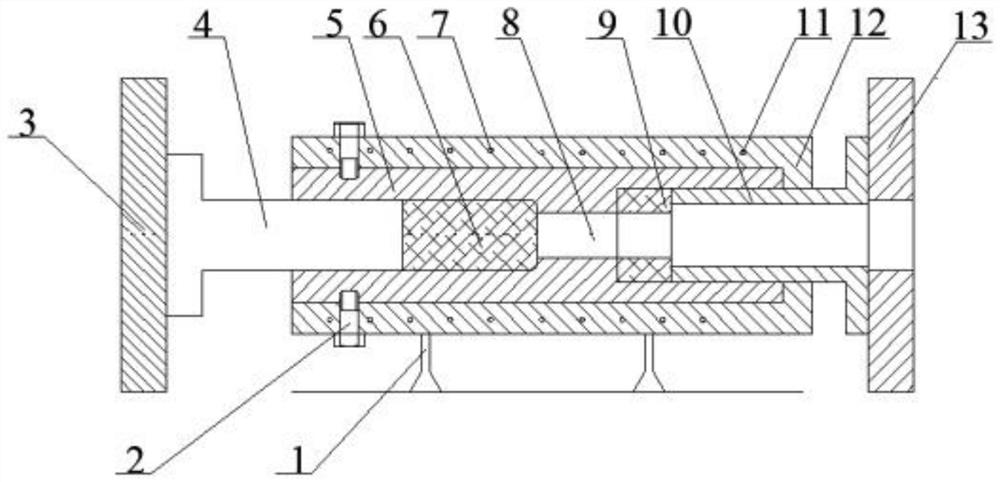

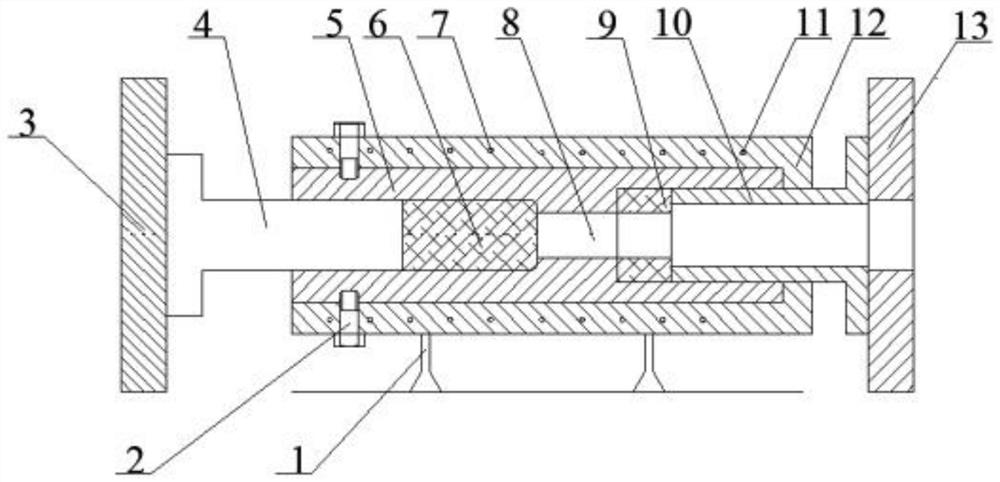

Vertical casting and extruding composite preparation device and method of coating structure metal composite material

The invention discloses a vertical casting and extruding composite preparation device and method of coating structure metal composite material. The device comprises a starting material blocking block,an extruding table, an extrusion female die, an extrusion male die, a casting female die and an extrusion composite cylinder, a plurality of connecting columns are arranged at the bottom of the extrusion table, the extrusion female die and the casting female die is arranged on the extrusion table, the extrusion male die is arranged in the extrusion female die, the extrusion table is provided witha discharge hole and a casting feed hole, the discharge hole corresponds to the discharge hole of the extrusion female die, the discharging hole of the casting female die is connected with the casting feeding hole, the outlet of the casting feeding hole is communicated with the discharging hole, the extruding composite cylinder is arranged at the bottom of the extruding table, the feeding port ofthe extrusion composite cylinder is communicated with the discharge hole, and a starting material blocking block is arranged at the discharge port at the bottom of the extrusion composite cylinder. The blank defect is eliminated by extruding the inner-layer blank, meanwhile, a new metal surface is generated, and the composite material which is high in surface binding force and excellent in mechanical property is obtained through subsequent extrusion composite forming.

Owner:HUNAN UNIV OF SCI & TECH

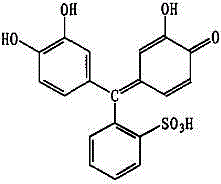

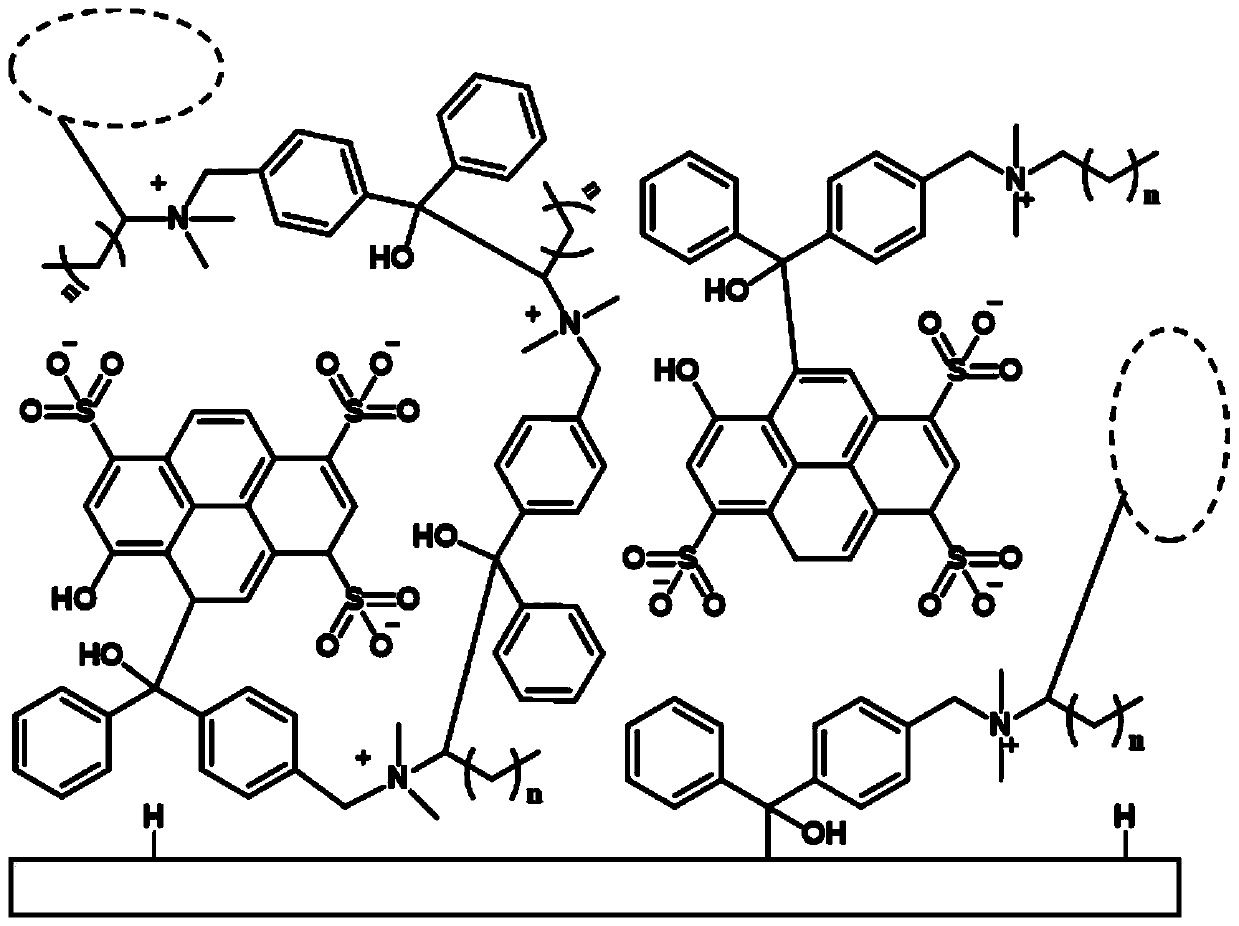

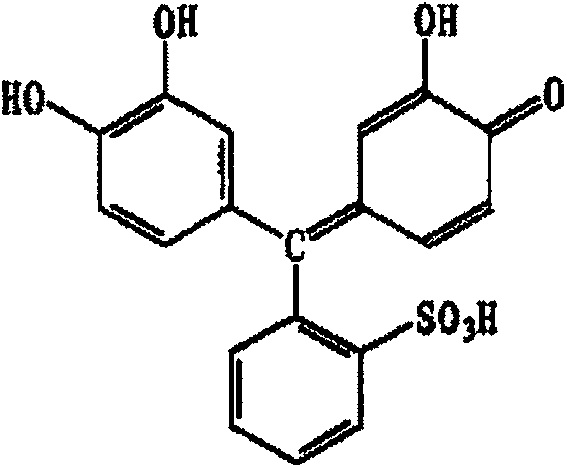

Antibacterial coating with pH monitoring function, functional material of antibacterial coating with pH monitoring function and preparation method thereof

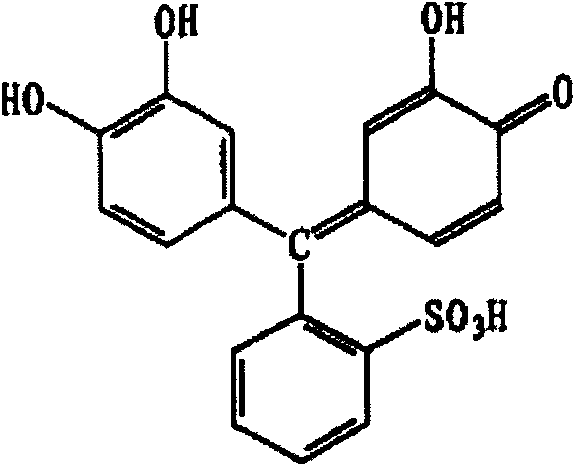

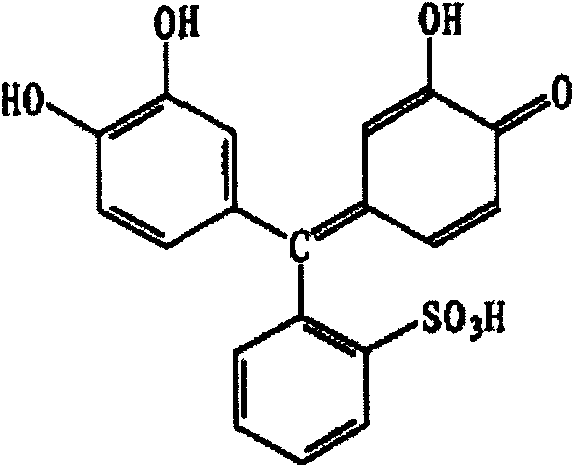

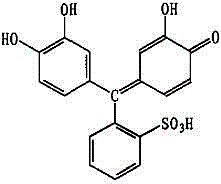

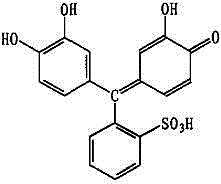

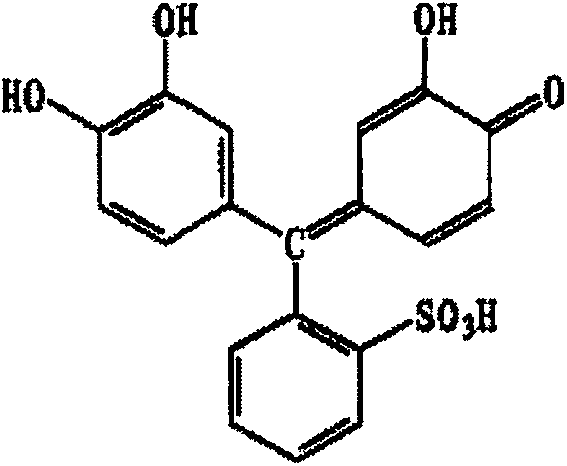

PendingCN110669243AStrong surface bindingHigh sterilization rateBiocideDisinfectantsPyranineCombinatorial chemistry

The invention provides an antibacterial coating with pH monitoring function. The antibacterial coating comprises a hydrogen abstraction type quaternary ammonium salt pyranine compound, which is obtained by reaction of trisodium 8-hydroxy-1, 3, 6-pyrene trisulfonate with the hydrogen abstraction type quaternary ammonium salt; and the hydrogen abstraction type quaternary ammonium salt has a structure shown as formula (I). A benzophenone functional group in the hydrogen abstraction type quaternary ammonium salt in the coating can undergo chemical bonding with a substrate material molecule, Pyranine and a hydrophobic alkyl chain, the inside of the coating undergoes mutual cross-linking to form a three-dimensional network structure, the self-stability of the coating can be improved, meanwhile,the coating and a coated substrate realize chemical bond cross-linking, so that the stability of the coating and the coated substrate is greatly improved, and the pH monitoring and antibacterial effect can be more durable. The method provided by the invention adopts an ultraviolet curing mode to form the coating, and has the characteristics of simple process, easy operation, and high feasibility.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +2

A method for reducing coking in cracking furnace tubes

The invention provides a method for alleviating coking of cracking furnace tubes. The following steps are adopted: before coating the coke suppression coating on the inner surface of the cracking furnace tube, the inner surface of the cracking furnace tube is pretreated; the inner surface of the cracking furnace tube is coated with an anti-coking coating; and the coking inhibitor is added to the cracking raw material. The present invention reduces the formation of coking by compounding anti-coking technology, greatly reduces the coking rate of high-temperature cracking of hydrocarbons, and prolongs the service life of hydrocarbon cracking equipment.

Owner:内蒙古冠泰环保科技有限公司

Water-borne wood lacquer color-repairing gloss oil, as well as preparation method and application thereof

InactiveCN108893043AImprove adhesionAccelerate graft crosslinkingAntifouling/underwater paintsPaints with biocidesLacquerAcrylic resin

The invention relates to the technical field of water-borne gloss oil, and particularly relates to water-borne wood lacquer color-repairing gloss oil, as well as a preparation method and an application thereof. The gloss oil is prepared from the following raw materials: water-soluble polyurethane resin, water-soluble acrylic resin, dipropylene glycol methyl ether, polyethylene imine, a water-bornedefoaming agent, a water-borne flattening agent, ethanol, a dispersant and deionized water. The preparation method comprises the following steps: a, mixing the components under a norm-temperature condition, and stirring for 20-25 minutes; and b, filtering with a filter screen having 300 meshes after uniform stirring. The water-borne wood lacquer color-repairing gloss oil is prepared by using transparent resin as components, and is easy in color matching in the using process; the polyethylene imine synthesized with the dipropylene glycol methyl ether in the raw materials can be used for effectively improving the adhesion performance of the water-borne wood lacquer color-repairing gloss oil, has strong binding force with a wood surface; and the polyethylene imine can react and bind with tanning and other acid substances in a wood material, so that the problems of discoloring and blackening of woods can be effectively relieved.

Owner:安徽江锐新材料有限公司

Electronic material and preparation method thereof

InactiveCN108327363ADoes not affect the curing processHigh densitySynthetic resin layered productsLaminationHeat resistanceMetal foil

The invention relates to an electronic material and a preparation method thereof. The preparation method comprises the following steps: mesoporous silica is modified firstly, then epoxy with monofunctional groups and epoxy with bifunctional groups are prepared, and a glue solution is obtained by mixing; the glue solution, a reinforcing material and metal foil are subjected to hot-press molding, and the electronic material can be obtained. The electronic material has the excellent flame retardance and heat resistance, and requirements for development and application of the electronic material are met.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

Preparation method of glue liquor material with high dielectric property

The invention relates to a preparation method of a glue liquor material with a high dielectric property. The preparation method comprises steps as follows: high dielectric filler is added to a bifunctional epoxy system and stirred at 130 DEG C for 20 min, a monofunctional epoxy system and nano alumina particles are added at the temperature of 95 DEG C, the mixture is stirred for 130 min, and a glue liquor is obtained; the solid content of the glue liquor is adjusted to be 60% with propylene glycol methyl ether acetate, and the glue liquor material with the high dielectric property is obtained.The glue liquor material has excellent flame retardance and heat resistance and particularly has the outstanding dielectric constant.

Owner:嘉兴立一新材料股份有限公司

Method for improving wear resistance of aluminum alloy electric power fittings

PendingCN110760783ASolve the problem of life and property safetySolve the wear-resistantMolten spray coatingEconomic benefitsUltimate tensile strength

The invention relates to the technical field of new material processing, and discloses a method for improving wear resistance of aluminum alloy electric power fittings. The method comprises the following steps: rapidly melting prepared ball-milled powder by using a plasma spraying technology to further form atomized molecules, spraying the atomized molecules to the surfaces of pretreated fittings,and rapidly condensing the atomized molecules to obtain a wear-resistant coating which plays an inert wear-resistant and corrosion-resistant barrier. The coating has a strong binding force with the surfaces of the aluminum alloy fittings, and a film layer is compact, has high hardness, and can withstand the impact of high-strength external force, so the surface performance of the fittings is comprehensively improved, and the safety and the service life of the electric power fittings are improved. The method can significantly improve the wear resistance of the aluminum alloy electric power fittings, solves the problem of no wear resistance of existing aluminum alloy electric power fittings, improves the surface strength and toughness, has stable chemical and mechanical properties, expandsthe application occasions, and significantly improves the economic and safety benefits.

Owner:安徽实友电力金具有限公司

Preparation method of modified epoxy resin material

InactiveCN108424536AExcellent thermal oxygen shielding effectExcellent heat resistance and flame retardancyPolytetrafluoroethylenePropylene glycol methyl ether acetate

The invention relates to a preparation method of a modified epoxy resin material. The preparation method comprises the following steps: adding modified silicon dioxide into a bifunctional epoxy system, adding a mono-functional epoxy system and a nanometer polytetrafluoroethylene particle to obtain a glue solution, regulating the solid content of the glue solution to 50% through propylene glycol methyl ether acetate, dipping a glass cloth into the glue solution, heating, and drying to obtain the modified epoxy resin material, and the modified epoxy resin material has an excellent flame retardant property and an excellent heat resisting property, and the abrasive resistance is particularly prominent.

Owner:嘉兴立一新材料股份有限公司

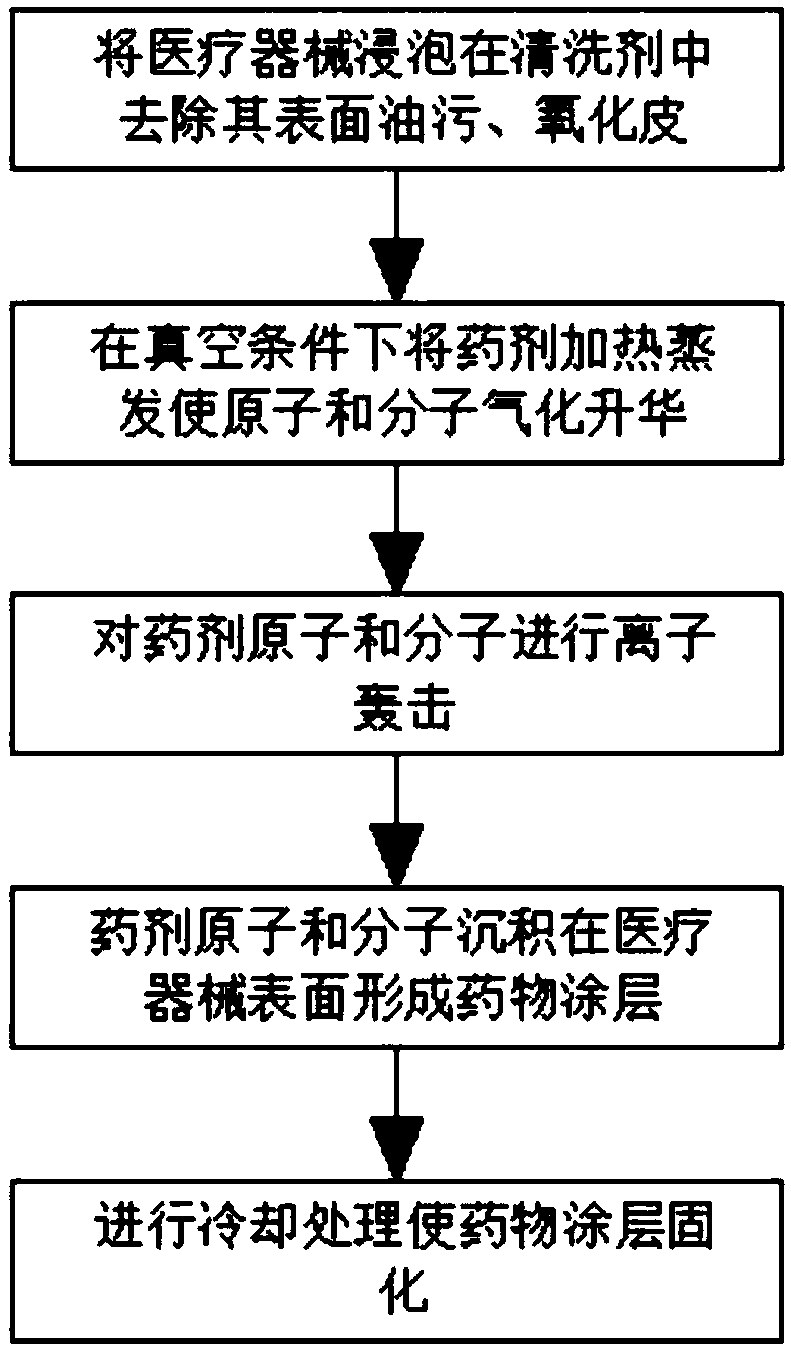

Energy-saving and environment-friendly coating method for medicine coating on implantable medical apparatus

InactiveCN108060394AStrong combinationGood around platingVacuum evaporation coatingSputtering coatingDrugNegative bias

The invention discloses an energy-saving and environment-friendly coating method for a medicine coating on an implantable medical apparatus and belongs to the technical field of energy saving and environmental friendliness. The method specifically comprises the following steps that S1, the medical apparatus is soaked in a cleaning agent to remove oil stains, rust spots, oxidized scales and acid-base residues on the surface of the medical apparatus; S2, a chemical is heated and evaporated under the vacuum condition so that a large number of atoms and molecules in the chemical can be gasified and sublimated; S3, the medical apparatus is baked, and is put in the chemical sublimating atmosphere for ion bombardment after the surface temperature of the medical apparatus rises; S4, the atoms andthe molecules in the chemical settle on the surface of the medical apparatus to form the medicine coating; and S5, afterwards the medicine coating is cooled to be solidified. The medicine coating hashigh bonding force with the surface of a medical apparatus body, is uniform and compact, has a good winding plating property under the negative bias action, can reduce the rejection reaction of organisms to implants, and has high abrasion resistance at the same time, and the service life of the implants is prolonged.

Owner:谢小坚

Preparation method of pouring material with high dielectric property

The invention relates to a preparation method of a pouring material with a high dielectric property. The preparation method comprises steps as follows: high dielectric filler is added to a bifunctional epoxy system and stirred at 130 DEG C for 20 min, a monofunctional epoxy system and nano alumina particles are added at the temperature of 95 DEG C, the mixture is stirred for 130 min, and a glue liquor is obtained; the glue liquor is subjected to vacuum defoamation and added to a mold, and the pouring material with the high dielectric property is obtained after hot-pressing curing. The pouringmaterial has excellent flame retardance and heat resistance and particularly has the outstanding dielectric constant.

Owner:嘉兴立一新材料股份有限公司

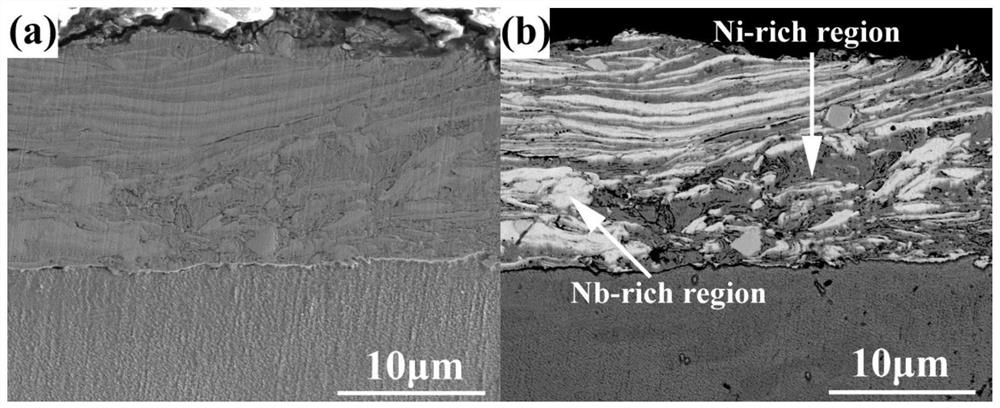

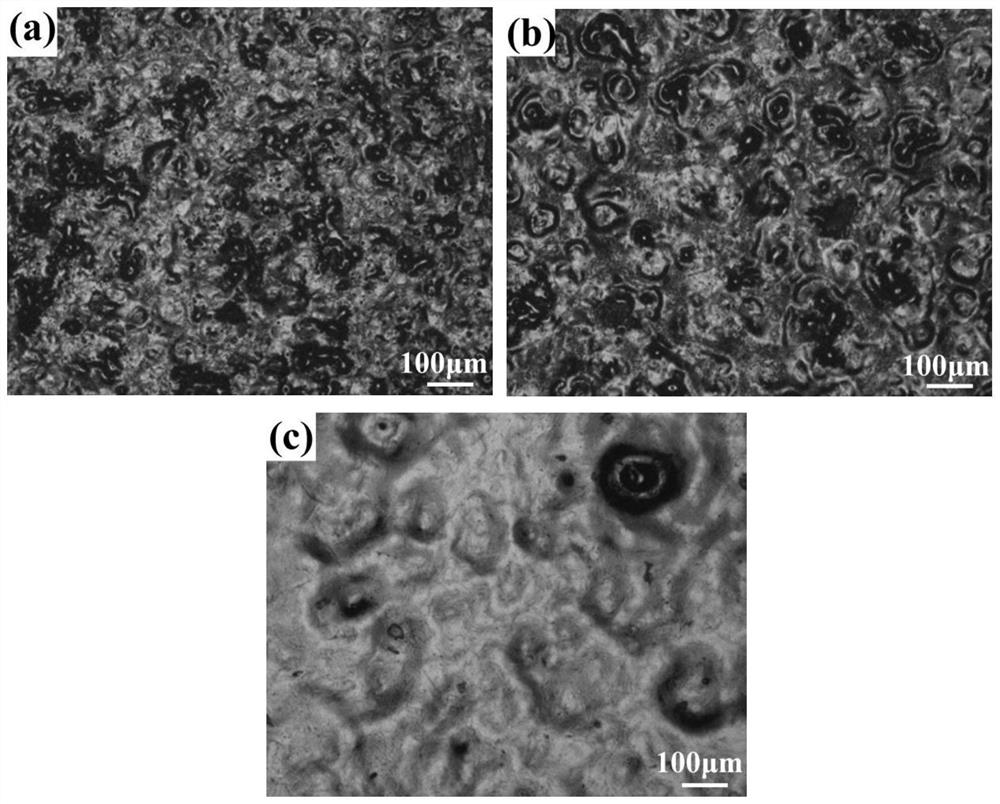

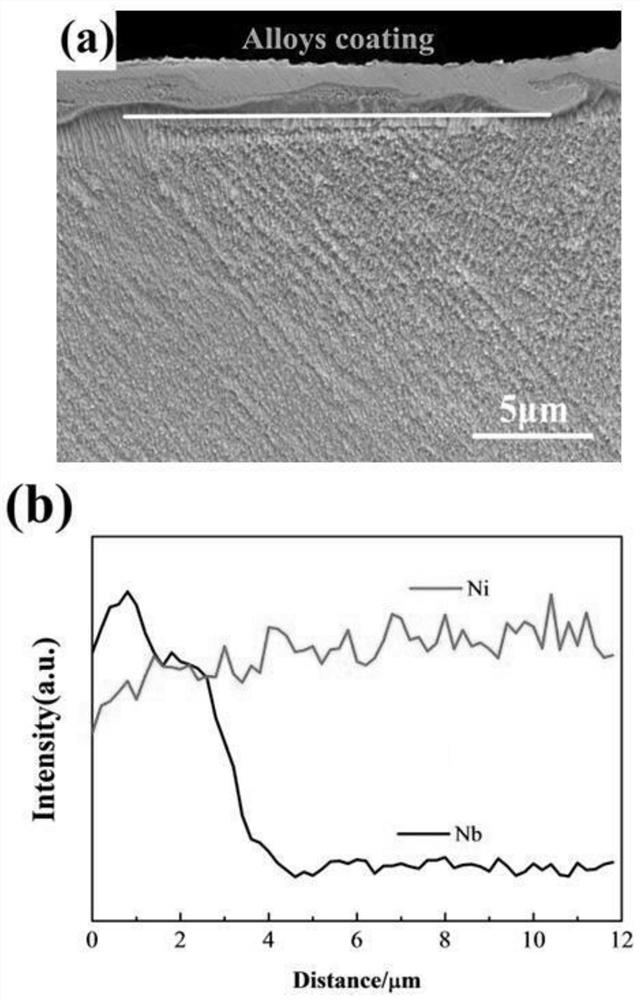

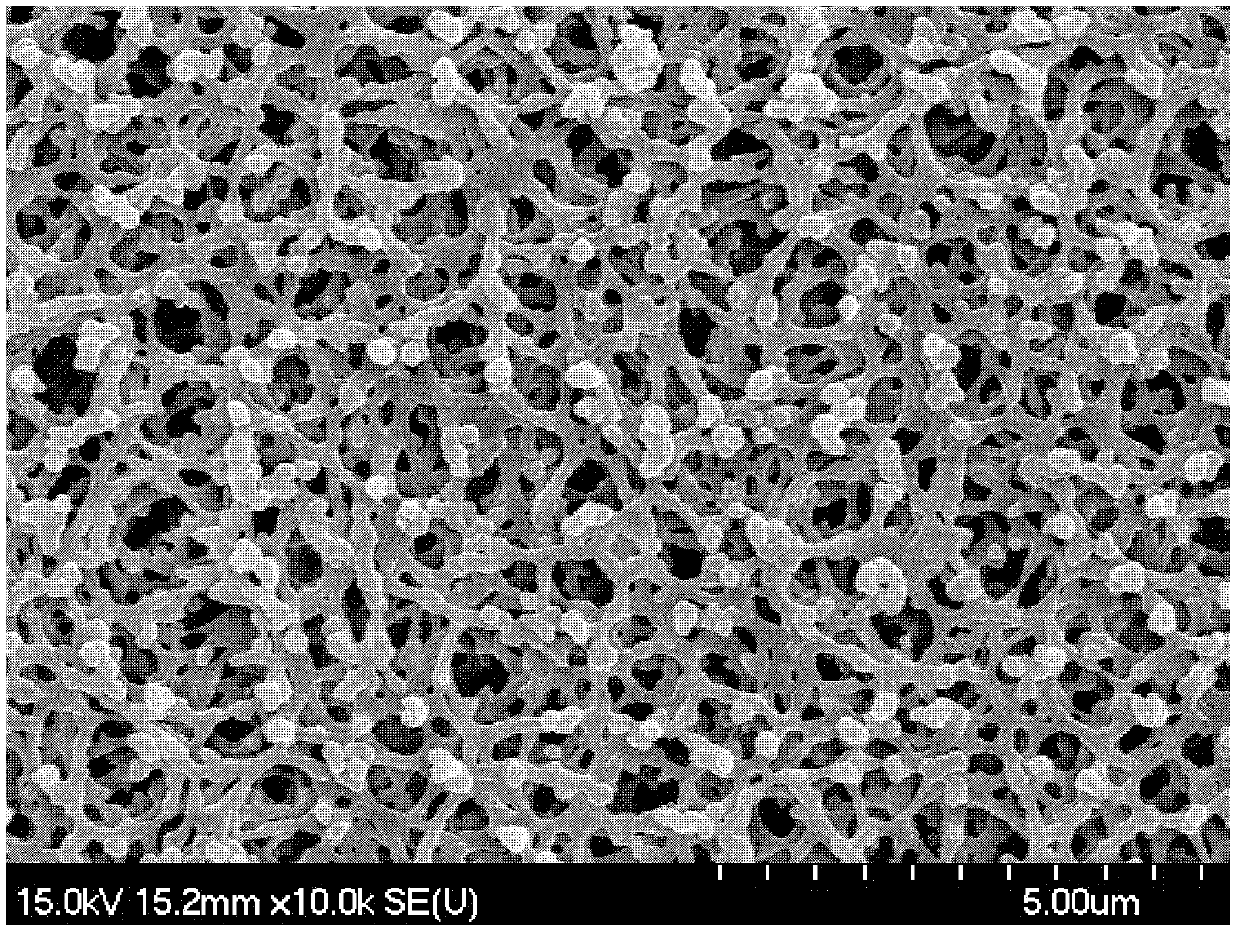

A kind of preparation method of high-performance ni-nb amorphous coating

ActiveCN110144578BStrong surface bindingImprove surface bindingMetallic material coating processesSurface engineeringMetallic materials

The invention relates to the technical field of material surface engineering, and is a method for preparing a high-performance Ni-Nb amorphous coating; specifically, it is prepared on the surface of a nickel-based alloy by combining mechanical coating with a high-current pulsed electron beam. The invention relates to a Ni-Nb amorphous coating with high strength and excellent wear resistance and corrosion resistance, which belongs to the technical field of metal material surface engineering. It relies on the violent impact and collision between the ball milling medium and the alloy powder to cause repeated cold welding and fracture between the powder particles, promote the diffusion of atoms in the powder particles, and obtain alloyed powder. At the same time, the alloy powder is coated on the surface of the material, and an alloy powder coating with a thickness of 20 μm is formed under the action of diffusion and deposition. Then use the high-current pulsed electron beam remelting effect to adjust the structure of the surface coating of the material.

Owner:JIANGSU UNIV

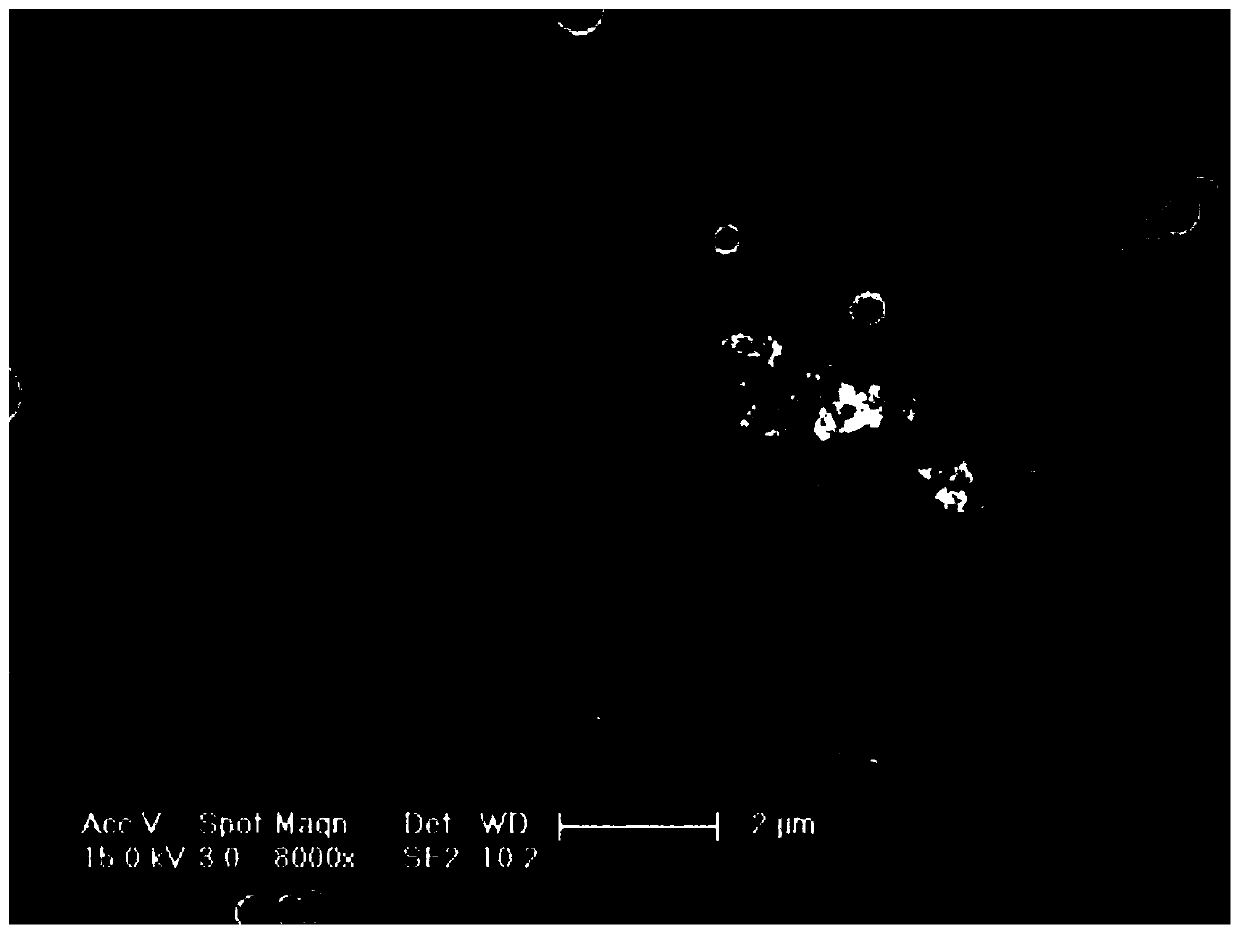

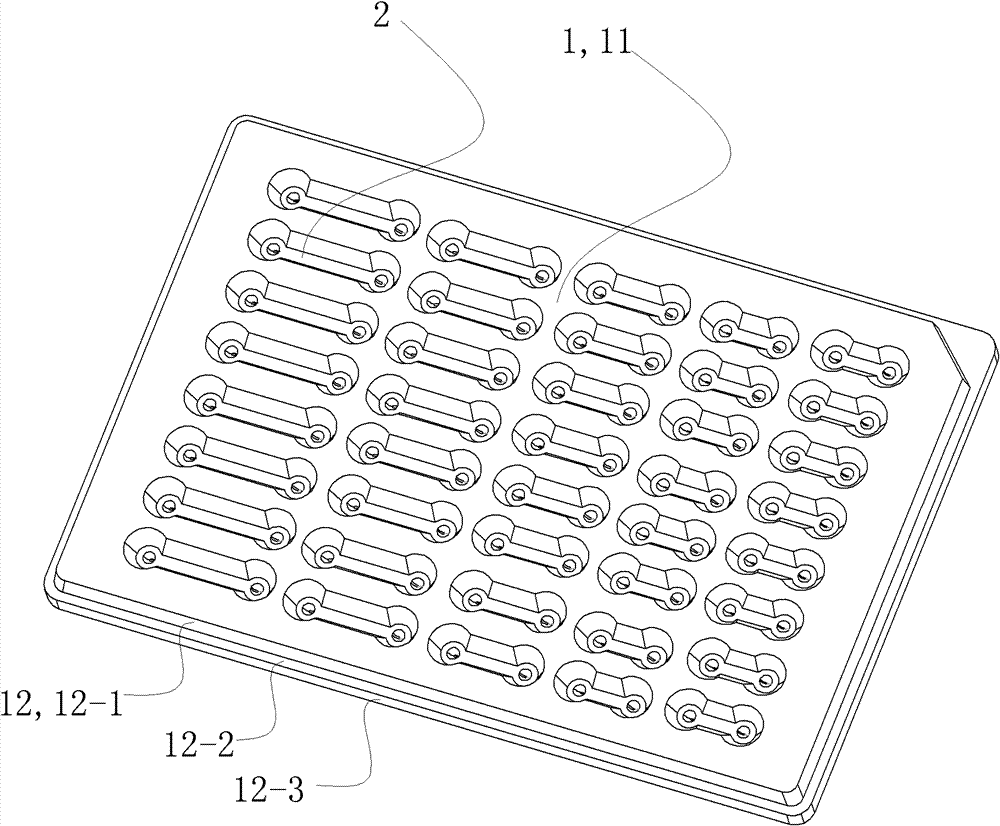

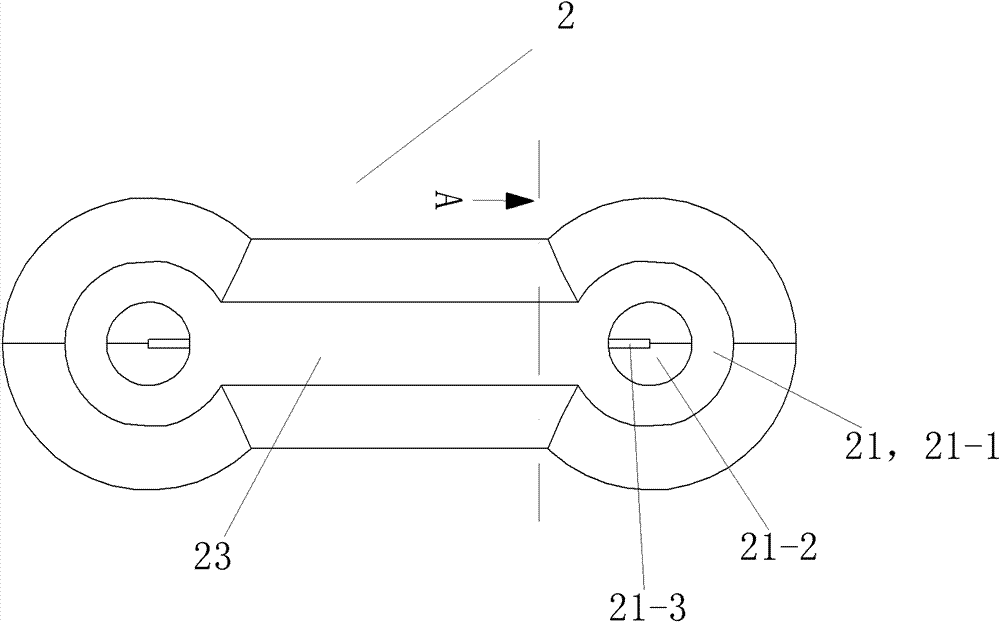

Method to promote protein crystallization with bioglass

InactiveCN102887939BEasy to useApplicable screeningPeptide preparation methodsProtein solutionAutomation

The invention discloses a method for prompting protein crystallization by the use of bioglass. According to the method, superfine bioglass particles are mixed with a liquid for increasing surface activity of bioglass to form a suspension with long service life and stable properties; and the suspension is mixed with a protein saturated solution so as to form an environment which is beneficial to crystallization. After bioglass is made into the suspension, bioglass can be dripped by the use of a dropper to a place where the bioglass is required. Therefore, an application method of bioglass is greatly improved, and automation can replace manual work. The method is more suitable for large-scale protein crystallization condition screening. As the suspension, bioglass can be fully mixed with a protein solution when in use, and the contact surface with protein is larger, which is beneficial to crystallization under various conditions.

Owner:江苏同庚电子科技有限公司

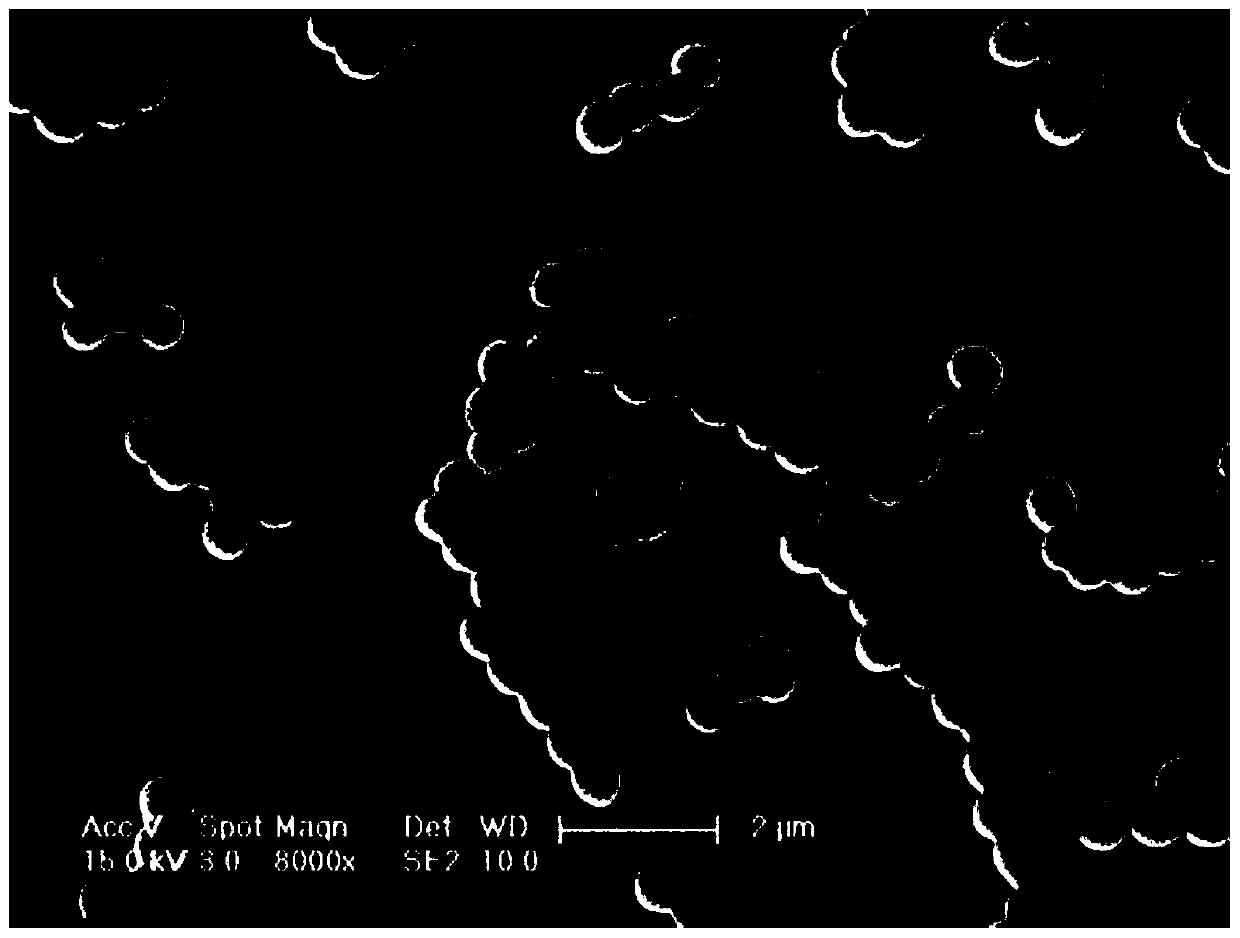

Siloxane-containing vinyl chloride copolymer, preparation method of the siloxane-containing vinyl chloride copolymer, battery division plate prepared from the siloxane-containing vinyl chloride copolymer, and manufacturing method of the battery division plate

ActiveCN102898573BControl macroscopic propertiesHigh strengthSynthetic resin layered productsCell component detailsPolymer scienceNonwoven fabric

The invention discloses a siloxane-containing vinyl chloride copolymer, a preparation method of the siloxane-containing vinyl chloride copolymer, a battery division plate prepared from the siloxane-containing vinyl chloride copolymer, and a manufacturing method of the battery division plate. The siloxane-containing vinyl chloride copolymer has molecular weight of 20000 to 50000 and is shown in the structural formula (1). The battery division plate comprises a porous non-woven fabric. Two copolymer film layers are respectively coated on surfaces of two sides of the porous non-woven fabric. Apertures are uniformly and densely arranged on the surfaces of the copolymer film layers and an average diameter of the apertures is in a range of 0.1 to 10 microns. The copolymer film layers comprise the siloxane-containing vinyl chloride copolymer or mainly comprise the siloxane-containing vinyl chloride copolymer. The battery division plate prepared from the siloxane-containing vinyl chloride copolymer has good strength and hydrophily. The battery division plate has good wettability, high acid adsorption capacity, good flexibility, good foldability, large mechanical strength and good penetration resistance, is suitable for tightening assembling, and can effectively improve use performances of a storage battery.

Owner:ZHEJIANG UNIV OF TECH

Modified epoxy resin system

InactiveCN108546389AExcellent thermal oxygen shielding effectExcellent heat resistance and flame retardancyPolymer chemistryPolytetrafluoroethylene

The invention relates to a modified epoxy resin system; preparation comprises the steps: adding modified silica into a bifunctional epoxy system, and adding a monofunctional epoxy system and nano-polytetrafluoroethylene particles, to obtain a glue solution; and adjusting the solid content of the glue solution to 50% by propylene glycol methyl ether acetate to obtain the modified epoxy resin system. A board prepared based on the modified epoxy resin system has excellent flame retardancy and heat resistance, especially prominent wear resistance.

Owner:嘉兴立一新材料股份有限公司

Device and method for preparing metal composite material with coating structure through bidirectional extrusion

The invention discloses a device and a method for preparing a metal composite material of a coating structure through bidirectional extrusion, and belongs to the technical field of metal composite material machining. The device comprises a fixed support, a combined extrusion die, an extrusion male die, an extrusion container, a forward extrusion device and a backward extrusion device, the combined extrusion die is arranged between the forward extrusion device and the backward extrusion device, a mounting base sleeves the outer side of the combined extrusion die and is fixedly connected with the fixed support, a forward extrusion female die is arranged at one end in the combined extrusion die, a backward extrusion female die is arranged at the other end, one end of the extrusion male die is matched with the forward extrusion female die, the other end of the extrusion male die is matched with the forward extrusion device, one end of the extrusion cylinder is matched with the backward extrusion female die, and the other end of the extrusion cylinder is matched with the backward extrusion device. According to the device and the method for preparing the metal composite material of the coating structure through bidirectional extrusion, blank defects are eliminated by extruding an inner-layer blank, a new metal surface is generated, and the composite material with high surface binding force and excellent material mechanical property is obtained through subsequent extrusion composite forming.

Owner:HUNAN UNIV OF SCI & TECH

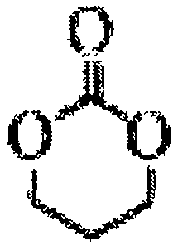

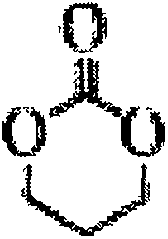

High dielectric property copper-clad board glue and preparation method thereof

InactiveCN108587063AImprove heat resistanceGuaranteed StrengthSynthetic resin layered productsElectrical equipmentDielectricCopper

The invention relates to high dielectric property copper-clad board glue and a preparation method thereof. The preparation method comprises adding methyl butynol into diglycidyl phthalate, stirring the mixture at 75 DEG C for 5 minutes, then adding 1, 8-octanedithiol and N, N-dicyclohexylcarbodiimide into the mixture, stirring the mixture for 5 minutes, then adding a modified silica system and nano-hollow alumina into the mixture, stirring the mixture for 15 minutes, finally, adding a modified epoxy system into the mixture, stirring the mixture at 125 DEG C for 2 hours, adding a butanone / PMA mixed solution into the mixture to obtain glue, dipping a 1080 glass cloth into the glue to obtain a prepreg, heating to dry the prepreg and preparing the modified epoxy resin-based copper clad board.The modified epoxy resin-based copper clad board has excellent dielectric properties and heat resistance and meets the development and application requirements of the modified epoxy resin-based copper-clad board.

Owner:苏州巨峰新材料科技有限公司

Modified epoxy resin-based copper clad laminate and preparation method thereof

InactiveCN107722562AHigh densityReduce filler reactivityElectrical equipmentFlat articlesEpoxyHeat resistance

The invention relates to a modified epoxy resin-based copper clad laminate and a preparation method thereof. The preparation method comprises: adding a modified silica foam system into a bifunctionalepoxy system, stirring for 30 min at a temperature of 120 DEG C, adding a monofunctional epoxy system and hollow nanometer alumina at a temperature of 95-105 DEG C, and stirring for 20 min to obtain aglue solution; and carrying out hot pressing molding on the glue solution, a reinforcing material and metal foil to obtain a modified epoxy resin-based copper clad laminate, wherein the obtained modified epoxy resin-based copper clad laminate has excellent flame retardancy and excellent heat resistance, such that the development and application of modified epoxy resin-based copper clad laminatescan be met.

Owner:苏州巨峰新材料科技有限公司

Semi-curing sheet for high dielectric property copper clad laminate and preparation method thereof

The invention relates to a semi-curing sheet for high dielectric property copper clad laminate and preparation method thereof. The method includes the following steps of: adding methyl butynol2-methylbutyraldehyde into diglycidyl phthalate, stirring at 75 DEG C for 5 minutes, then adding 1, 8-octanedithiol, N, N-dicyclohexylcarbodiimide and stirring for 5 minutes, then adding modified silicon dioxide system, nano hollow alumina and stirring for 15 minutes, finally adding modified epoxy system, stirring at 125 DEG C for 2 hours to obtain the glue solution; adjusting the solid content of the glue solution to be 65% by using butanone / PMA mixture, then dipping the reinforced material 1080 glass cloth into the glue solution to obtain the prepreg. The prepreg is heated and dried to obtain thesemi-curing sheet for the high dielectric property copper clad laminate. The modified epoxy resin-based copper clad laminate is prepared, has excellent dielectric property and heat resistance, and meets the development and application of the modified epoxy resin-based copper clad plate.

Owner:苏州巨峰新材料科技有限公司

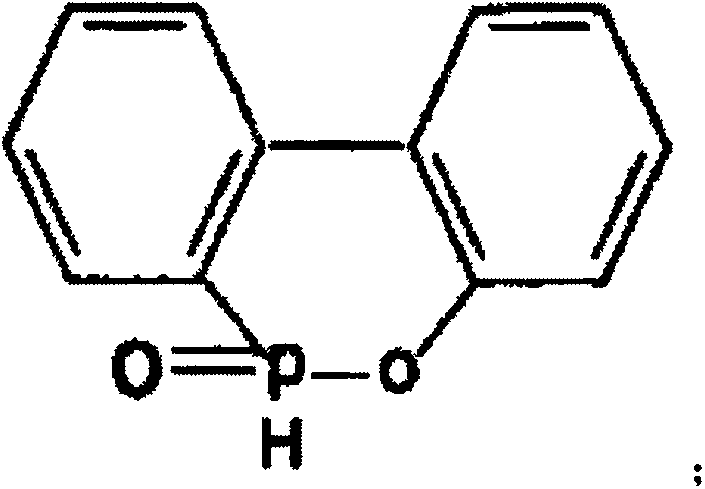

Preparation method of heat-resistant composite magnetic material

InactiveCN105261437AHigh strengthImprove heat resistanceOrganic/organic-metallic materials magnetismInductances/transformers/magnets manufacturePhosphateMonomer

The invention relates to a preparation method of a heat-resistant composite magnetic material. The method comprises the following steps: mixing a phenolic compound with a bisphenol A cyanate ester monomer, and adding endo-methylene tetrahydro-biphenyl dimethylbenzene anhydride, pentaerythritol tetraacrylate and bisphenol A epoxy resin to obtain a resin prepolymer; mixing the resin prepolymer with methylene bis(dialkylthiocarbamate), a modified magnetic filler and a heterogeneous undecanol polyoxyethylene ether phosphate kalium salt to obtain a composite system; injecting the composite system into a mold coated with a release agent, and carrying out mold pressing in a vacuum condition; and finally turning off a power supply, naturally cooling the product and demolding the product to obtain the heat-resistant composite magnetic material. The heat-resistant composite magnetic material has excellent flame retardant property and heat resistance, and meets development and application of the heat-resistant composite magnetic material.

Owner:苏州凯欧曼新材料科技有限公司

Hot-pressed material with high dielectric properties

The invention relates to a hot-pressed material with high dielectric properties. The hot-pressed material is prepared by the steps: adding high-dielectric filler into an epoxy system containing doublefunctional groups, carrying out stirring at 130 DEG C for 20min, then, adding an epoxy system containing single functional group and aluminum oxide nanoparticles at 95 DEG C, and carrying out stirring for 130min to obtain a rubber solution; regulating the solid content at 60% by using propylene glycol monomethyl ether acetate, then, dipping glass cloth into the rubber solution, and carrying out heating for drying to obtain the hot-pressed material with high dielectric properties. The hot-pressed material with high dielectric properties has excellent flame retardance and heat resistance and particularly has a remarkable dielectric constant.

Owner:嘉兴立一新材料股份有限公司

Lightweight high-strength heat preservation felt as well as preparation method and application thereof

ActiveCN113831130AStrong surface bindingEffective application of mechanical propertiesChemical industryCeramicwarePolymer scienceCarbon felt

The invention discloses a lightweight high-strength heat preservation felt, which relates to the technical field of heat preservation and insulation materials. The lightweight high-strength heat preservation felt comprises a prefabricated soft carbon felt, and the surface of the prefabricated soft carbon felt is covered with a carbon nanotube layer. The invention also provides a preparation method and application of the lightweight high-strength heat preservation felt. The heat preservation felt has the beneficial effects that the surface of the prefabricated soft carbon felt is coated with the carbon nano tube layer, and the carbon nano tube has excellent mechanical property due to the special nano structure of the carbon nano tube. When external force acts on the light high-strength heat preservation felt, the force can be transmitted to the carbon nano tube layer through an interface, the carbon nano tubes bear loads applied to the prefabricated soft carbon felt, the mechanical performance of the carbon nano tubes is effectively applied, the prefabricated soft carbon felt has high toughness, and the mechanical strength of the prefabricated soft carbon felt is integrally improved.

Owner:ANHUI HONGCHANG NEW MATERIAL CO LTD

Modified epoxy resin material

The invention relates to a modified epoxy resin material. A preparation method comprises the following steps of adding modified silicon dioxide into a bifunctional epoxy system; adding a monofunctional epoxy system and nanometer polytetrafluoroethylene particles to obtain glue liquid; regulating the solid content of the glue liquid to be 50 percent by propylene glycol methyl ether acetate; then, soaking glass fabric into the glue liquid; next, performing heating and drying to obtain the modified epoxy resin material. The modified epoxy resin material has excellent flame retardant performance and heat resistant performance, and particularly has excellent wear-resistant performance.

Owner:嘉兴立一新材料股份有限公司

Filler used for flame-retardant heat-resistant copper-clad laminate and preparation method of filler

InactiveCN107973934AReasonable compositionUniform dispersionSynthetic resin layered productsLaminationMethyltrichlorosilaneCopper

The invention relates to a filler used for a flame-retardant heat-resistant copper-clad laminate and a preparation method of the filler. The method comprises the following steps: taking nano silicon dioxide foam, dodecylbenzene sulfonic acid, bismuth nitrate pentahydrate, methyl trichlorosilane, polyoxyethylene sorbitan monooleate as raw materials to obtain the filler. According to the filler provided by the invention, the filler is used for preparing the flame-retardant heat-resistant copper-clad laminate, and the filler has excellent flame-retardant performance and heat-resistant performance, and satisfies the development and application of the flame-retardant heat-resistant copper-clad laminate.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

A device and method for preparing clad structural metal composite materials by bidirectional extrusion

ActiveCN112756414BStrong surface bindingReduce defectsExtrusion diesMechanical propertySurface bonding

The invention discloses a device and method for preparing metal composite materials with cladding structure by bidirectional extrusion, which belongs to the technical field of processing metal composite materials and includes: a fixed bracket, a composite extrusion die, an extrusion punch, an extrusion cylinder, a positive A forward extrusion device and a reverse extrusion device, the composite extrusion die is arranged between the forward extrusion device and the reverse extrusion device; the outer side of the composite extrusion die is provided with a mounting base, and the mounting base is fixedly connected with the fixed bracket; One end of the composite extrusion die is provided with a forward extrusion die, and the other end is provided with a reverse extrusion die; one end of the extrusion punch is matched with the forward extrusion die; the other end of the extrusion punch is matched with the positive extrusion die. Cooperate with the extrusion device; one end of the extrusion cylinder cooperates with the reverse extrusion die; the other end of the extrusion cylinder cooperates with the reverse extrusion device. The invention eliminates the defects of the blank by extruding the inner layer blank, and the generated new metal surface is subsequently extruded and compositely formed to obtain a composite material with strong surface bonding force and excellent mechanical properties of the material.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com