POSS (polyhedral oligomeric silsesquioxanes) modified high barrier three-layer co-extrusion packaging film and preparation method thereof

A three-layer co-extrusion and packaging film technology, which is applied in the field of packaging films, can solve the problems affecting the barrier properties of films, LLDPE and EVOH incompatibility, etc., to improve mechanical properties and heat resistance, ensure transparency, and improve barrier properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

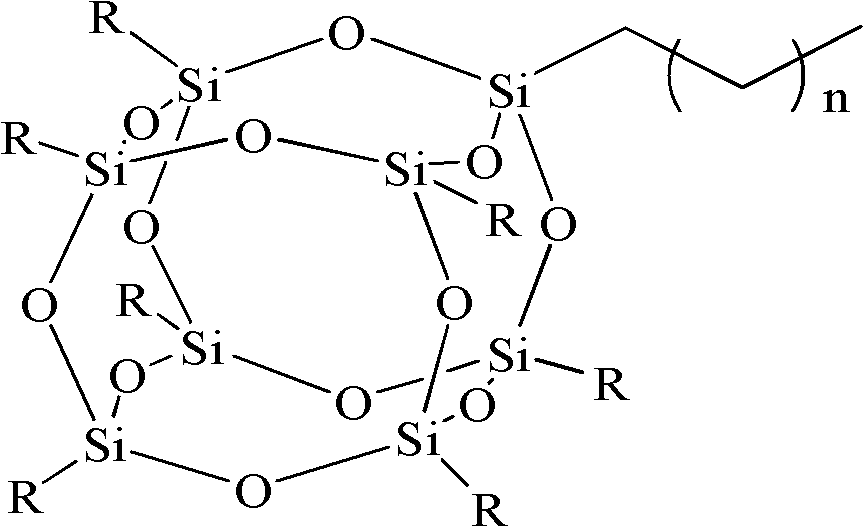

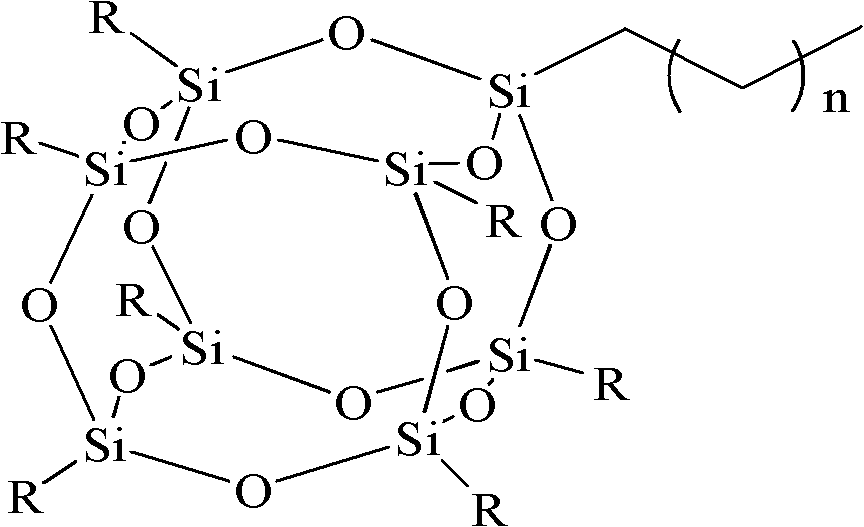

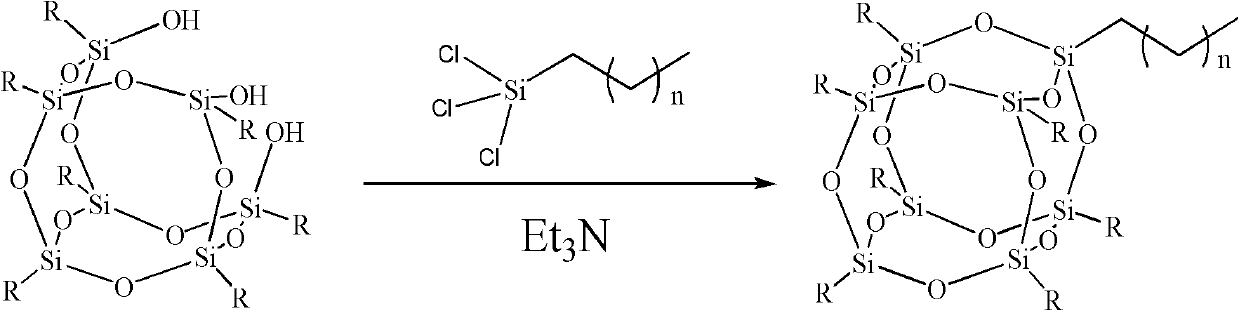

[0027] Step 1: In a flask filled with high-purity nitrogen, add (i-C 4 h 9 ) 7 Si 8 o 9 (OH) 3 7.119g, THF 25ml and Et 3 N 2.732g, then slowly inject n-alkyltrichlorosilane CH 3 (CH 2 ) n CH 2 SiCl 3 (n=1) 1.598 g. After stirring overnight, it was filtered, and the filtrate was rotovapped to obtain a pale yellow solid powder. Crystallize in a solution of toluene and acetonitrile to obtain a POSS modifier, and dry it in vacuum at 50°C for 12 hours before use.

[0028] Step 2: Put LDPE, LLDPE, and POSS modifiers into the blender according to the ratio of 10:87:3 and mix them evenly, then use a twin-screw extruder to melt and extrude to pelletize, and the heating temperature in the 9th zone is 170, 180 , 200, 210, 210, 200, 190, 190, 180°C. The prepared masterbatch is dried under vacuum condition, and the POSS content in the masterbatch is 3%. .

[0029] Step 3: Mix the middle layer (EVOH:PE-g-MAH=85:15) and the inner layer (LDPE:LLDPE:oleic acid amide=20:79:1) in ...

Embodiment 2

[0032] Step 1: In a flask filled with high-purity nitrogen, add (i-C 4 h 9 ) 7 Si 8 o 9 (OH) 3 7.910g, THF 30ml and Et 3 N 3.036g, then slowly inject n-alkyltrichlorosilane CH 3 (CH 2 ) n CH 2 SiCl 3 (n=4) 2.195 g. After stirring overnight, it was filtered, and the filtrate was rotovapped to obtain a pale yellow solid powder. Crystallize in a solution of toluene and acetonitrile to obtain a POSS modifier, and dry it in vacuum at 70°C for 12 hours before use.

[0033] Step 2: Same as Example 1.

[0034] Step 3: Mix the middle layer (EVOH: PE-g-MAH=90:10) and the inner layer (LDPE: LLDPE: oleic acid amide = 10:89:1) in a blender, and then mix them with the outer masterbatch ( LDPE:LLDPE:POSS modifier=10:87:3) co-extruded and casted by a three-layer co-extrusion cast film machine to obtain a POSS modified high-barrier three-layer co-extruded packaging film with a film thickness of 60 μm.

[0035] Step 4: After placing the sample at room temperature for 3 days, test ...

Embodiment 3

[0037] Step 1: In a flask filled with high-purity nitrogen, add (i-C 4 h 9 ) 7 Si 8 o 9 (OH) 3 8.701g, THF 30ml and Et 3 N 3.340g, then slowly inject n-alkyltrichlorosilane CH 3 (CH 2 ) n CH 2 SiCl 3 (n=6) 2.732 g. After stirring overnight, it was filtered, and the filtrate was rotovapped to obtain a pale yellow solid powder. Crystallize in a solution of toluene and acetonitrile to obtain a POSS modifier, and dry it in vacuum at 70°C for 12 hours before use.

[0038] Step 2: Put LDPE, LLDPE, and POSS modifier into a mixer at a ratio of 20:74:6 and mix evenly, and the POSS content in the masterbatch is 6%. Then use a twin-screw extruder to melt-extrude and granulate, and the heating temperatures in zone 9 are 180, 200, 220, 220, 220, 210, 210, 200, and 190°C, respectively. The prepared masterbatch is dried under vacuum conditions.

[0039] Step 3: Mix the middle layer (EVOH: PE-g-MAH=85:15) and the inner layer (LDPE: LLDPE: oleic acid amide = 10:89:1) in a blender...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com