Water-based high-barrier coating liquid and production method thereof

A coating liquid, high barrier technology, applied in the direction of coating, can solve problems such as poor dispersibility, avoid secondary agglomeration, improve compactness, and improve poor dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

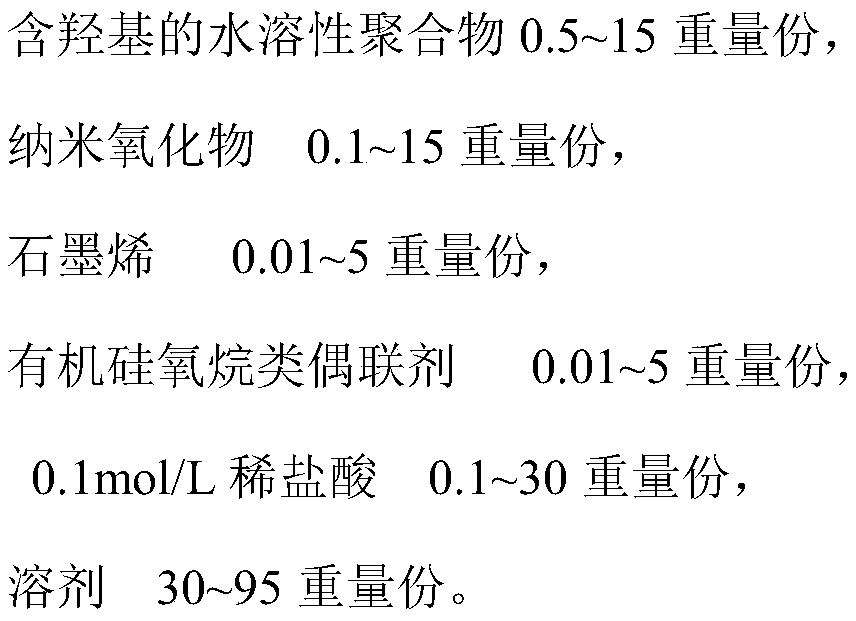

[0055] First, the preparation method of polyvinyl alcohol solution A, nano-silica dispersion B and silane coupling agent hydrolyzate D is described, and the specific process includes:

[0056] Preparation of polyvinyl alcohol solution A:

[0057] Add 50 parts by weight of PVA (degree of alcoholysis 99%, degree of polymerization 2400) in 900 parts by weight of water and 50 parts by weight of methanol mixed solvent, first fully swell in a water bath at 50°C, then heat up to 95°C under stirring , stirred at constant temperature for 0.5h, after being completely dissolved and naturally cooled to room temperature, a PVA solution A with a solid content of 5.0% was obtained.

[0058] Preparation of nano-silica dispersion B:

[0059] Add 360 parts by weight TEOS (99.9% purity) to a mixed solvent of 170 parts by weight methanol and 468 parts by weight water, then add 2 parts by weight hydrochloric acid (0.1% by mass fraction) and stir at room temperature for hydrolysis and condensation...

Embodiment 1

[0063] 2.0 parts by weight of graphene aqueous solution (product model "FNG-C100", manufactured by Qualcomm New Materials, solid content of 10%) was added to 68.6 parts by weight of nano-silica dispersion B, and stirred for 1 h at normal temperature and pressure to make it Uniform dispersion; then add 19.6 parts by weight of PVA solution A to the above dispersion liquid, and then add 9.8 parts by weight of coupling agent hydrolyzate D while the above mixed solution is fully stirred, and finally add 1.0 parts by weight of The delayed crosslinking agent sodium sulfate, 0.5 parts by weight of leveling agent Silok8000 and 0.5 parts by weight of adhesion promoter Silok628 were stirred and mixed for 0.5 hours to obtain high barrier coating solution TC-1.

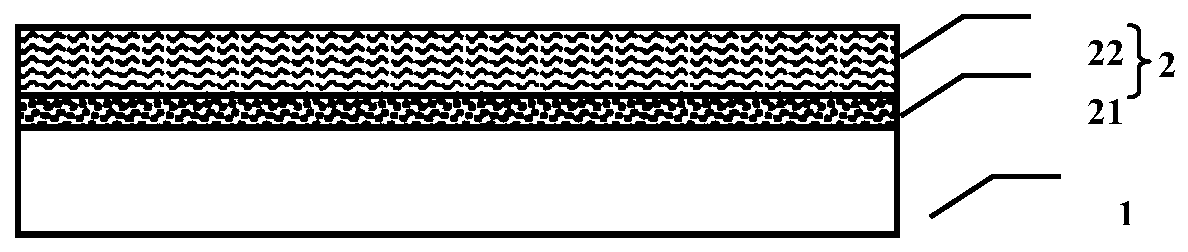

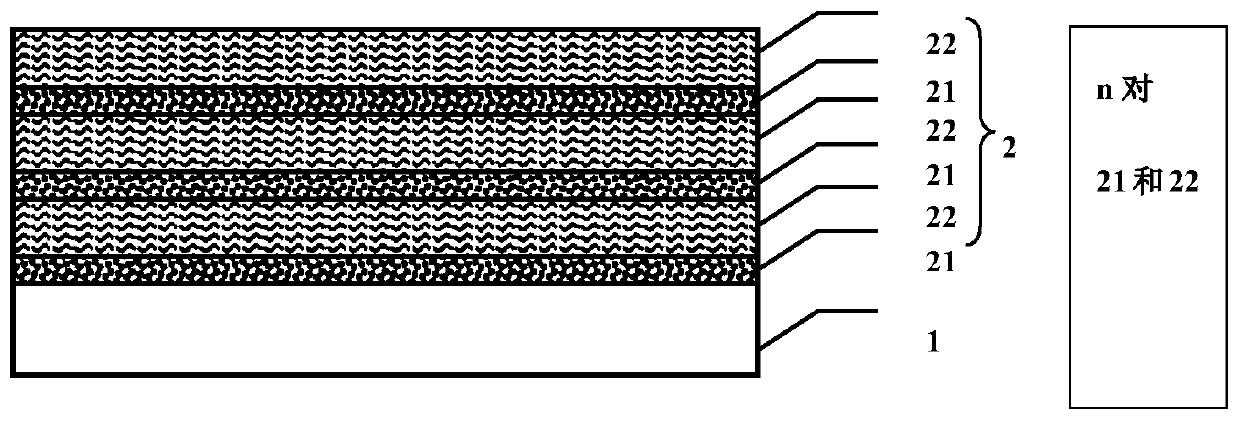

[0064] Use a micro-gravure coater to coat the above-mentioned TC-1 coating solution on a 12 μm PET base film on which a 30 nm thick silicon oxide coating has been deposited in such a way that the dry thickness of the coating film i...

Embodiment 2

[0066] Except that the addition amount of the graphene aqueous solution was changed to 0.5 parts by weight, other operations were the same as in Example 1 to obtain high barrier coating liquid TC-2. Using the coating solution, the same procedure as in Example 1 was carried out to obtain barrier film No. 2 with a laminated structure of an inorganic substance deposition layer and a barrier layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com