A nano-toughened carbon fiber composite material and preparation method thereof

A composite material and carbon fiber technology, applied in the direction of nanotechnology, carbon compound, nanotechnology, etc., can solve the problems of modulus decrease, composite material heat resistance decrease, etc., achieve the effect of increasing toughness, improving poor dispersion, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

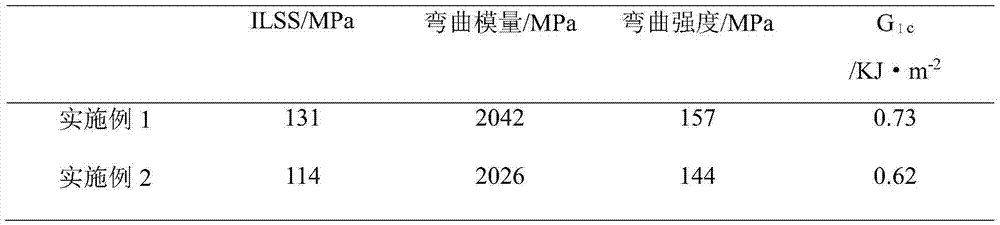

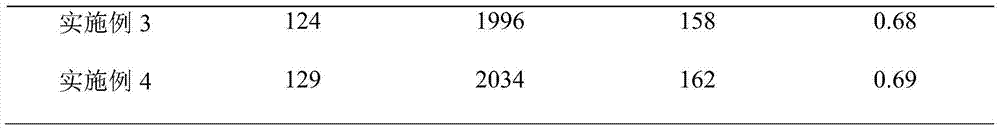

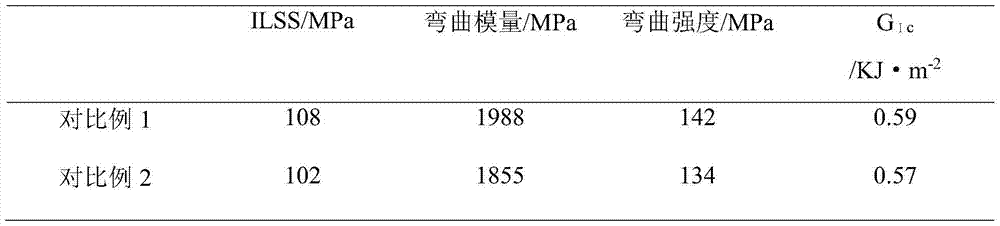

Examples

Embodiment 1

[0047] An active graphene halloysite nanotube composite film used for interlayer toughening of prepregs, the composite film is composed of graphene and halloysite nanotubes according to the following steps, and the specific preparation method is as follows:

[0048] a) React 10 g of the purchased halloysite nanotubes with 300 ml of hydrochloric acid with a concentration of 1 mol / L for 24 hours, and let stand for 1 day. Pour off the supernatant, centrifuge with distilled water to pH=6.0, dry at 60°C, and grind to obtain powder I.

[0049] b) Add 300ml of 1mol / L sodium chloride solution to powder I, stir for 48 hours, then centrifuge with distilled water until no chloride ions are contained (tested with silver nitrate), dry at 105°C, and grind to obtain powder II.

[0050] c) Take 5g of powder II and add 250ml of 0.014mol / L cetyltrimethylammonium bromide, stir in an oil bath at 60°C for 12h, centrifuge with ethanol, dry at 90°C, and grind to obtain the modified grafted long chain ...

Embodiment 2

[0068] An active graphene / halloysite nanotube composite film used for interlayer toughening of prepregs, the composite film is composed of graphene and halloysite nanotubes according to the following steps, and the specific preparation method is as follows:

[0069] k) React 10 g of the purchased halloysite nanotubes with 300 ml of hydrochloric acid with a concentration of 1 mol / L for 24 hours, and let stand for 1 day. Pour off the supernatant, centrifuge with distilled water to pH=6.0, dry at 60°C, and grind to obtain powder I.

[0070] l) Add 300ml of 1mol / L sodium chloride solution to powder I, stir for 48 hours, then centrifuge with distilled water until no chloride ions are contained (tested with silver nitrate), dry at 105°C, and grind to obtain powder II.

[0071] m) Take 5g of powder II and add 250ml of 0.014mol / L cetyltrimethylammonium bromide, stir in an oil bath at 60°C for 12h, centrifuge with ethanol, dry at 90°C, and grind to obtain the modified grafted long chai...

Embodiment 3

[0087] An active graphene / halloysite nanotube composite film used for interlayer toughening of prepregs, the composite film is composed of graphene and halloysite nanotubes according to the following steps, and the specific preparation method is as follows:

[0088] a) React 10 g of the purchased halloysite nanotubes with 300 ml of hydrochloric acid with a concentration of 1 mol / L for 24 hours, and let stand for 1 day. Pour off the supernatant, centrifuge with distilled water to pH=6.0, dry at 60°C, and grind to obtain powder I.

[0089] b) Add 300ml of 1mol / L sodium chloride solution to powder I, stir for 48 hours, then centrifuge with distilled water until no chloride ions are contained (tested with silver nitrate), dry at 105°C, and grind to obtain powder II.

[0090] c) Take 5g of powder II and add 250ml of 0.014mol / L cetyltrimethylammonium bromide, stir in an oil bath at 60°C for 12h, centrifuge with ethanol, dry at 90°C, and grind to obtain the modified grafted long chai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com