Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

151results about How to "No phase separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

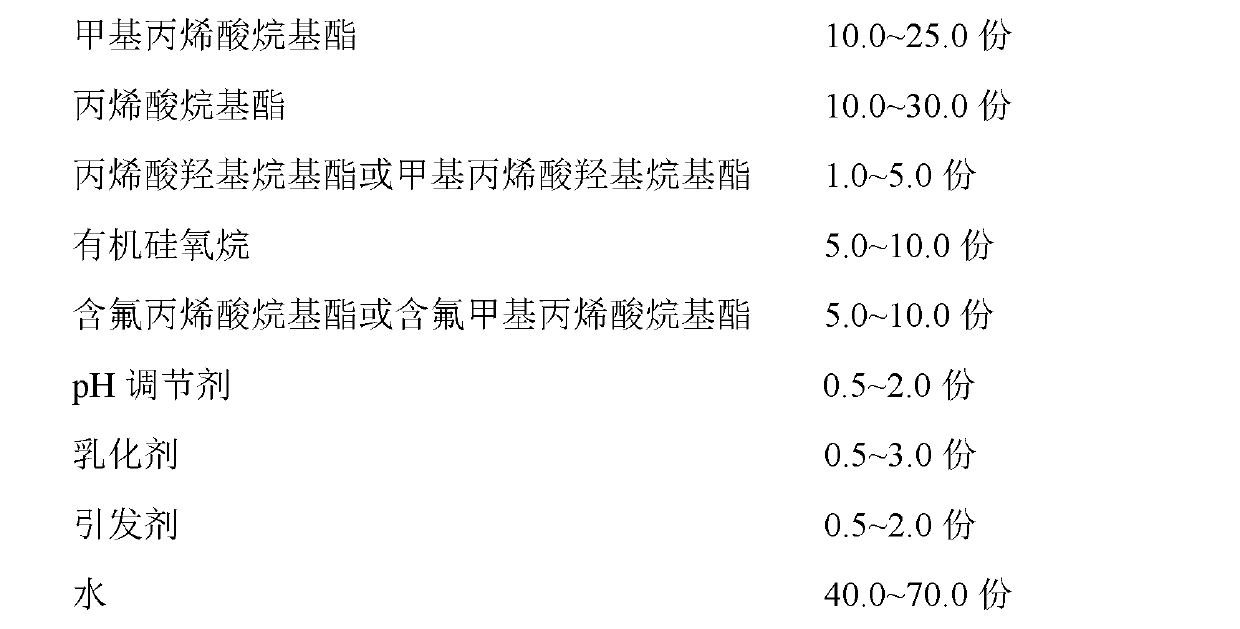

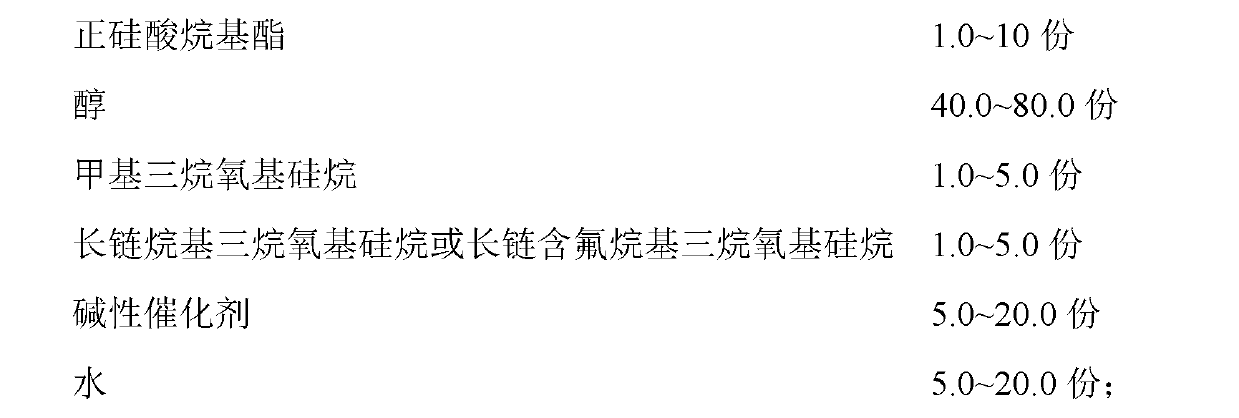

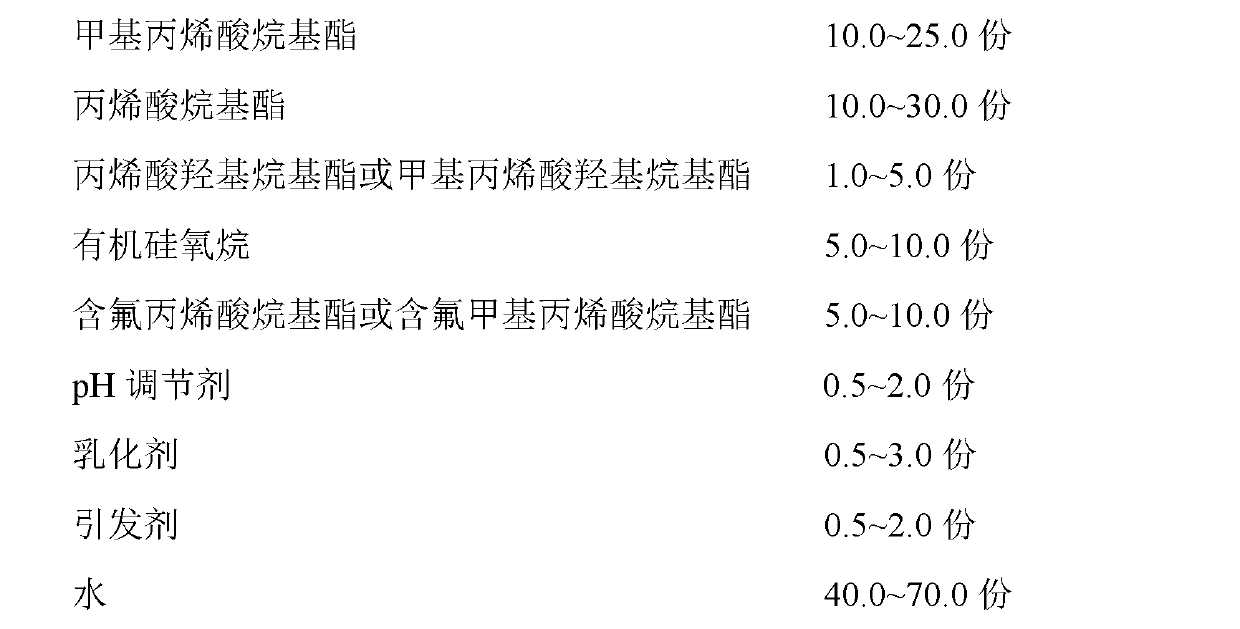

Preparation method of super-hydrophobic surface of glass

The invention relates to the field of super-hydrophobic surfaces. In order to solve the problems of poor binding force between the existing super-hydrophobic SiO2 micro-nano double rough structural layer and a glass substrate and insufficient hydrophobicity, the invention provides a preparation method of the super-hydrophobic surface of glass. The method comprises the following steps of: firstly, preparing fluorosilicone modified acrylic ester emulsion; secondly, preparing modified SiO2 sol; and finally preparing the super-hydrophobic surface of glass. The preparation method is simple and low in cost; a hydrophobic coating has excellent hydrophobicity and has excellent binding force with the glass; and the coating can maintain super-hydrophobicity for a long time.

Owner:HANGZHOU NORMAL UNIVERSITY

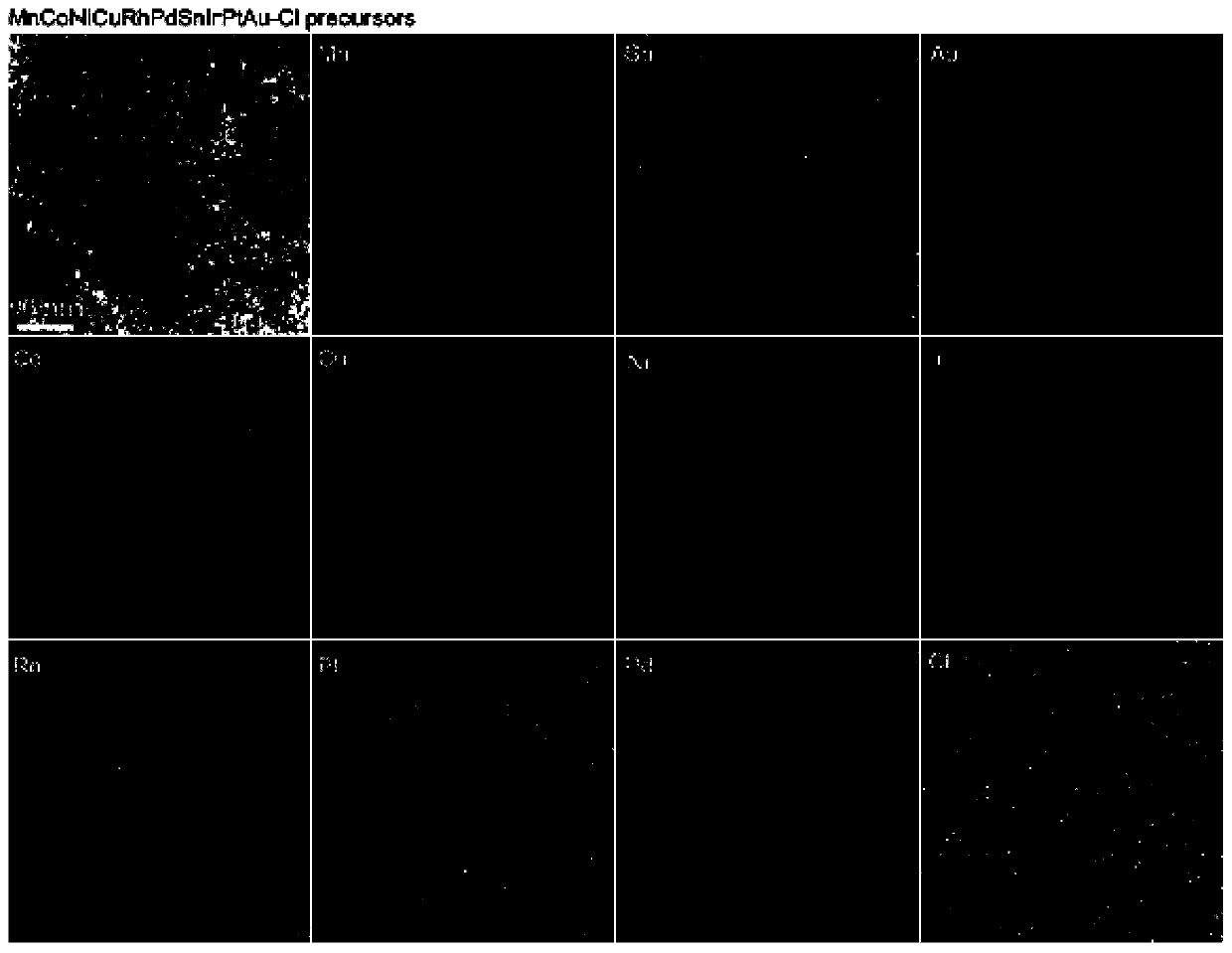

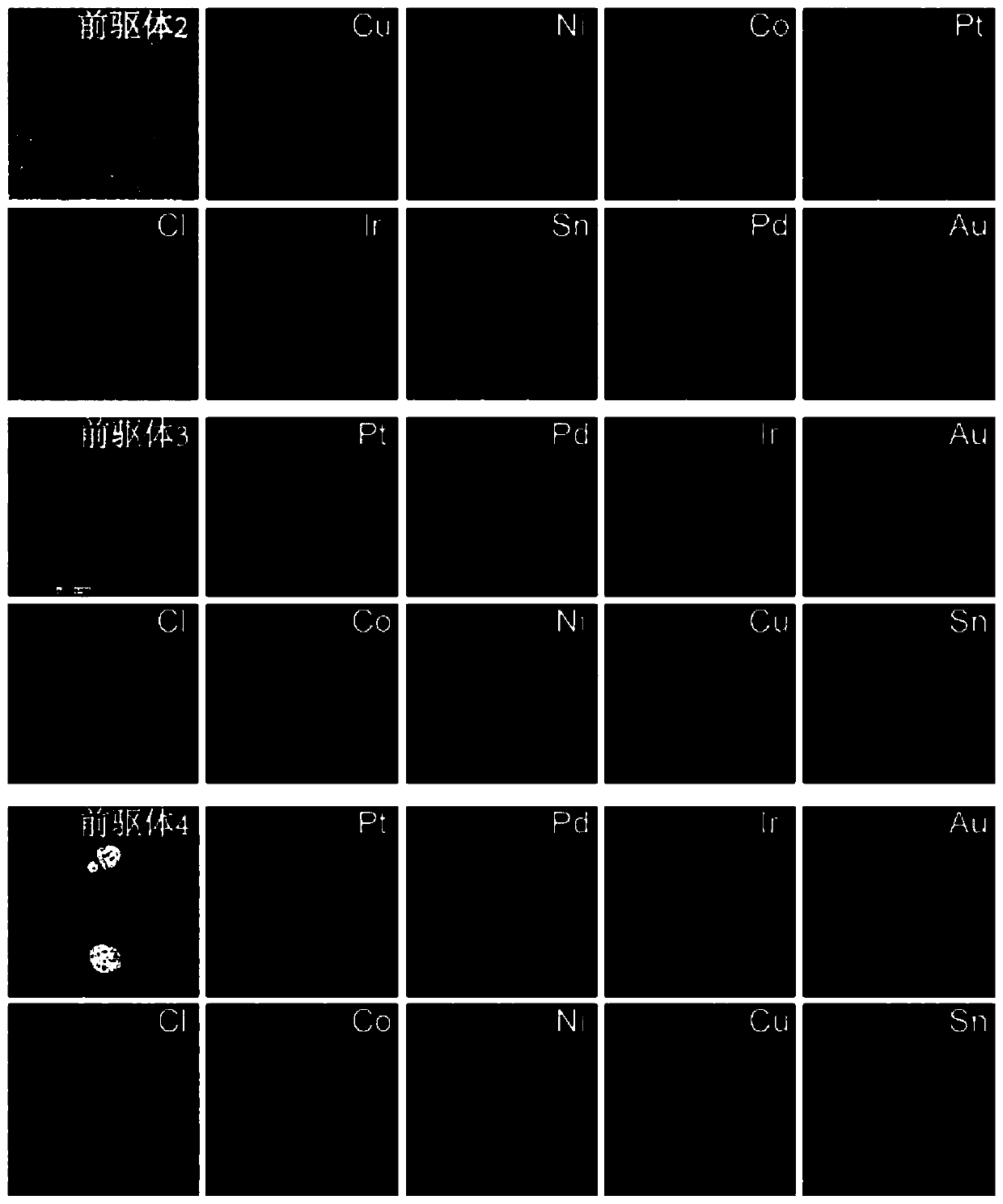

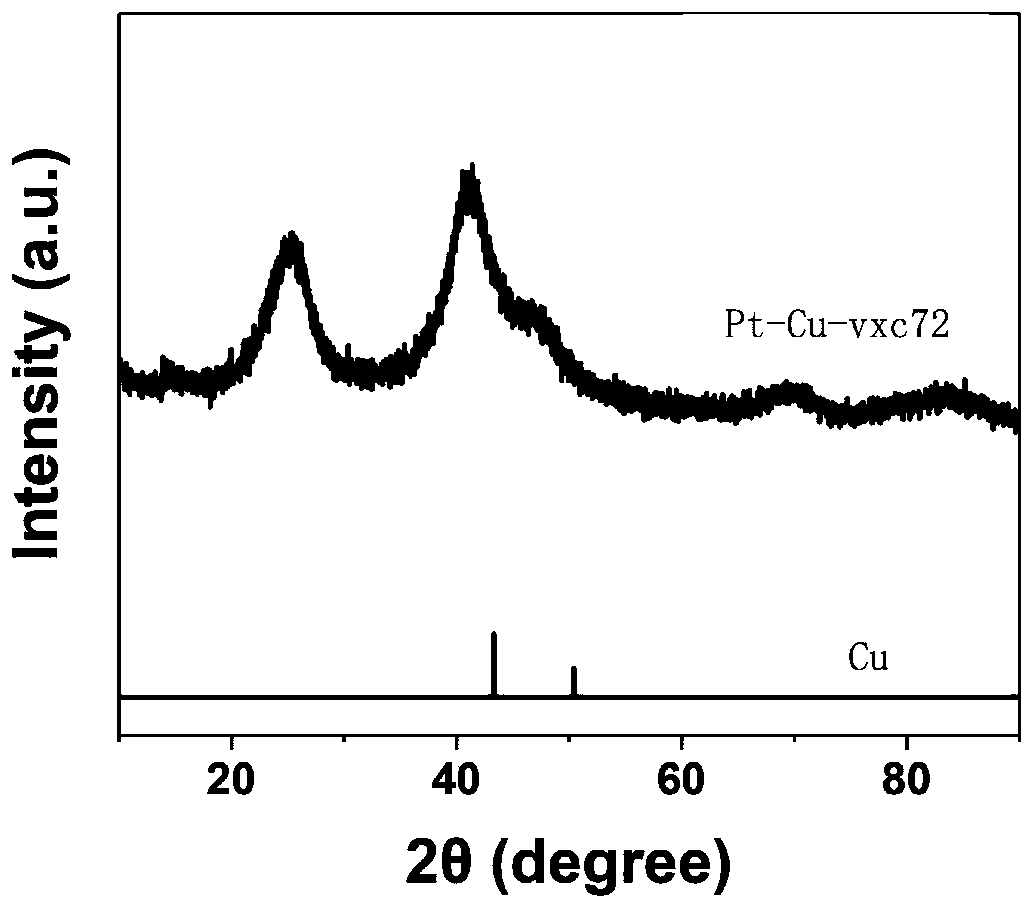

Alloy nanoparticles, preparation method and applications thereof

ActiveCN110560081AImprove catalytic performanceRich varietyMetal/metal-oxides/metal-hydroxide catalystsElectrodesNano catalystFaraday efficiency

The invention discloses alloy nanoparticles, a preparation method and applications thereof. According to the method, a metal precursor loaded on a substrate is rapidly reduced at a high temperature, wherein the metal is rapidly nucleated to avoid the generation of the split-phase alloy so as to form the alloy nanoparticles with ultra-small particle size; and by controlling the types of the metal salts in the precursor, the components in the alloy nanoparticles can be effectively regulated. According to the present invention, the FeCoPtPdIr@GO (FeCoPtPdIr alloy particles are loaded on the surface of graphene oxide) prepared in the embodiments of the invention shows excellent electrochemical hydrolysis hydrogen production performance, can stably operate for 150 h under a condition of 10 mA.cm<-2>, has excellent electrochemical stability, and has the Faraday efficiency of 99.4%, wherein the eta 10 of the product of the present invention is equal to 42 mV, and far exceeds the eta 10 of thecommercial Pt / C of 64 mV (the smaller the eta 10, the better the electrochemical hydrolysis hydrogen production performance); and the new thought is provided in the preparation of alloy nanoparticlesand alloy nanometer catalysts, and the development of alloy nanometer catalysts in catalysis and energy is promoted.

Owner:ZHEJIANG UNIV

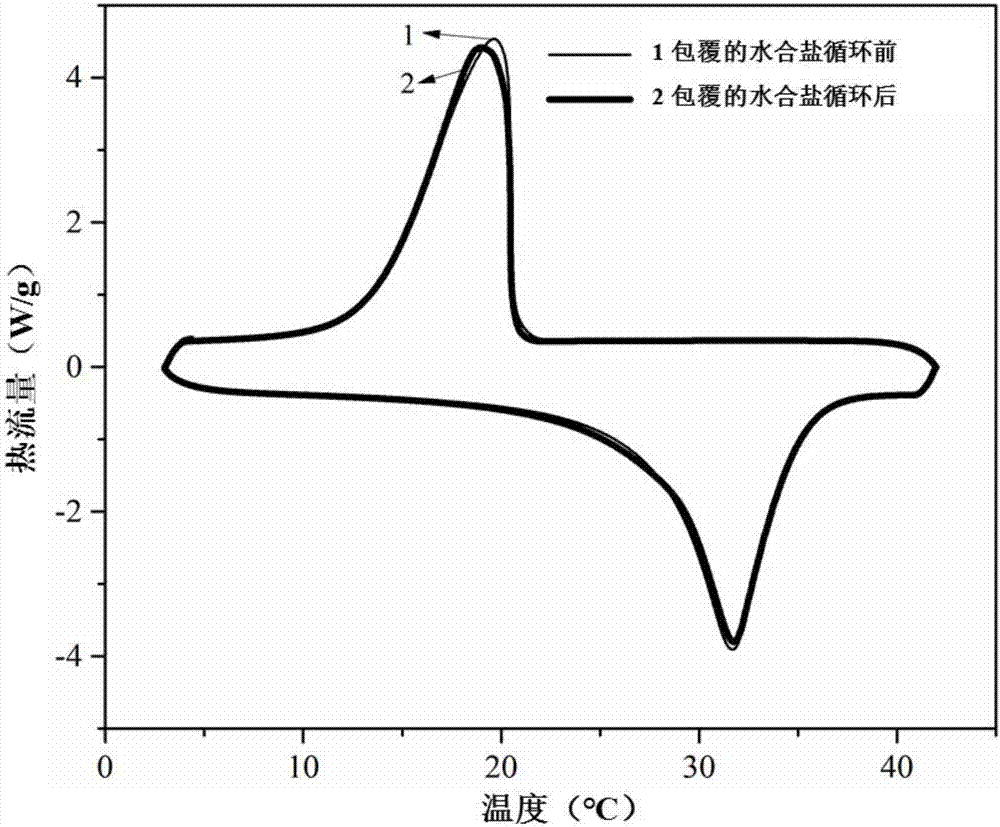

Coated hydrous salt heat-storage material and preparation method

InactiveCN107216859AHigh phase change enthalpyImprove cycle performanceHeat-exchange elementsInorganic saltsHeat storage material

The invention discloses a coated hydrous salt heat-storage material and a preparation method. The coated hydrous salt heat-storage material is composed of an inner core material and an outer wall material. The preparation method comprises the following steps of: firstly, dissolving inorganic salt, a nucleating agent and a thickener in water to obtain a mixed solution; mixing a porous adsorption material with the mixed solution and uniformly mixing the mixture to obtain a composite material; crystallizing the composite material to prepare a compound phase change material; preparing a photocured resin solution by a resin monomer and a prepolymer; and spraying the photocured resin to the composite phase change material, and lighting the material under an UV lamp after uniform spraying to obtain the coated hydrous salt heat-storage material. The heat storage material prepared by the method has the advantages of non-phase separation, no toxicity and corrosion, small degree of supercooling, no liquid leakage and the like. Meanwhile, the heat storage material has the advantage of great heat conductivity coefficient of a carbon material, and the heat storage performance and the heat stable performance are good.

Owner:SOUTH CHINA UNIV OF TECH

Synthetic method of hybrid non-isocyanate polyurethane

ActiveCN102731779ASynthetic circuit is simpleInterpenetrating network structurePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsIsocyanatePolymer chemistry

The invention discloses a synthetic method of hybrid non-isocyanate polyurethane, comprising the following steps: adding epoxy resin and catalyst in a high pressure reaction vessel, sealing the high pressure reaction vessel, and opening to stir, heating up to 60-150 DEG C under continuously stirring, continuously introducing air to keep the CO2 pressure at 0.5-2 MPa, reacting for 1-4 h to generate epoxy-terminated cyclic carbonate, then reacting the epoxy-terminated cyclic carbonate with amine in the presence of a solvent at 30-60 DEG C for 2-10 h to obtain a hybrid non-isocyanate polyurethane solution, wherein the additional amount of the catalyst is 0.1-2 wt% of that of the epoxy resin; pouring the non-isocyanate polyurethane solution in a mold, and removing the solvent to obtain a non-isocyanate polyurethane solution film. The synthetic method of the invention has the advantages of environmental protection and simpleness, and the synthetic product has excellent performances of epoxy resin and polyurethane simultaneously, and has excellent caking property, acid and alkali corrosion resistance, solvent resistance, mechanical strength and other physical properties.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

Phase-change thermal interface material and preparation method thereof

InactiveCN103333447ADoes not affect phase change propertiesNo phase separationHeat-exchange elementsCross-linkPolymer science

The invention discloses a phase-change thermal interface material and a preparation method thereof. The phase-change thermal interface material mainly comprises phase-change resin, one or more of heat-conducting powder, a cross-linking agent, a polymerization initiator and a coupling agent. The preparation method of the phase-change thermal interface material comprises the following steps of: adding the polymerization initiator to the phase-change resin, and initially polymerizing the phase-change resin through light polymerization or thermal polymerization; then adding the coupling agent, uniformly mixing, then adding the heat-conducting powder for multiple times, and then fast stirring to promote the combination of the coupling agent and the heat-conducting powder; after mixing for certain time, adding the cross-linking agent and supplementing the polymerization initiator to obtain the phase-change thermal interface material. According to the invention, a polymer generates a certain degree of cross-linking; the phase-change thermal interface material disclosed by the invention has the advantage that a heat-conducting fin can not generate phase separation under the condition without influencing phase-change property when being increased in temperature in such a way that the cross-linking degree of the polymer is controlled.

Owner:SUZHOU TIANMAI THERMAL TECH

Fatty acid composition

ActiveCN101233852AImprove stabilityImprove the bactericidal effectBiocideSurface-active detergent compositionsAlkaneForm solution

The invention relates to a fatty acid composition, which is diluted at normal temperature and in cold water to form solution used for cleaning of sterilization, fungicide and antivirus. The fatty acid composition comprises at least the following components: component A: food fatty acid comprising at least octyl decanoic acid and nonanoic acid; component B: surfactant comprising alkane sulfonate; component C: acid. The fatty acid composition has the advantages that the fatty acid composition or the diluted solution thereof has good stability, bactericidal and antiviral activity under the water temperature of 4-20 DEG C, no phase separation or crystallization, thus having safer use performance, and active components are low in cost, having more broad-spectrum bactericidal activity which can kill various bacteria, epiphytes and viruses. The fatty acid composition or the diluted solution thereof can be used for sterilization, fungicide and antivirus, which has high-efficient and quick killing effect; the sterilizing rate can reach more than 99.999 percent with contact time less than 1 minute; The fatty acid composition or the diluted solution thereof also has strong cleaning ability, and can keep effective even in hard water; the killing ratio for poliovirus reaches 99.9999 percent and the poliovirus can be killed immediately.

Owner:SICHUAN LOMON BIO TECH CO LTD +1

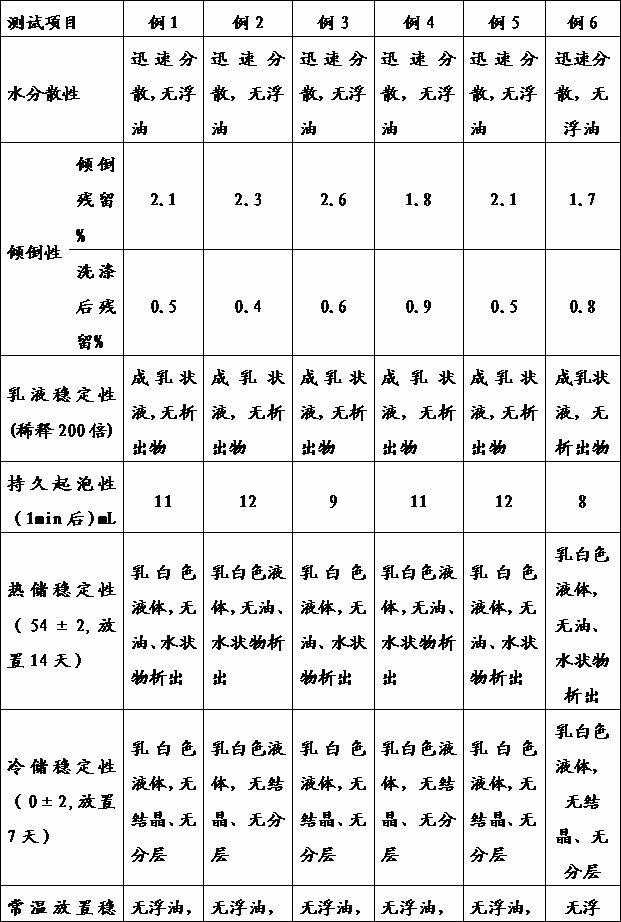

Water emulsion pesticide system and preparation method thereof

ActiveCN102301996AGood dispersionImprove adsorption capacityPlant growth regulatorsBiocideSolubilityAdjuvant

The invention provides a water emulsion pesticide system capable of substituting for the traditional oil emulsion. The system comprises the following raw materials by weight percent: 0.5-60% of crude pesticide or pesticide crude oil, 0.5-5% of macromolecule emulsifier, 0.5-10% of micromolecule emulsifier, 0-15% of cosolvent, 0-5% of adjuvant and the balance of deionized water, wherein the macromolecule emulsifier is an amphiphilic polymer which is formed by polymerizing a component 1, a component 2 and a component 3 at a mole ratio of 1:(0.05-0.5):(0-0.5) and is in a micro-crosslinked structure; the viscosity of the 1% deionized water dispersion of the polymer is between 100 mPa.s to 10000 mPa.s at PH value of 5-9 and 25 DEG C, and a relative molecular weight of the polymer is between 0.5million to 20 million; the component 1 is acrylic acid or acrylic ester with carbon molecular number not more than 36; the component 2 is alkenyl ammonium chloride with carbon molecular number not more than 25; and the component 3 is allyl amide with carbon molecular number not more than 5. The water emulsion pesticide system provided by the invention enables the crude pesticide with tiny solubility in water, oil or organic solvents to form the water emulsion with low toxicity, high efficiency, and good stability. The invention further provides a preparation method of the water emulsion pesticide.

Owner:SHANTOU SHENTAI NEW MATERIAL TECH DEV CO LTD +1

Dynamic vulcanization thermoplastic polyurethane/polysiloxane elastomer and preparation method thereof

ActiveCN108587123AGood dispersionAvoids problems associated with direct addition of high-viscosity polysiloxanesCross-linkPolymer science

The invention discloses a preparation method of a dynamic vulcanization thermoplastic polyurethane / polysiloxane elastomer. The preparation method comprises the following steps: firstly premixing thermoplastic polyurethane, methyl vinyl siloxane, a reinforcing filler and a chain extender, then carrying out melt extrusion pelletization inside an internal mixer or a double screw extrusion machine together with a catalyst to prepare a polyorganosiloxane master batch, then uniformly mixing thermoplastic polyurethane, the polyorganosiloxane master batch, a compatilizer and a polymerization inhibitor, and then adding a cross-linking agent and the catalyst for dynamic vulcanization. The methyl vinyl siloxane used for preparing the master batch is relatively low in viscosity and easy for good dispersion, and simultaneously chain growth can also be realized under the effect of the catalyst, and the viscosity and molecular weight of polyorganosiloxane are improved, so that the obtained elastomercan be of preferable mechanical property and sooth hand feeling, is easy for machining, and can be used in the application fields with high requirements such as buildings, automobile spare parts, electric wires and cables, medical apparatus and instruments and wearable equipment.

Owner:CHENGDU SILIKE TECH

Blood separation gel used for blood collection vessel and preparation method thereof

InactiveCN102309870AImprove physical propertiesGood compatibilityNon-miscible liquid separationMaterial analysisBlood Collection TubeManufacturing technology

The invention relates to the technical field of blood collection equipment separation gel manufacture, and in particular relates to a blood separation gel used for a blood collection vessel and a preparation method thereof. After the blood separation gel is mixed with blood, thixotropy is caused by shearing force to divide the blood into three layers namely hemocyte visible components / separation gel / serum or blood plasma. The blood separation gel comprises the following components: proportion regulator chlorcosane, organic gelling agent dibenzylidene sorbitol, thixotropic agent nano silica, viscosity regulator polyisobutene and the like. The preparation method comprises the following steps: adding polyisobutene, chlorcosane and dibenzylidene sorbitol in an planetary mixer, heating to 120 DEG C and then fully stirring and mixing; fully dissolving and evenly stirring the components and then cooling to less than 60 DEG C; adding nano silica; decompressing, vacuumizing, stirring and evenly mixing, and cooling to room temperature, so as to obtain the blood separation gel. According to the invention, the physical characteristic of the blood separation gel is obviously improved; and the blood separation gel prepared by the method provided by the invention can bear gamma rays in conventional sterilization amount, and is suitable for the environment which requires precise blood detection.

Owner:SHANGHAI KEHUADIAGNOSITIC MEDICAL PRODS

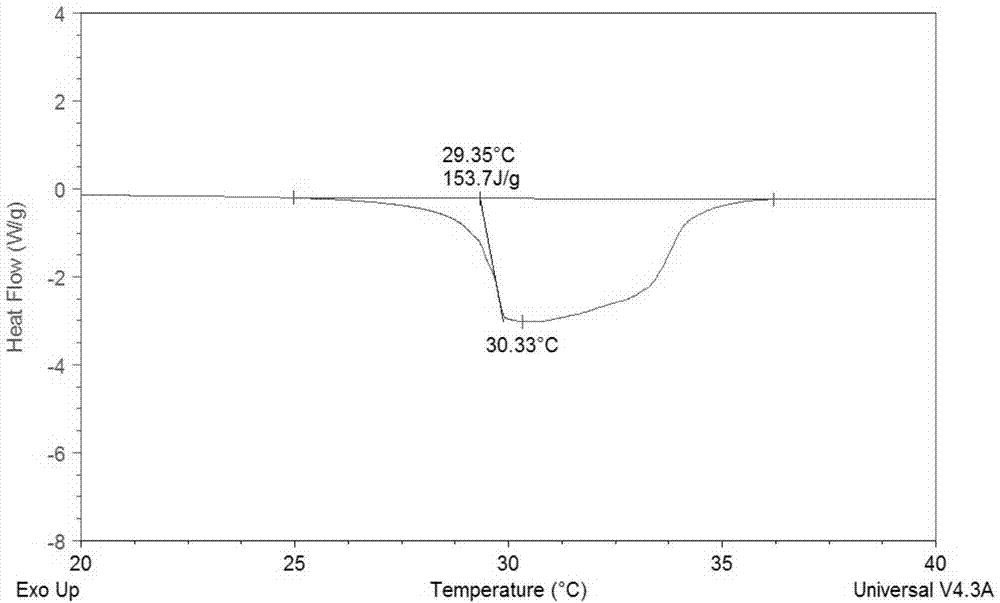

Low-temperature calcium chloride hexahydrate heat-storage material and preparation method

InactiveCN103923613AHigh phase change enthalpyPhase transition temperature is suitableHeat-exchange elementsCelluloseCalcium Chloride Hexahydrate

The invention discloses a low-temperature calcium chloride hexahydrate heat-storage material and a preparation method. The prepared low-temperature calcium chloride hexahydrate phase-change heat-storage material comprises a nucleating agent and a thickener according to mass percent, wherein the nucleating agent is borax, alumina or sodium metasilicate nonahydrate, the thickener is sodium carboxymethl cellulose (CMC), wherein calcium chloride hexahydrate is a phase-change base material, and the usage amount of the calcium chloride hexahydrate is 95%-98%; the preparation method comprises the step of: respectively adding 1wt% of borax and 1% of CMC or 1% alumina and 4% of CMC or 1% of sodium metasilicate nonahydrate and 2% CMC for modifying the calcium chloride hexahydrate, to obtain the low-temperature calcium chloride hexahydrate heat-storage material. The phase-change latent heat of the low-temperature calcium chloride hexahydrate heat-storage material is about 150J / g, the phase-change temperature of the low-temperature calcium chloride hexahydrate heat-storage material is at 25-30DEG C, the cooling degree is less than 2DEG C, and the heat suction and release performances of the low-temperature calcium chloride hexahydrate heat-storage material after being circulated for 3000 times are stable. The low-temperature calcium chloride hexahydrate heat-storage material has excellent application prospects in agricultural facilities and residential housing.

Owner:NORTHWEST A & F UNIV

Phase change energy storage material for heat preservation at night and preparation method

InactiveCN103205242ALower eutectic pointLower melting temperatureHeat-exchange elementsCalcium Chloride HexahydrateMagnesium chloride hexahydrate

The invention relates to a phase change energy storage material for heat preservation at night. The medium consists of a CaC12-MgCl2-H2O water salt system and a nucleating agent; the CaC12-MgCl2-H2O water salt system consists of 80-95 % of calcium chloride hexahydrate, 1-7 % of magnesium chloride hexahydrate and 3-15 % of deionized water by mass; and the content of the nucleating agent is 0.5-2.0 % of the total amount of the CaC12-MgCl2-H2O water salt system. The phase change energy storage material has the advantages of high phase change latent heat, relatively low melting temperature and adjustable solidification temperature, can be used for avoiding the phase separation phenomenon, and can be applied to different seasons and different regions.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

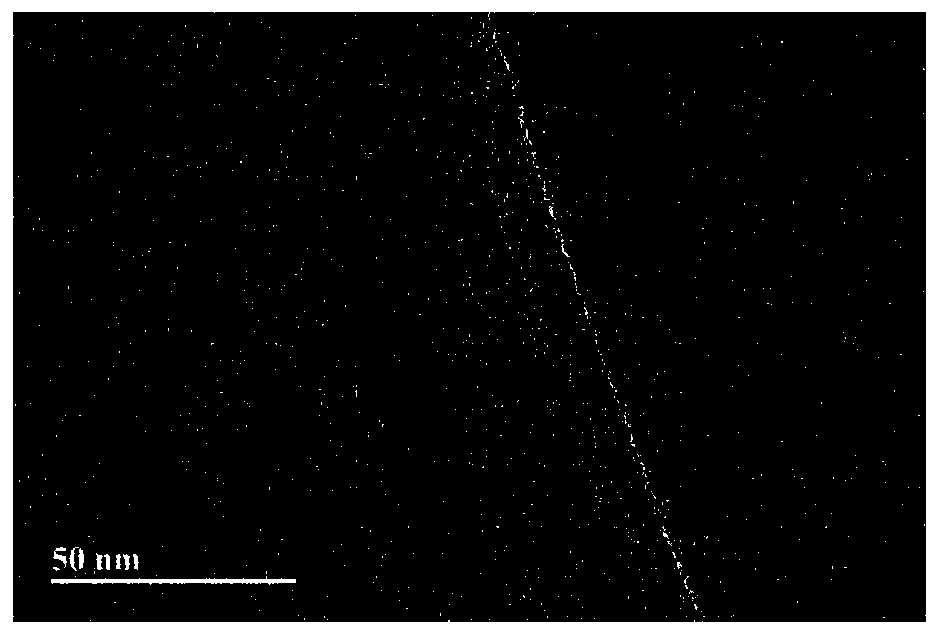

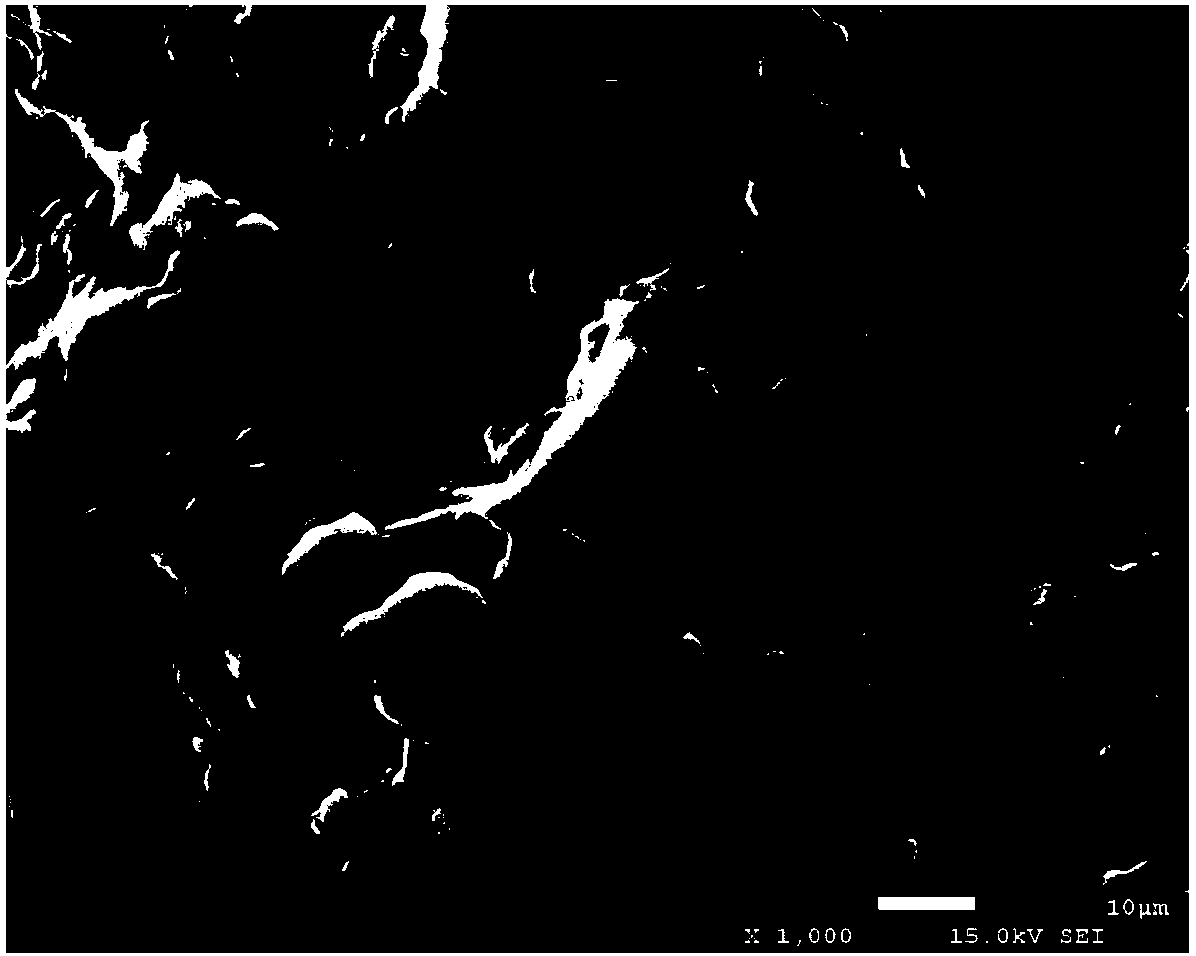

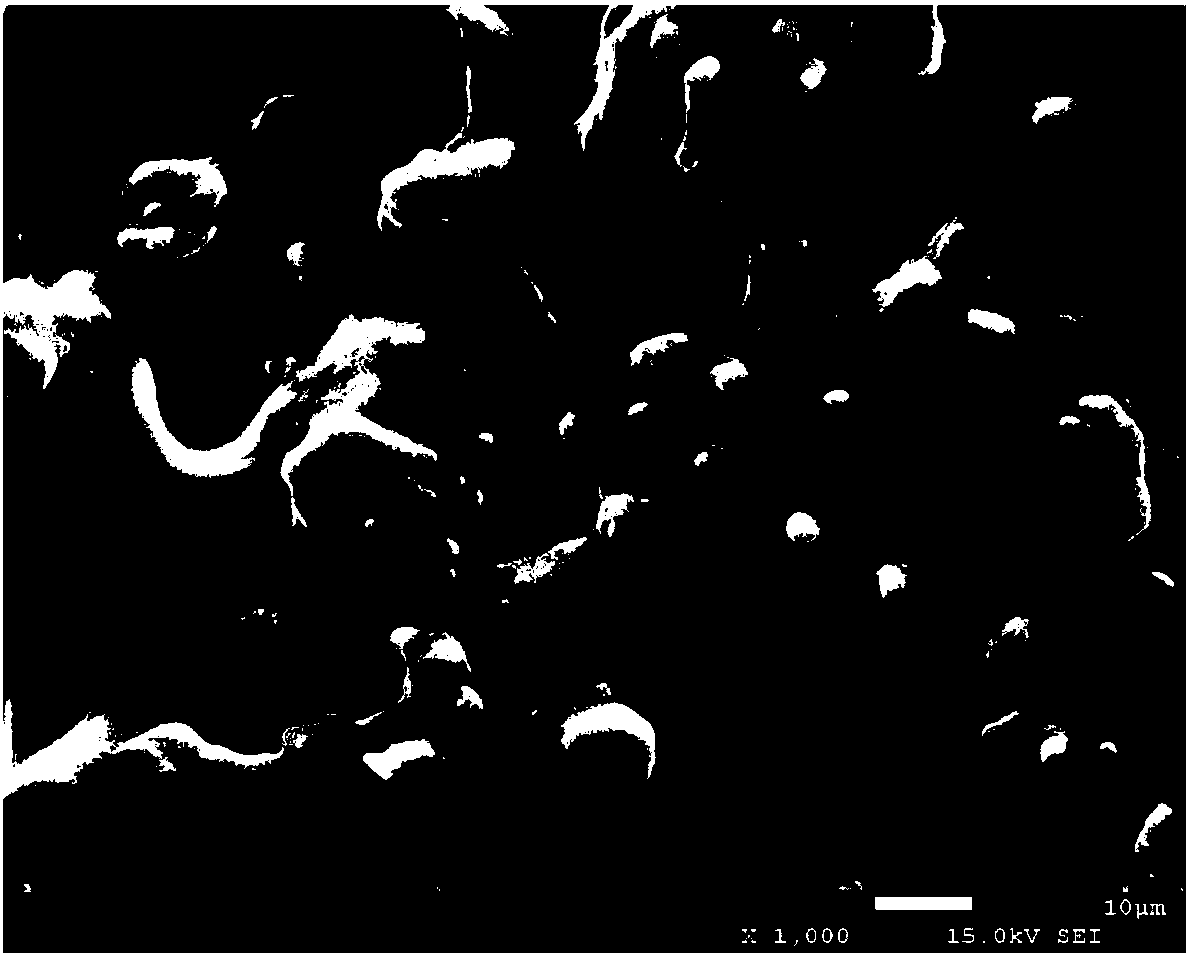

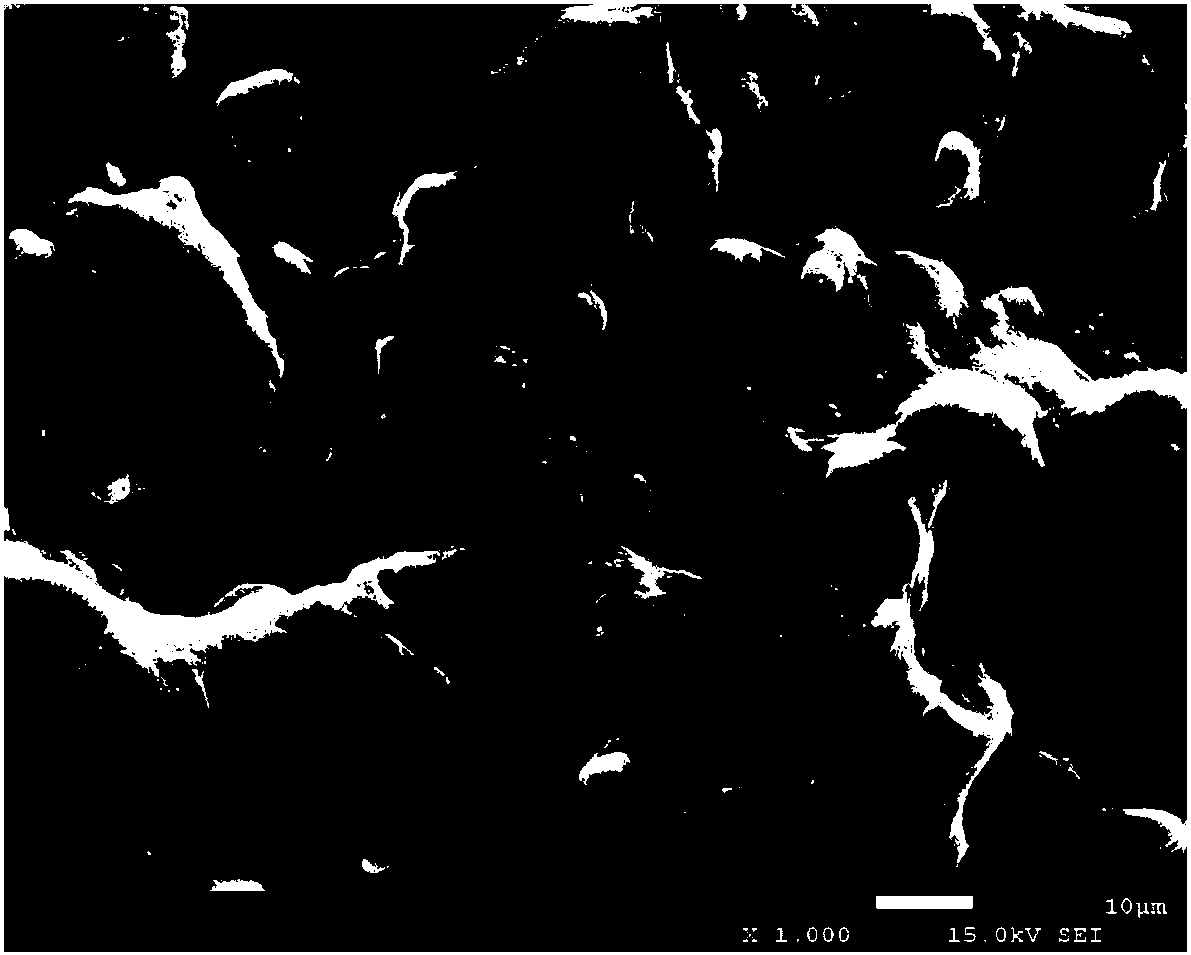

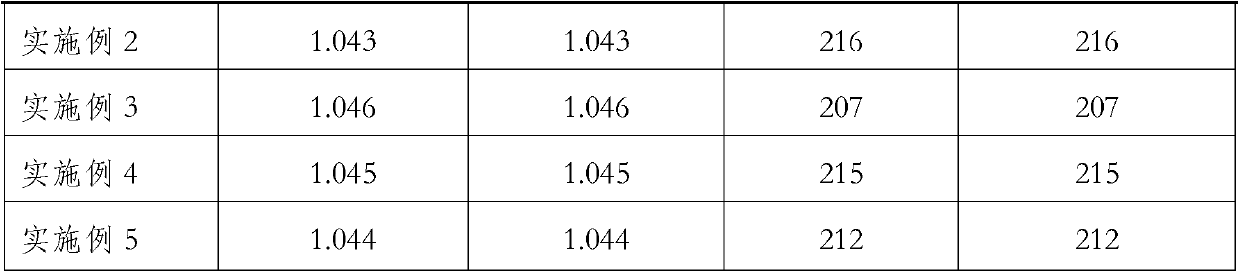

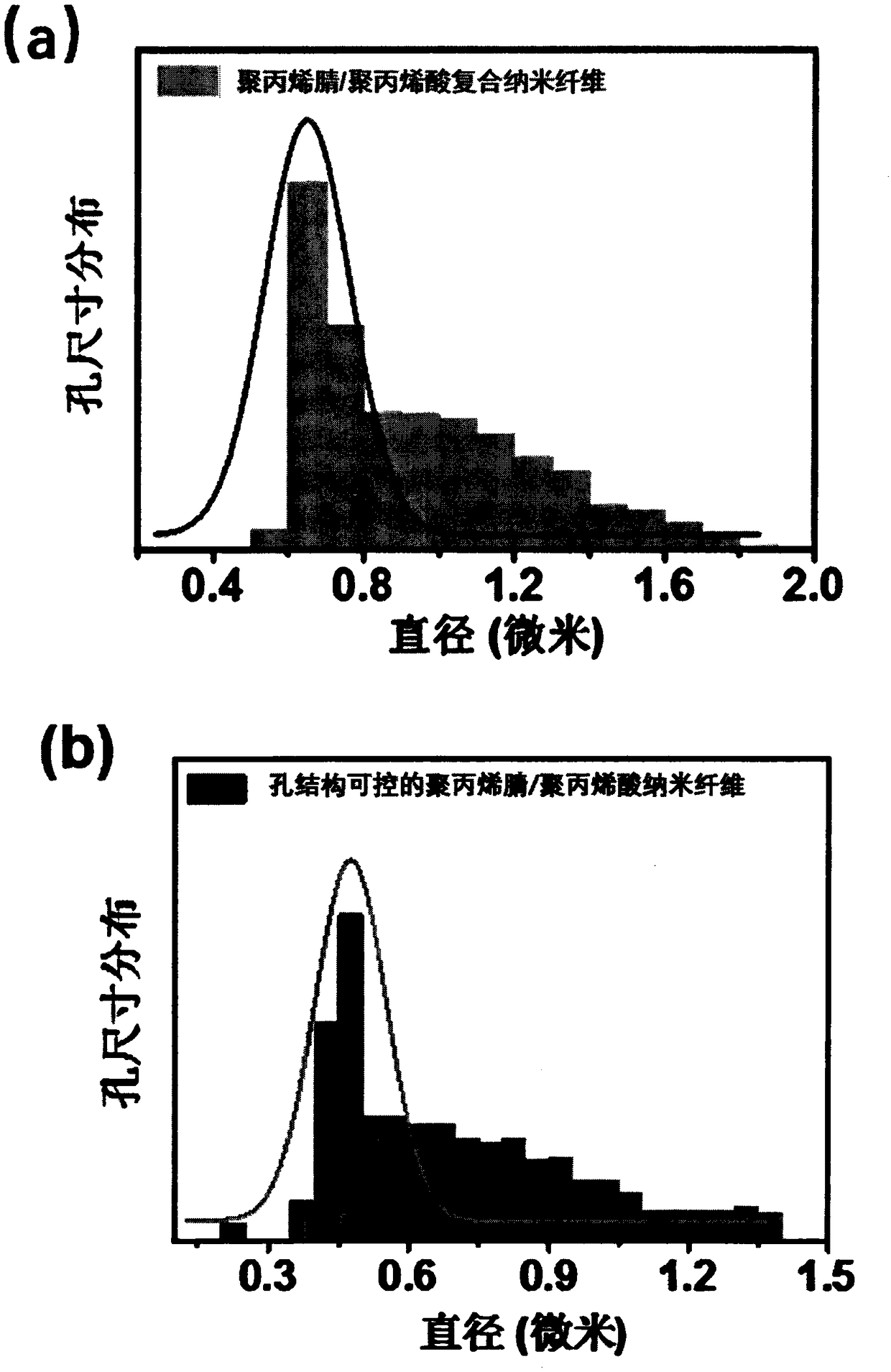

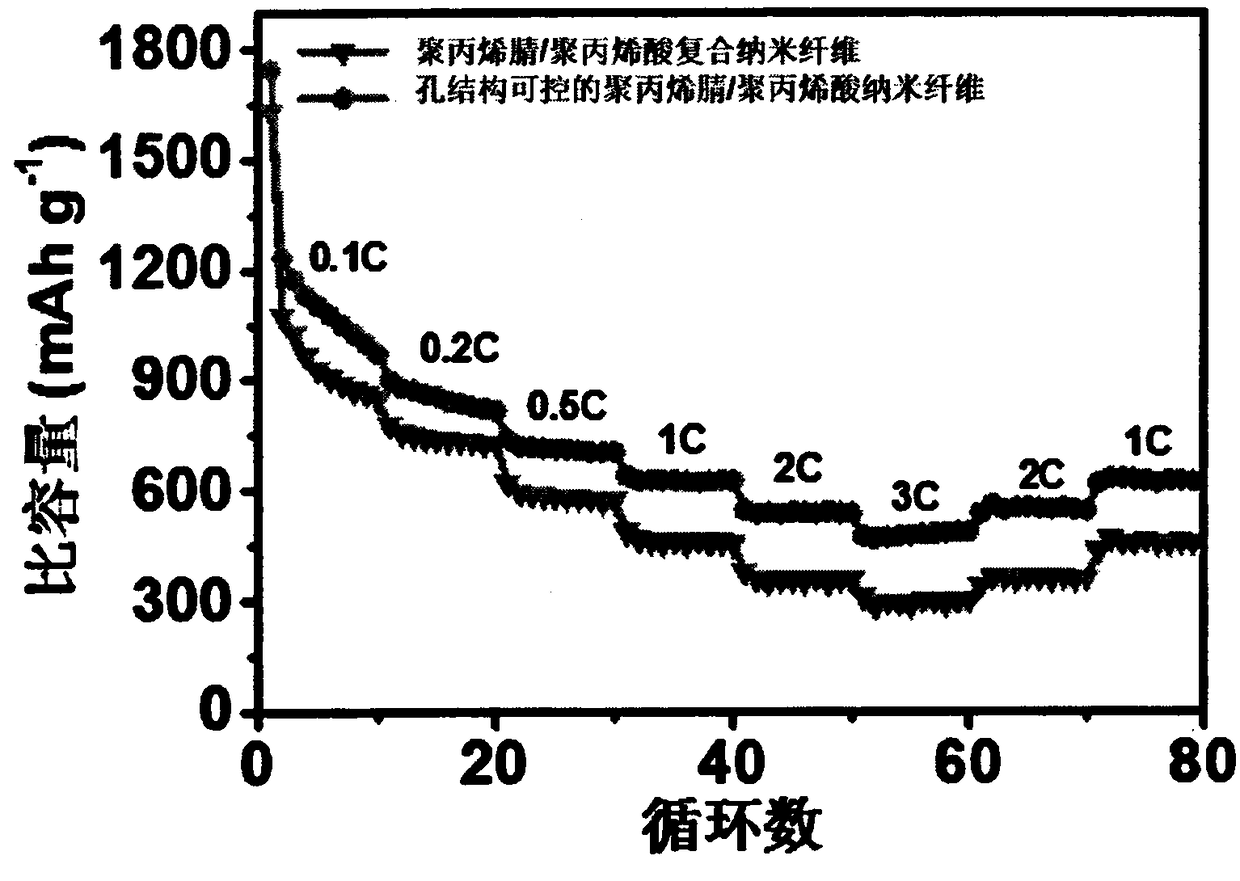

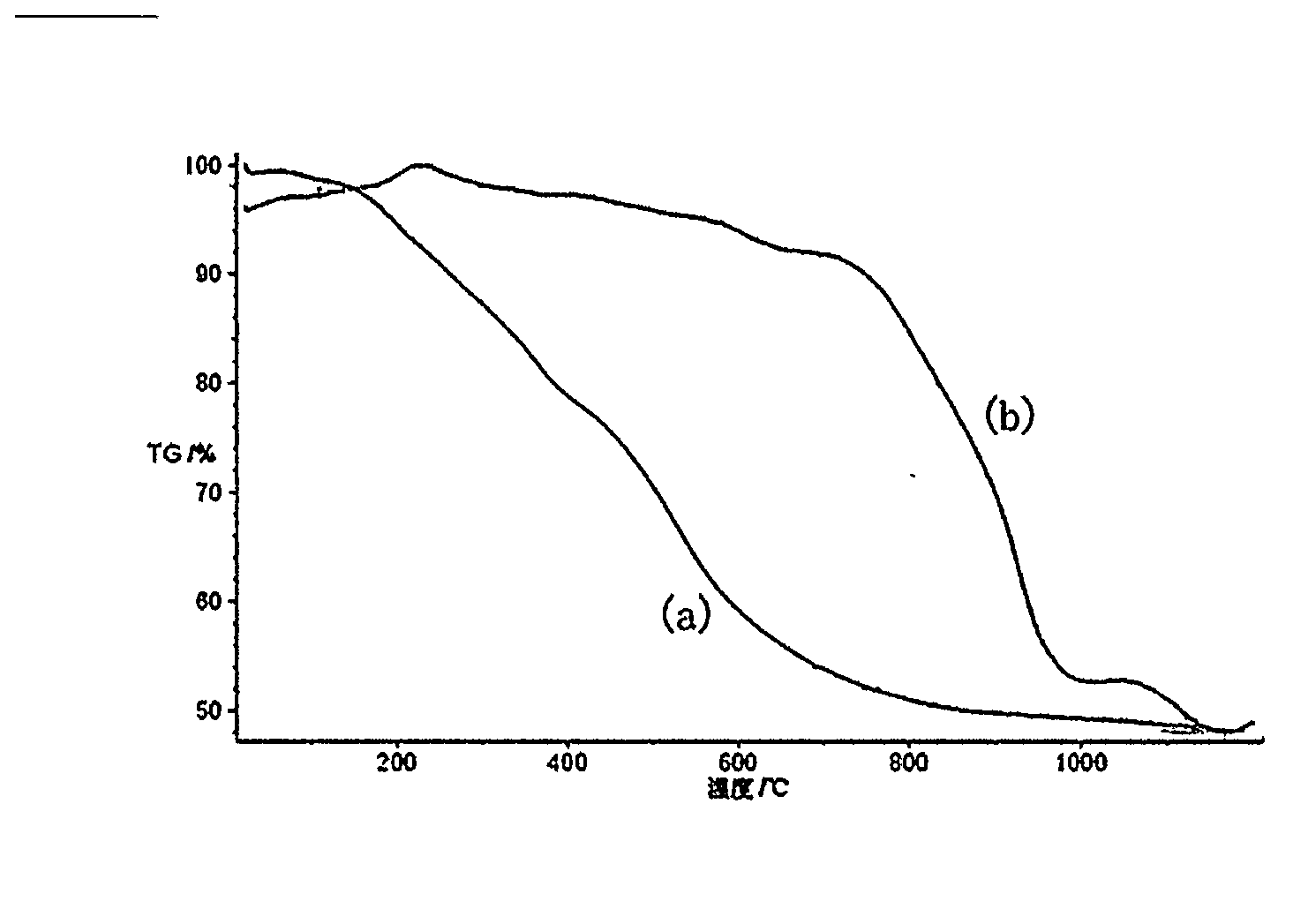

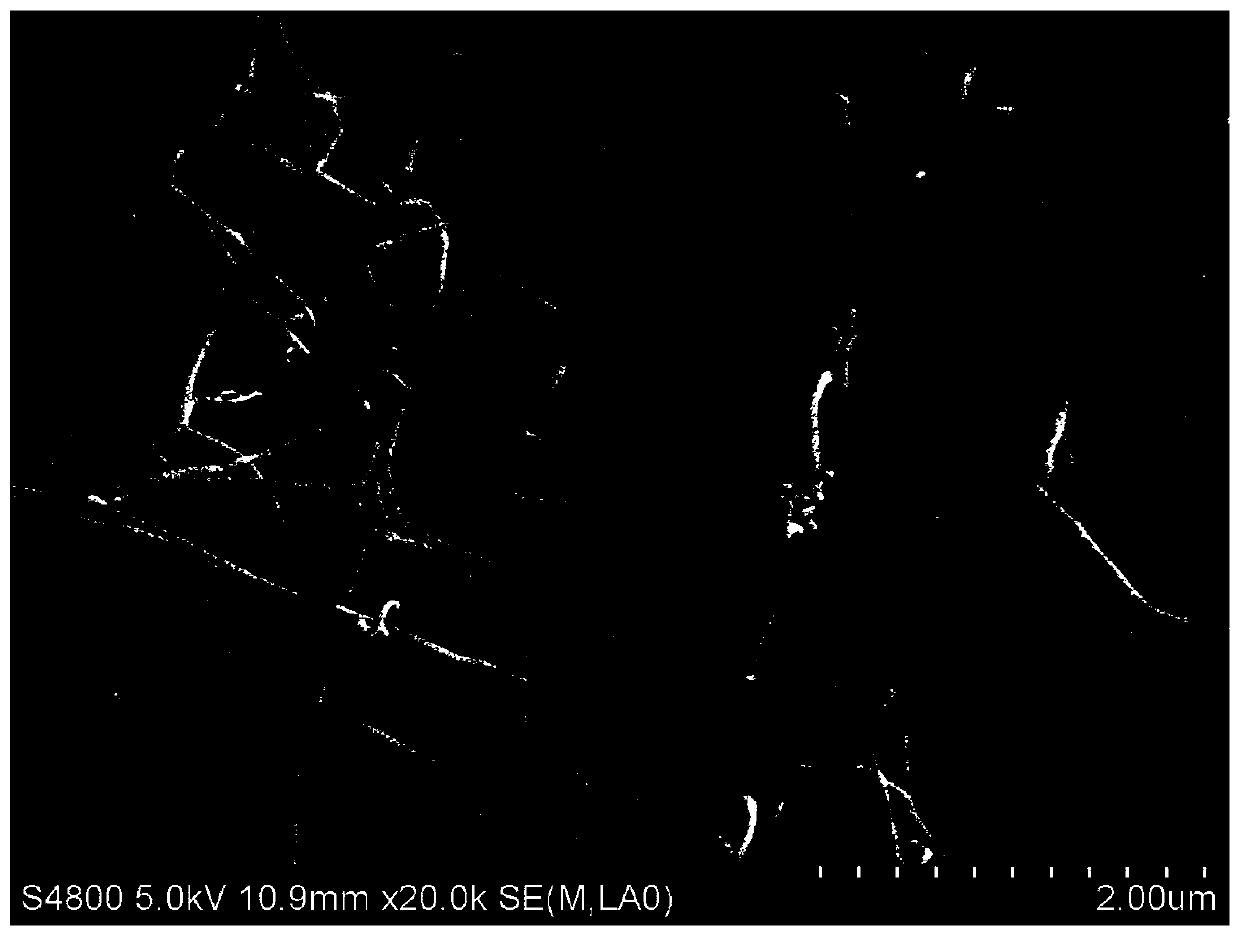

Polyacrylonitrile/polyacrylic acid nanofiber lithium sulfur battery diaphragm with controllable pore structure

InactiveCN108589034AUniform shapeControllable pore structureFibre typesElectro-spinningChemistryNanofiber

The invention provides a polyacrylonitrile / polyacrylic acid nanofiber lithium sulfur battery diaphragm with a controllable pore structure. A preparation method of the polyacrylonitrile / polyacrylic acid nanofiber lithium sulfur battery diaphragm with the controllable pore structure is characterized by comprising the following steps: preparing polyacrylonitrile / polyacrylic acid composite nanofibersby electrospinning; performing ethanol vapor treatment to obtain the polyacrylonitrile / polyacrylic acid composite nanofibers with the controllable pore structure. The prepared composite material has the characteristics of complete fiber morphology, uniform pore size distribution and the like. Polyacrylonitrile can act as a composite nanofiber framework while polyacrylic acid is used as a structurecontrol material of the composite nanofibers. The composite nanofiber diaphragm has the advantages of environmental friendliness, high efficiency, precise regulation of pore size and porosity, stablephysical and chemical properties and the like.

Owner:DONGHUA UNIV

Environment-friendly cardanol, urea synergistically modified phenolic resin and application thereof to high temperature resistant friction material

The invention belongs to the technical field of high polymer material, and more specifically relates to a method for preparation of an environment-friendly high temperature resistant friction material from cardanol and urea double-modified phenolic resin. The specific steps are as follows: first, mixing solid paraformaldehyde, cardanol and phenol in the presence of an alkaline catalyst, regulating the pH value to 8.0-9.0, heating to 60-80 DEG C and insulating and reacting for 60-80 min; and then adding modified urea when the temperature drops to 45-50 DEG C, then regulating the pH value to 2-4 in the presence of an acid catalyst, heating to 75 DEG C, insulating for 90 min, and adjusting the pH value to 7 by an alkaline solution; and finally, conducting vacuum dewatering, adding ethanol diluted resin, mixing evenly and discharging. The invention also relates to preparation of a high temperature resistant friction material. A preparation method is characterized by comprising the steps of: mixing 10wt%-20wt% of an adhesive of modified phenolic resin, 5wt%-15wt% of a modifier of rubber, 0.5wt%-5wt% of a curing agent hexamethylenetetramine, 25wt%-35wt% of a fiber reinforced material and 35wt%-45wt% of a filler, and pressing to obtain a finished product; and conducting heat treatment on the finished product to obtain the heat resistant friction material.

Owner:谢再锋

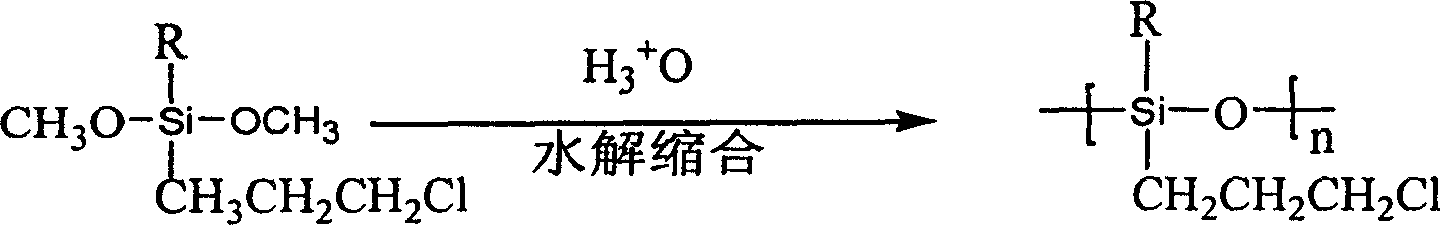

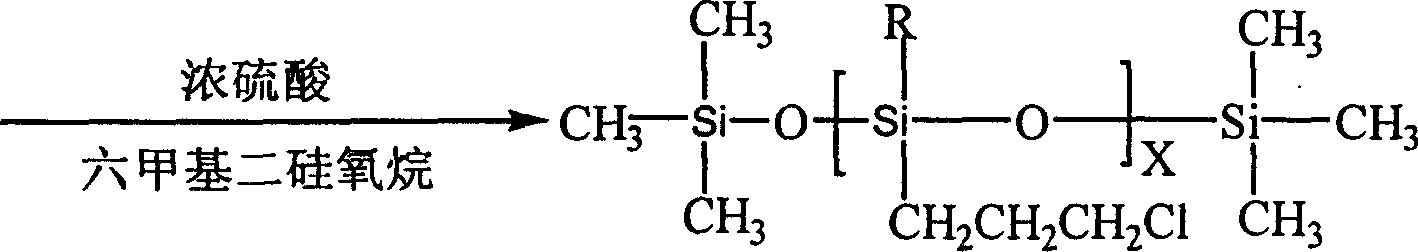

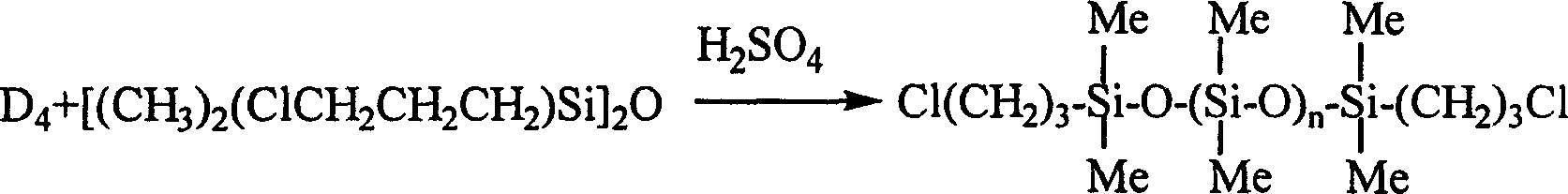

Production of Redix with siloxane structural unit

Production of epoxy resin with silicone structural unit is carried out by reacting chlorsilane or chlorsilicone with silicone or its ring from acid catalyst, obtaining silicone small molecule or oligomer containing at least two chlor-groups in molecular chain, reacting dimethyl-silicone small molecule containing dichlorpropyl with bisphenol A salt in non-protonic polar solution, adding epoxy chloropropane into reaction mixture, reacting at 60í½140íÒC, filtering reaction mixture, de-pressuring and distilling to remove excess epoxy chloropropane and solvent, and obtaining epoxy resin with silicone structural unit. It achieves clear molecular structure, easy synthesis and better flexibility.

Owner:NANJING UNIV

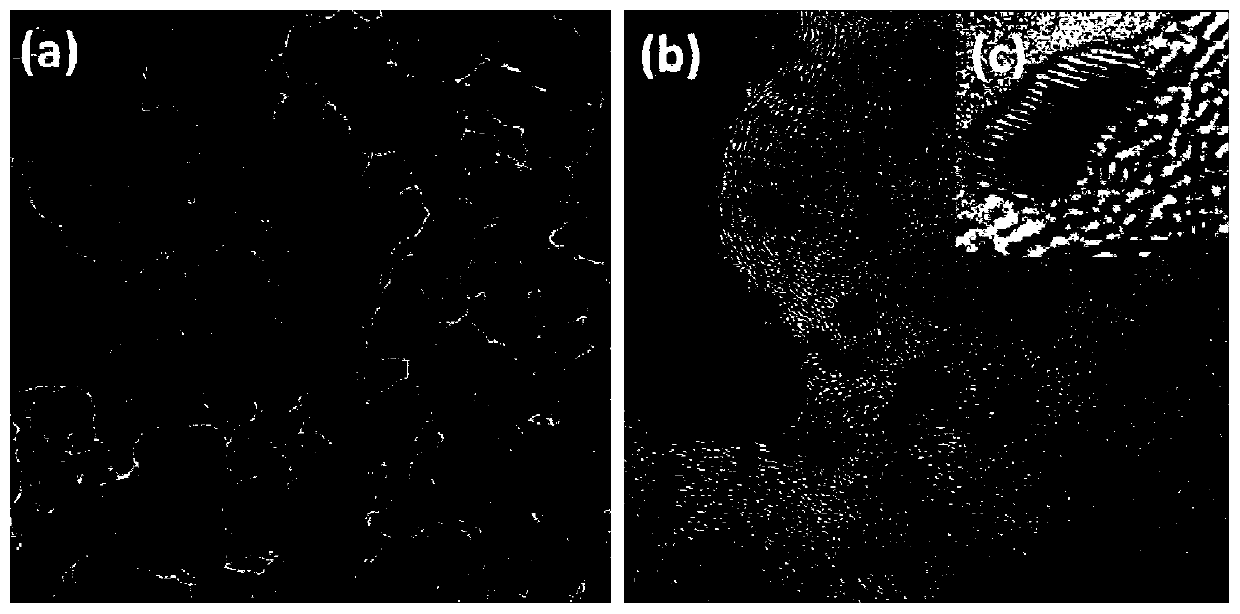

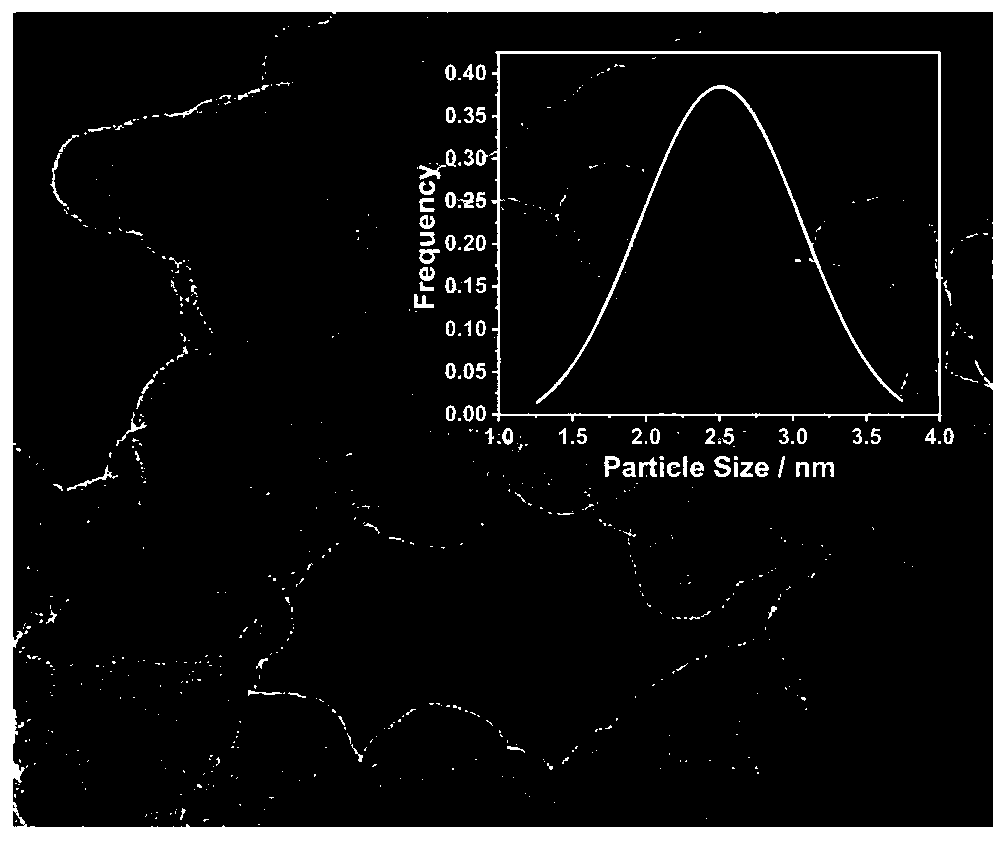

Preparation method of metal and alloy nanocrystalline

ActiveCN110578069AGood repeatabilityThe synthesis process is simpleMaterial nanotechnologyTransportation and packagingAlloySolvent

The invention relates to a preparation method of metal and alloy nanocrystalline, and belongs to the field of inorganic nano materials. A metal precursor is taken as a raw material, and under the condition that no surfactant is added, alloy nanocrystalline with ultra-small (less than 3 nm) and uniform size is rapidly (less than 2 min) prepared at room temperature by means of shearing assistance, the metal and alloy nanocrystalline with different compositions and a controllable size can be obtained by controlling the volume of a reducing agent, a reactant molar ratio, a concentration, reactiontime and other parameters, and the prepared carbon-supported nanocrystalline is used as a hydrogen evolution electrocatalyst and has excellent performance. The method has the characteristics of high reaction speed, simple operation, recyclable solvent, low cost, easy industrial amplification production and the like.

Owner:QINGDAO UNIV

Phase change cold storage material for freshness retaining of partial-frozen chilled food and preparation method

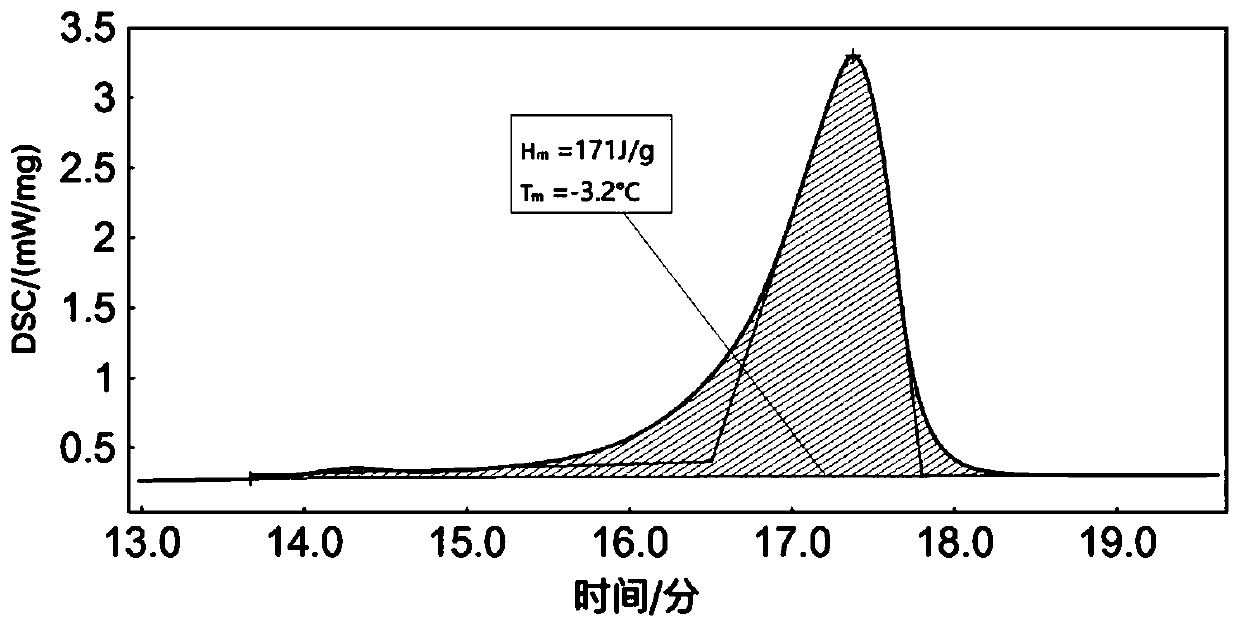

InactiveCN110003863ALow thermal conductivityNo phase separationHeat-exchange elementsCarbon nanotubeDodecyl Alcohol

The invention provides a phase change cold storage material for freshness retaining of partial-frozen chilled food and a preparation method. The phase change cold storage material for partial-frozen fruits and vegetables uses a mixed solution of decyl alcohol and dodecyl alcohol as main base liquid and uses hydroxylated multi-wall carbon nanotubes and sodium dodecylbenzenesulfonate as additives toimprove the thermal conductivity of the phase change cold storage material. The phase change temperature of the phase change cold storage material is -3.2 DEG C; and the latent heat of phase change is 171 J / g and the thermal conductivity is 0.3462 W / (m.K). After low and high temperatures are circulated for 100 times, the composite phase change cold storage material still has excellent thermal stability. The obtained phase change cold storage material can be applied to freshness retaining of foods such as meat and vegetables. The invention further provides a preparation method of a composite phase change cold storage material.

Owner:SHANGHAI MARITIME UNIVERSITY

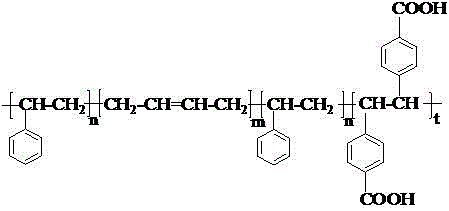

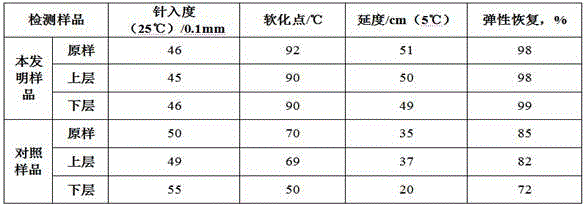

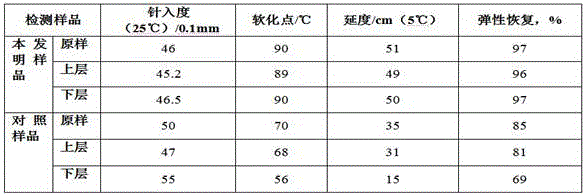

Road asphalt modifying agent containing modified styrene-butadiene-styrene block copolymer, and preparation method of road asphalt modifying agent

ActiveCN106167624AHigh softening pointImprove low temperature ductilityBuilding insulationsButadiene-styrene rubberAntioxidant

The invention relates to a road asphalt modifying agent containing a modified styrene-butadiene-styrene block copolymer, and a preparation method of the road asphalt modifying agent, and belongs to the technical field of a road asphalt modifying agent. According to the road asphalt modifying agent containing the modified styrene-butadiene-styrene block copolymer, and the preparation method of the road asphalt modifying agent disclosed by the invention, a modified styrene-butadiene-styrene block copolymer is synthesized to be used as a main modifying agent of road asphalt, and lignin fibers, an antioxidant, a stabilizing agent, a cross-linking agent and other modified addition agents are combined with the modified styrene-butadiene-styrene block copolymer for performing chemical modification on base asphalt, so that the needle penetration, the softening point and the ductility of the base asphalt can be effectively improved. The addition quantity of the road asphalt modifying agent disclosed by the invention is low, when the addition quantity is 3-7wt%, improvement requirements can be met, and the road asphalt modifying agent is economic and environmental-friendly. The preparation method is simple and easy to operate, the operation is convenient, the yield is as high as 99.1% or above, and the road asphalt modifying agent is suitable for large-scale production and application.

Owner:浙江程路沥青技术有限公司

Soft moisture-absorbing curly fiber easy to dye and preparation method thereof

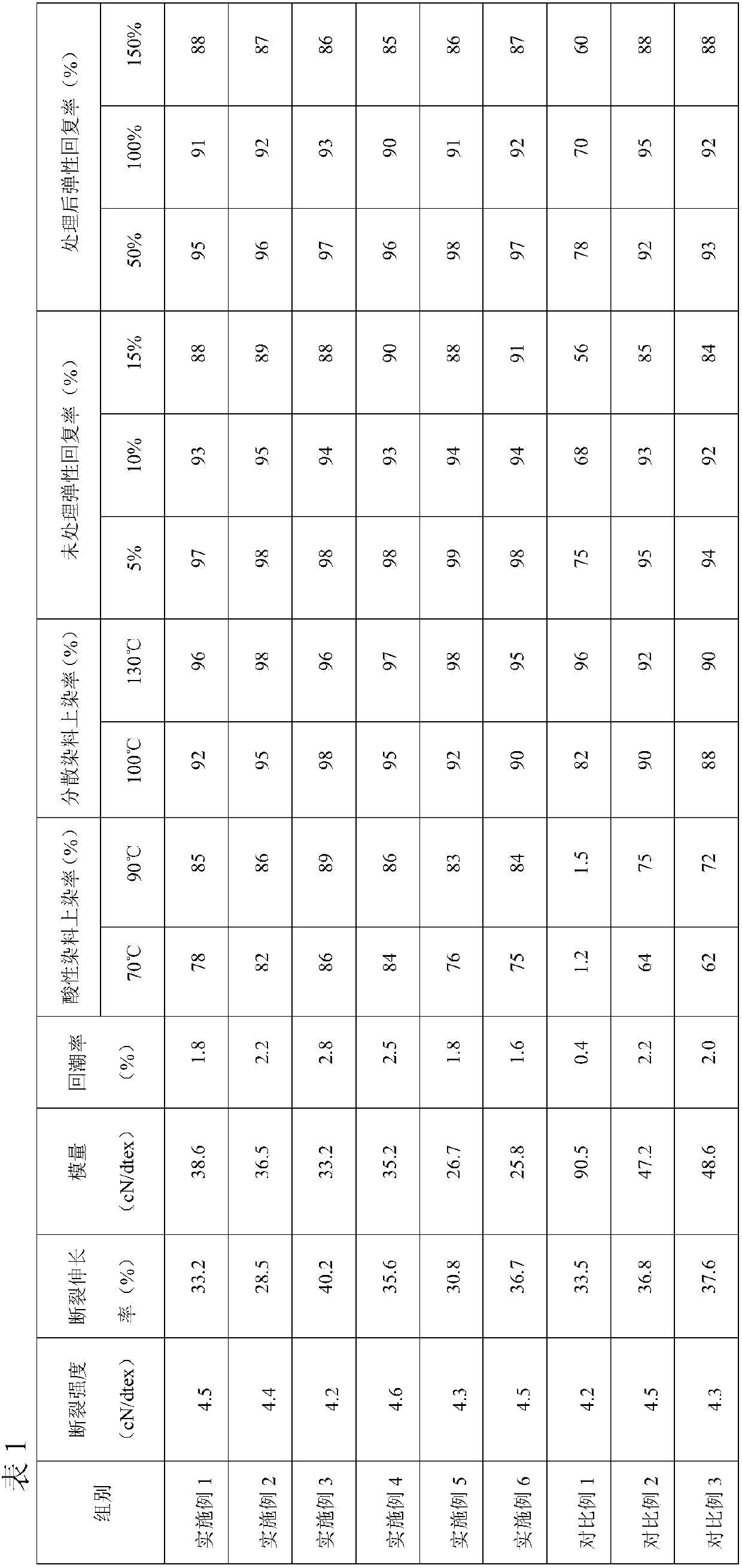

ActiveCN109943913AEasy to absorb moistureEasy to dyeFilament forming substance formingArtificial filament heat treatmentDisperse dyePolyamide

The invention provides a soft moisture-absorbing curly fiber easy to dye and a preparation method thereof. The soft moisture-absorbing curly fiber easy to dye comprises, by mass, 10-50% of polyamide 5X and 50-90% of polyester. By means of the preparation method, the fiber which is easy to dye by acid dyes and disperse dyes at the low temperature can be obtained at a low cost in a simple process.

Owner:CATHAY R&D CENT CO LTD +2

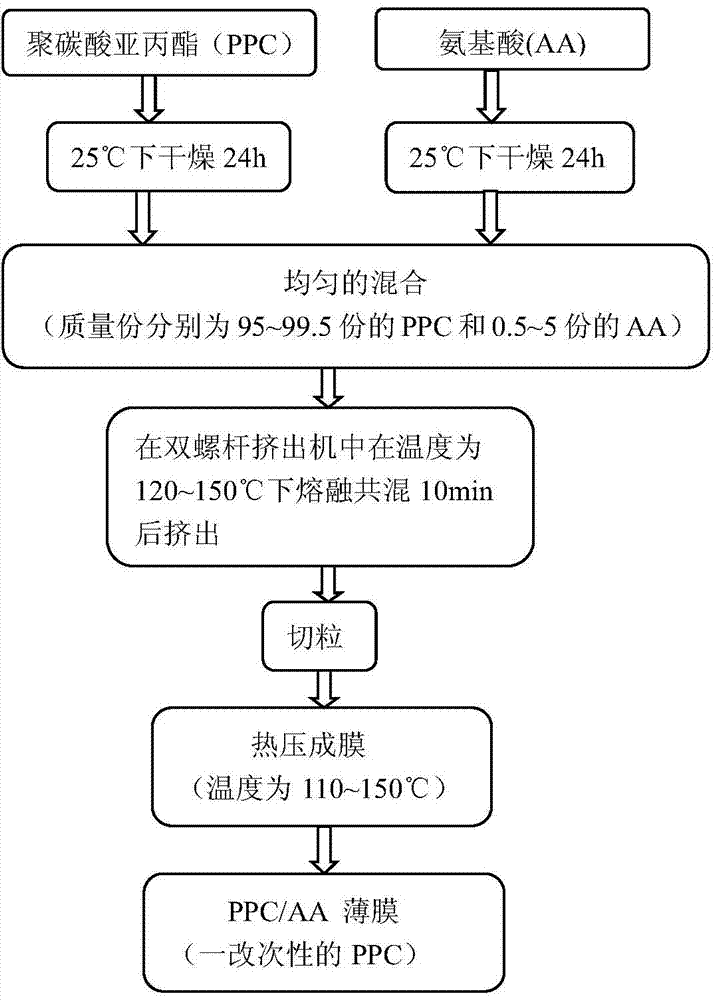

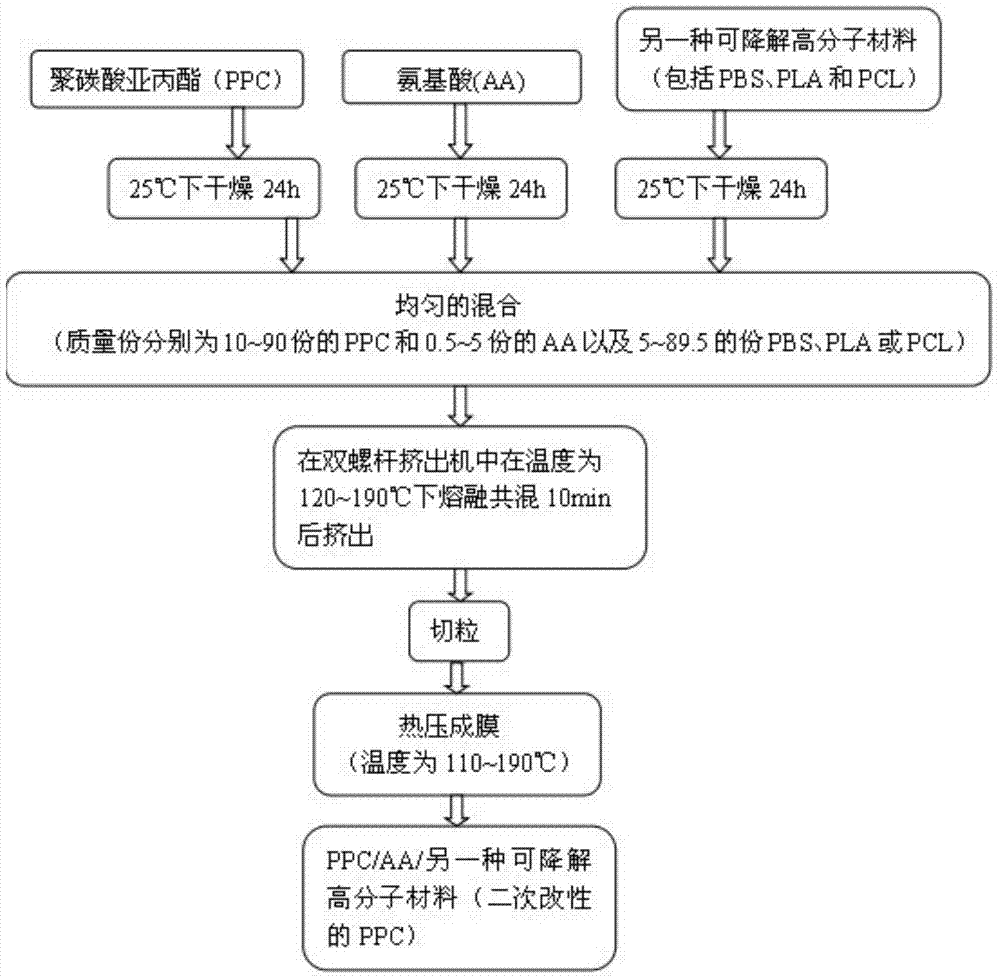

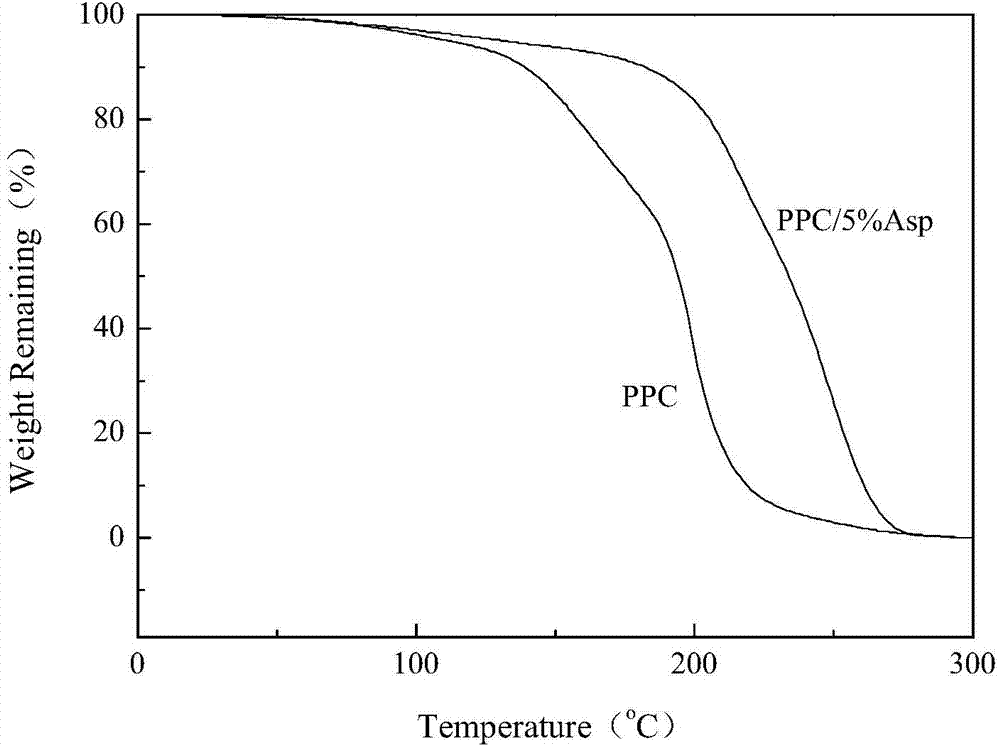

Method for preparing modified polycarbonate sub-lactone material

The invention provides a method for preparing a modified polycarbonate sub-lactone material. The polycarbonate sub-lactone is modified twice, wherein the primary modification components comprise 95-99.5 parts of polycarbonate sub-lactone and 0.5-5 parts of amino acids; and the secondary modification components comprise 10-90 parts of polycarbonate sub-lactone, 0.5-5 parts of amino acids and 5-89.5 parts of polylactic acid or poly(butylene succinate) or poly-caprolactone. The method comprises the following steps: adding the mixture into a twin-screw extruder, performing melt blending, extruding and granulating, and preparing the composite material. The thermal stability and mechanical strength of the composite material subjected to modification twice far exceed those of pure polycarbonate sub-lactone, so that the processability of the modified polycarbonate sub-lactone is improved. The method is simple in process, high in production efficiency, low in cost and pollution-free and is suitable for industrial production.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

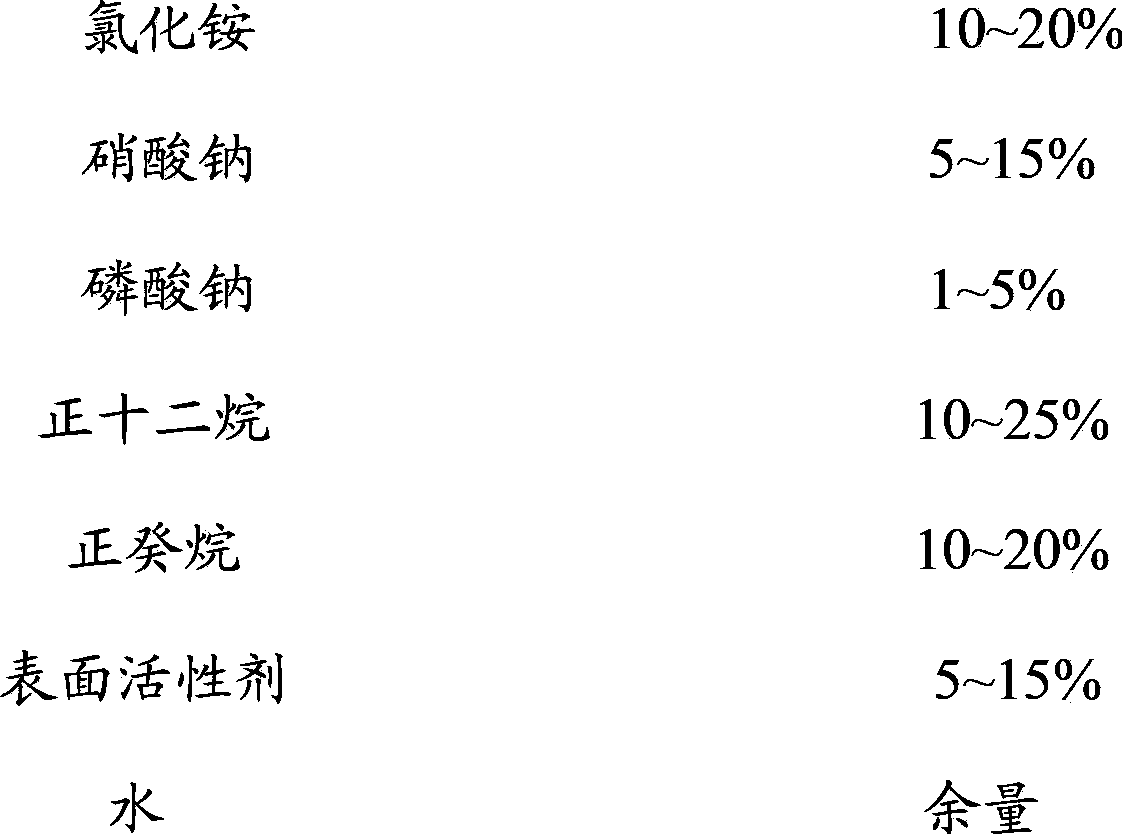

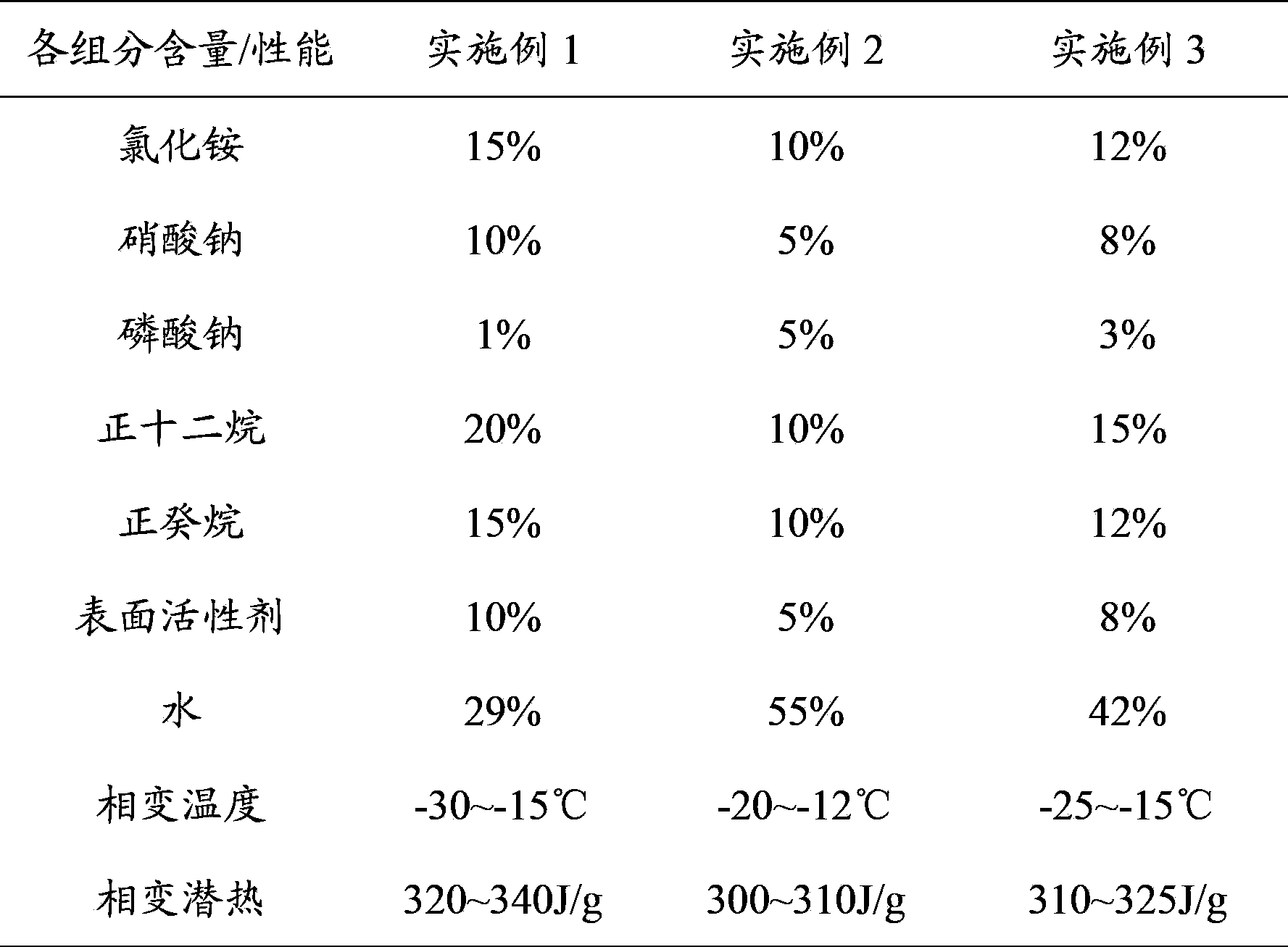

Long-acting low-temperature phase-change cool-storage material, and preparation method thereof

InactiveCN103897665AWide solidification temperature rangeLarge latent heat of phase changeHeat-exchange elementsCool storageDecane

The invention discloses a long-acting low-temperature phase-change cool-storage material, and a preparation method thereof. The long-acting low-temperature phase-change cool-storage material is composed of, by weight, 10 to 15% of ammonium chloride, 5 to 10% of sodium nitrate, 1 to 5% of sodium phosphate, 10 to 20% of n-dodecane, 10 to 15% of n-decane, 5 to 10% of a surfactant, and the balance water. The preparation method comprises following steps: (a) ammonium chloride, sodium nitrate, and sodium phosphate are dissolved in water, and an obtain mixture liquid is stirred so as to realize complete dissolving; (b) n-dodecane, n-decane, and the surfactant are mixed, and an obtained mixed solution is stirred to be uniform; (c) the mixture liquid is mixed with the mixed solution, and an obtained product is stirred to be uniform. Solidification temperature of the long-acting low-temperature phase-change cool-storage material ranges from -30 to -12 DEG C, phase change latent heat ranges from 300 to 340J / g, and long-term refrigeration can be realized.

Owner:SHANGHAI CHANCE ENERGY EFFICIENCY TECH

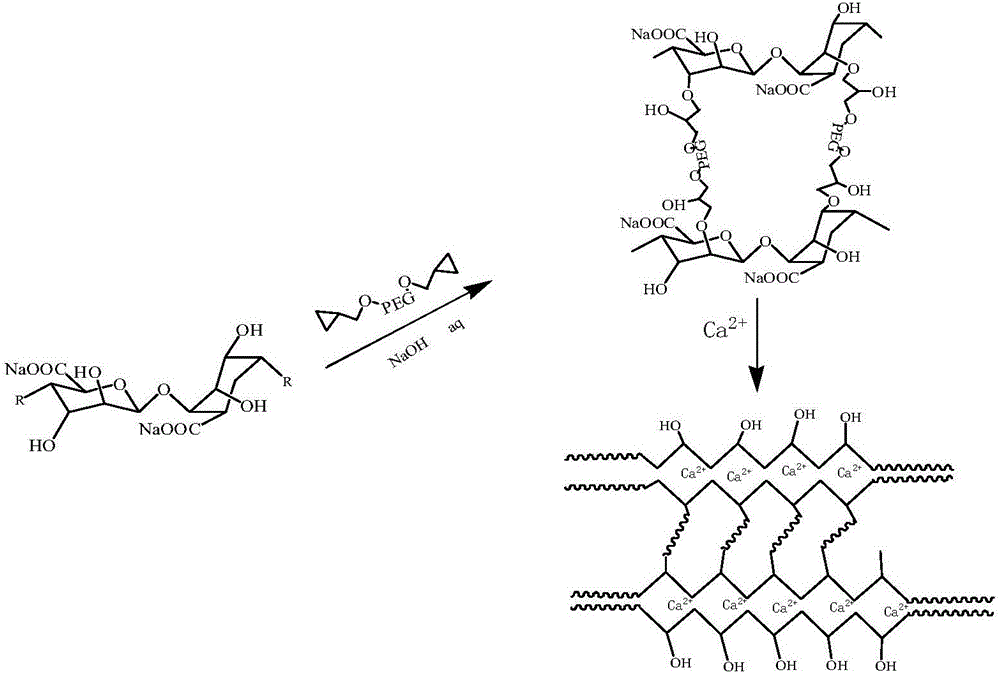

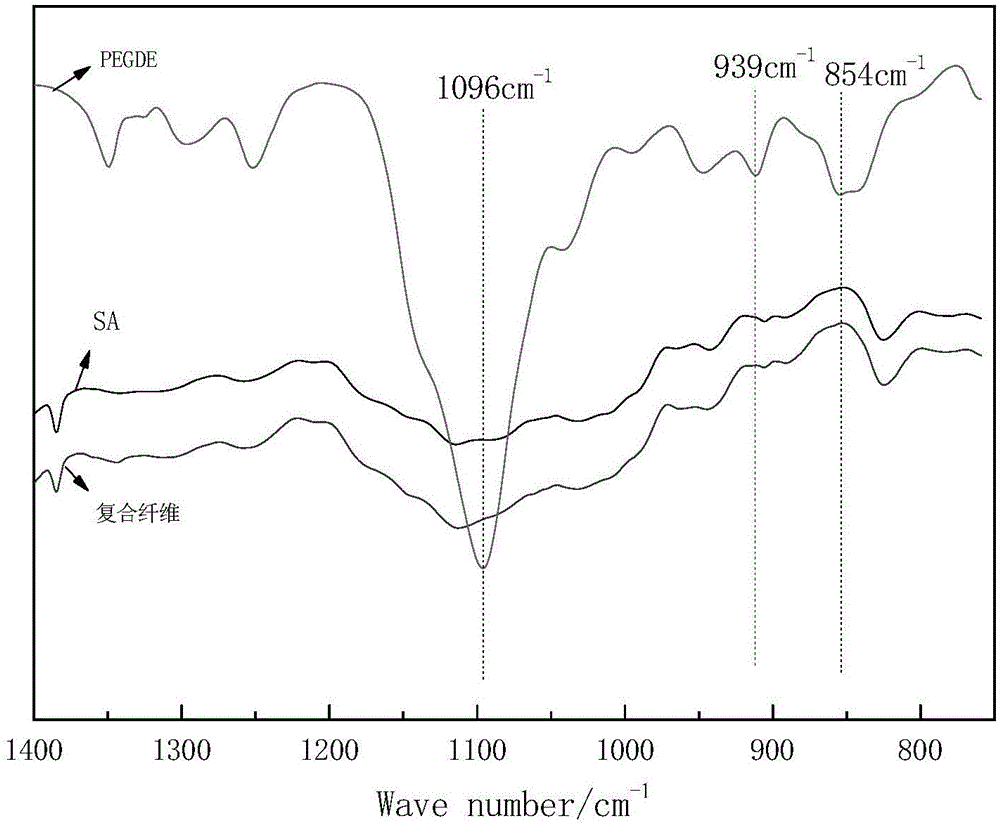

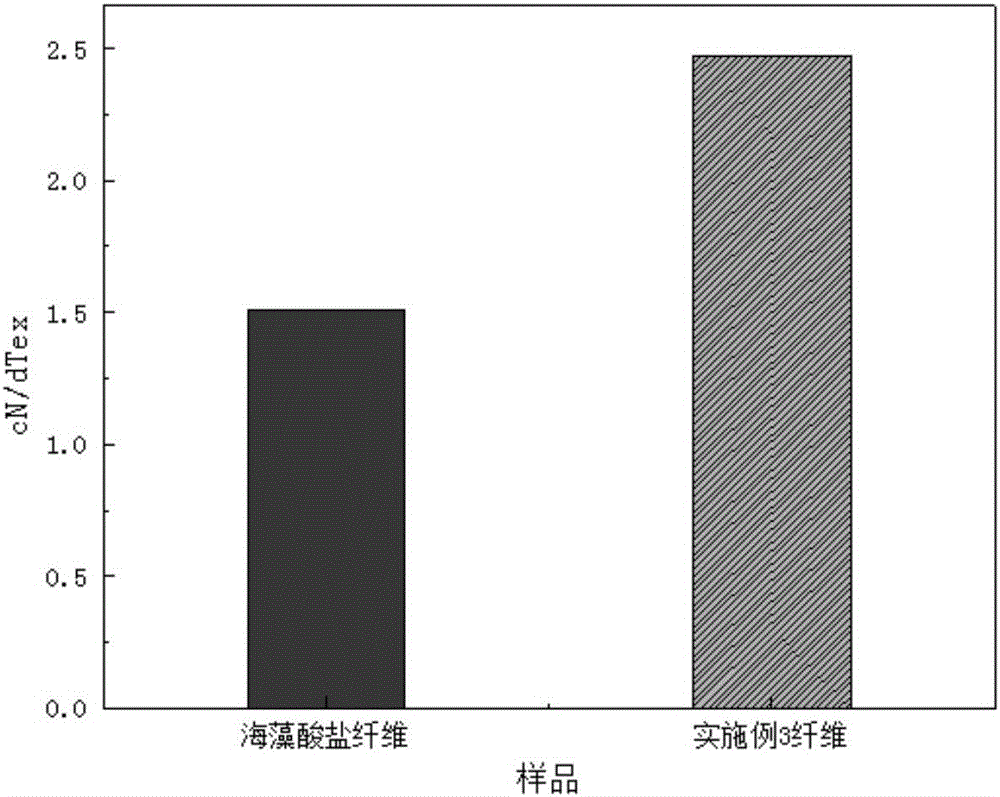

Chemically cross-linked modified alginate fiber and preparation method thereof

ActiveCN106435833ANo phase separationHigh strengthAlginate artificial filamentsPolymer scienceSpinning

The invention discloses a chemically cross-linked modified alginate fiber and a preparation method thereof. The chemically cross-linked modified alginate fiber is formed by dissolving a pH adjusting agent, sodium alginate and a crosslinking agent in water, and conducting crosslinking and solidification, wherein the concentration of the pH adjusting agent is 0.05 to 0.15 mol / L, the concentration of the sodium alginate is 1% to 3%, and the mass ratio of the sodium alginate to the crosslinking agent is 100: 10 to 100: 50. The chemically cross-linked modified alginate fiber has high fiber breaking strength; in the preparation process of the chemically cross-linked modified alginate fiber, the cross-linking degree of alginate is controlled by controlling the amount of the crosslinking agent so as to adjust the balance between fiber strength and spinning fluid processing performance and meet the actual processing and application requirements.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Preparation method for transparent polyimide/silicon dioxide hybrid film

The invention relates to a preparation method for a transparent polyimide / silicon dioxide hybrid film, which belongs to the technical field of high polymer materials. The method includes the steps: dissolving 2, 2'-bis(trifluormethyl) benzidine and 4, 4'-bis(3-aminophenoxy) diphenyl sulfone, which serve as diamine monomer, into polar solvent; adding 4, 4'-(hexafluoroisopropylidene) diphthalic anhydride serving as dianhydride monomer; mixing to carry out polycondensation at the room temperature; then adding 3-aminopropyltriethoxysilane for continuous reaction to obtain siloxane-terminated polyamide acid solution; adding tetraethyl orthosilicate and hydrochloric acid into the solution for sol-gel reaction; and subjecting the mixed solution to film spreading and gradual curing to obtain thetransparent hybrid film. Silicon dioxide in the polyimide / silicon dioxide hybrid film is high in dispersity and avoids phase separation, and the transparent polyimide / silicon dioxide hybrid film is excellent in light transmission, mechanical property and heat resistance, and is suitable for use as protecting films for flexible display screens and optical devices and substrate materials for transparent conducting films.

Owner:TSINGHUA UNIV

Ultrasonic-mediated silk fibroin composite collagen hydrogel and preparation method thereof

InactiveCN110698866AWide variety of sourcesIncreased external resistance to enzymatic hydrolysisProsthesisPolymer scienceCollagenan

The invention discloses an ultrasonic-mediated silk fibroin composite collagen raw hydrogel and a preparation method thereof. A regenerated silk fibroin solution is treated in ultrasonic short time topromote conformation transformation and physical crosslinking, and then the regenerated silk fibroin solution is mixed with collagen solution according to a certain proportion and uniformly stirred,the solution pH value is regulated, and the incubation is performed under a certain temperature to generate composite hydrogel. The mass ratio of the silk fibroin to the collagen is 99: 1-1: 99. The ultrasonic-mediated fibroin composite collagen hydrogel prepared by the invention is safe, nontoxic, good in biocompatibility, short in gelation time, controllable in degradation time, excellent in mechanical property, simple in preparation process, energy-saving, environment-friendly, low in cost and easy to industrialize, popularize and apply, and is physically blended in the whole process.

Owner:SICHUAN UNIV

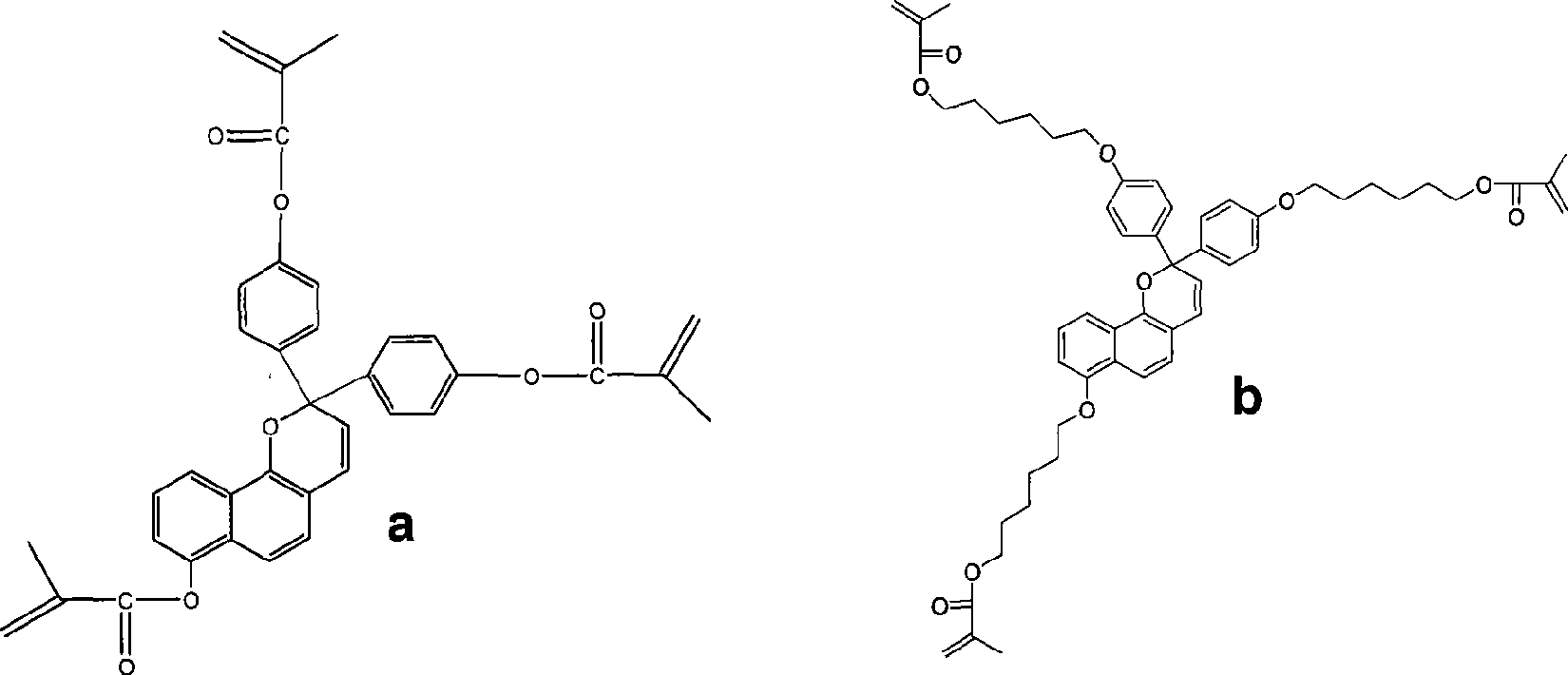

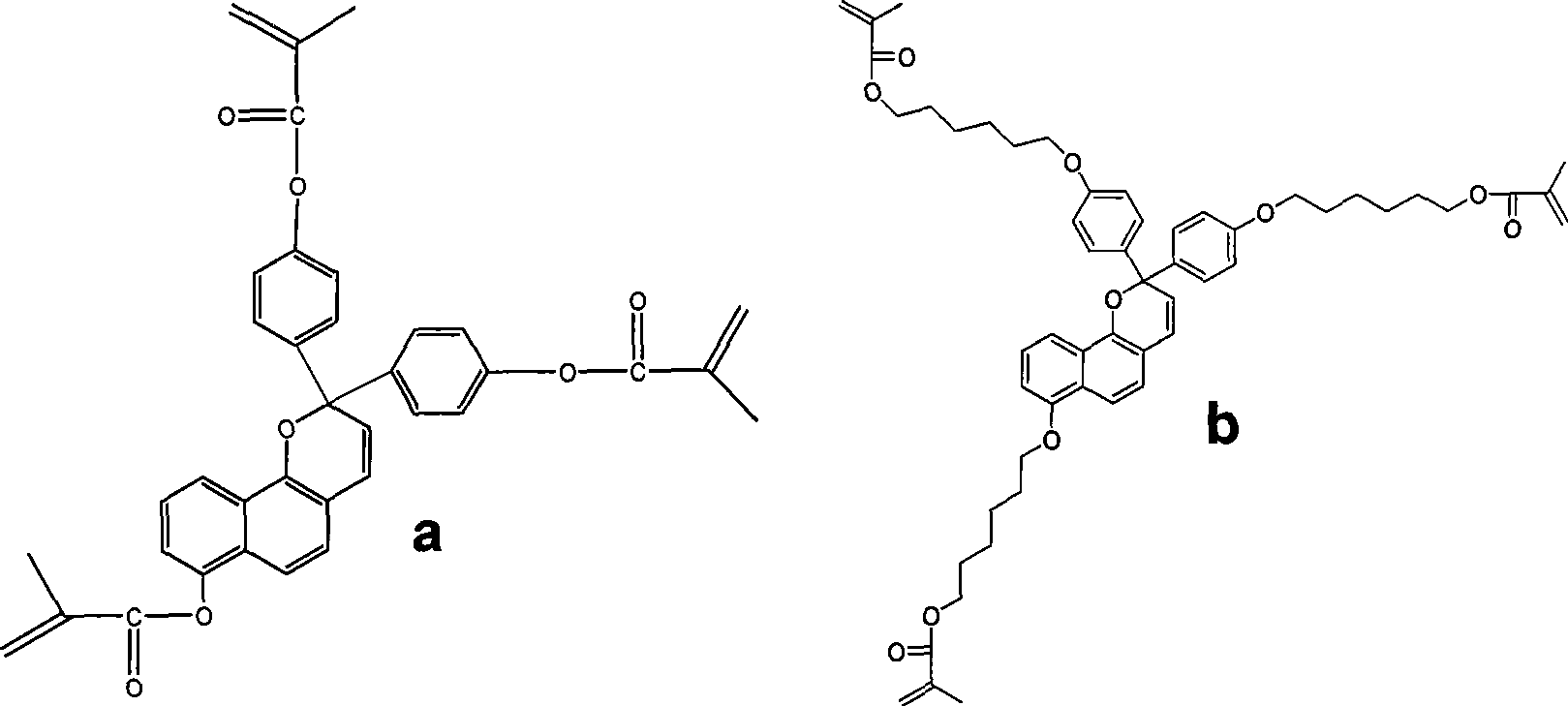

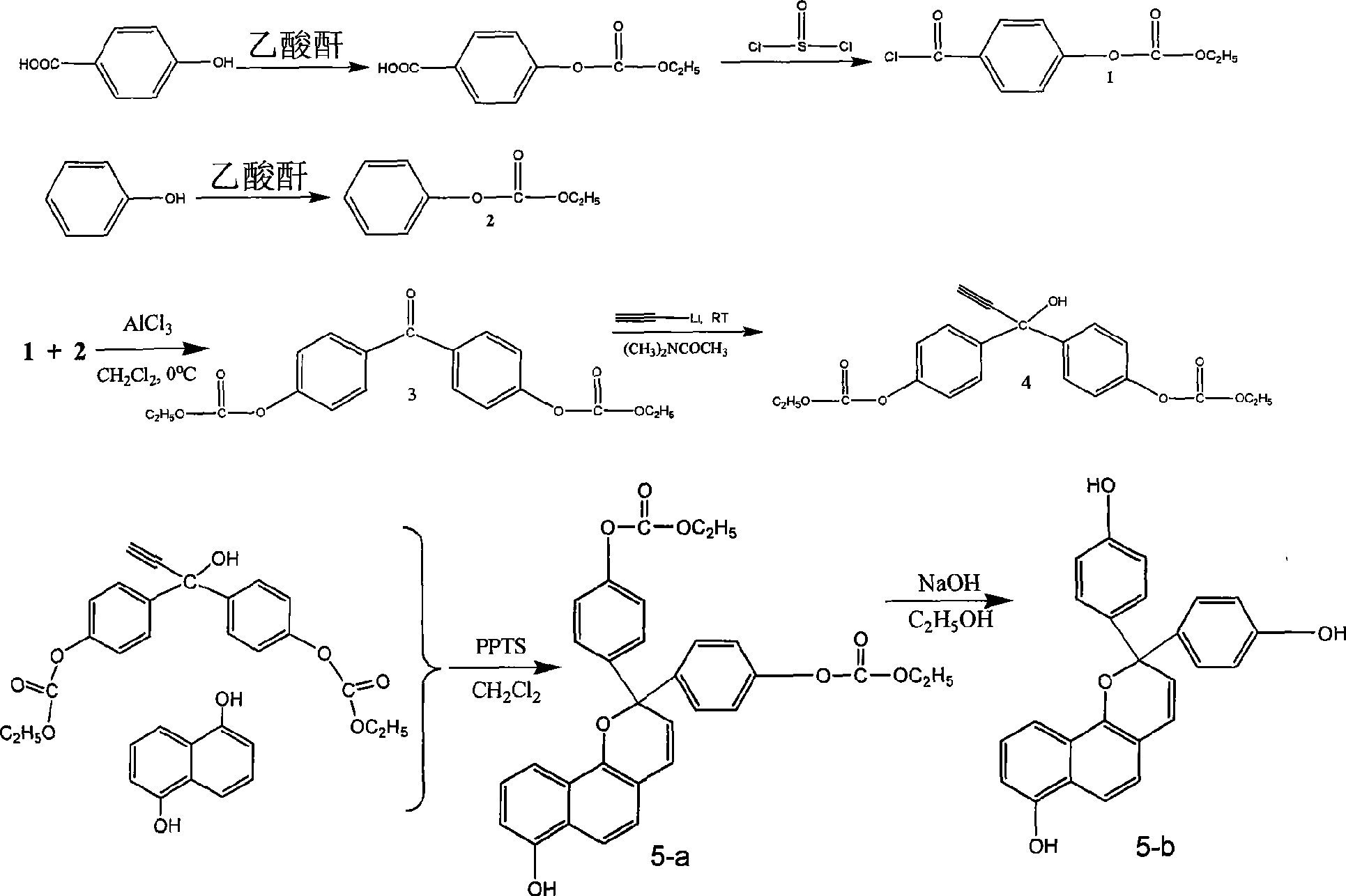

Method for synthesizing photochromic cross-linked polymer containing naphthyl hydroxide pyran group

The invention belongs to a synthetic method of an organic / polymeric material, in particular relates to a synthetic method of photochromic crosslinked polymers containing naphthol pyran groups. The synthetic method comprises the following steps: firstly preparing diphenyl ketone containing different groups, then converting carbonyl in the obtained diphenyl ketone into hydroxyl and alkynyl, allowing the hydroxyl and the alkynyl to react with naphthol to prepare naphthol pyran molecules, and finally grafting a methacrylic acid polymerization unit to the naphthol pyran molecules to form a polymeric monomer containing three polymerization units. During the reaction process, an acetate group is adopted for protecting the hydroxyl and unprotected after synthesizing the naphthol pyran molecules. After the monomer is obtained, a free radical polymerization method can be adopted, in the method, a single monomer or synthesized different monomers are polymerized with other monomers, thus obtaining various photochromic crosslinked polymers. The synthetic method fills a gap of research on the crosslinked polymers containing the naphthol pyran monomers at home and abroad and provides a new application prospect for photochromic materials.

Owner:NORTHEAST NORMAL UNIVERSITY

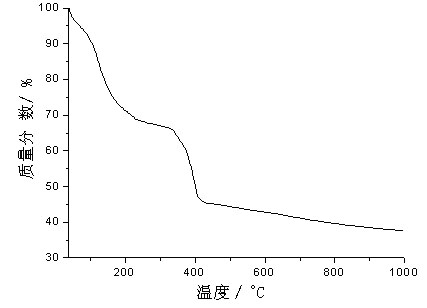

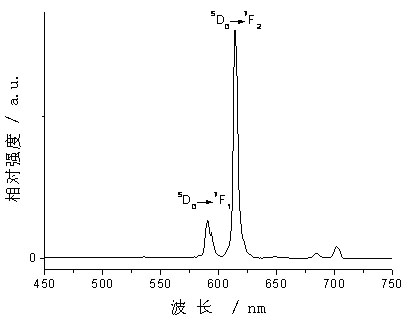

Method for preparing polymethylacrylic acid functionalized rare-earth polymer composite luminescent material

InactiveCN102002358AImprove luminous efficiencyRegular microscopic morphologyLuminescent compositionsPolymer scienceFluorescence

The invention belongs to the field of rare-earth polymer composite luminescent materials and in particular relates to a method for preparing a polymethylacrylic acid functionalized rare-earth polymer composite luminescent material. A functional polymer is prepared through addition polymerization; a rare-earth ion is compounded to a polymer chain through a coordinate bond to prepare a rare-earth polymer compound; and the obtained compound is embedded in a Si-O network substrate by a sol-gel method. On the basis, in order to improve the optical performances of the material, an organic micromolecule is further introduced into the system to obtain the rare-earth polymer composite luminescent material with stable chemical and thermodynamic properties and characteristic fluorescence-emission. The experiment condition of the method is mild; the operability is strong; and the quality of the obtained product is stable.

Owner:TONGJI UNIV

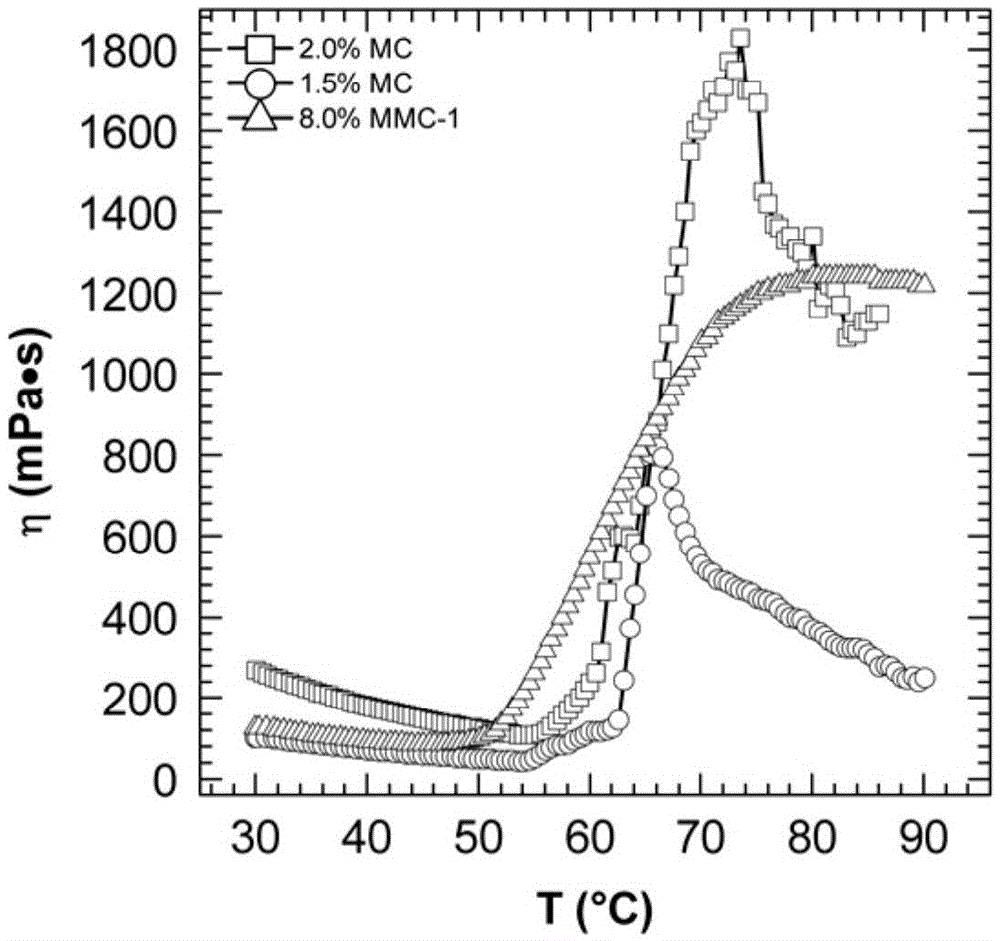

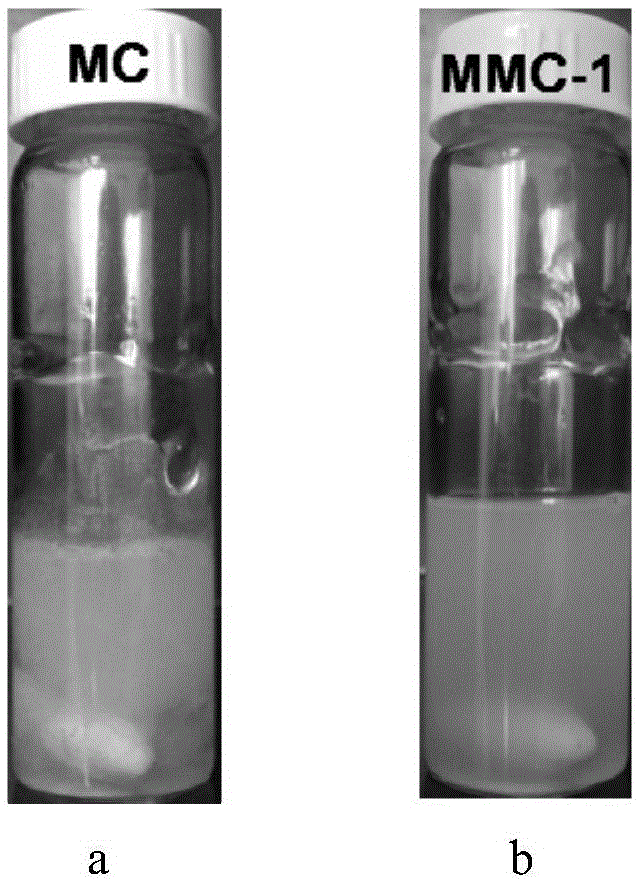

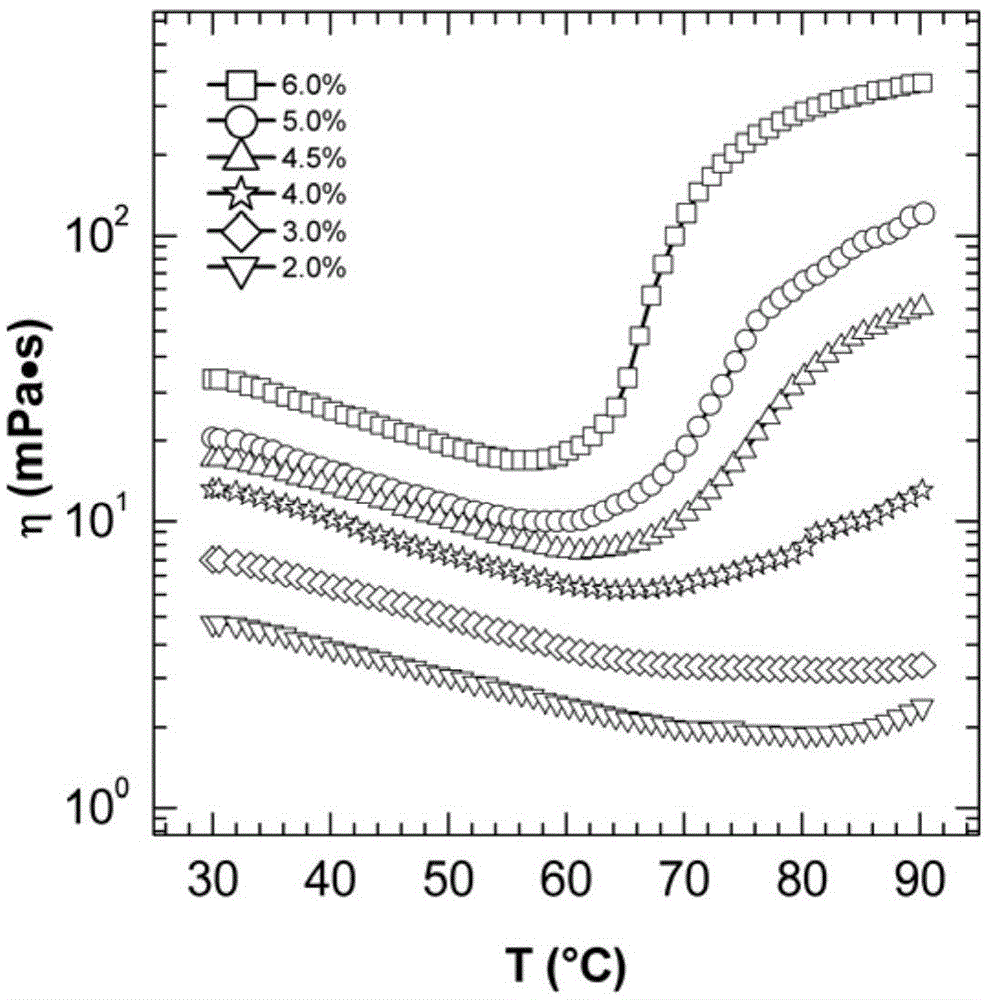

Hydrophilic modification method of methyl cellulose

ActiveCN105601820AElimination of macroscopic phase separationSimple processWater solubleMethyl cellulose

The invention discloses a hydrophilic modification method of methyl cellulose. Firstly, a methyl cellulose solution with the mass concentration of methyl cellulose being 1.0-5.0% is prepared through alkali liquid, then water-soluble monomers are added, stirred and dissolved to form mixed liquid, reaction is performed for 12-48 h under the condition of stirring at the temperature of 20-40 DEG C, reaction liquid is neutralized to be neural, and intermediate products are obtained; secondly, the obtained intermediate products are dissolved in alkali liquid to prepare a solution with the mass concentration of the intermediate products being 1.0-5.0%, an oxidizing agent is added, reaction is performed at 10-30 DEG C under the conditions of stirring and light avoidance, an excessive number of reduction agent is added when the reaction time is 2-10 h, reaction products are precipitated through anhydrous ethanol, and the hydrophilic modified methyl cellulose is obtained through filtering, washing and drying. By means of the method, the macroscopic phase separation phenomenon in the temperature raising process of methyl cellulose can be eliminated, and therefore it is avoided that viscosity of methyl cellulose is violently reduced in a temperature-sensitive effect, and of application value is lost.

Owner:SICHUAN UNIV

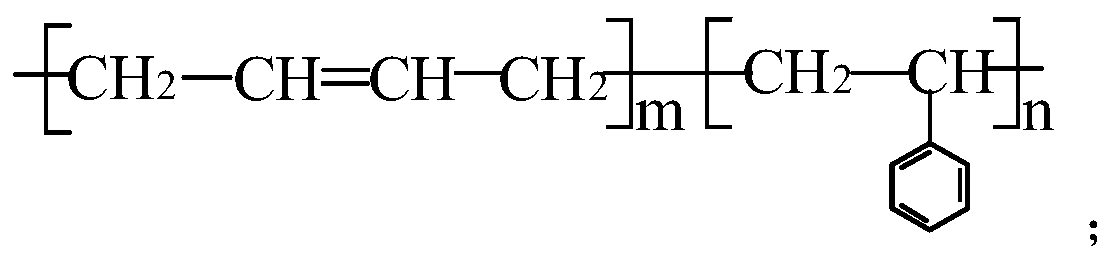

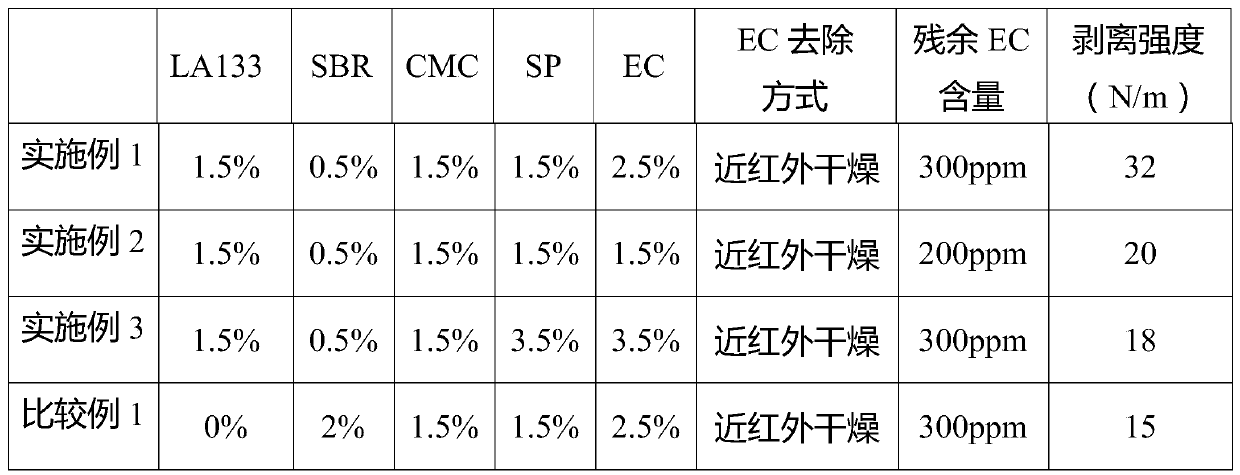

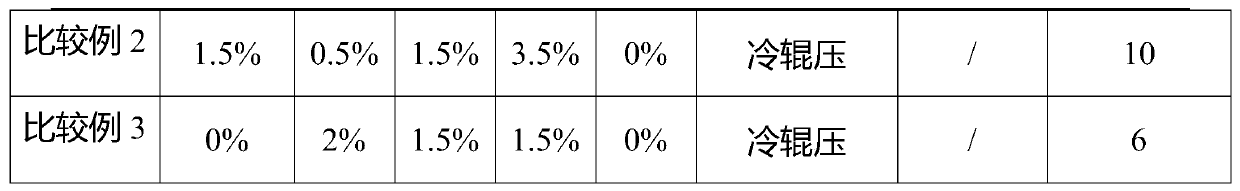

Negative electrode slurry, negative electrode plate and preparation method of negative electrode plate

ActiveCN111509231AEvenly dispersedEvenly distributedNegative electrodesSecondary cellsAcrylonitrileBattery cell

The invention provides negative electrode slurry, a negative electrode plate and a preparation method of the negative electrode plate. The negative electrode slurry comprises an active substance, a binder, a water-based thickener, a conductive agent and ethylene carbonate, the binder comprises a first binder and a second binder, the first binder is an acrylonitrile multipolymer emulsion, and the second binder is styrene-butadiene latex or styrene-acrylic latex. The negative electrode slurry prepared by the invention has excellent bonding performance, does not have a dry cracking phenomenon during coating, and can greatly improve the peel strength of a negative plate and the cycle performance and low-temperature performance of a battery.

Owner:湖南领湃新能源研究院有限公司

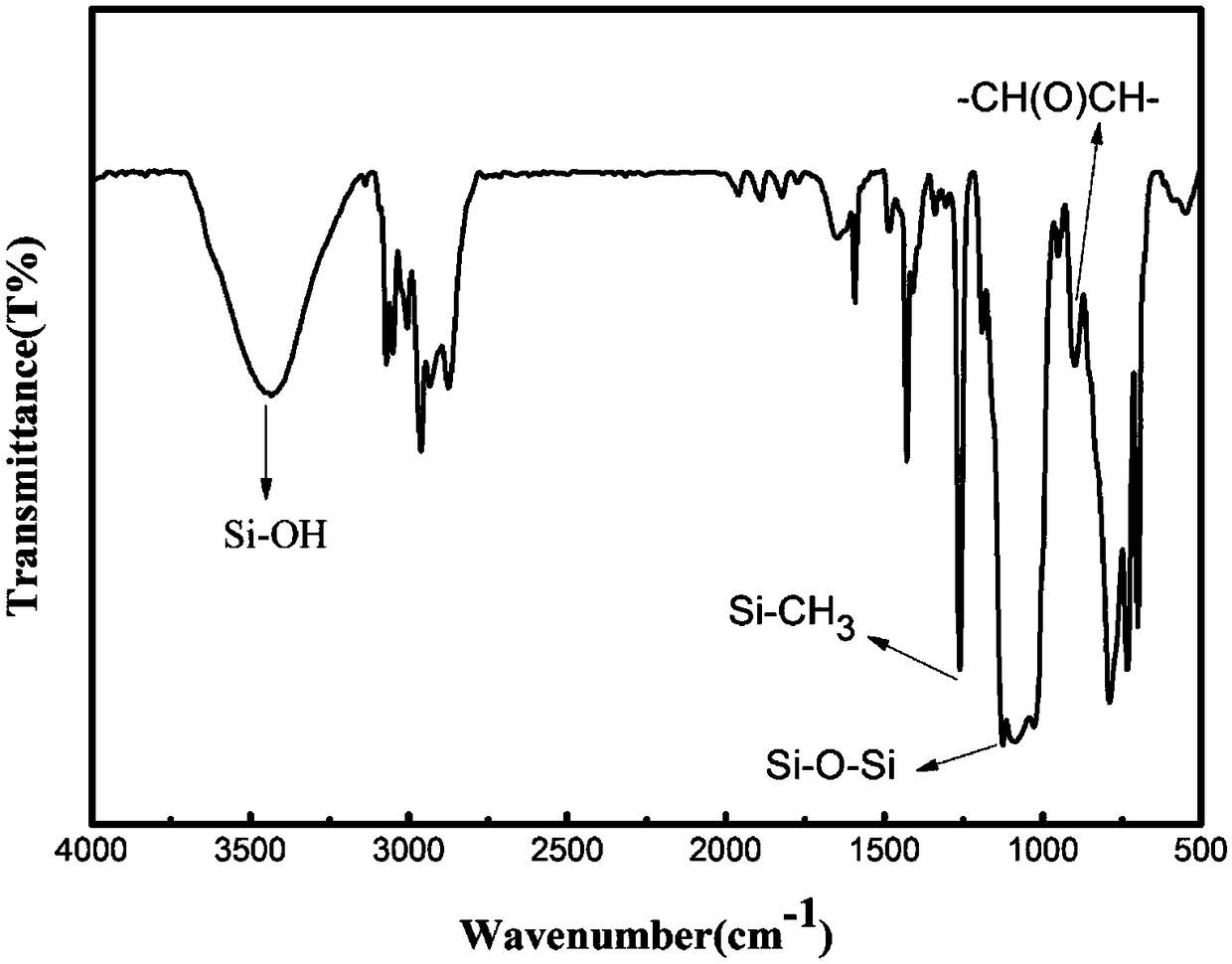

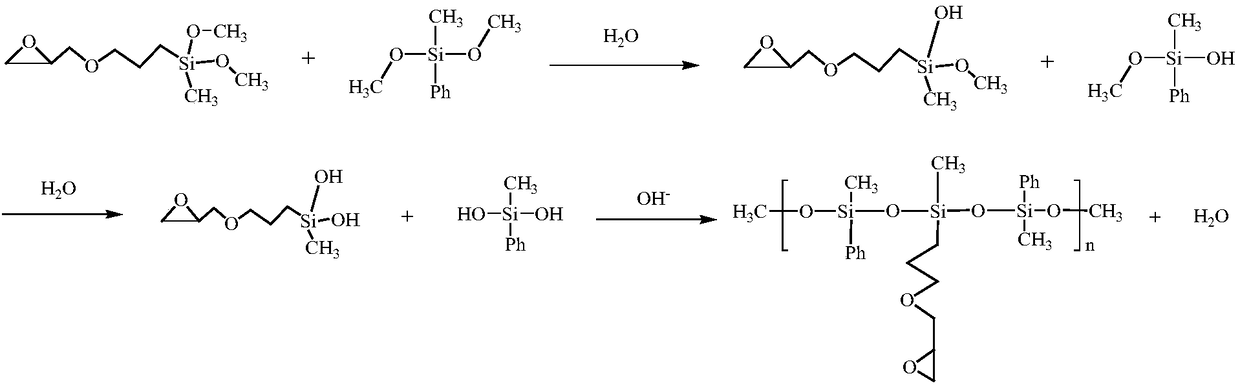

Epoxidized modified methylphenyl silicone resin for LED (Light Emitting Diode) packaging adhesive and preparation method thereof

InactiveCN108384010AImprove thermal stabilityImprove adhesionAdhesivesSemiconductor devicesSilicone resinTransmittance

The invention belongs to the technical field of preparation of organic silicon modified epoxy resin and in particular relates to epoxidized modified methylphenyl silicone resin for an LED (Light Emitting Diode) packaging adhesive and a preparation method thereof. According to the method provided by the invention, 3-glycidoxypropyldimethoxymethylsilane and dimethoxymethylphenylsilane are used as raw materials and are subjected to hydrolytic condensation reaction to synthesize the epoxidized modified methylphenyl silicone resin. A preparation technology is simple to operate and easy to control and has good repeatability and controllability; an organic solvent is not needed so that the preparation technology is green and environmentally friendly. The epoxidized modified methylphenyl siliconeresin prepared by the method has low impurity content and no phase splitting phenomenon, and has the characteristics of high light transmittance, high refractive index, high thermal stability, high binding performance and the like of organic silicon resin and epoxy resin; large-scale production is extremely easy to realize in industry.

Owner:SOUTH CHINA UNIV OF TECH

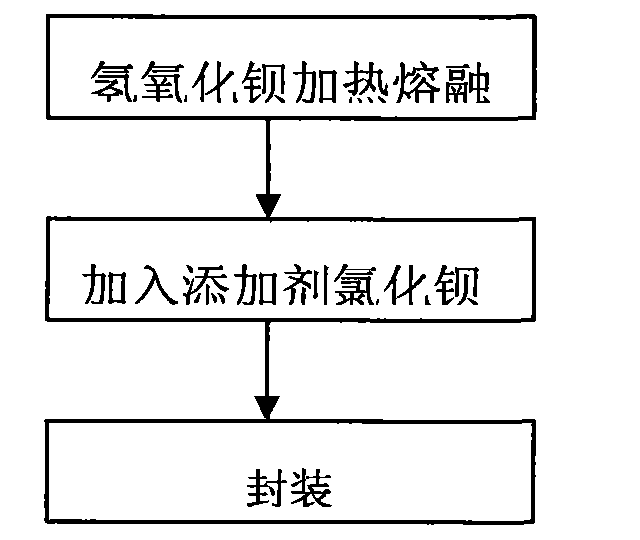

Material for storing heat of phase change in low temperature, and preparation method

InactiveCN1958712AImprove performanceExothermic stableHeat-exchange elementsSuper coolingAluminum ammonium sulfate

This invention discloses a method for preparing low-temperature phase transition heat-storage material, which is prepared from aluminum ammonium sulfate (major component), CaF2 (additive), carbon (additive) and deionized water (additive). The method comprises: heating aluminum ammonium sulfate to melt, adding CaF2 and carbon powder uniformly mixed at normal temperature, stirring uniformly, adding deionized water, stirring, heating the mixture for mixing uniformly, filling into a container, and packaging. The low-temperature phase transition heat-storage material has a high latent heat of phase transition, and the phase transition temperature is between 93-95 deg.C. Experiments show that the super-cooling degree of the material is below 4 deg.C, and no phase separation occurs.

Owner:SHANGHAI MARITIME UNIVERSITY

Phase change heat storage material and preparation method thereof

ActiveCN101671546AImprove performanceLarge latent heat of phase changeHeat-exchange elementsBarium dichlorideExothermic process

The invention discloses a phase change heat storage material, which consists of a main material barium hydroxide and an additive barium chloride, wherein the main material and the additive play a role in preventing overcooling and preventing phase separation. A preparation method of the material comprises the following steps: (1) heating and melting pure barium hydroxide; (2) adding the additive barium chloride, and fully mixing the mixture evenly into a fluid substance; and (3) filling the mixture into a container to perform packaging. The phase change heat storage material has the advantages of large phase change latent heat, stable heat release process, fewer additive types, simple preparation method and convenient production; besides, the phase change heat storage material is easy forpackaging after being melted into the state of an even fluid substance.

Owner:SHANGHAI MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com