Coated hydrous salt heat-storage material and preparation method

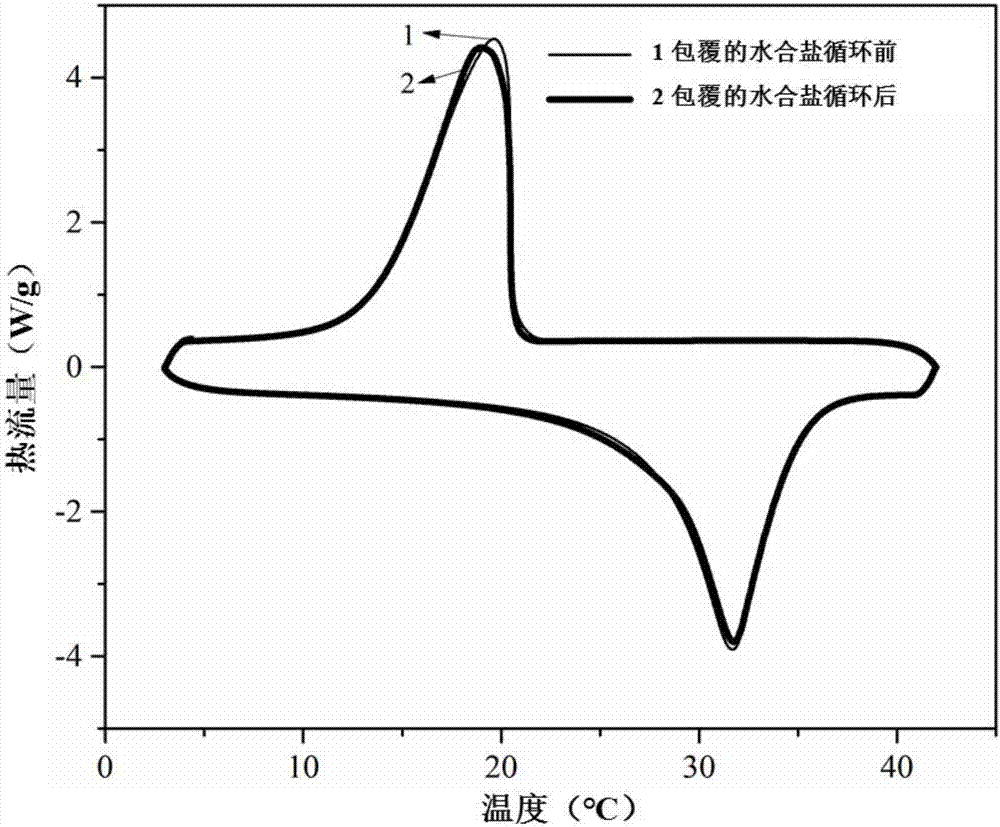

A heat storage material and hydrated salt technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of corrosion and liquid leakage, and achieve high phase change enthalpy, avoid liquid leakage, phase reversible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) At room temperature, weigh 22.2g of anhydrous calcium chloride and dissolve in 21.6g of water to form a clear and transparent calcium chloride solution, then weigh 0.9g of nucleating agent borax and 0.15g of thickener hydroxyethyl cellulose Add the element into the calcium chloride solution and stir evenly at 50°C to form a phase change mother solution;

[0043] 2) Weigh 5.0 g of porous material expanded graphite, add it to the phase change mother liquor in step 1), stir it evenly, put it in an environment of 5° C. to cool down and crystallize;

[0044] 3) Weigh 1.5g of methyl methacrylate, 0.5g of urethane acrylate and 0.1g of α, α-diethoxyacetophenone to make a photocurable resin solution, put it in a sprayer, and take out step 2 ) crystallized composite material, after spraying evenly with a sprayer, quickly put it under an ultraviolet lamp to illuminate, and after curing, a coated calcium chloride hexahydrate composite phase change heat storage material is obtain...

Embodiment 2

[0048] 1) At room temperature, weigh 35.7g of anhydrous calcium chloride and dissolve it in 34.8g of water to form a clear and transparent calcium chloride solution, then weigh 25g of magnesium chloride hexahydrate solid and add it to the calcium chloride solution. The homogenizer is 5000r / min homogenization for 2 minutes, finally weigh and add 6.1g nucleating agent strontium chloride hexahydrate, 1.0g strontium carbonate and 0.4g thickening agent hydroxyethyl cellulose, continue homogenization for 2 minutes at a speed of 5000r / min , forming a phase change mother liquor;

[0049] 2) Weigh 4.5g of expanded perlite, a porous material, and add it to the phase-change mother liquor in step 1), stir it evenly, and put it in an environment of 5°C to cool down and crystallize;

[0050] 3) Take by weighing 4.5g of n-butyl acrylate, 1.5g of polyurethane and 0.3g of α-hydroxyalkyl phenone, make it into photocurable resin solution, put it in a sprayer, take out step 2) after crystallizat...

Embodiment 3

[0055] 1) At room temperature, weigh 11.1g of anhydrous magnesium nitrate and dissolve it in 8.1g of water to form a clear and transparent magnesium nitrate solution, then weigh 19.2g of magnesium chloride hexahydrate solid and add it to the magnesium nitrate solution, homogenizer 3000r / min Homogenize for 5 minutes, finally weigh and add 0.8g of nucleating agent barium hydroxide, 0.5g of strontium carbonate and 0.2g of thickener carboxymethyl cellulose, and continue homogenizing for 5 minutes at a speed of 3000r / min to form a phase change mother liquor ;

[0056] 2) Weigh 4.4g of diatomite, a porous material, and add it to the phase change mother liquor in step 1), stir it evenly, and put it into room temperature to crystallize;

[0057] 3) Weigh 3.5g of n-butyl methacrylate, 1.0g of polyurethane methacrylate and 0.25g of 2,4-dihydroxybenzophenone to prepare a photocurable resin solution and put it in a sprayer. Take out the crystallized composite material in step 2), spray i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| solidification point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com