Preparation method of super-hydrophobic surface of glass

A technology of hydrophobic surface and glass super-hydrophobicity, applied in the field of preparation of glass super-hydrophobic surface, can solve the problems of poor adhesion between the micro-nano double-rough structure layer and the glass substrate and insufficient hydrophobicity, so as to improve the surface hydrophobicity and improve the Adhesive force and tight bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Preparation of fluorosilicone modified acrylate emulsion;

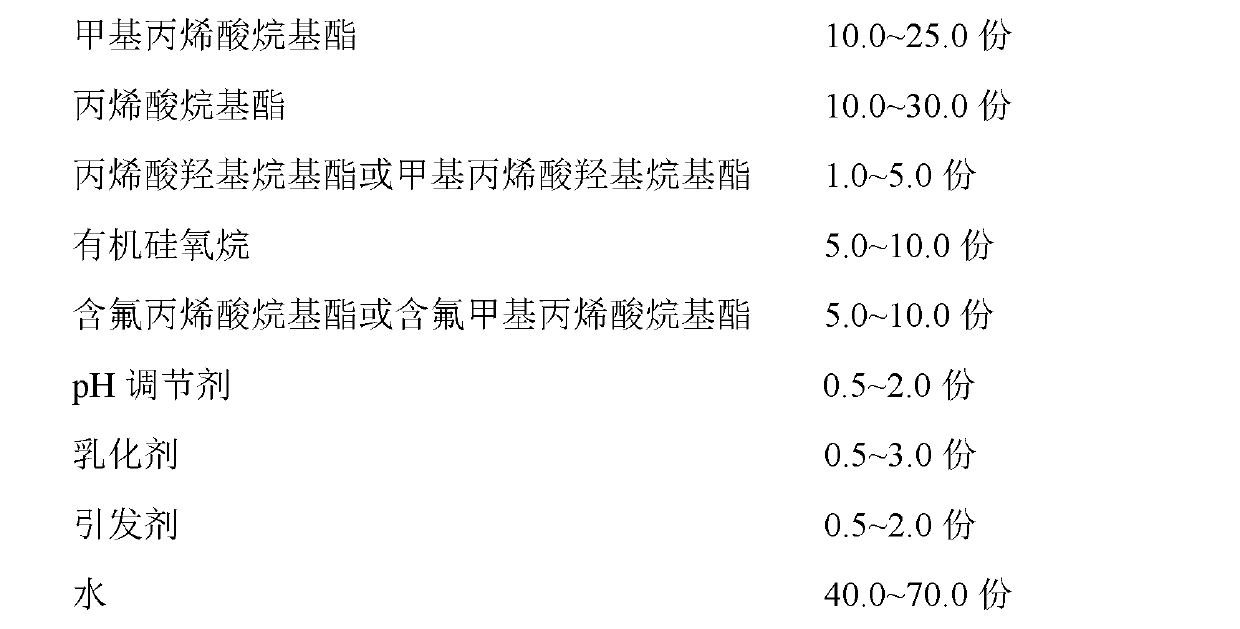

[0056] (a) The components of the fluorosilicon-modified acrylate emulsion are shown in Table 1 below. Mix alkyl methacrylate and alkyl acrylate in the step components to make monomer I, hydroxyalkyl acrylate or hydroxyalkyl methacrylate, organosiloxane, fluorine-containing alkyl acrylate or Alkyl fluoromethacrylate is mixed to make monomer II;

[0057]

[0058] (b) Add 55% of water in step (a), 55% of the mass of the mixture of SDS and AMPS-Na, 60% of potassium persulfate, and sodium bicarbonate into the reaction kettle, stir for 15 minutes and then heat up to 75 ° C, take 10% of the monomer I was added to the reactor in 15 minutes, and kept for 15 minutes after the dropwise addition, and then 50% of the monomer I was added dropwise in the reactor within 2.5 hours, and kept for 15 minutes after the dropwise addition, to obtain Lotion;

[0059] (c) Dissolve the remaining emulsifier and initiator in the...

Embodiment 2

[0069] (1) Preparation of fluorosilicone modified acrylate emulsion;

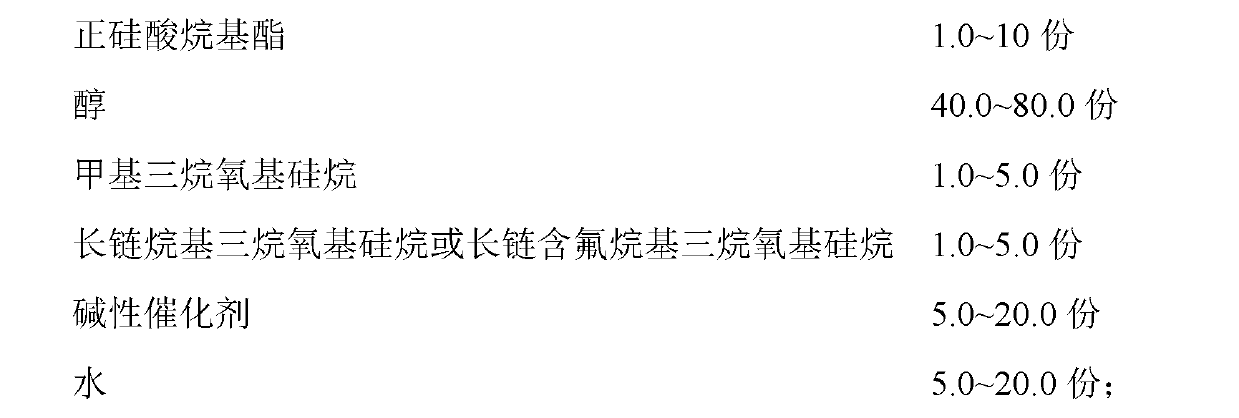

[0070] (a) The components of the fluorosilicon-modified acrylate emulsion are shown in Table 2 below. Mix alkyl methacrylate and alkyl acrylate in the step components to make monomer I, hydroxyalkyl acrylate or hydroxyalkyl methacrylate, organosiloxane, fluorine-containing alkyl acrylate or Alkyl fluoromethacrylate is mixed to make monomer II;

[0071]

[0072](b) Combine 65% of water, LAS and AMPS-NH in step (a) 4 Add 65% and 70% of the mixture's mass of ammonium persulfate and potassium bicarbonate into the reaction kettle, stir for 20 minutes and then heat up to 78 °C, take 20% of monomer I and add it to the reaction kettle in 20 minutes, keep it warm after the dropwise addition After 20 minutes, add 60% of the monomer I dropwise to the reaction kettle within 3.5 hours, keep the temperature for 20 minutes after the dropwise addition, and obtain the emulsion;

[0073] (c) Dissolve the remaining emul...

Embodiment 3

[0084] (1) Preparation of fluorosilicone modified acrylate emulsion;

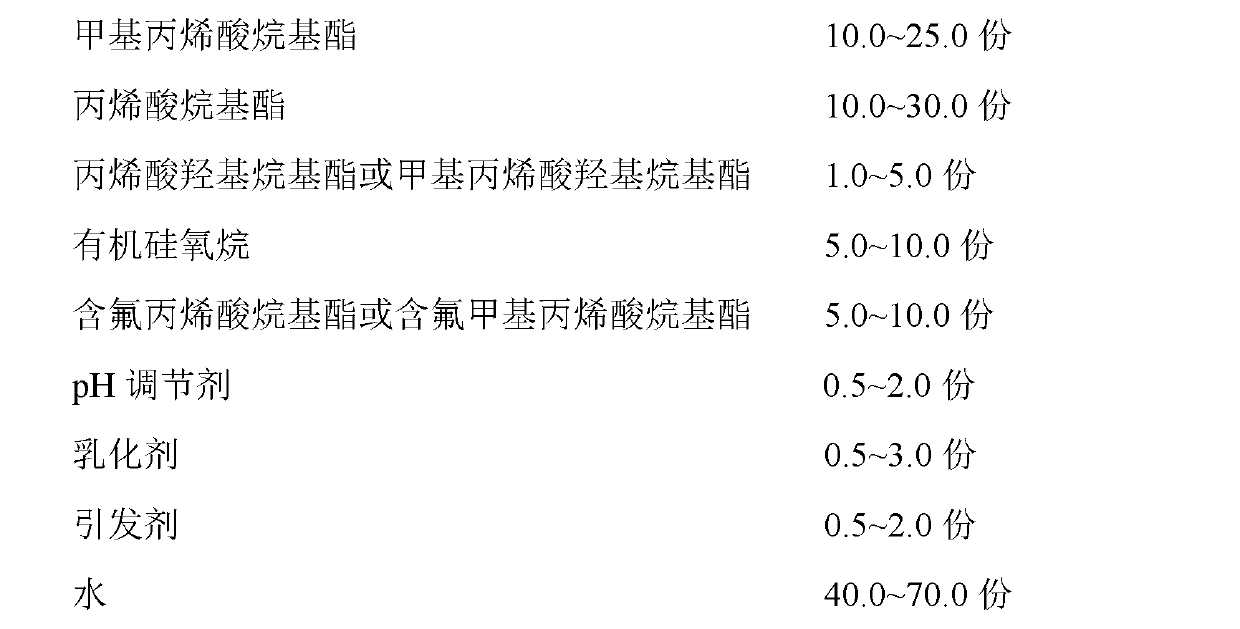

[0085] (a) The components of the fluorosilicon-modified acrylate emulsion are shown in Table 3 below. Mix alkyl methacrylate and alkyl acrylate in the step components to make monomer I, hydroxyalkyl acrylate or hydroxyalkyl methacrylate, organosiloxane, fluorine-containing alkyl acrylate or Alkyl fluoromethacrylate is mixed to make monomer II;

[0086]

[0087] (b) Add 55% of water in step (a), 75% of the mass of the mixture of DSB and HPMAS, 75% of sodium persulfate, and potassium dihydrogen phosphate into the reaction kettle, stir for 15 minutes and then heat up to 80 °C, take a single 15% of monomer I was added to the reactor in 30 minutes, and after the dropwise addition was completed, it was kept warm for 30 minutes, and then 60% of monomer I was added dropwise into the reactor within 4 hours, and after the dropwise addition was completed, it was kept warm for 25 minutes to obtain Lotion;

[0088...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com