Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Stay superhydrophobic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transparent super-hydrophobic coating material and method for preparing transparent super-hydrophobic coating by transparent super-hydrophobic coating material

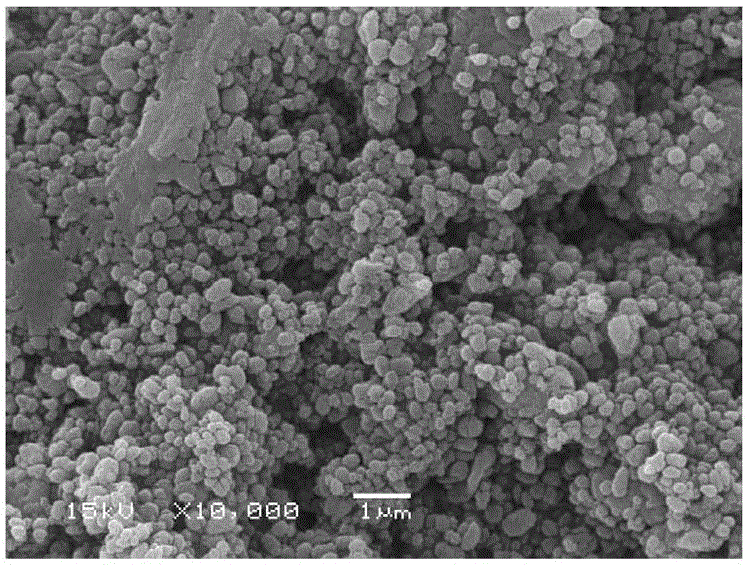

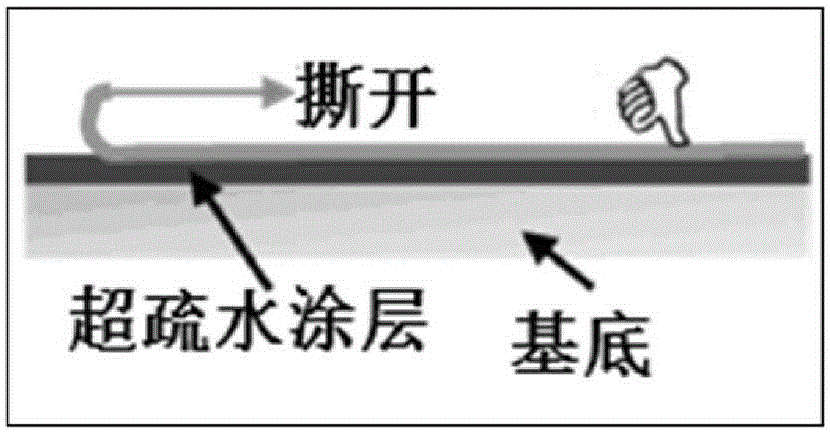

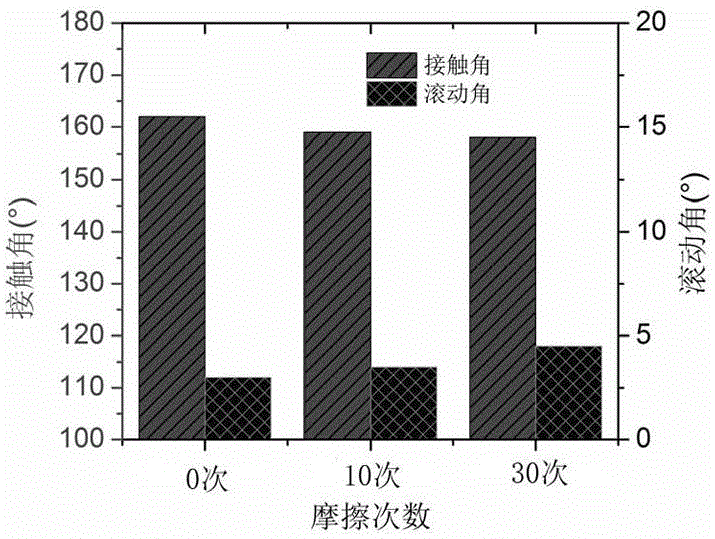

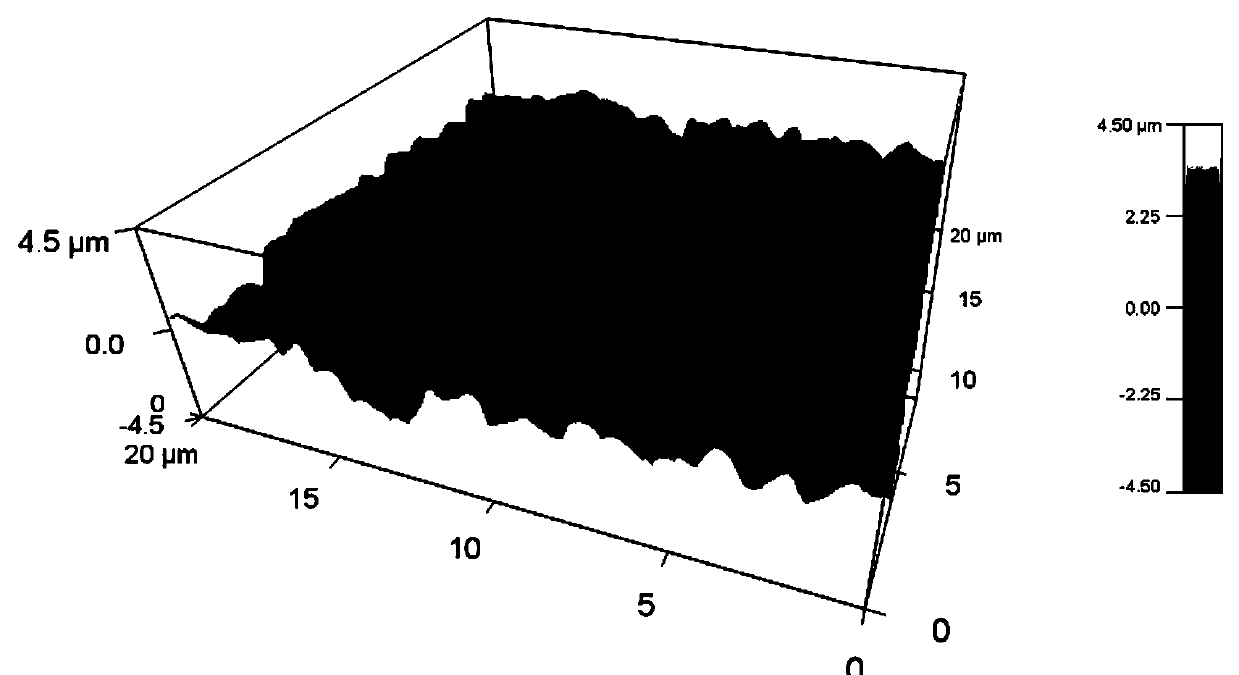

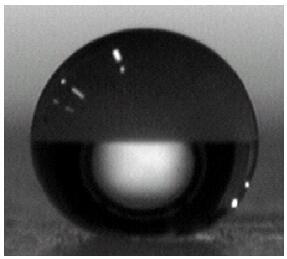

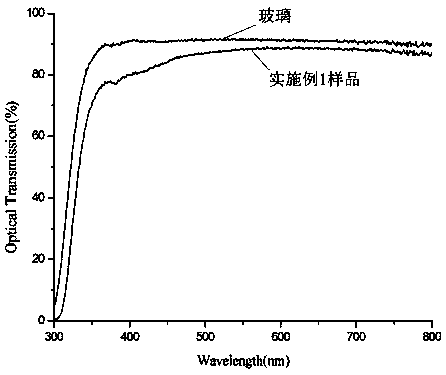

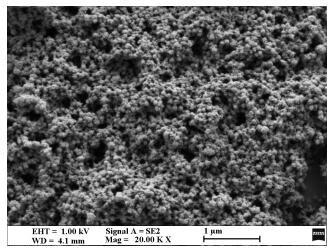

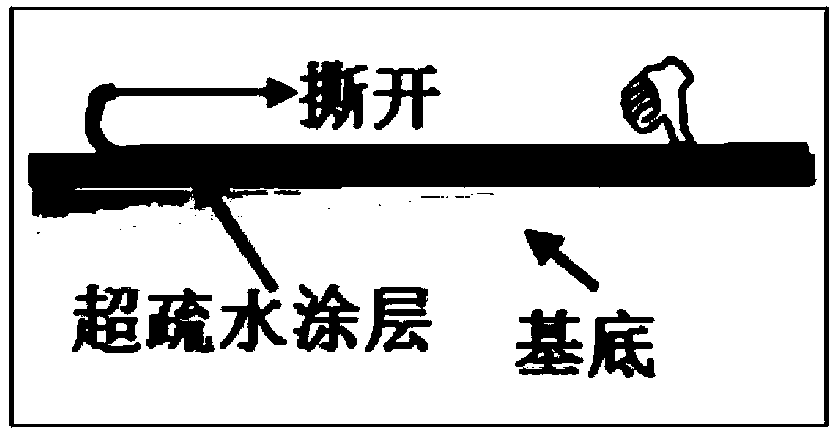

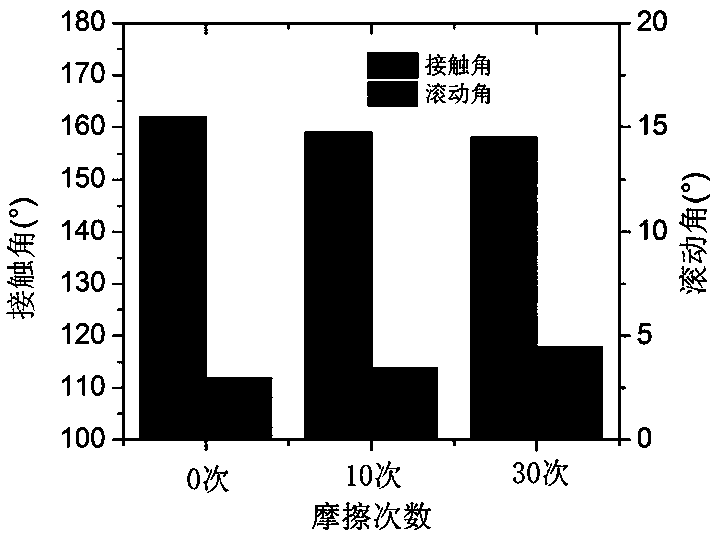

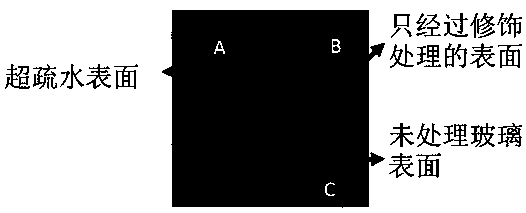

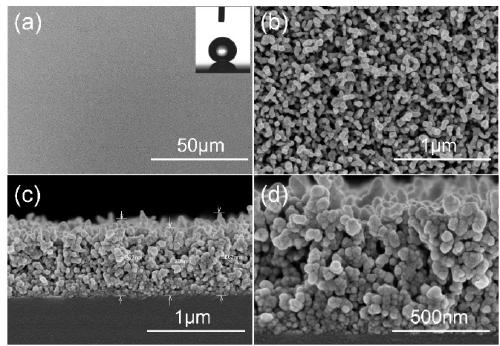

ActiveCN104449357AEasy to prepareDoes not damage surface propertiesPolyurea/polyurethane coatingsSpecial surfacesMicro nanoGas phase

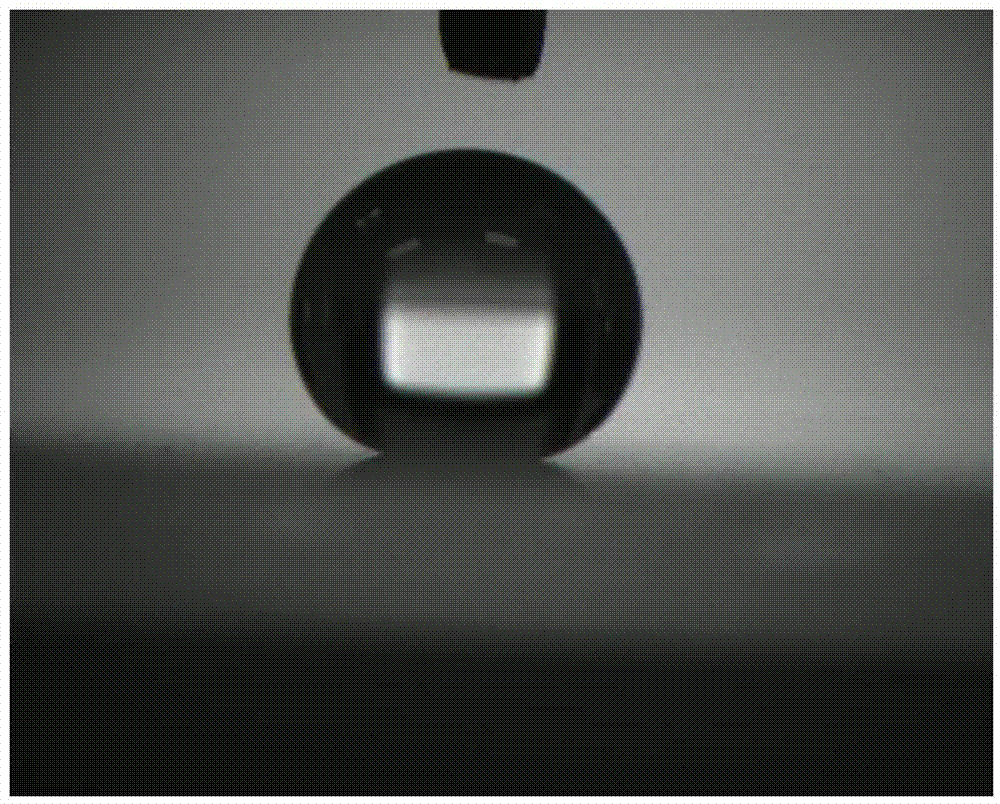

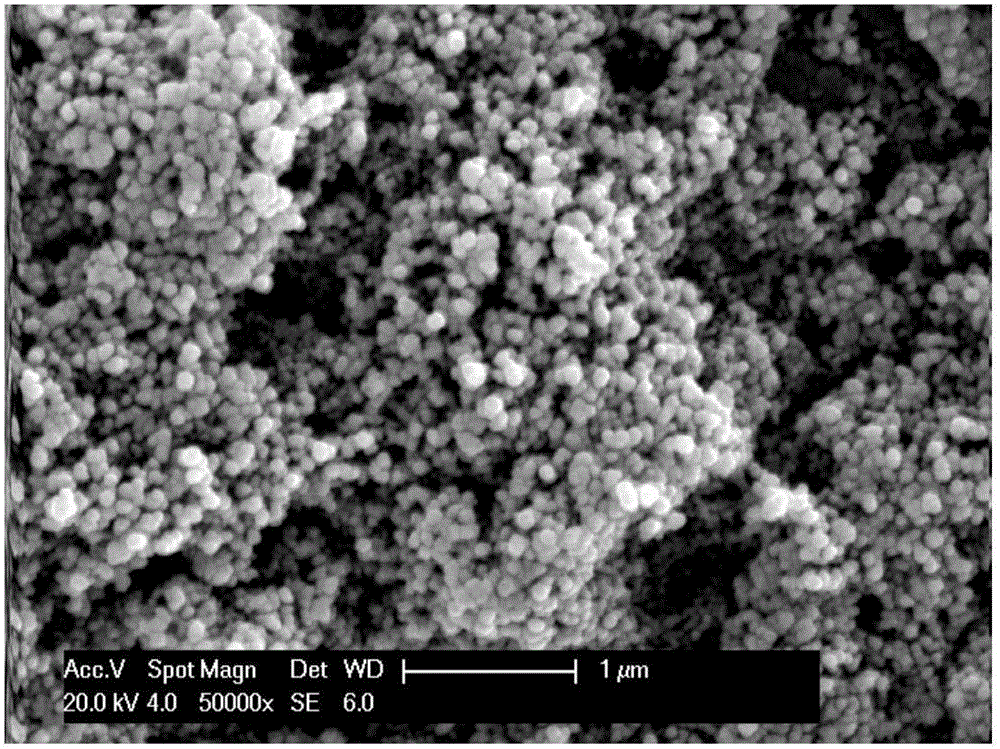

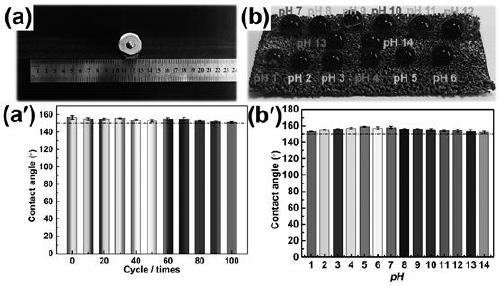

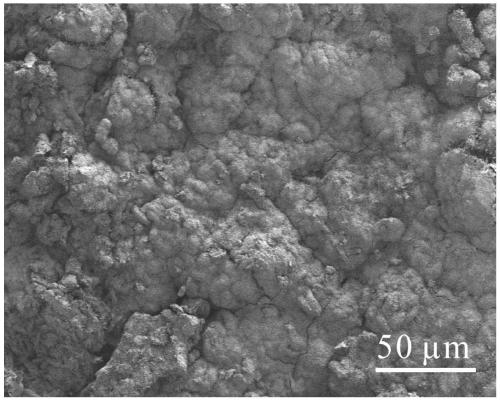

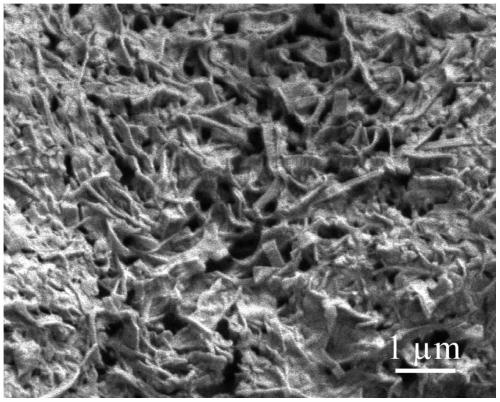

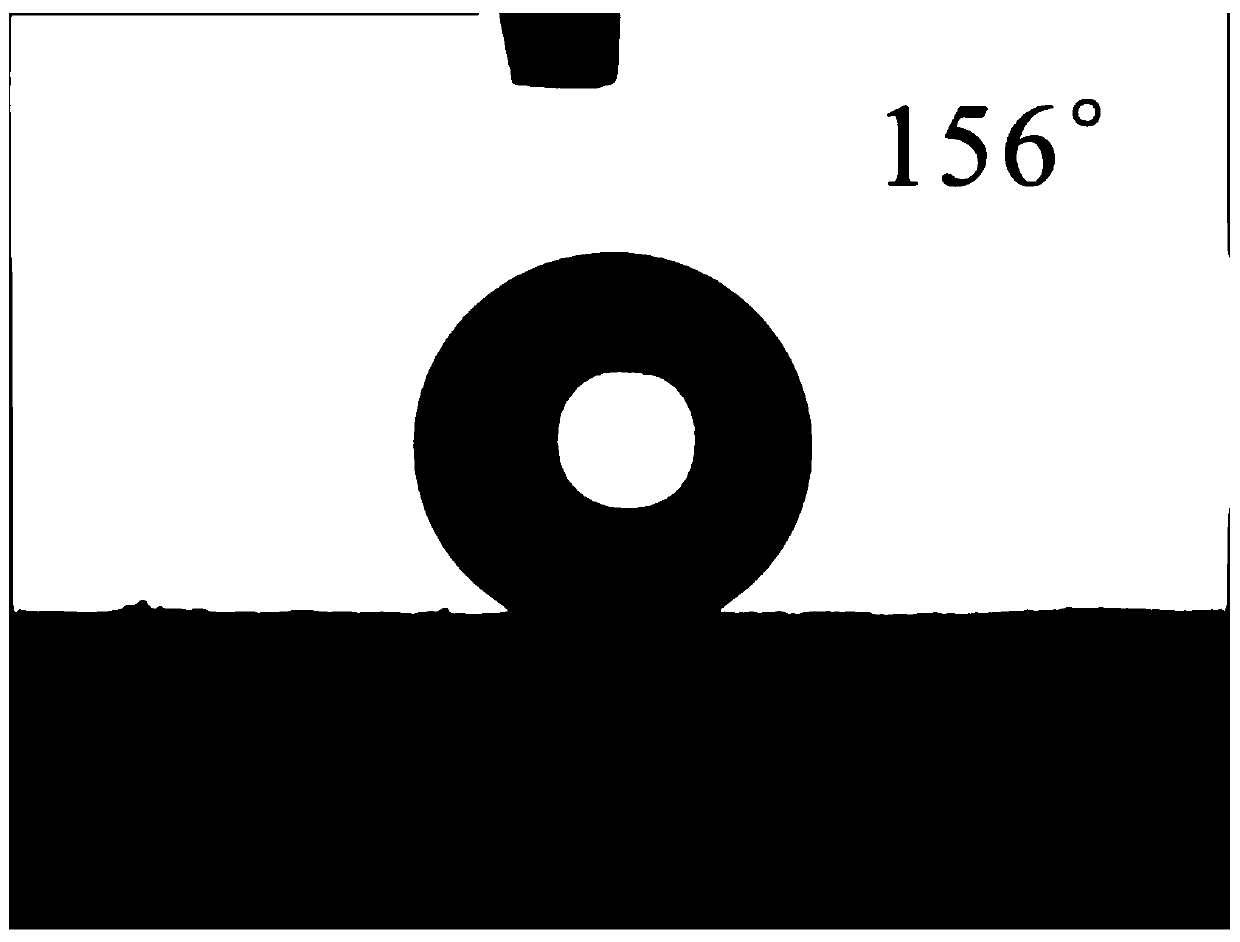

The invention discloses a transparent super-hydrophobic coating material. The raw materials of the transparent super-hydrophobic coating material comprise gas-phase silica nano-particle dispersion liquid which consists of gas-phase silica nano-particles and a solvent, and a hydrophobic treating agent. The invention further discloses a preparation method of a transparent super-hydrophobic coating; a coating of a micro-nano structure is prepared by rubbing and coating a substrate with the gas-phase silica nano-particle dispersion liquid, and then the coating is subjected to surface hydrophobization treatment by the hydrophobic treating agent to obtain the transparent super-hydrophobic coating. According to the super-hydrophobic coating material provided by the invention, hydrophobization treatment manners can be changed flexibly according to the difference of coated substrates; the method for preparing the super-hydrophobic coating has low requirement on equipment; the using cost is extremely low; the method is simple; the coating application is convenient; a large-area high-efficiency super-hydrophobic coating can be prepared; the prepared super-hydrophobic has excellent super-hydrophobicity, high transparency, droplet impact resistance, temperature and pH stability, durability, and repeated rubbing and coating capacity, and can be applied to almost all currently known solid surfaces.

Owner:ZHEJIANG UNIV

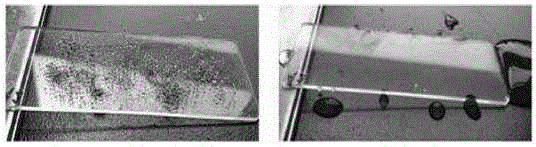

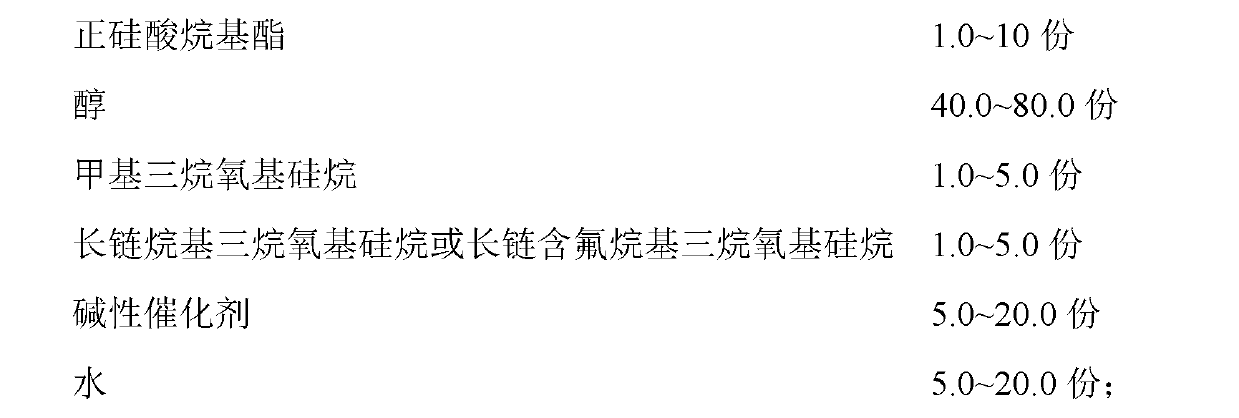

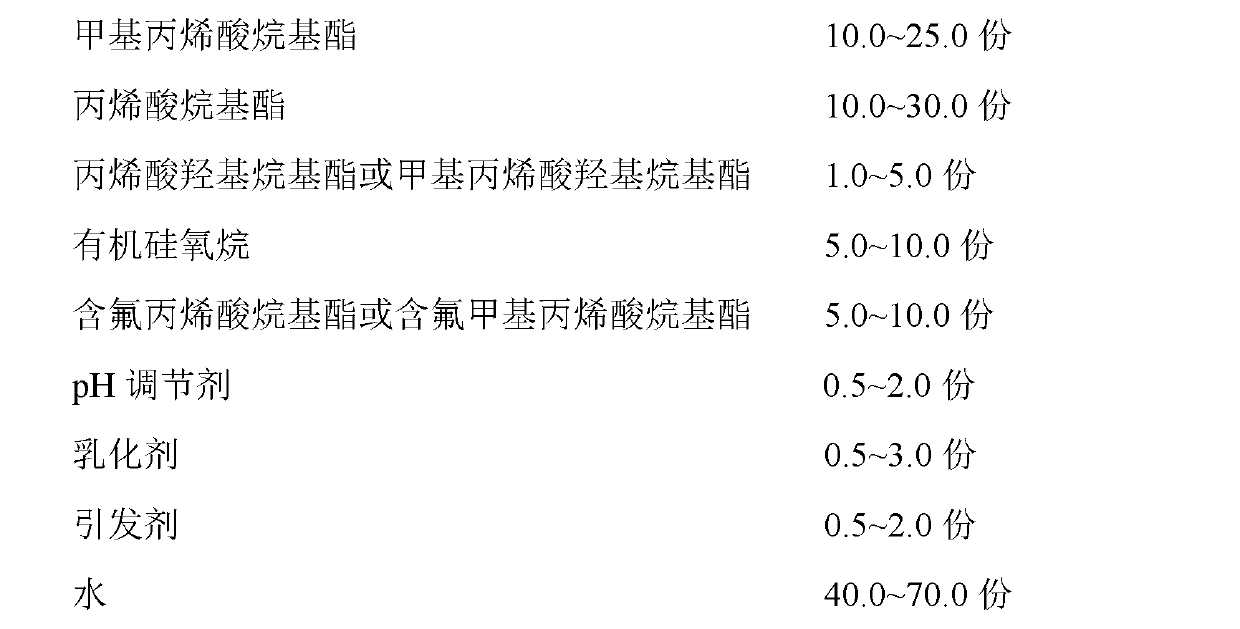

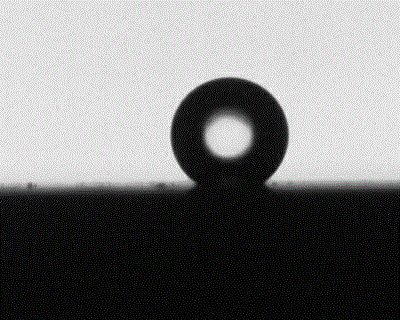

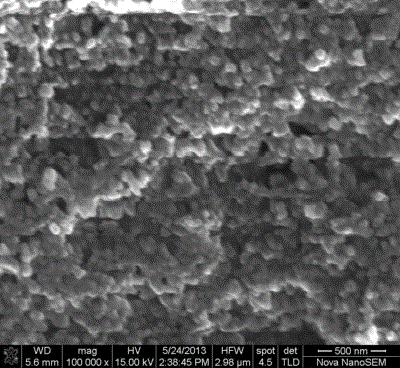

Preparation method of super-hydrophobic surface of glass

The invention relates to the field of super-hydrophobic surfaces. In order to solve the problems of poor binding force between the existing super-hydrophobic SiO2 micro-nano double rough structural layer and a glass substrate and insufficient hydrophobicity, the invention provides a preparation method of the super-hydrophobic surface of glass. The method comprises the following steps of: firstly, preparing fluorosilicone modified acrylic ester emulsion; secondly, preparing modified SiO2 sol; and finally preparing the super-hydrophobic surface of glass. The preparation method is simple and low in cost; a hydrophobic coating has excellent hydrophobicity and has excellent binding force with the glass; and the coating can maintain super-hydrophobicity for a long time.

Owner:HANGZHOU NORMAL UNIVERSITY

Semiconductor superhydrophobic paint and preparation method thereof

ActiveCN104403453ALong-term superhydrophobicityLong-term self-cleaningPolyurea/polyurethane coatingsElectrically-conductive paintsThermoplasticOrganic solvent

The invention relates to the field of hydrophobic paint, in particular to a semiconductor superhydrophobic paint and a preparation method thereof. The method comprises the steps of: a. firstly shearing and stirring hydrophobic nanoparticles and a semiconductive filler evenly, then adding 70%-80% of an organic solvent and conducting mixing; b. mixing thermoplastic film-forming resin with the remaining organic solvent, and performing shearing and stirring evenly; c. mixing the solution obtained in step a with the solution obtained in step b, then adding a low surface energy substance, a curing agent and an additive; and d. subjecting the solution obtained in step c to ultrasonic treatment for 2-20min, and then conducting stirring for 5min-2h till uniform stirring, thus obtaining the product. The semiconductor superhydrophobic paint adopting the scheme provided by the invention can realize self-repair, has no power consumption, and does not decompose surface organic substances.

Owner:CHONGQING UNIV +1

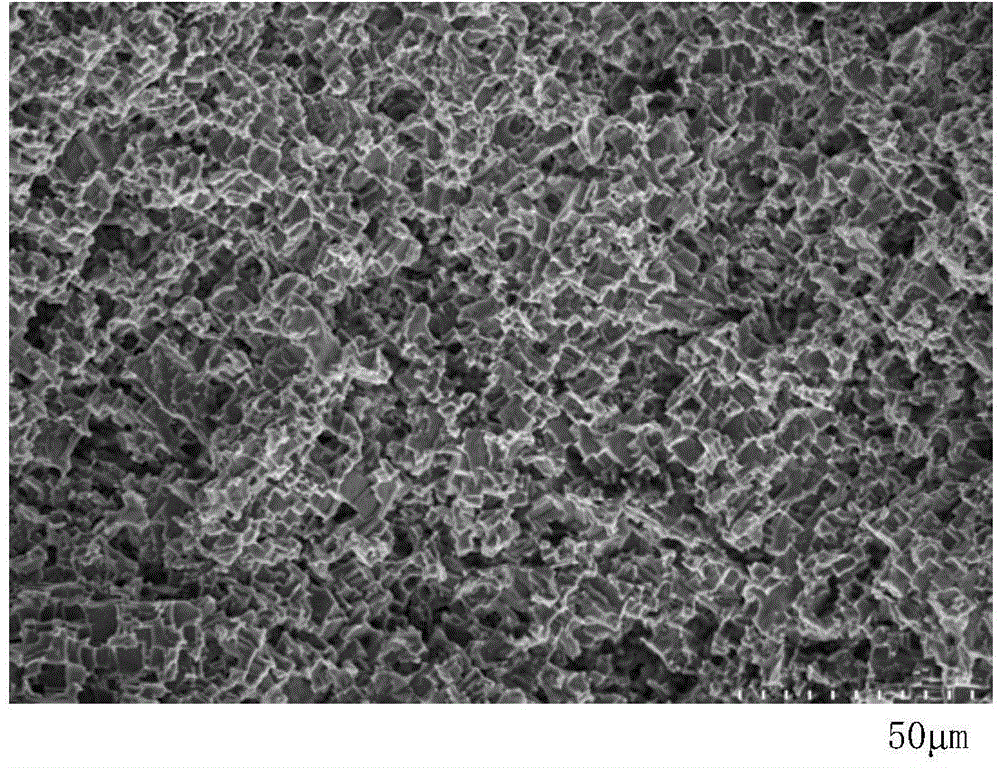

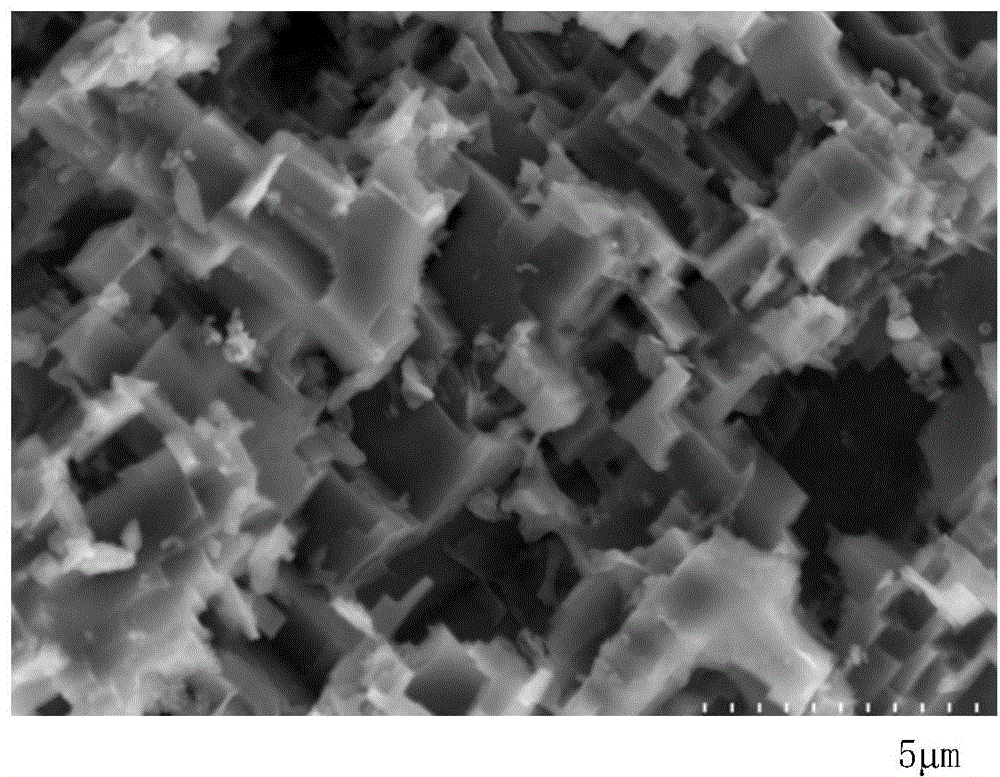

Preparation method of persistent icing-resistant superhydrophobic coating

ActiveCN106883650AImproved long-lasting anti-icing performanceLong-lasting anti-icing performanceAntifouling/underwater paintsPaper coatingSuperhydrophobePolymer science

The invention relates to the field of preparation of superhydrophobic coatings, in particular to a preparation method of a persistent icing-resistant superhydrophobic coating. The preparation method comprises the following steps: firstly, carrying out cleaning and sand-blasting roughen treatment on the surface of a substrate; secondly, blending epoxy resin, a curing agent and a first solvent to obtain an epoxy resin solution; thirdly, dispersing submicron particles and nanoparticles into a second solvent, and then adding a silane coupling agent to obtain particle composite suspension; fourthly, spraying the epoxy resin solution obtained in the second step on the surface of the substrate treated in the first step, and partially curing epoxy resin adhesive; fifthly, spraying the particle composite suspension obtained in the third step on the surface of the substrate obtained in the fourth step and completely curing; sixthly, obtaining the persistent icing-resistant superhydrophobic coating. The persistent icing-resistant superhydrophobic coating disclosed by the invention has the beneficial effects that the superhydrophobic coatings prepared on the surfaces of all the substrates have good durability and firmness and persistent icing-resistant property.

Owner:哈尔滨毓干科技有限公司

Super-hydrophobic coating and preparation method thereof

ActiveCN103753908ALow costBroaden applicationSynthetic resin layered productsPolyurea/polyurethane coatingsBoiling pointSolvent

The invention discloses a super-hydrophobic coating. The super-hydrophobic coating comprises an inorganic layer and an organic layer which are alternatively coated on a substrate, wherein the inorganic layer is an inorganic nanoparticle layer, the organic layer is an organic silicone-modified polyurethane layer, and the bottommost layer and the topmost layer are organic layers. The invention further discloses a preparation method for the super-hydrophobic coating, and is not required for expensive materials and instruments, low in cost and convenient to apply, and capable of carrying out large-area application work; the prepared super-hydrophobic coating has the advantages of being super-high in hydrophobicity, high in transparency and durability, and free from the damage of corrosive liquid, and has no special requirement on the material of the substrate, and the used solvent is non-toxic, low in boiling points, and easy to volatilize, and no residuals exist after the coating is formed.

Owner:ZHEJIANG UNIV

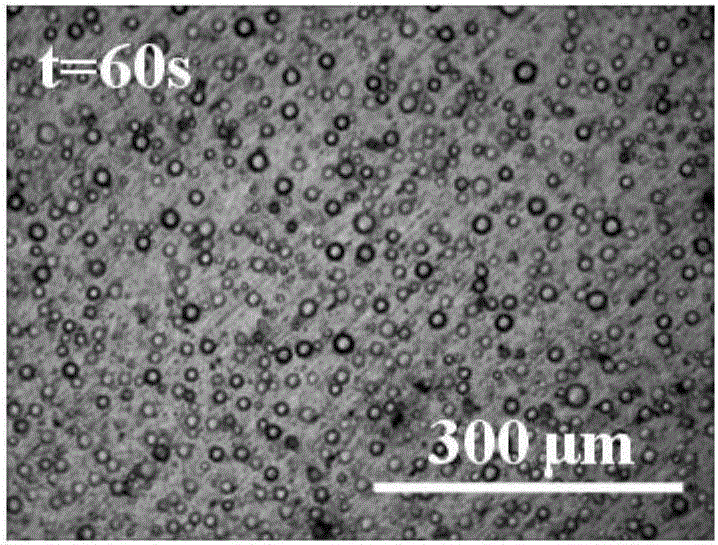

Super-hydrophilic particle hybridized super-hydrophobic coating and preparation method thereof

The invention relates to a super-hydrophilic particle hybridized super-hydrophobic coating and a preparation method thereof. A substrate is ultrasonically cleaned through acetone, absolute ethyl alcohol and deionized water in sequence for 15 min, and oil stain and dust on the surface are removed; then, absolute ethyl alcohol is used for elution, and cold-blast air is used for drying for use. Nanometer SiO2 sol is subjected to fluoroalkyl silane modification, a super-hydrophobic coating spraying solution is obtained, a super-hydrophilic monodisperse sphere type nanometer SiO2 solution, silica powder and glass beads are added into the super-hydrophobic coating spraying solution, stirred to be uniform and sprayed on the substrate, and after solidification, the super-hydrophilic particle hybridized super-hydrophobic coating is obtained. The coating has the low adhesion and super-hydrophobicity, and the condensation and dewfall efficiency and the dewdrop adsorption amount are remarkably high compared with a super-hydrophobic coating. The preparation technology is simple, no pollution is caused, operation is easy, the apparent mass is good, the cost is low, and wide application prospect and huge market benefits are achieved on the aspects of heat exchangers, water collection, seawater desalination and the like.

Owner:SOUTHEAST UNIV

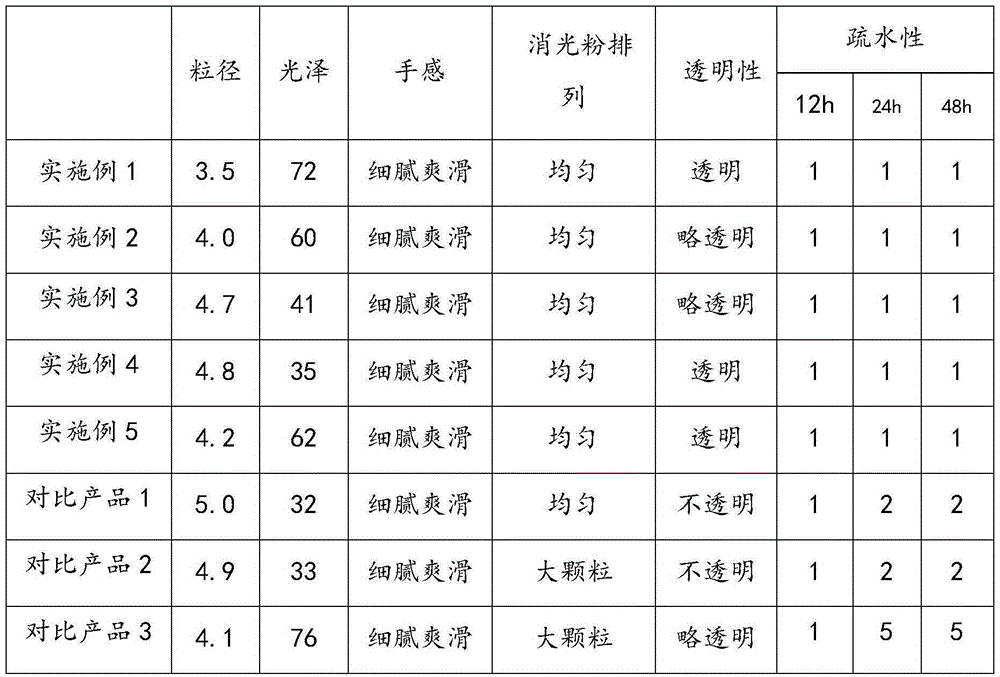

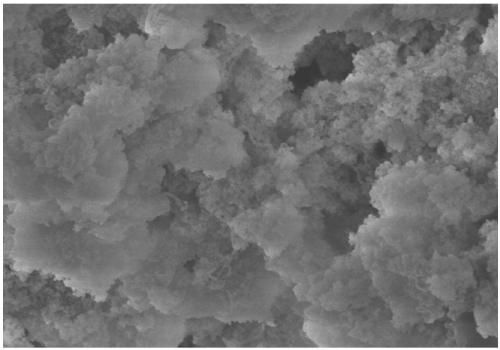

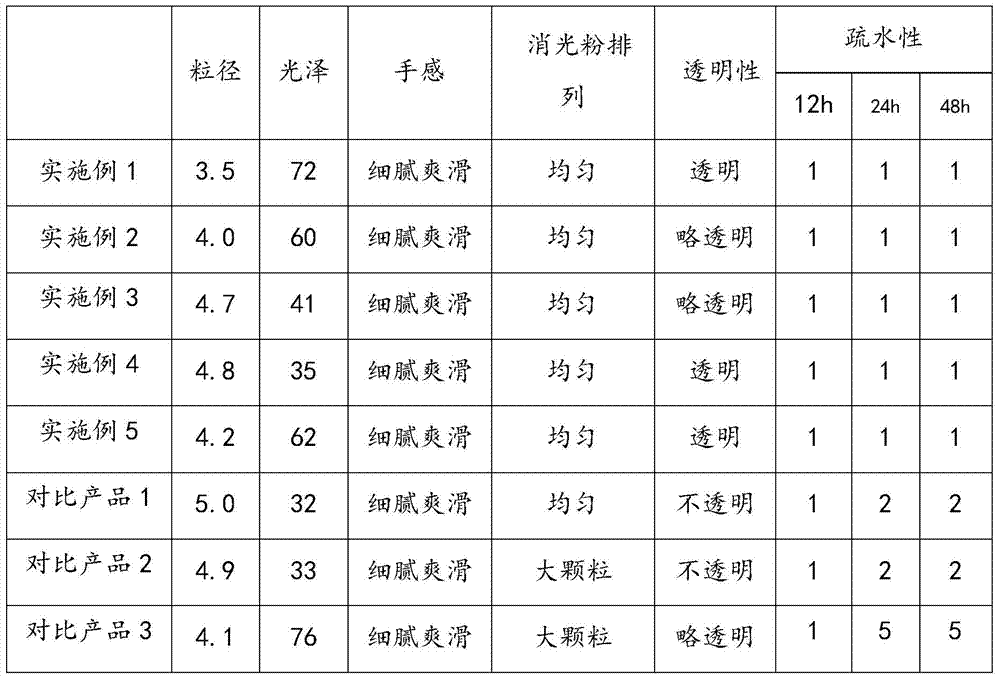

Preparation method of modified silicon dioxide obtained via super-hydrophobic modification

ActiveCN105400239AReduce post-processing stepsReduce energy consumptionCoatingsPigment treatment with macromolecular organic compoundsAcetic acidMixed states

The invention discloses a preparation method of modified silicon dioxide obtained via super-hydrophobic modification. The preparation method comprises following steps: 1) a raw material A (a silicon dioxide base material, dry powder) is delivered into a mixer, a mixed state is maintained, a raw material C (a super-hydrophobic modification accessory ingredient prepared via mixing of 1.5% acetic acid aqueous solution and isopropanol at a mass ratio of 1-3:4-10) is atomized, and is sprayed into the mixed uniformly, and stirring is kept; 2) a raw material B (a hydrophobic modification agent organic silane coupling agent) is atomized, and is sprayed into the mixer uniformly, and stirring is kept; 3) aging is carried out; and 4) ultrafine grinding is carried out so as to obtain a finished product. Fewer processing steps are needed; energy consumption is low; requirements of industrialized large-scale production can be satisfied; particle size distribution of the modified silicon dioxide obtained via super-hydrophobic modification is uniform; pore structures are stable; and hydrophobic performance is stable. The prepared super-hydrophobic silicon dioxide prepared via the preparation method is taken as a flatting agent, and can be used for providing paint with super hydrophobic performance; film forming coating particle arrangement is uniform; and luster is soft.

Owner:北京航天赛德科技发展有限公司

Fully-organic multiply-fluorinated epoxy super-hydrophobic composite coating and preparation method and utilization method thereof

ActiveCN105885564AImprove corrosion resistanceImprove wear resistanceAnti-corrosive paintsPolyether coatingsPolymer scienceCoating system

The invention discloses a fully-organic multiply-fluorinated epoxy super-hydrophobic composite coating and a preparation method and a utilization method thereof. The coating comprises a coating system and a curing agent; the coating system comprises epoxy resin, polytetrafluoroethylene particles, polyperfluoromethyl isopropyl ether and an organic solvent; the curing agent is prepared by reaction of diethylenetriamine and perfluorobutyric acid. The preparation method includes preparation of the coating system and preparation of the curing agent. The utilization method includes: dissolving the curing agent into a diluent, adding an obtained curing agent solution into the coating system, well mixing, coating to a required surface and curing. The fully-organic multiply-fluorinated epoxy super-hydrophobic composite coating has advantages of excellent super-hydrophobic property, favorable abrasion resistance, water impact resistance, corrosion resistance, high adhesive power, wide application range and the like. The preparation method is simple and easy to implement and suitable for large-scale application.

Owner:NAT UNIV OF DEFENSE TECH

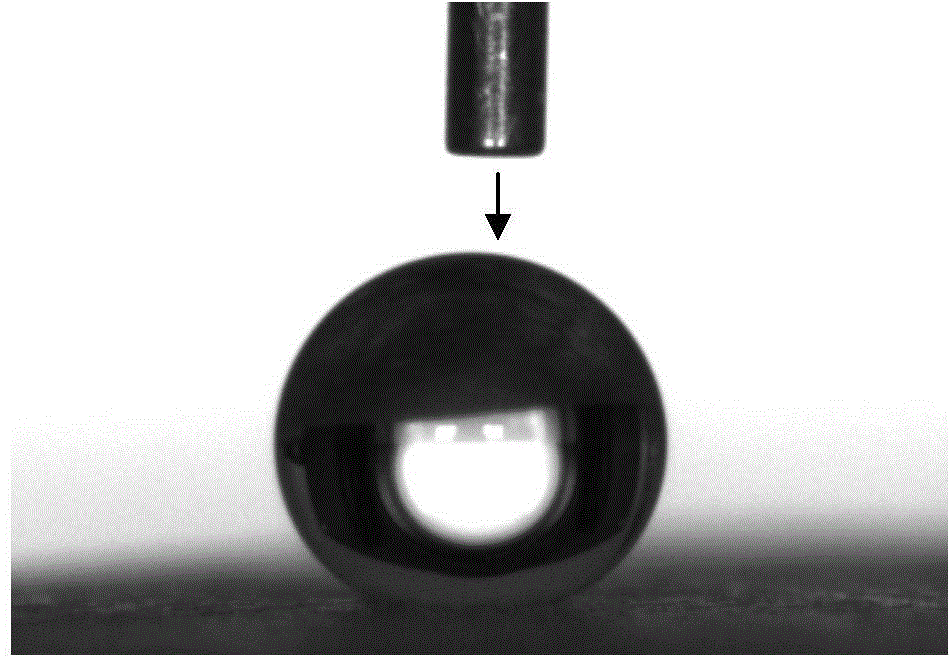

Preparation method of super-hydrophobic aluminum sheet

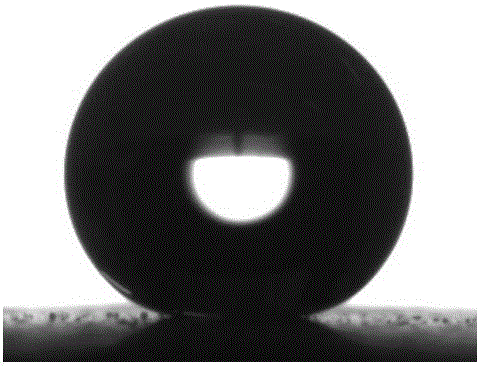

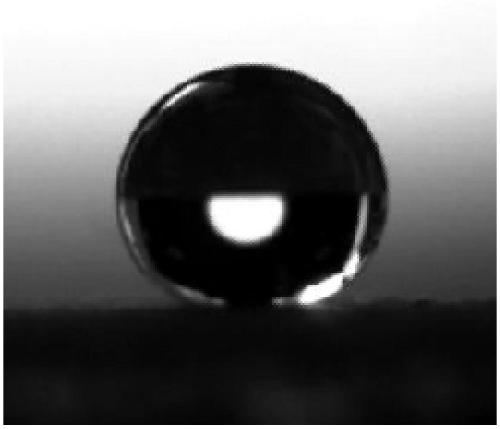

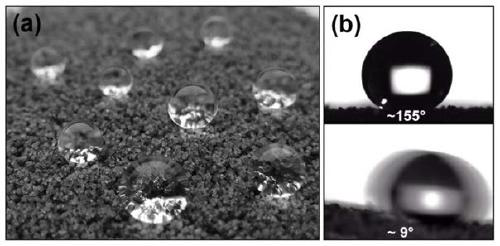

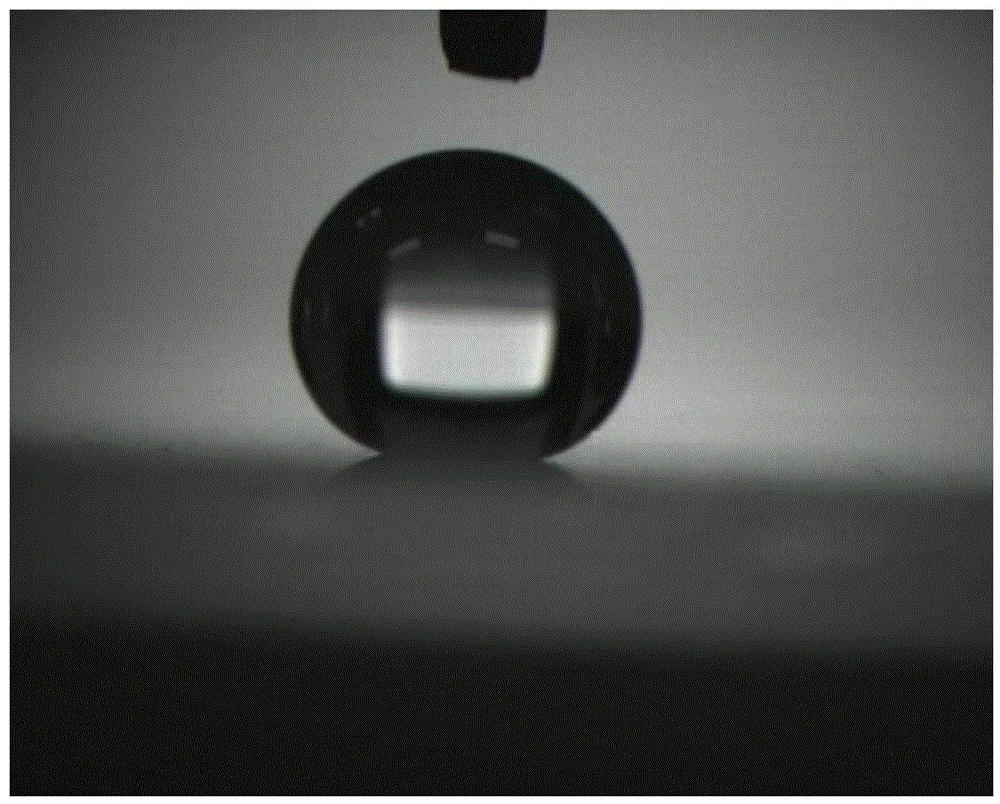

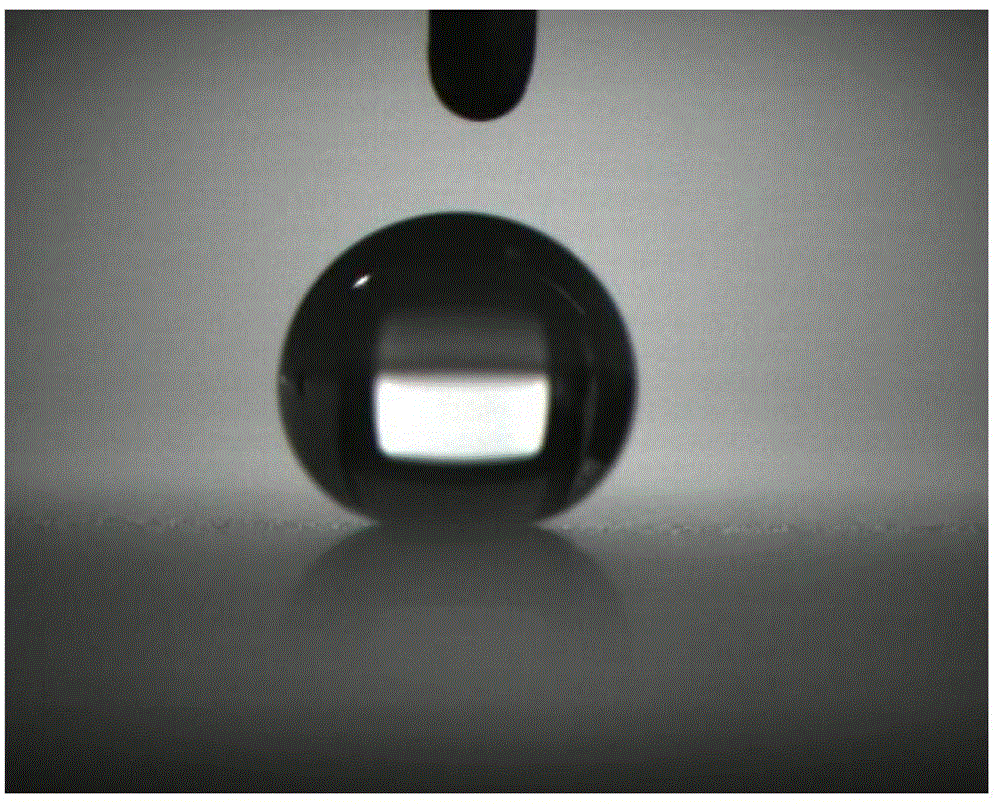

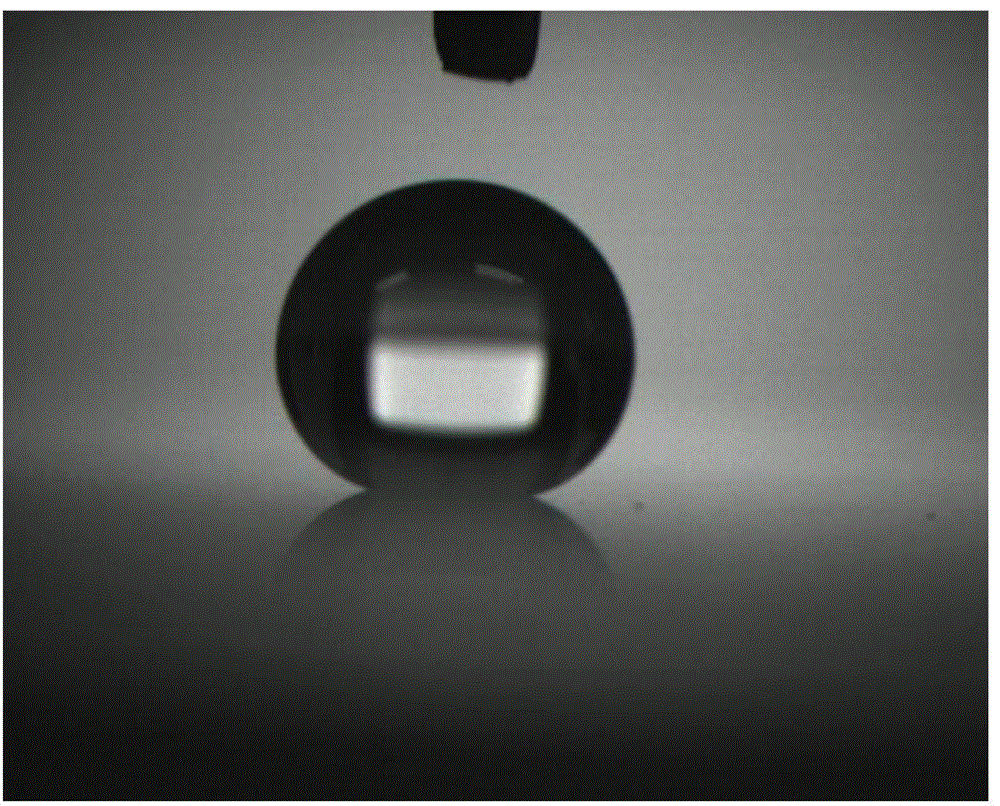

The invention relates to a preparation method of an aluminum sheet, in particular to a preparation method of a super-hydrophobic aluminum sheet. The preparation method of the super-hydrophobic aluminum sheet concretely comprises the steps of removing a surface oxidation layer of the aluminum sheet, then cleaning, baking, allowing the aluminum sheet to serve as a positive pole and inert metal as a negative pole, electrolyzing the positive pole and the negative pole, cleaning again, drying, placing the aluminum sheet in a surface modifier to be soaked, cleaning, then drying, and obtaining the super-hydrophobic aluminum sheet. According to the preparation method, materials are easy to obtain, low in cost, safe and nontoxic; sodium chloride serves as an electrolyte; a direct current power supply can be replaced by a dry battery; a container containing an electrolytic solution for electrolysis can be replaced by a glass cup; stearine and tetradecanoic acid are safe and nontoxic, does not pollute the environment, and can be purchased in the market easily; the steps are simple; the preparation is convenient; an aluminum or aluminium alloy super-hydrophobic surface prepared by the method has very good surface hydrophobicity; a contact angle of the super-hydrophobic surface is about 160 degrees; a rolling angle of the super-hydrophobic surface is about 9 degrees; longer super-hydrophobicity can be kept at room temperature; and articles for daily use, such as sodium chloride, the direct current power supply, a lead wire and absolute ethyl alcohol can be used for preparing the super-hydrophobic aluminum surface.

Owner:XIAMEN UNIV

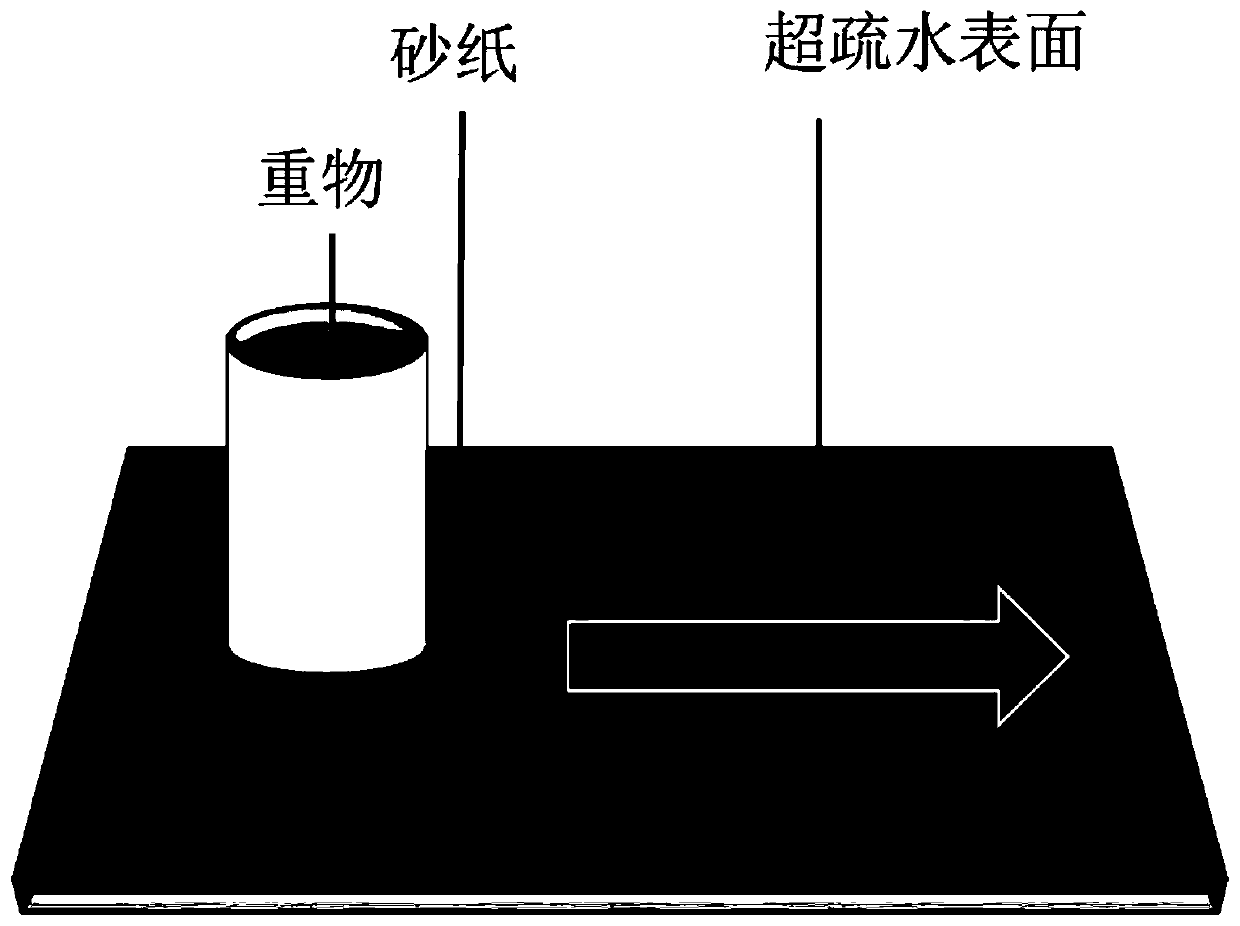

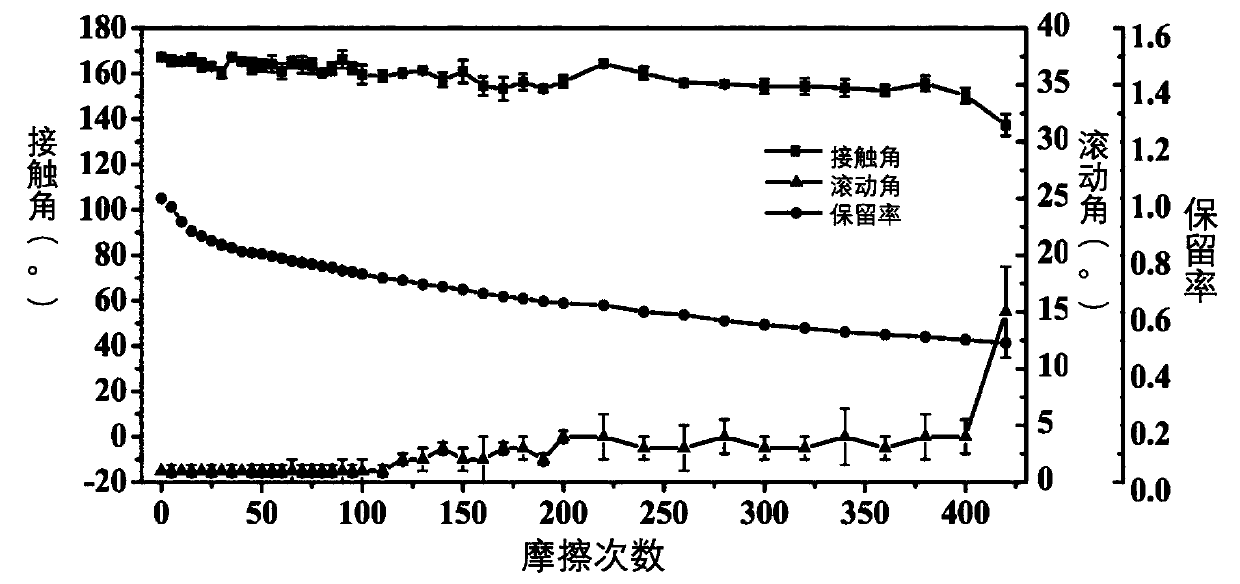

Wear-resistant superhydrophobic coating and preparation method thereof

ActiveCN109825165AExcellent superhydrophobic propertiesGood resistance to linear frictionAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention discloses a wear-resistant superhydrophobic coating and a preparation method thereof. The wear-resistant superhydrophobic coating comprises resin A and resin B, wherein the resin A is prepared from, by weight, 2.5g of hydrophobic epoxy resin, 0.6g-1.3g of a curing agent and 3g-4g of a diluent; the resin B is prepared from, by weight, 4g of hydrophobic epoxy resin, 0.96g-2.08g of a curing agent, 16g-60g of a diluent and 4g-16g of a filler. The preparation method includes: successively coating a substrate with the raw materials corresponding to the resin A and the resin B. The wear-resistant superhydrophobic coating has the advantages of good superhydrophobic performance, good linear wear resistance, good corrosion resistance, good adhesive tape adhesion resistance, good particle impact resistance and the like and is suitable for large-scale preparation and industrial application.

Owner:NAT UNIV OF DEFENSE TECH

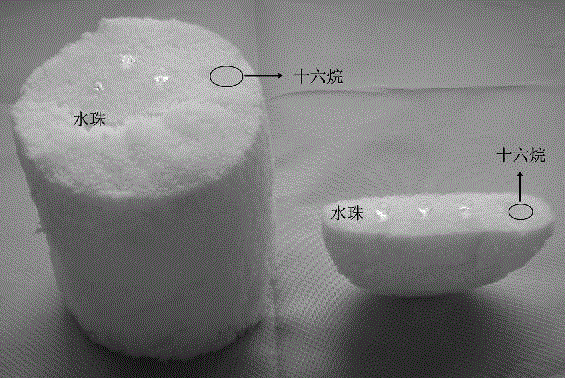

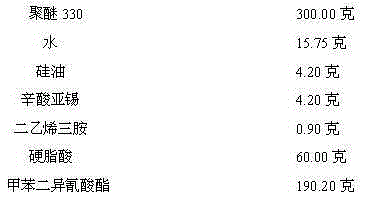

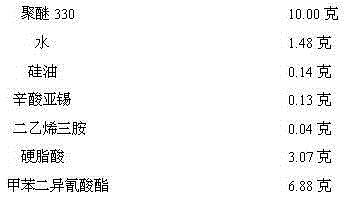

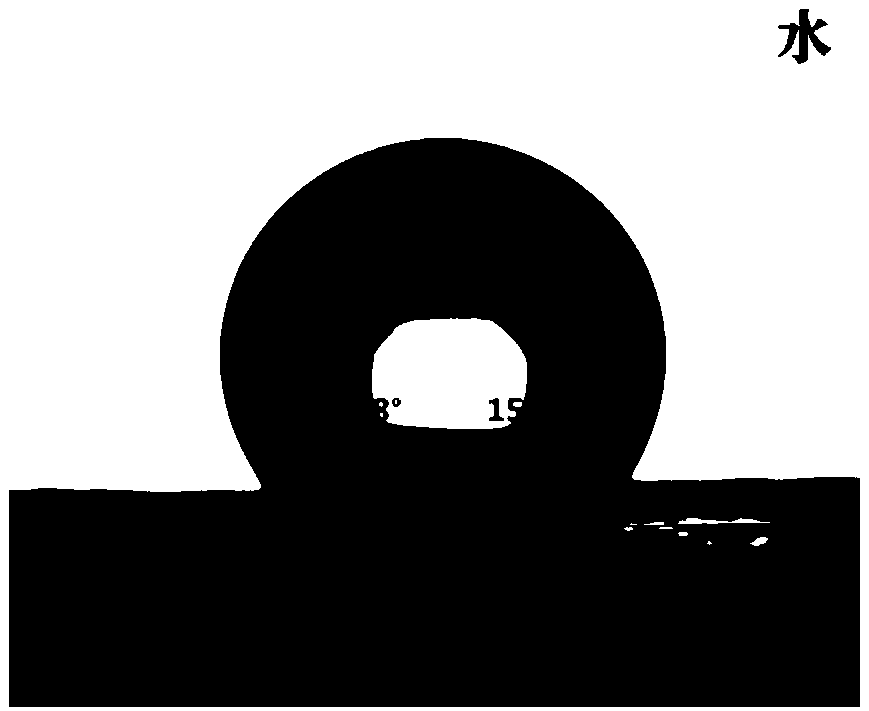

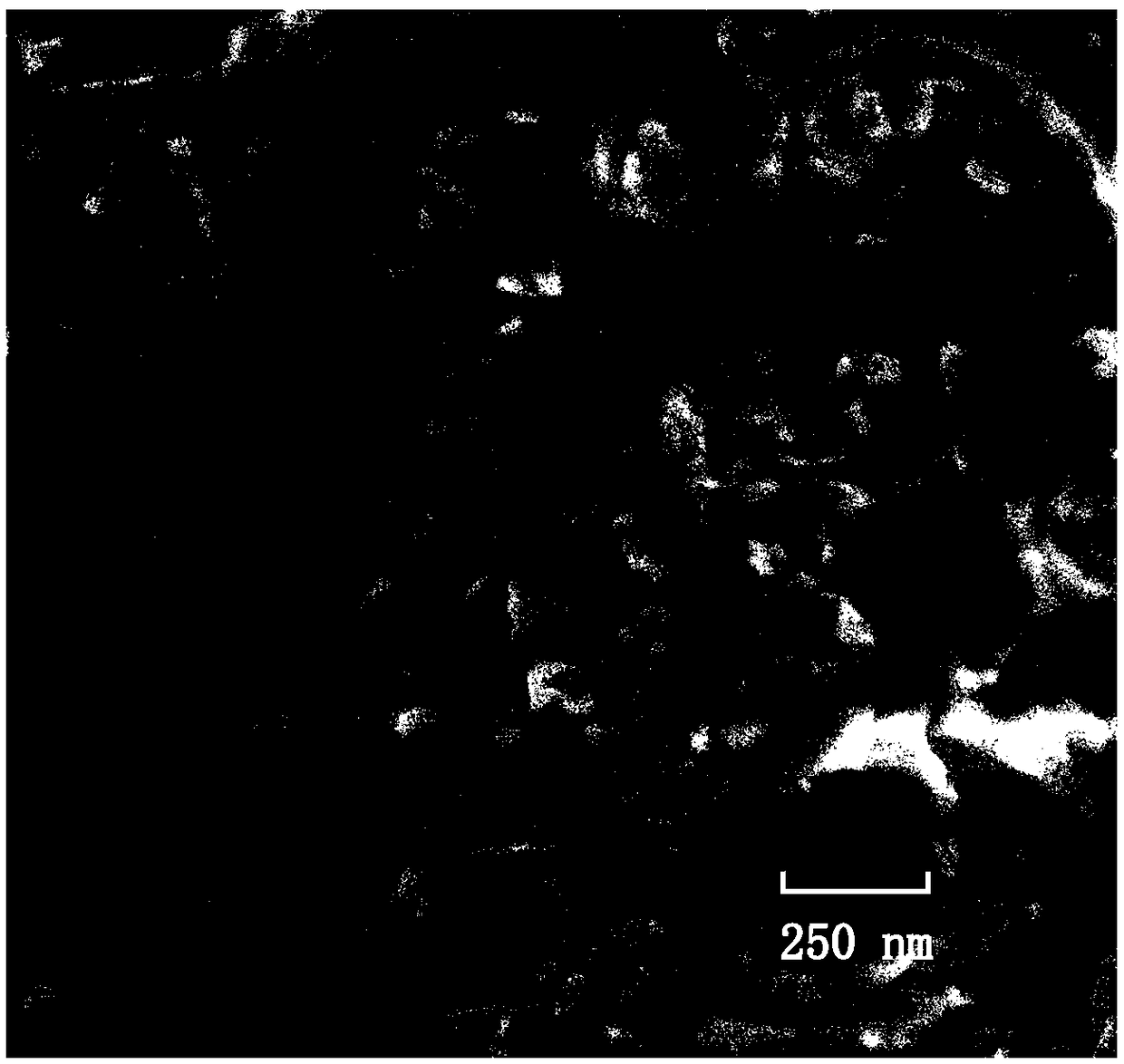

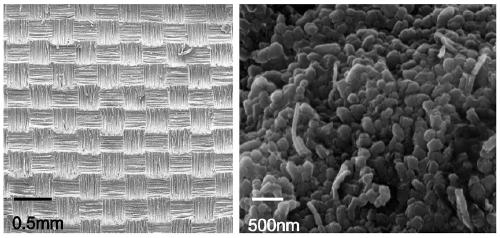

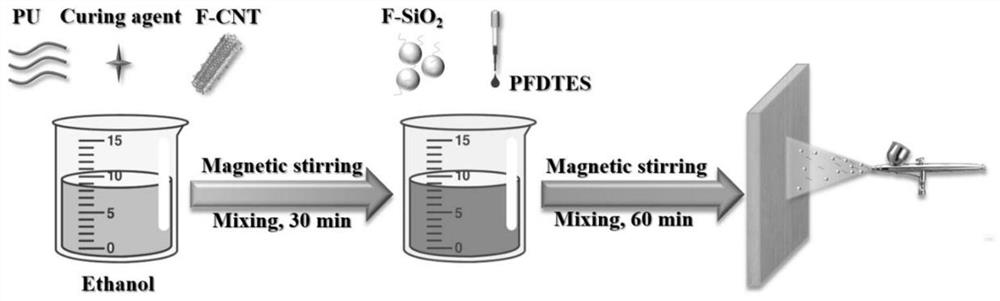

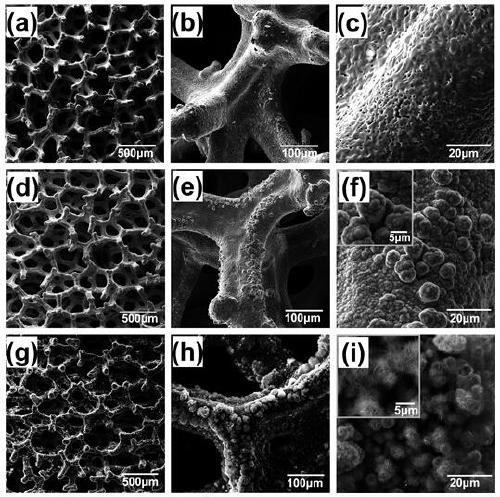

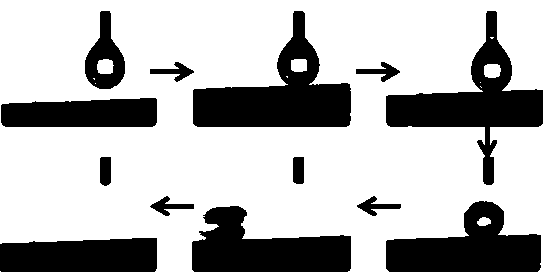

Method for preparing novel super-hydrophobic polyurethane oil-water separation material with no solvent

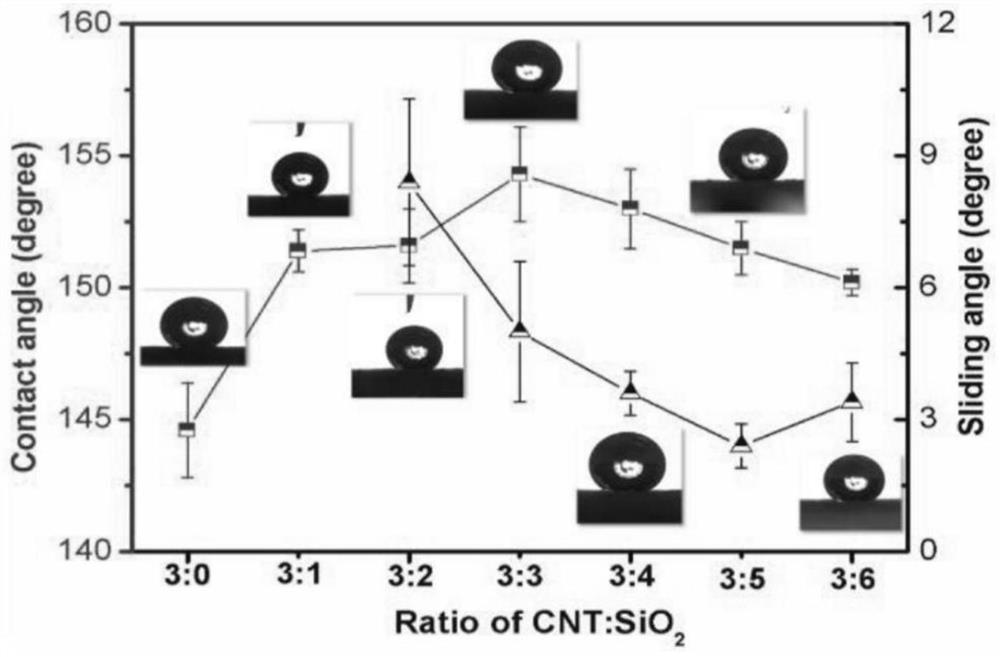

ActiveCN105251240AStay superhydrophobicIncrease roughnessLiquid separationDiethylenetriamineOil water

The invention discloses a method for preparing a novel super-hydrophobic polyurethane oil-water separation material with no solvent. The method comprises the following steps that stearic acid is dissolved in polyether330 through ultrasound, water, silicone oil, stannous octoate and diethylenetriamine are added on the conditions that the temperature is 30-40 DEG C and the rotating speed is 1000-1500 r / min, and stirring is carried out for 1-5 min; at the temperature of 30-40 DEG C, toluene diisocynate is added, and a reaction solution is foamed after 5-10 s; after foaming is carried out for 10-15 min, the product is taken out to be placed in a drying oven with the temperature of 50-70 DEG C and treated for 4-6 h to obtain the super-hydrophobic polyurethane foam. The defect that a large amount of solvent is used in a traditional preparation method is overcome, the raw material sources are wide, and super-hydrophobicity, super-lipophilicity and mechanical property stability are achieved through the polymerization reaction of gel materials, foaming materials and modified materials.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Superamphiphobic self-cleaned fluorosilicone coating material and preparation method thereof

ActiveCN108659600ASimple methodStable superphobicityAntifouling/underwater paintsPaints with biocidesSide effectAlcohol

The invention discloses a superamphiphobic self-cleaned fluorosilicone coating material which comprises raw materials, namely a fluorosilicone amphiphobic treatment agent and a solvent, wherein the fluorosilicone amphiphobic treatment agent is prepared from an amino alkyl silane coupling agent and a hexafluoro oxygen-containing propane tripolymer in a mole ratio of 1 to 1 through reactions at onestep; the solvent is an alcohol or water-alcohol mixed agent. The invention further discloses a method for preparing a superamphiphobic self-cleaned coating from the coating material. The method comprises the following steps: brushing or spraying the prepared coating material to the surface of a substrate, so as to obtain thesuperamphiphobic self-cleaned coating after the solvent is completely volatilized. The fluorosilicone coating material disclosed by the invention is simple in preparation process, a small number of types of raw materials with low cost are used, in addition, the material isfree of toxic and / or side effects on human beings or the environment. The prepared coating has superamphiphobic and self-cleaned functions, meanwhile has pH value stability and durability, and in addition is reversible in coating process, free of damage to base material surface colors or air permeability, applicable to nearly all building base material surfaces, and applicable to on-scale industrial production.

Owner:曹颐戬

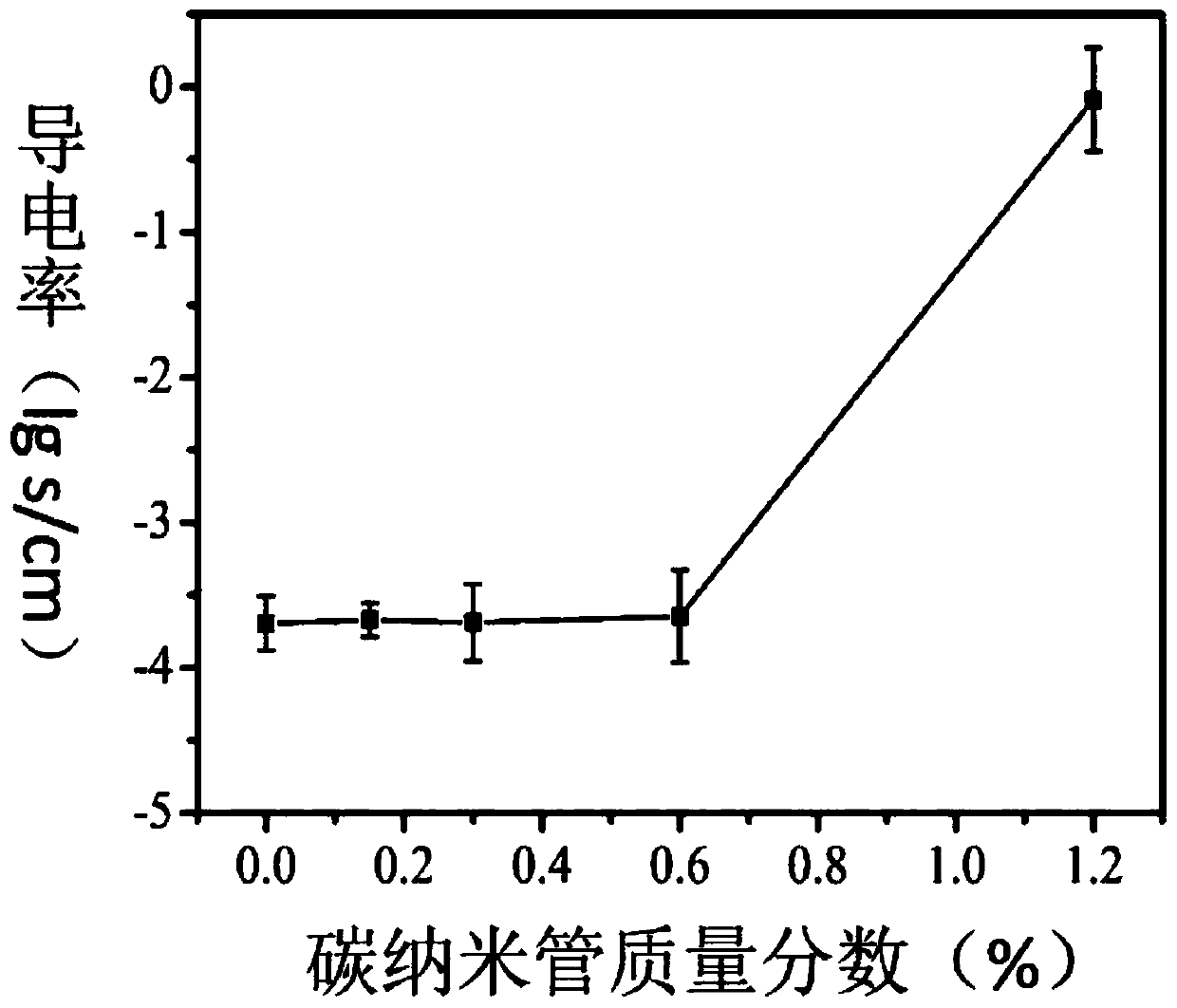

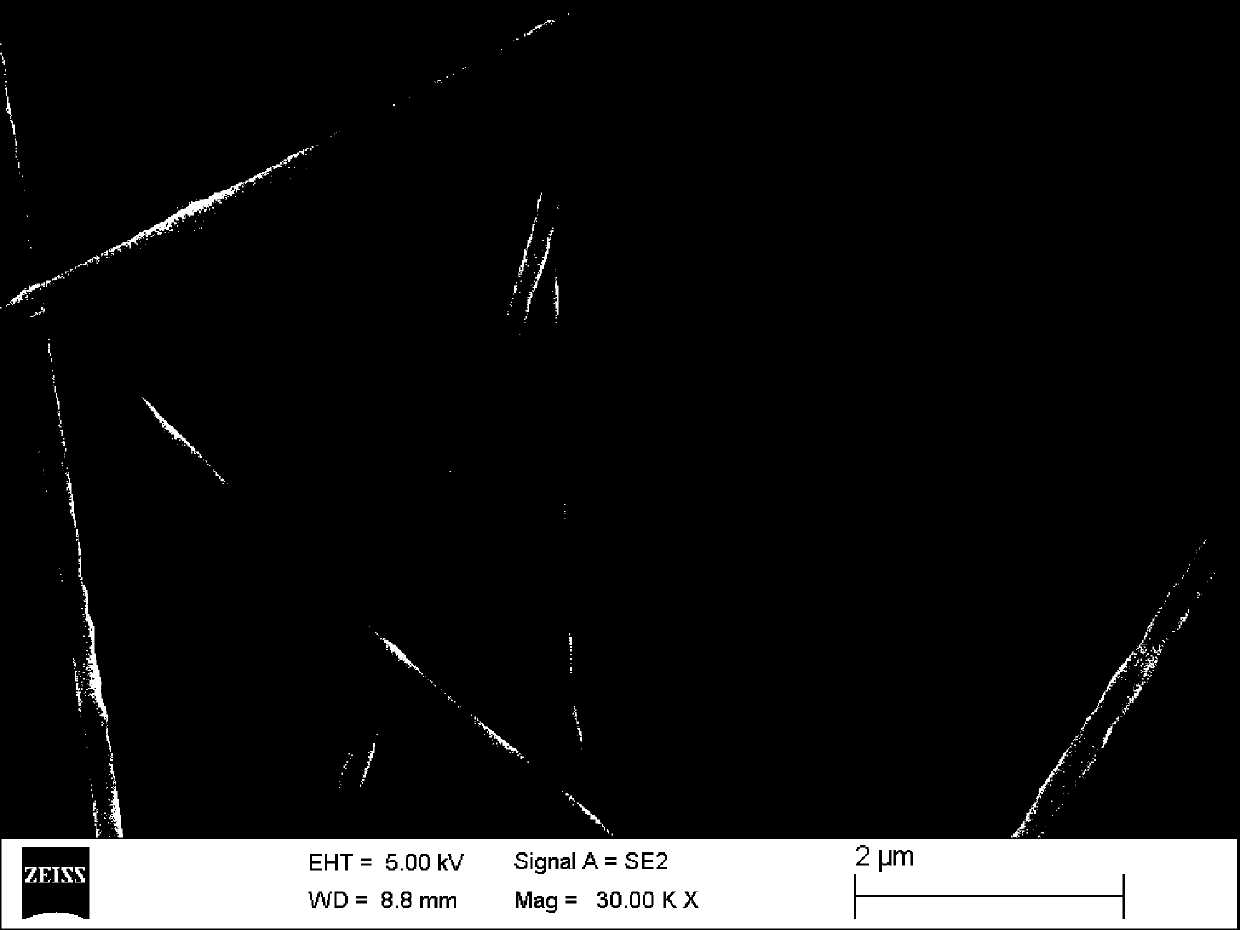

Epoxy-based super-hydrophobic fiber reinforced composite material and preparing method thereof

ActiveCN109777012AImprove corrosion resistanceExcellent superhydrophobic propertiesEpoxyTetrafluoroethylene

The invention discloses an epoxy-based super-hydrophobic fiber reinforced composite material and a preparing method thereof. The composite material includes a fiber fabric, and a resin and filler part, wherein the resin and filler part includes 100 g of epoxy resin, 220-400 g of polytetrafluoroethylene particles, 242-610 g of an organic solvent, 25-40 g of a curing agent and 3-6 g of carbon nanotubes. The method includes preparing the resin and filter part, preparing a prepreg material and curing the prepreg material to obtain the composite material. The composite material has good super-hydrophobic performance, good wear resistance, good corrosion resistance, good resistance to water flow shock, good adhesive force, high electrical conductivity, and the like, and has high application value and a good application prospect. The method is simple in process and convenient to operate, is suitable for large-scale preparation and facilitates industrial application.

Owner:NAT UNIV OF DEFENSE TECH

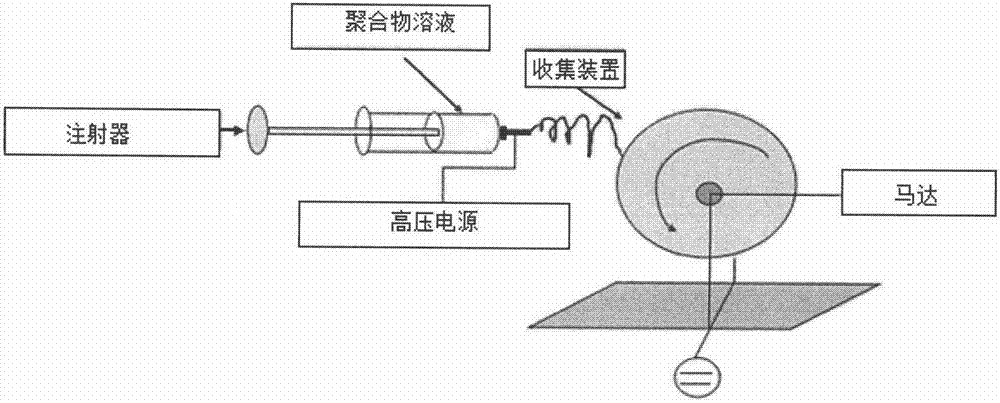

Fluorinated graphene-containing waterproof and moisture-permeable composite fabric and preparation method thereof

ActiveCN110973743AReduce weightGood water repellencySynthetic resin layered productsLaminationFiberHuman body

The invention belongs to the field of electrostatic spinning functional materials, and relates to a preparation method of a material capable of being applied to the waterproof and moisture permeable field, in particular to a fluorinated graphene-containing waterproof and moisture-permeable composite fabric and a preparation method thereof. The composite fabric has the advantages of super-hydrophobicity, high efficiency, better air and moisture permeability, energy conservation and the like. The average diameter of the fiber is 130 to 150 nm, the nanofiber waterproof and moisture permeable composite film is of a three-dimensional network structure, the hole diameter is small, a curved communication hole structure is formed, breathability is good, external severe weather infringement can beeffectively avoided, rain and snow penetration is prevented, sweat and moisture generated by movement of a human body can be discharged in time, so that the microenvironment of the human body is regulated and controlled, good comfort is provided for the human body, the protection function and the heat and moisture comfort of the garment fabric are unified, and the composite fabric is innovativelyapplied to the fields of medical treatment and public health, building outer walls, aerospace, aquatic product industry and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Fluorine-free polyphenylene sulfide super-hydrophobic coating and preparation method thereof

ActiveCN109337573AImprove anti-corrosion performanceExtend the invasion pathFireproof paintsAnti-corrosive paintsFiberNanofiber

The invention discloses a fluorine-free polyphenylene sulfide super-hydrophobic coating. The fluorine free polyphenylene sulfide super-hydrophobic coating is characterized by being prepared from the following raw materials in parts by weight: 70-95 parts of polyphenylene sulfide resin, 5-30 parts of silicone resin, 0.1-10 parts of nano sheet particles, 0.5-10 parts of nano fibers, 0.1-3 parts of cysteine, 200-500 parts of ethanol, 10-30 parts of water and 10-30 parts of a surfactant. The invention also discloses a method of preparing the fluorine-free polyphenylene sulfide super-hydrophobic coating. The coating solves the problems that an existing polyphenylene sulfide super-hydrophobic coating needs the addition of fluorine-containing substances and the wear resistance of the existing polyphenylene sulfide super-hydrophobic coating is insufficient.

Owner:NORTHEAST GASOLINEEUM UNIV

Preparation method and application of ultra-hydrophobic coating

InactiveCN104292890AStay superhydrophobicWith self-cleaning functionPretreated surfacesAnti-corrosive paintsDip-coatingSuperhydrophobic coating

The invention provides a preparation method of an ultra-hydrophobic coating. The preparation method includes following steps: (1) forming an inorganic substance coating by an inorganic dispersing system on a base material; and (2) performing surface modification to the inorganic substance coating obtained through the step (1) with fluorine-containing chlorosilane. In the step (1), the inorganic dispersing system including inorganic substance particles and a surfactant coats a surface of the base material in manners of spraying, brushing, spin-coating and dip-coating. In the step (2), the base material with the inorganic substance coating thereon is impregnated in a fluorine-containing chlorosilane solution for 1-24 hours and then the coating is dried to form the ultra-hydrophobic coating. A test result proves that the ultra-hydrophobic coating can be maintained to have an ultra-hydrophobic property even being soaked in a concentrated acid or concentrated alkali solution. The ultra-hydrophobic coating, due to the durable ultra-hydrophobic property, has a self-cleaning function and an excellent corrosion-resistant performance. A contact angle of the ultra-hydrophobic coating after being corroded is more than 150 degrees.

Owner:SIEMENS AG

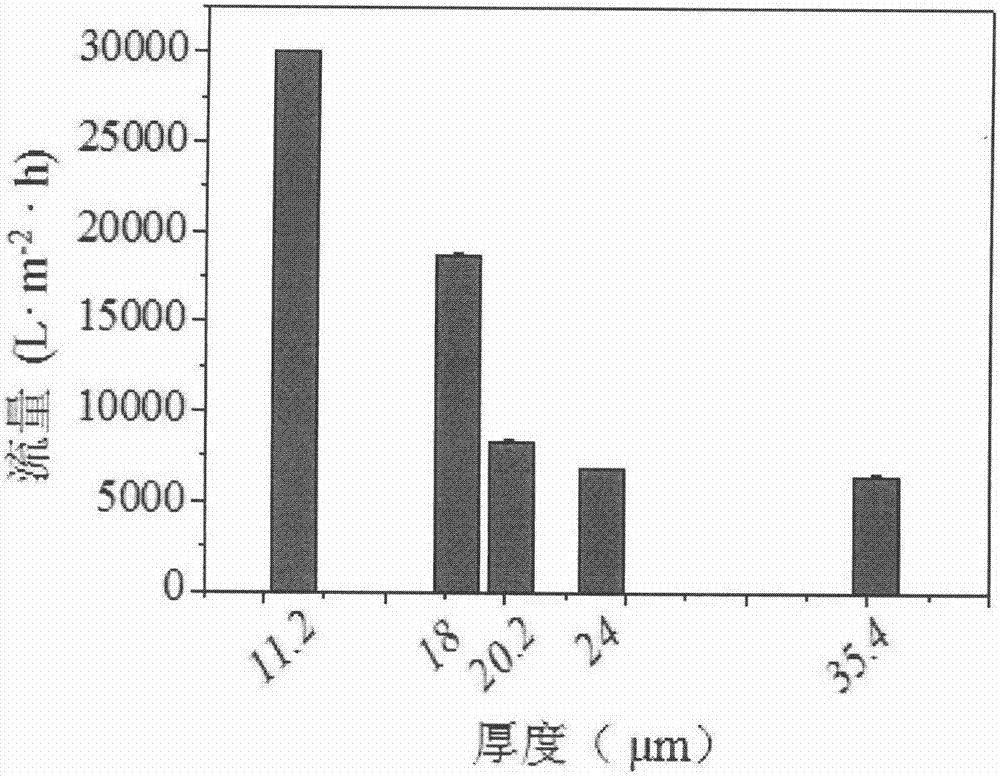

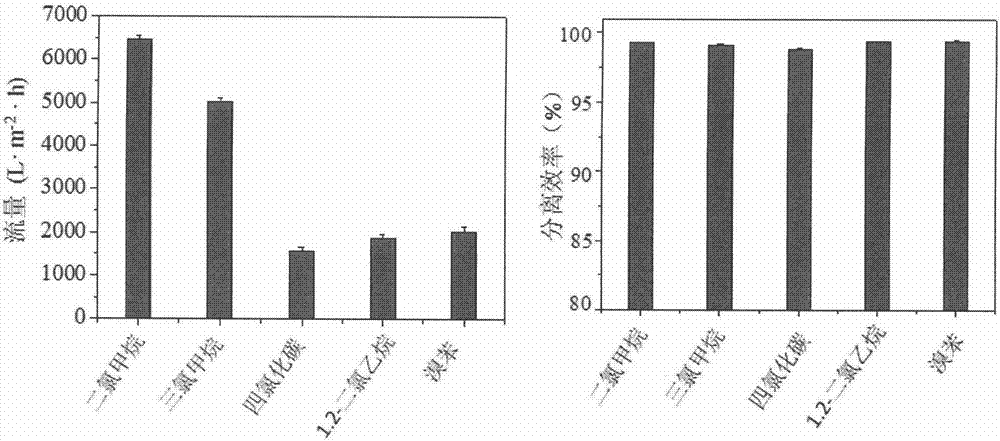

Preparation method of high-flux pH-responsive oil-water separation membrane

InactiveCN107321192AHigh separation flowEasy to separateSemi-permeable membranesFatty/oily/floating substances removal devicesFiberSilica nanoparticles

The invention relates to a preparation method of a high-flux pH-responsive oil-water separation membrane. The preparation method comprises: synthesizing polyamide acid (PAA); electro-spinning a PAA nanometer fiber membrane, and imidizing the PAA nanometer fiber membrane to a polyimide (PI) membrane; preparing pH-responsive silica nanoparticles (SNPs) / DA-TiO2 sol; modifying the PI nanometer fiber membrane with SNPs / DA-TiO2; characterizing pH responsiveness of the SNPs / DA-TiO2 / PI nanometer fiber membrane through a contact angle experiment; and testing the separation flux and efficiency via an oil-water separation experiment. The preparation method has advantages that through surface modification of a high-strength PI fiber membrane, a PI nanometer fiber membrane with biodegradability, low cost, nontoxicity, high flux and pH responsiveness is obtained. The high performance membrane material has bright application prospects in oil-water separation, sewage treatment and deep sea petroleum leakage.

Owner:NANJING FORESTRY UNIV

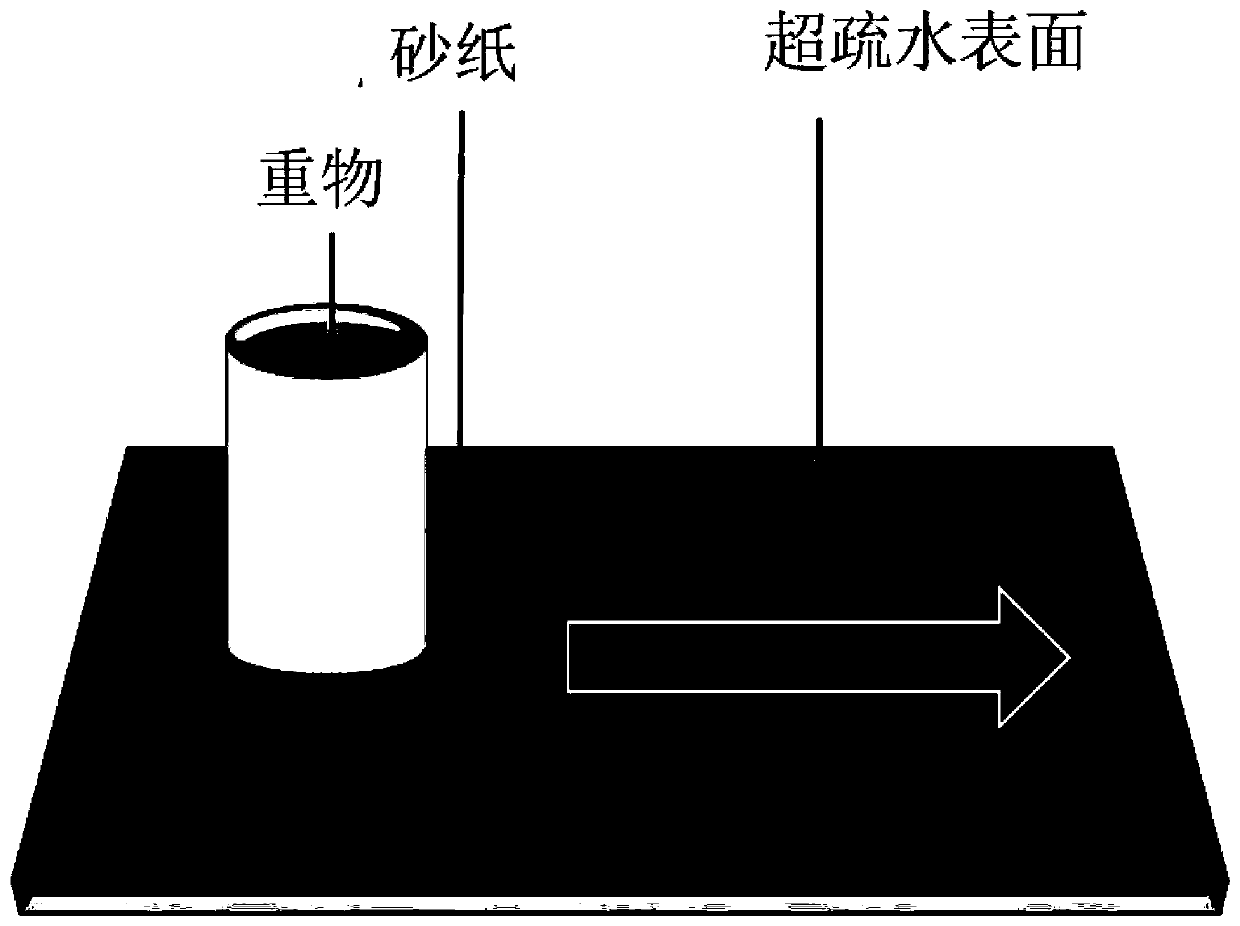

Preparation method of high-wear-resistance self-repairing super-hydrophobic coating

The invention provides a preparation method of a high-wear-resistance self-repairing super-hydrophobic coating. The preparation method comprises the following steps: step 1, adding a low-surface-energy siloxane solution into absolute ethyl alcohol, dispersing acetic acid into the solution, conducting magnetic stirring to obtain a solution A, mixing deionized water and ethanol to obtain an aqueous ethanol solution, adding a filler into the aqueous ethanol solution, performing ultrasonic dispersion to obtain a solution B, dropwise adding the solution B into the solution A, performing magnetic stirring, and centrifuging, cleaning and drying a precipitate to obtain a micron-sized modified filler and a nanometer modified filler; and step 2, adding the micron-sized modified filler, polyol and a curing agent into an ethanol solution, carrying out ultrasonic treatment, adding the nanometer modified filler and a siloxane solution, conducting stirring, spraying a formed mixture onto a substrate by using a spray gun, and subjecting the coated substrate to standing in an oven to obtain the super-hydrophobic coating. The high-durability super-hydrophobic coating prepared by the method disclosed by the invention is still a super-hydrophobic surface after being abraded by abrasive paper, scraped by a knife, scraped by a steel wire ball and the like, which proves that the coating has very high durability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

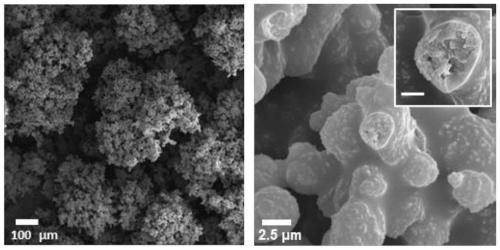

A kind of preparation method of superhydrophobic sand

ActiveCN106866010BSimple processRaw materials are easy to getCoatingsSpecial surfacesMaterials preparationWater contact

The invention belongs to the technical field of superhydrophobic material preparation, and particularly relates to a method for converting hydrophilic sand into super-hydrophobic sand. The method mainly comprises the following steps: carrying out the structured processing and the low surface energy substance modification of sand surfaces. The water contact angle of the prepared super-hydrophobic sand is greater than 150 degrees, and water can freely roll on the surface of the sand without permeating. In addition, the super-hydrophobic sand exhibits extremely good thermostability, and still has good hydrophobicity at a temperature of 400DEG C. Meanwhile, the super-hydrophobic sand can be used for realizing the storage and the transportation of water, and has a good drag reduction effect. The preparation method disclosed by the invention has the advantages of simple technology, abundant raw materials, no toxin, environment protection, low cost and high thermostability, is suitable for large-area preparation and application, can be applied to the surface of a building to realize a super-hydrophobic wall, and also can be applied to the storage and the transportation of desert water so as to realize the irrigation and transportation engineering of the water in a desert.

Owner:HUBEI UNIV

Preparation method and application of super-hydrophobic foam iron

ActiveCN111530126ANot corrosiveComposition is stableLiquid separationSuperhydrophobePhysical chemistry

The invention discloses a preparation method and application of super-hydrophobic foam iron. The preparation method comprises the following steps: firstly, electro-depositing a high-entropy alloy on super-hydrophilic foam iron, then carrying out super-hydrophobic surface treatment to obtain super-hydrophobic foam iron, and then applying the super-hydrophobic foam iron to a designed oil-water separation device to carry out oil-water separation. The method is simple in preparation process, low in production cost, green, efficient and suitable for large-scale industrial production. The prepared super-hydrophobic foam iron has the characteristics of self-cleaning, pollution prevention, long-term corrosion resistance, high oil-water separation efficiency and the like, the static contact angle of the super-hydrophobic foam iron is larger than 150 degrees, and the rolling angle of the super-hydrophobic foam iron is smaller than 10 degrees. The designed oil-water separation device can realizecontinuous oil-water separation and is suitable for oil-water separation of light oil and heavy oil, and has high separation efficiency in the separation process.

Owner:TAIYUAN UNIV OF TECH

Super hydrophobic aluminium alloy surface with wear resistance and heat resistance and preparation method thereof

ActiveCN109778169AReduce pollutionLow costAbrasion apparatusMetallic material coating processesWear resistantPerfluorooctanoic acid

The invention belongs to the field of new materials, and relates to the technical field of surface modification, and particular to a super hydrophobic aluminium alloy surface with wear resistance andheat resistance and a preparation method thereof. Aiming at the problem of poor mechanical durability of a super hydrophobic surface in the prior art, the technical scheme of the invention is that thepreparation method comprises the following steps: (1) performing pre-treatment on an aluminium alloy surface, namely, performing the pre-treatment on the aluminium alloy surface through a sand blasting process, and cleaning and drying the pre-treated aluminium alloy sample; and (2) soaking, namely, soaking the aluminium alloy sample which is treated by the step (1) in a perfluorooctanoic acid solution for performing surface modification, and drying to obtain the super hydrophobic aluminium alloy surface finally after the surface modification is completed. The preparation method is applicableto preparing super hydrophobic aluminium alloy materials in various fields, such as aerospace, navigation, bridges and buildings.

Owner:SOUTHWEST JIAOTONG UNIV

A kind of preparation method of superhydrophobic modified silicon dioxide

ActiveCN105400239BReduce post-processing stepsReduce energy consumptionCoatingsPigment treatment with macromolecular organic compoundsAcetic acidMixed states

The invention discloses a preparation method of modified silicon dioxide obtained via super-hydrophobic modification. The preparation method comprises following steps: 1) a raw material A (a silicon dioxide base material, dry powder) is delivered into a mixer, a mixed state is maintained, a raw material C (a super-hydrophobic modification accessory ingredient prepared via mixing of 1.5% acetic acid aqueous solution and isopropanol at a mass ratio of 1-3:4-10) is atomized, and is sprayed into the mixed uniformly, and stirring is kept; 2) a raw material B (a hydrophobic modification agent organic silane coupling agent) is atomized, and is sprayed into the mixer uniformly, and stirring is kept; 3) aging is carried out; and 4) ultrafine grinding is carried out so as to obtain a finished product. Fewer processing steps are needed; energy consumption is low; requirements of industrialized large-scale production can be satisfied; particle size distribution of the modified silicon dioxide obtained via super-hydrophobic modification is uniform; pore structures are stable; and hydrophobic performance is stable. The prepared super-hydrophobic silicon dioxide prepared via the preparation method is taken as a flatting agent, and can be used for providing paint with super hydrophobic performance; film forming coating particle arrangement is uniform; and luster is soft.

Owner:北京航天赛德科技发展有限公司

A kind of preparation method of highly transparent wear-resistant superhydrophobic composite coating

ActiveCN107022279BEasy to prepareWide applicabilityEpoxy resin coatingsWear resistantSuperhydrophobic coating

Owner:FUZHOU UNIV

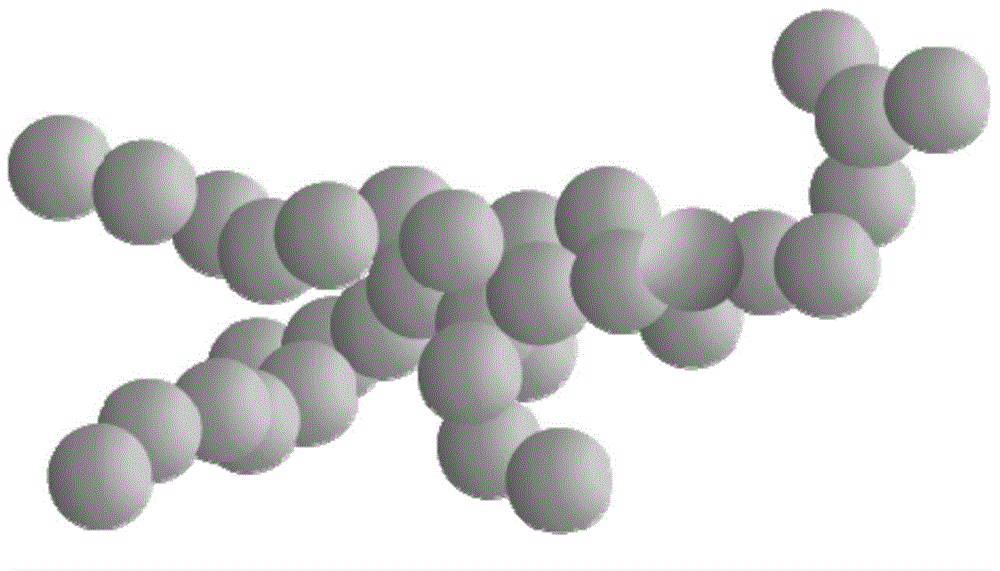

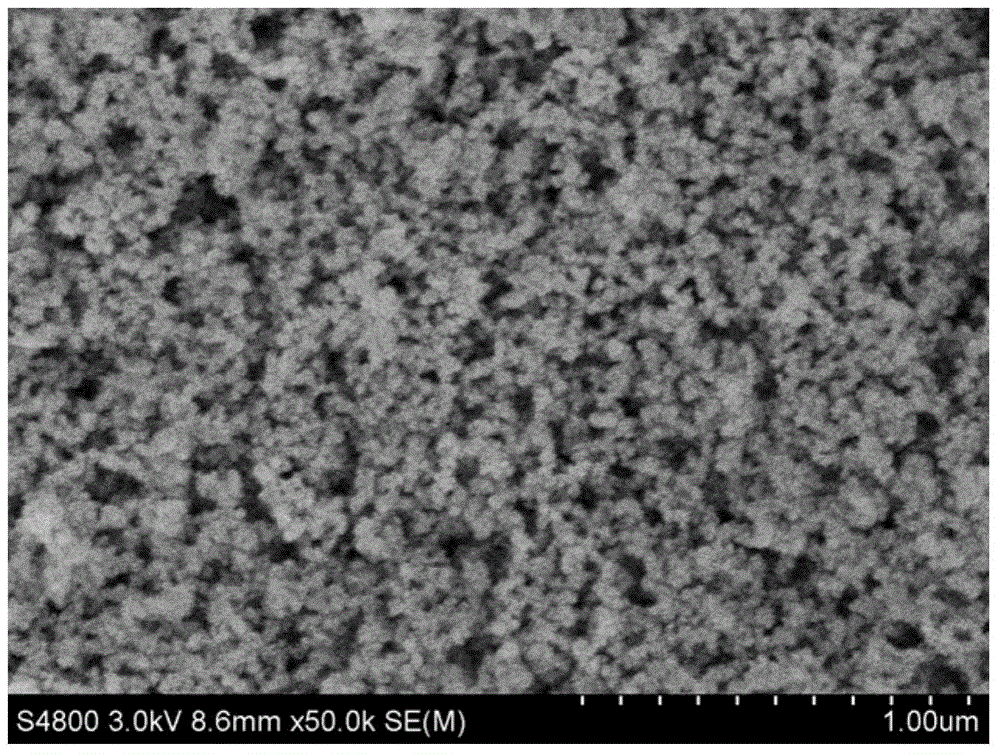

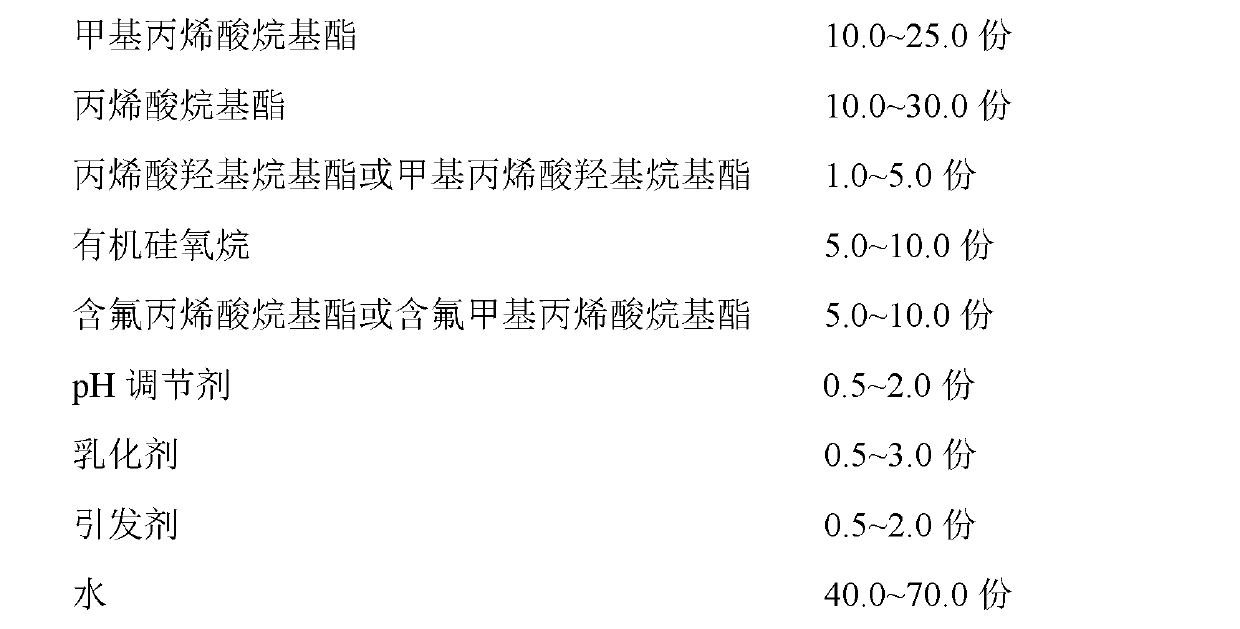

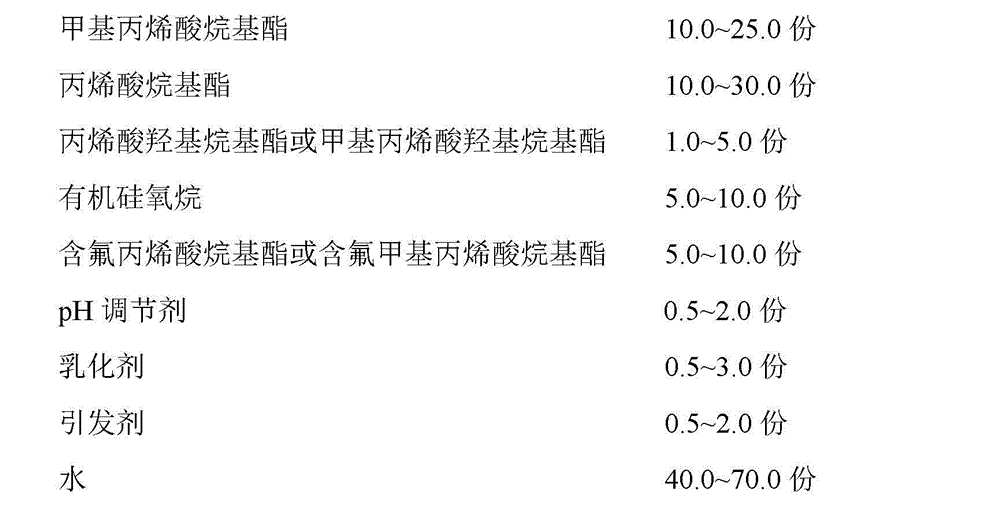

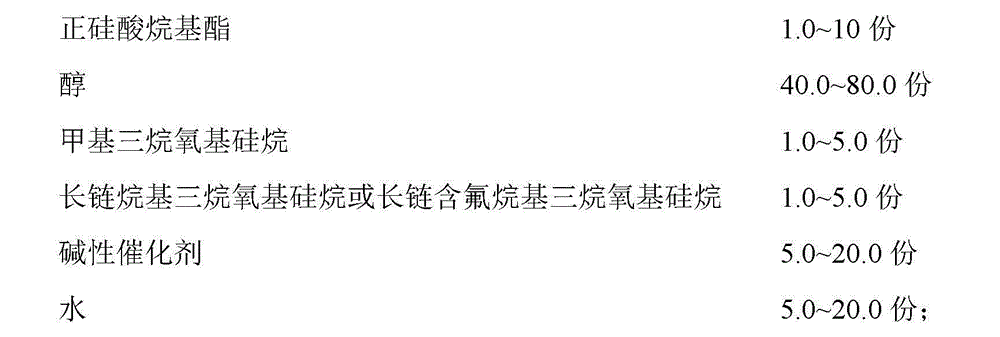

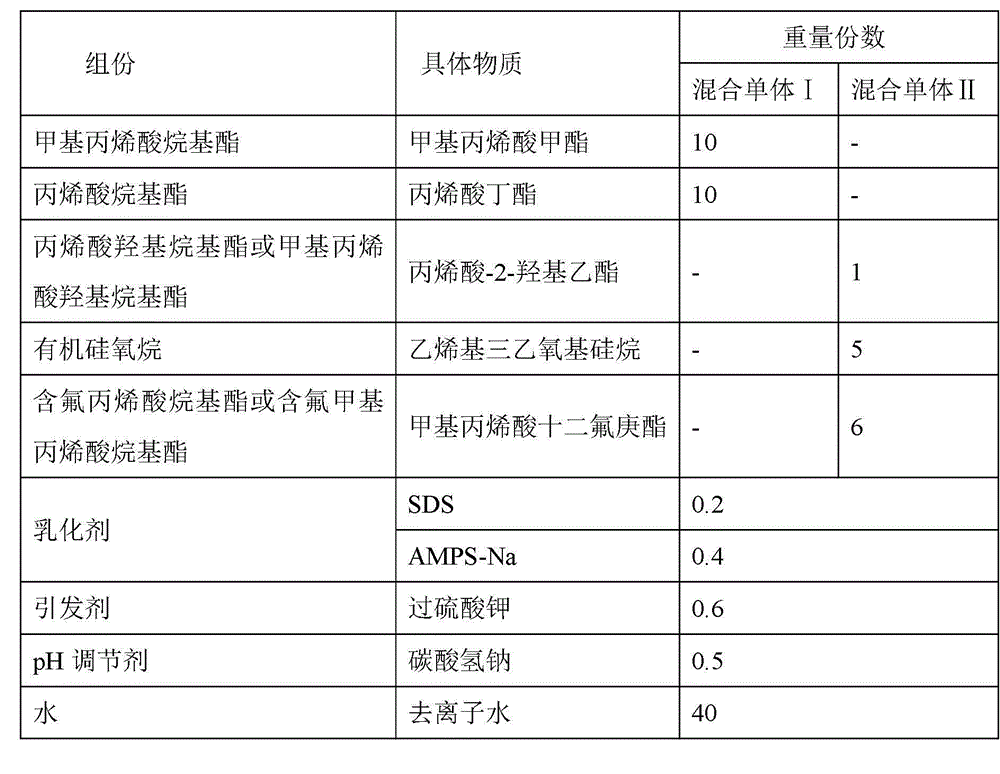

Preparation method of super-hydrophobic surface of glass

The invention relates to the field of super-hydrophobic surfaces. In order to solve the problems of poor binding force between the existing super-hydrophobic SiO2 micro-nano double rough structural layer and a glass substrate and insufficient hydrophobicity, the invention provides a preparation method of the super-hydrophobic surface of glass. The method comprises the following steps of: firstly, preparing fluorosilicone modified acrylic ester emulsion; secondly, preparing modified SiO2 sol; and finally preparing the super-hydrophobic surface of glass. The preparation method is simple and low in cost; a hydrophobic coating has excellent hydrophobicity and has excellent binding force with the glass; and the coating can maintain super-hydrophobicity for a long time.

Owner:HANGZHOU NORMAL UNIVERSITY

All-organic multi-fluorinated epoxy superhydrophobic composite coating and preparation method and use method thereof

ActiveCN105885564BImprove corrosion resistanceImprove wear resistanceAnti-corrosive paintsPolyether coatingsEpoxyOrganic solvent

The invention discloses a fully-organic multiply-fluorinated epoxy super-hydrophobic composite coating and a preparation method and a utilization method thereof. The coating comprises a coating system and a curing agent; the coating system comprises epoxy resin, polytetrafluoroethylene particles, polyperfluoromethyl isopropyl ether and an organic solvent; the curing agent is prepared by reaction of diethylenetriamine and perfluorobutyric acid. The preparation method includes preparation of the coating system and preparation of the curing agent. The utilization method includes: dissolving the curing agent into a diluent, adding an obtained curing agent solution into the coating system, well mixing, coating to a required surface and curing. The fully-organic multiply-fluorinated epoxy super-hydrophobic composite coating has advantages of excellent super-hydrophobic property, favorable abrasion resistance, water impact resistance, corrosion resistance, high adhesive power, wide application range and the like. The preparation method is simple and easy to implement and suitable for large-scale application.

Owner:NAT UNIV OF DEFENSE TECH

Transparent super-hydrophobic film and preparation method and application thereof

InactiveCN109338304AExcellent superhydrophobic propertiesGood light transmissionVacuum evaporation coatingSputtering coatingSputteringRadio frequency magnetron sputtering

The invention relates to a transparent super-hydrophobic film and a preparation method and application thereof. The transparent super-hydrophobic film comprises a zinc oxide film and a cetyl trimethoxysilane film loaded on the surface of the zinc oxide film, wherein the transparent super-hydrophobic film is 500 nm to 1000 nm thick, the visible light transmittance is 50% to 90%, the contact angle with water is 165 degrees or above, and the rolling angle with water is 2 degree or blow. The preparation method comprises the following steps: 1, preparing a zinc film by using the RF magnetron sputtering system, and then annealing the zinc film to obtain the zinc oxide film; and 2, modifying the zinc oxide film obtained in the step 1 to obtain the transparent super-hydrophobic film. The transparent super-hydrophobic film is used in building facades, window glass, optoelectronic devices or optical elements. The surface of the transparent super-hydrophobic film is of a nano-rod structure, and the film has excellent super-hydrophobic property, light transmission property, self-cleaning property and anti-fogging property, and can improve light transmittance of glass surface on rainy, snowy and foggy days and reduce glass surface stains.

Owner:CHONGQING UNIV

Preparation of chemically-stable super-hydrophobic wood

InactiveCN111805662AHas superhydrophobic propertiesGood dimensional stabilityWood treatment detailsWood impregnation detailsPolymer scienceMicrosphere

The invention provides a preparation method of chemically-stable super-hydrophobic wood, belonging to the technical field of functional modification of wood matrix surfaces. The preparation method comprises the following concrete steps: (1) synthesizing silicon dioxide microspheres by using a Stber method, and carrying out solution self-assembly on a low-surface-energy substance to obtain modifiedsilicon dioxide nanoparticles; (2) preparing a PDMS body mixed solution; (3) alternately dispensing SiO2 with particle sizes of 500 nm and 100 nm on the surface of wood to obtain a micro-nano structure surface; and (4) dispensing a PDMS layer for connection. According to the preparation method of the chemically-stable super-hydrophobic wood in the invention, the hydrophilic performance of the surface of the wood is changed, corrosion of corrosive liquid is effectively prevented, and the wood has good chemical stability. The problem that the stability of wood surface modification is poor is solved. The method is simple in preparation and low in cost, prolongs the service life of the wood, relieves the contradiction between supply and demand of the wood, and has wide application prospects.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Super-hydrophobic/super-oleophilic multilevel structure polyether sulfone oil-water separation membrane and preparation method thereof

ActiveCN110559882AExcellent superhydrophobic propertiesImprove corrosion resistanceMembranesSemi-permeable membranesPorositySilicon dioxide

The invention discloses a super-hydrophobic / super-oleophilic multilevel structure polyether sulfone oil-water separation membrane and a preparation method thereof and belongs to the technical field ofoil-water separation materials. The super-hydrophobic / super-oleophilic multilevel structure polyether sulfone oil-water separation membrane is prepared with two steps of a non-solvent induced phase method and a sol-gel method by taking polyether sulfone, silicon dioxide micro powder, tetraethyl silicate and hexadecyltrimethoxysilane as basic raw materials. The prepared super-hydrophobic / super-oleophilic multilevel structure polyether sulfone oil-water separation membrane has excellent super-hydrophobic property with a contact angle greater than 150 degrees, a rolling angle less than 10 degrees and an oil contact angle less than 10 degrees, has the characteristics of high porosity and high flux with the porosity reaching up to 79.59 percent and the flux reaching up to 2388.53L / h.m2, can effectively separate different kinds of water-in-oil emulsions as well as has the separation efficiency greater than 99 percent as for an emulsifier-free emulsion and greater than 98 percent as for an emulsifier-contained emulsion.

Owner:JILIN UNIV

A kind of super-oleophilic super-hydrophobic coating and its preparation method and application

ActiveCN109518462BSimple processRaw materials are easy to getLiquid repellent fibresNon-miscible liquid separationOrganic solventNanoparticle

The invention discloses a super-oleophilic and super-hydrophobic coating and its preparation method and application. The super-oleophilic and super-hydrophobic coating is mainly made of raw materials in the following proportions by weight: 50-100 parts of volatile organic solvent, slightly hydrophobic 0.1-2 parts of nanoparticles, 0.5-2 parts of water-resistant resin, and 0.05-0.2 parts of curing agent. The contact angle of the textiles prepared by using the coating of the present invention with water is greater than 150°, and the contact angle with oil droplets is close to 0°, and the treated textiles have good mechanical properties, UV resistance, acid and alkali resistance, and have certain self-repairing functions. After repeated oil-water separation experiments, the separation efficiency still remains above 95%. At the same time, the preparation process is simple and easy, the process is easy to control, non-toxic and harmless, and can be used for large-scale production.

Owner:SOUTHEAST UNIV

A kind of superhydrophobic coating and preparation method thereof

ActiveCN103753908BLow costGood light transmissionSynthetic resin layered productsPolyurea/polyurethane coatingsBoiling pointSolvent

The invention discloses a super-hydrophobic coating. The super-hydrophobic coating comprises an inorganic layer and an organic layer which are alternatively coated on a substrate, wherein the inorganic layer is an inorganic nanoparticle layer, the organic layer is an organic silicone-modified polyurethane layer, and the bottommost layer and the topmost layer are organic layers. The invention further discloses a preparation method for the super-hydrophobic coating, and is not required for expensive materials and instruments, low in cost and convenient to apply, and capable of carrying out large-area application work; the prepared super-hydrophobic coating has the advantages of being super-high in hydrophobicity, high in transparency and durability, and free from the damage of corrosive liquid, and has no special requirement on the material of the substrate, and the used solvent is non-toxic, low in boiling points, and easy to volatilize, and no residuals exist after the coating is formed.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com