Preparation method and application of super-hydrophobic foam iron

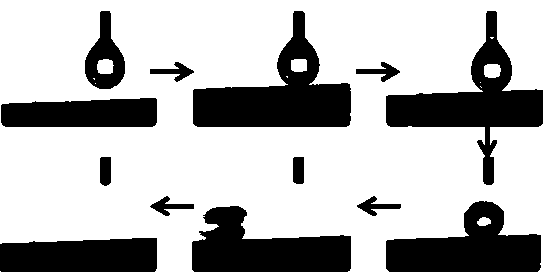

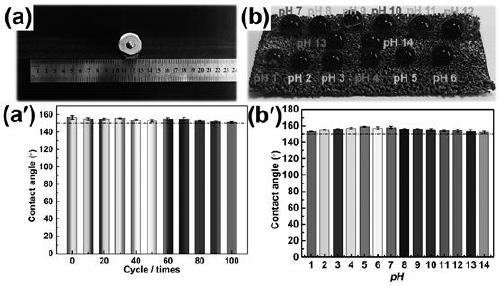

A foam iron and super-hydrophobic technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve problems such as endangering human health and cumbersome processes, and achieve low production costs, high separation efficiency, and good corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

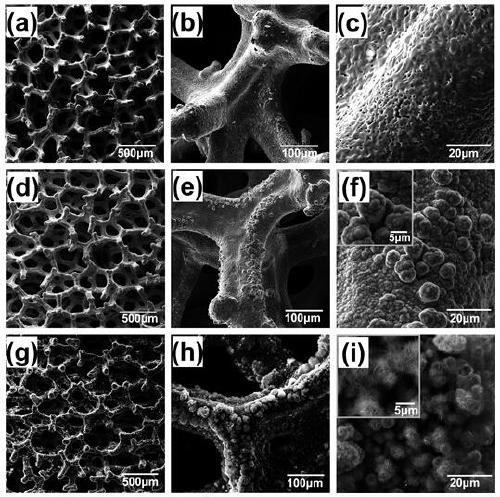

Embodiment 1

[0050] (1) Configuration of the high-entropy alloy electrolytic bath: first mix 0.01 mol / L zinc chloride, 0.01 mol / L ferric sulfate heptahydrate, 0.01 mol / L cobalt sulfate, 0.01 mol / L nickel sulfate and 0.01 mol / L of manganese sulfate is mixed and dissolved to form a mixed solution; then the mixed solution is added to the glycerin solution to obtain an organic system electrolytic bath with glycerin as the electrolyzer;

[0051] (2) Preparation of high-entropy alloy thin film: the foam iron sample to be plated is used as the cathode, and the platinum sheet is used as the anode, placed in the electrolytic bath prepared in step (1), and prepared by -3V constant potential polarization electrodeposition High-entropy alloy thin film, electrodeposition time is 10min;

[0052] (3) Preparation of superhydrophobic high-entropy alloy film: the foam iron sample containing high-entropy alloy film coating prepared in step (2) was first cleaned with deionized water and dried, and the sample...

Embodiment 2

[0062] (1) Configuration of the high-entropy alloy electrolytic bath: first mix 0.015mol / L zinc sulfate, 0.017mol / L ferric sulfate heptahydrate, 0.014mol / L cobalt chloride, 0.015mol / L nickel sulfate and 0.016mol / L of manganese sulfate is mixed and dissolved to form a mixed solution; then the mixed solution is added to the glycerin solution to obtain an organic system electrolytic bath with glycerin as the electrolyzer;

[0063] (2) Preparation of high-entropy alloy thin film: the iron foam sample to be plated is used as the cathode, and the platinum sheet is used as the anode, placed in the electrolytic bath prepared in step (1), and prepared by -2V constant potential polarization electrodeposition High-entropy alloy thin film, electrodeposition time is 15min

[0064] (3) Preparation of superhydrophobic high-entropy alloy film: the foam iron sample containing high-entropy alloy film coating prepared in step (2) was first cleaned with deionized water and dried, and the sample ...

Embodiment 3

[0066] (1) Configuration of the high-entropy alloy electrolytic bath: first mix 0.051mol / L zinc sulfate, 0.051mol / L ferric sulfate heptahydrate, 0.045mol / L cobalt chloride, 0.052mol / L nickel sulfate and 0.050mol / L of manganese chloride is mixed and dissolved to form a mixed solution; then the mixed solution is added to the glycerin solution to obtain an organic system electrolytic bath using glycerin as the electrolyte

[0067] (2) Preparation of high-entropy alloy thin film: the iron foam sample to be plated is used as the cathode, and the platinum sheet is used as the anode, placed in the electrolytic bath prepared in step (1), and prepared by -6V constant potential polarization electrodeposition High-entropy alloy thin film, electrodeposition time is 10min;

[0068](3) Preparation of superhydrophobic high-entropy alloy film: the foam iron sample containing high-entropy alloy film coating prepared in step (2) was first cleaned with deionized water and dried, and the sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com