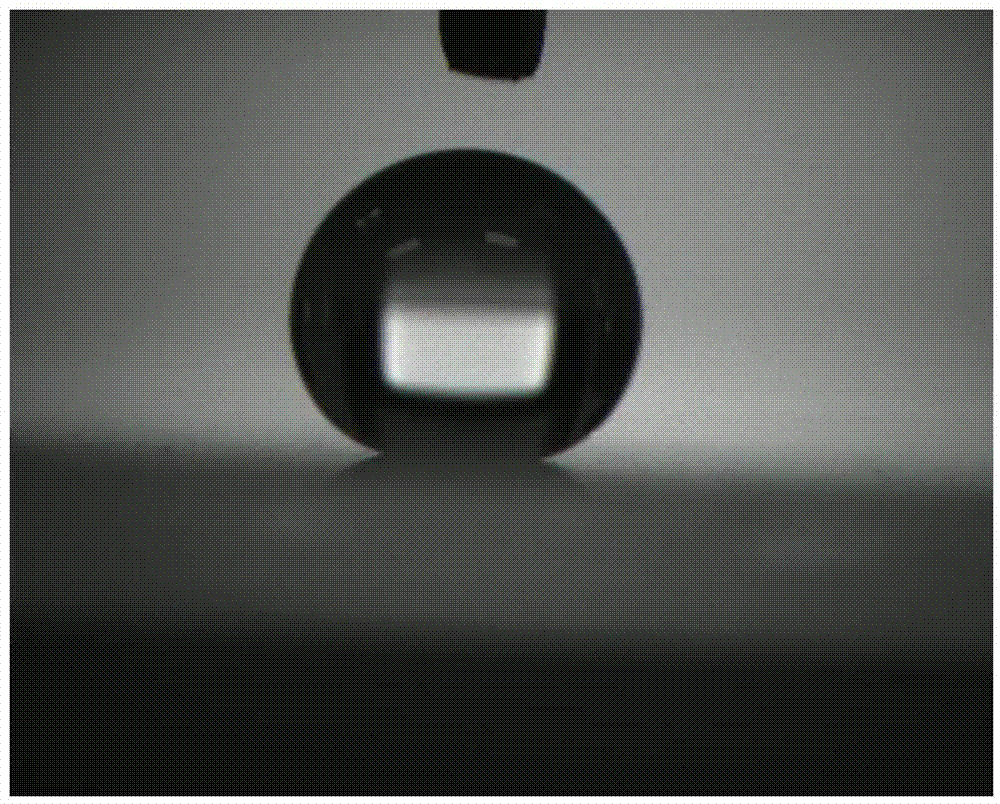

Super-hydrophobic coating and preparation method thereof

A super-hydrophobic coating and coating technology, which is applied in the direction of coatings, chemical instruments and methods, and layered products, can solve the problems of high potential hazards, poor coating transparency, and easy residue, etc., and achieve low cost and easy application. Convenience, good durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1, Sol-gel method to prepare nano-silica nanoparticle dispersion: add 100mL deionized water and 40mL tetraethyl orthosilicate to 600mL absolute ethanol, add 14mL concentrated ammonia water drop by drop under stirring to obtain a particle size of about 100nm The mass fraction is 20% ethanol dispersion of silica particles.

[0049]2. Preparation of silicone-modified polyurethane: use aminoethylaminopropylmethyldimethoxysilane and hydroxyl silicone oil (hydroxyl content 3%) to react to obtain amino-terminated silicone, dissolve it in isopropanol, and use TDI and dimethoxysilane Hydroxyl polyether (PPG, hydroxyl content 4.2%) was reacted to obtain a polyurethane prepolymer with an isocyanate content of 10%, dissolved in isopropanol, and the amino-terminated silicone solution and the polyurethane prepolymer solution were mixed and reacted at a molar ratio of 2:1 Obtaining mass fraction is 1% organosilicon modified polyurethane solution, the infrared spectrum of intermedia...

Embodiment 2

[0058] 1, Preparation of nano-silica dispersion by sol-gel method: add 100mL deionized water and 40mL tetraethyl orthosilicate to 600mL absolute ethanol, add 14mL concentrated ammonia water drop by drop under stirring, and obtain a particle size of about 100nm The fraction is 20% silica ethanol dispersion.

[0059] 2. Preparation of silicone-modified polyurethane: react with aminoethylaminopropylmethyldimethoxysilane and hydroxyl silicone oil to obtain amino-terminated silicone (3% hydroxyl content), dissolve it in isopropanol, and use TDI and dihydroxy Polyether (PPG, hydroxyl content 4.2%) is reacted to obtain a polyurethane prepolymer with an isocyanate content of 10%, which is dissolved in isopropanol, and the amino-terminated silicone solution and polyurethane prepolymer solution are mixed and reacted at a molar ratio of 1:2 to obtain Silicone-modified polyurethane solution with a mass fraction of 0.5%.

[0060] 3. Spin-coat the organosilicon-modified polyurethane solu...

Embodiment 3

[0064] 1, Preparation of nano-silica dispersion by sol-gel method: add 100mL deionized water and 40mL tetraethyl orthosilicate to 600mL absolute ethanol, add 14mL concentrated ammonia water drop by drop under stirring, and obtain a particle size of about 100nm A 20% silica isopropanol dispersion.

[0065] 2. Preparation of silicone-modified polyurethane: react with aminoethylaminopropylmethyldimethoxysilane and hydroxyl silicone oil to obtain amino-terminated silicone (5% hydroxyl content), dissolve it in isopropanol, and use MDI and dihydroxy Polyether (PPG, hydroxyl content 4.2%) is reacted to obtain a polyurethane prepolymer with an isocyanate content of 10%, which is dissolved in isopropanol, and the amino-terminated silicone solution and polyurethane oligomer solution are mixed and reacted at a molar ratio of 2:1 to obtain Silicone-modified polyurethane solution with a mass fraction of 8%.

[0066] 3. Spin-coat the organosilicon-modified polyurethane solution and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com