Transparent super-hydrophobic coating material and method for preparing transparent super-hydrophobic coating by transparent super-hydrophobic coating material

A super-hydrophobic coating, transparent technology, applied in coatings, polyurea/polyurethane coatings, devices for coating liquids on surfaces, etc., can solve the problem that super-hydrophobic coatings cannot achieve transparency, durability and erasability and repeated coating, temperature and pH stability, droplet impact resistance, versatility, etc., to achieve the effect of simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] 1. Weigh 0.2g fumed silica nanoparticles (specific surface area is 300m 2 / g) and 20g of absolute ethanol, the fumed silica nanoparticles are dispersed in ethanol by magnetic stirring and an ultrasonic disperser to obtain a uniform and stable dispersion.

[0071] 2. Cut out a textile cloth of a certain size, and soak the textile cloth with the dispersion liquid in step 1. Wipe the glass surface with the woven cloth.

[0072] 3. After the ethanol is completely volatilized, put the wiped glass and 200 μL of 1H,1H,2H,2H-perfluorodecyltriethoxysilane into a closed desiccator and heat it. Incubate at 180°C for 3h. The glass is then taken out of the desiccator to obtain a superhydrophobic coating.

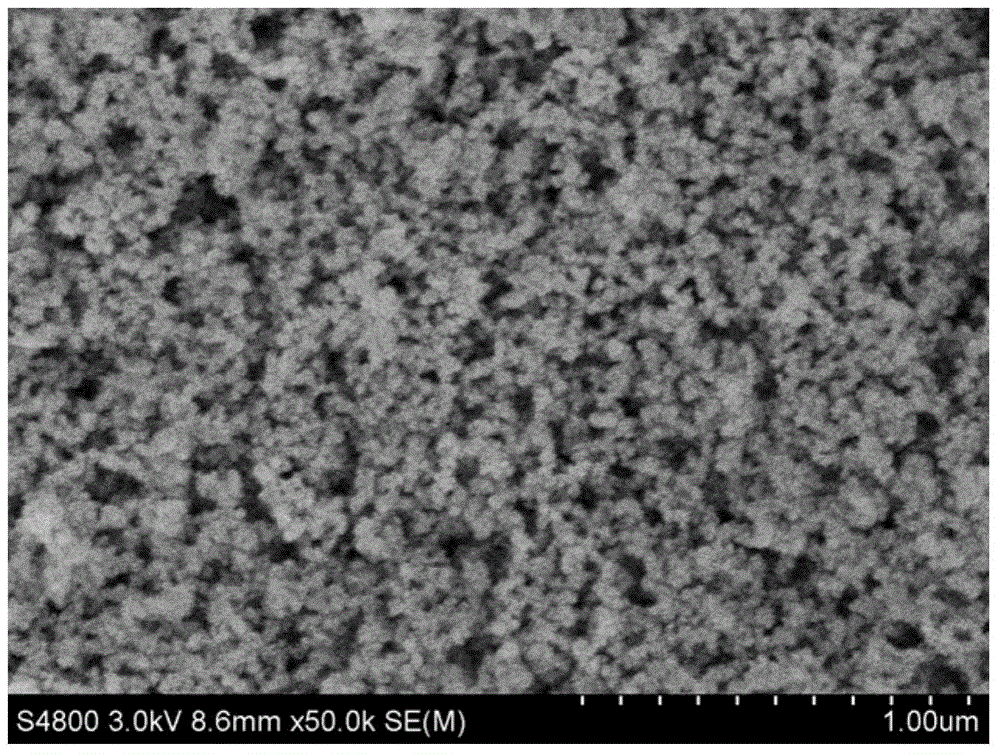

[0073] SEM observation showed that the coating had a porous microstructure ( figure 2 ). The contact angle of the superhydrophobic coating to the droplet is measured by a contact angle tester to be 165.7 ° ( image 3 ), the roll angle is 1°. Figure 4 It shows that the sup...

Embodiment 2

[0075] 1. Weigh 0.2g fumed silica nanoparticles (specific surface area is 100m 2 / g) and 20g of water, the fumed silica nanoparticles are dispersed in water by magnetic stirring and ultrasonic disperser to prepare a uniform and stable dispersion.

[0076] 2. Cut out a non-woven fabric of a certain size, soak the non-woven fabric with the dispersion in step 1, and then wipe it on the glass surface.

[0077]3. After the water is completely evaporated, put the coated glass and 200 μL of 1H,1H,2H,2H-perfluorodecyltriethoxysilane into a closed desiccator and heat it. Incubate at 100°C for 3h. The glass is then removed from the desiccator to produce a superhydrophobic coating.

[0078] The superhydrophobic coating has a contact angle of 162.1° and a rolling angle of 2°. Other properties such as transparency, self-cleaning ability, etc. are the same as in Example 1.

Embodiment 3

[0080] 1. Weigh 0.1g fumed silica nanoparticles (specific surface area is 600m 2 / g) and 50g of absolute ethanol, the fumed silica nanoparticles were dispersed in ethanol by magnetic stirring and ultrasonic disperser to prepare a uniform and stable dispersion.

[0081] 2. Cut out a textile cloth of a certain size, soak the textile cloth with the dispersion in step 1, and then wipe the glass surface.

[0082] 3. After the ethanol is completely volatilized, put the coated glass and 200 μL of 1H,1H,2H,2H-perfluorodecyltriethoxysilane into a closed desiccator and heat it. Incubate at 160°C for 3h. The glass is then removed from the desiccator to produce a superhydrophobic coating.

[0083] The superhydrophobic coating has a contact angle of 168.5° and a rolling angle of 2°. Transparency is better than Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com