A kind of super-oleophilic super-hydrophobic coating and its preparation method and application

A super-hydrophobic coating and super-oleophilic technology, which is applied in separation methods, chemical instruments and methods, textiles and papermaking, etc., can solve problems such as limiting the application of super-hydrophobic coatings and complex operation processes, and achieve a wide range of oil-water separation and high-tech Simple, readily available ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of superhydrophobic fiber treatment solution: Add 1 part of titanium dioxide nanoparticles and 2 parts of polyvinyl butyral to a mixed solution of 20ml of ethanol and 30ml of isopropanol, stir magnetically at 800rpm for 2h, and then sonicate Disperse for 30 minutes, and finally add 1 part of silicone resin and 0.1 part of propyltriethoxysilane curing agent into the tetrahydrofuran solvent, and ultrasonicate for 30 minutes to obtain the superhydrophobic fiber treatment solution.

[0031] (2) Preparation of super-hydrophobic fabric: Soak the polyester in the solution for 5 minutes, and finally take out the fabric and dry it at 90°C for 1 hour to obtain a super-hydrophobic fabric.

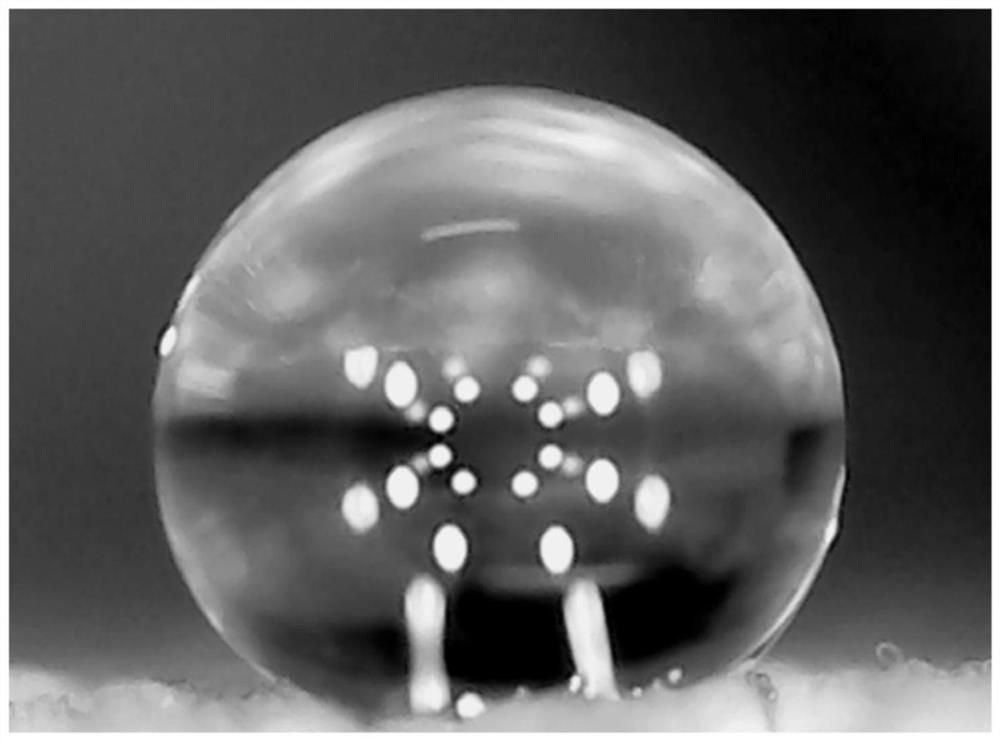

[0032] figure 1 Optical photographs of water droplet contact angles of superhydrophobic polyester fabrics. The prepared superhydrophobic cotton fabric was repeated 35 times in the process of sticking and peeling off with tape, and the water contact angle remained above 150°, sh...

Embodiment 2

[0034] (1) Preparation of superhydrophobic fiber treatment solution: Add 0.2 parts of silica nanoparticles and 2 parts of polyvinyl butyral to 80 parts of isopropanol solution, stir magnetically at 600 rpm for 1 hour, and then ultrasonically disperse After 30 minutes, add 1 part of silicone resin and 0.05 part of vinyltrimethoxysilane curing agent into the volatile solvent, and ultrasonicate for 20 minutes to obtain the superhydrophobic fiber treatment solution.

[0035] (2) Preparation of superhydrophobic fabric: Soak the pure cotton fabric in the solution for 3 minutes, and finally take out the fabric and dry it at 120° C. for 0.5 hour to obtain the superhydrophobic fabric.

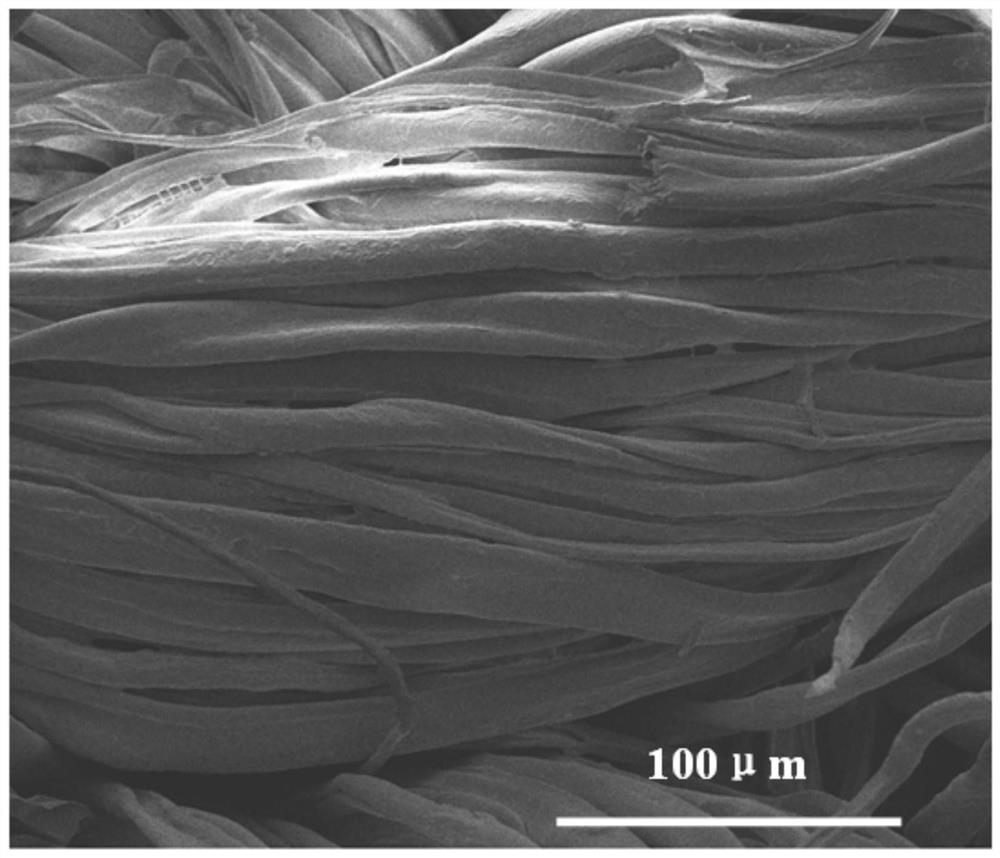

[0036] figure 2 A low-magnification SEM image of a superhydrophobic cotton fabric. The prepared superhydrophobic cotton fabric has a water contact angle of more than 150° after being polished with a weight of 200g on 600-mesh sandpaper for a distance of 240cm, showing good mechanical properties.

Embodiment 3

[0038] (1) Preparation of superhydrophobic fiber treatment solution: Add 0.3 parts of octadecylamine to 40 parts of ethanol and 60 parts of isopropanol solution, stir magnetically at 1000 rpm for 2 hours, then ultrasonically disperse for 15 minutes, and finally mix 1 part of hydrophobic Non-toxic fluorocarbon resin, 0.2 parts of hexamethylene diisocyanate curing agent, add to volatile solvent, ultrasonic for 15 minutes, you can get super-hydrophobic fiber treatment solution.

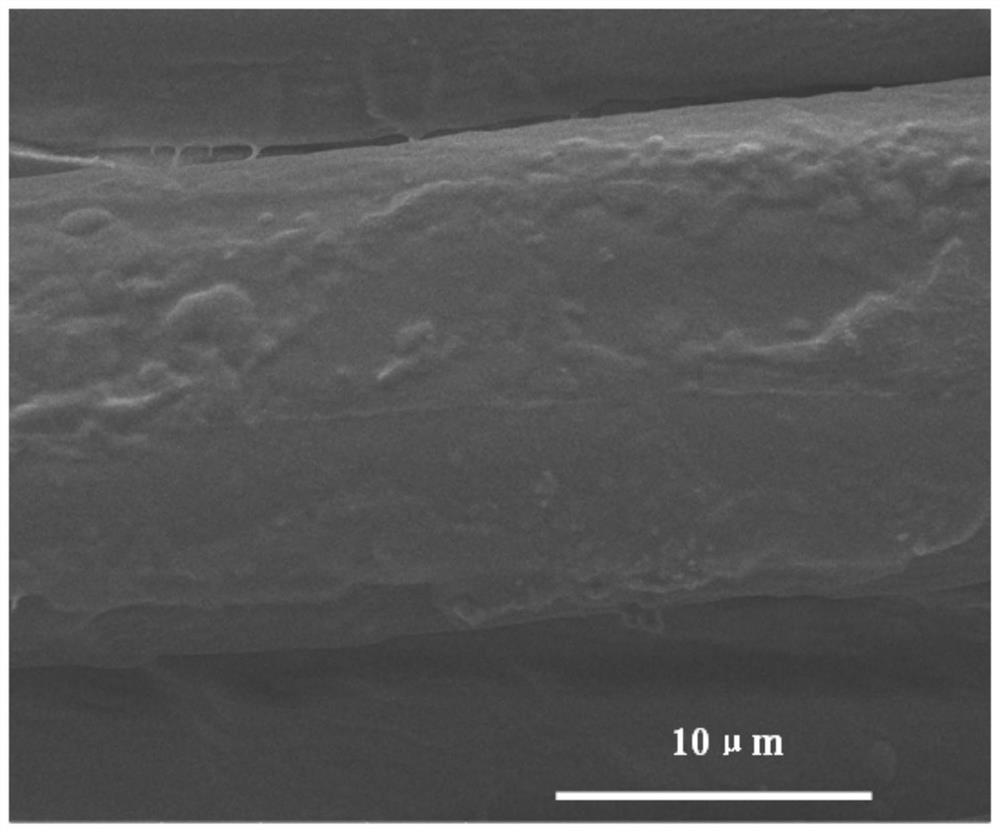

[0039] (2) Preparation of super-hydrophobic fabric: Soak the pure cotton fabric in the solution for 5 minutes, and finally take out the fabric and dry it at 120° C. for 0.5 hour to obtain the super-hydrophobic fabric. image 3 This is a high-magnification scanning electron microscope image of a superhydrophobic cotton fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com