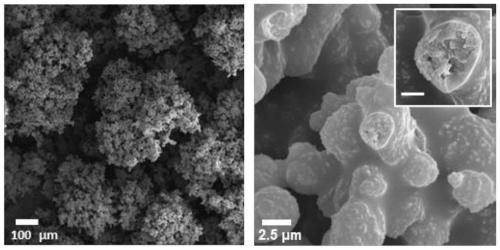

Wear-resistant superhydrophobic coating and preparation method thereof

A super-hydrophobic coating and hydrophobic technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of super-hydrophobic surface wear resistance and corrosion resistance that are difficult to apply on a large scale, and achieve high practical value, Good application prospects, good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

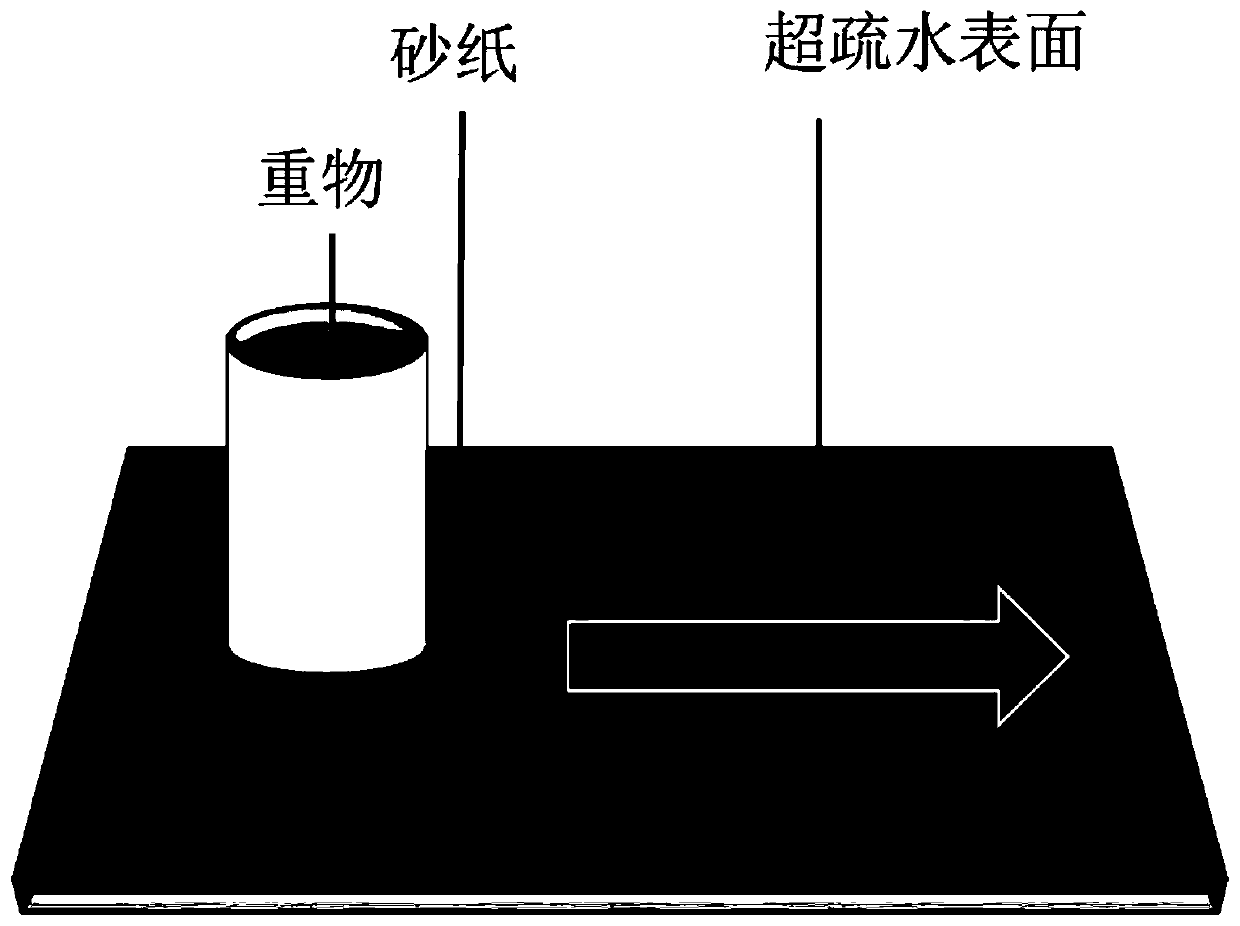

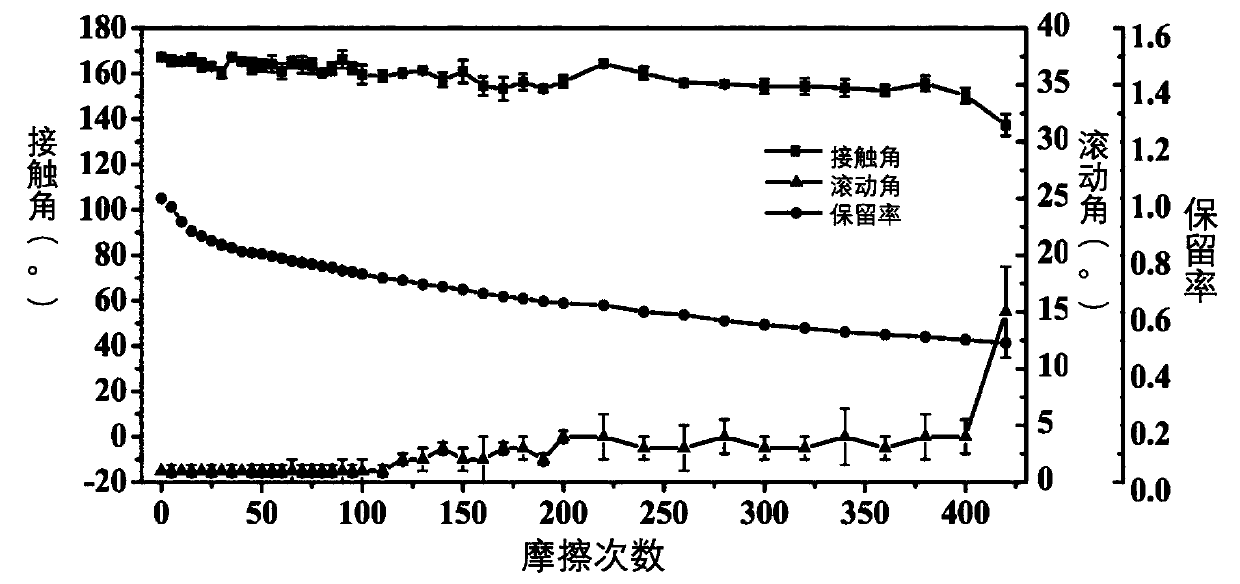

Method used

Image

Examples

Embodiment 1

[0065] A wear-resistant super-hydrophobic coating, comprising resin A and resin B, wherein resin A comprises the following raw material components in parts by mass:

[0066] Hydrophobic epoxy resin 2.5g,

[0067] Curing agent 0.78g,

[0068] Thinner 3.3g;

[0069] Resin B includes the following raw material components in parts by mass:

[0070]

[0071] In this example, in resin A, the curing agent includes 0.32 g of diaminodiphenylmethane (DDM) and 0.46 g of polyetheramine D-400, and the diluent is ethyl acetate.

[0072] In this example, in resin B: the curing agent is 0.52g diaminodiphenylmethane (DDM) and 0.74g polyetheramine D-400, the diluent is ethyl acetate, the filler is nanoscale aluminum oxide particles, and the nanoscale The average particle size of the aluminum oxide particles was 30 nm.

[0073] In this example, the used hydrophobic epoxy resin was prepared by the following method: 6.28g of γ-glycidyl etheroxypropyltrimethoxysilane (KH560), absolute ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com