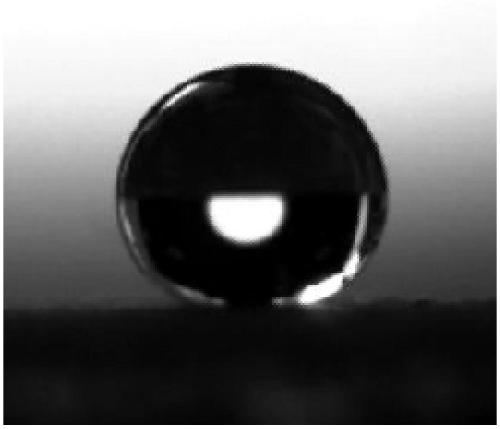

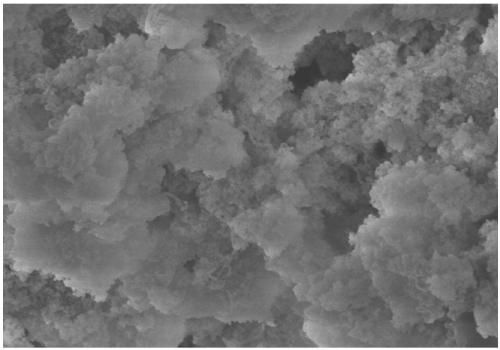

Fluorine-free polyphenylene sulfide super-hydrophobic coating and preparation method thereof

A super-hydrophobic coating, polyphenylene sulfide technology, applied in coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problems of insufficient wear resistance of fluorine-containing polyphenylene sulfide super-hydrophobic coatings, and improve friction performance. , Adhesion enhancement, anti-corrosion effect enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Preparation of fluorine-free polyphenylene sulfide superhydrophobic coating

[0047] (1) Metal substrate surface pretreatment:

[0048] Adopt 1000 mesh sandpapers to remove its surface oxide film after the metal surface is polished, put into 95% ethanol solution and carry out ultrasonic cleaning, remove impurities such as its surface grease, dust, take out and dry naturally, set aside.

[0049] (2) Coating preparation:

[0050] 90 parts of polyphenylene sulfide, 10 parts of silicone resin and 1 part of cysteine were added to 300 parts of ethanol and ball milled for 5 h, which was recorded as suspension A;

[0051] 0.8 parts of carbon nanotubes and 0.2 parts of graphene were added to 120 parts of ethanol solution containing 15 parts of KH550 and 15 parts of water for ultrasonic treatment for 30 min, and then magnetically stirred for 24 h at room temperature; solution B was obtained;

[0052] Mix A and B according to the ratio of 1:1 to get spray coating C.

[005...

Embodiment 2

[0067] 1. Preparation of polyphenylene sulfide coating

[0068] (1) Metal substrate surface pretreatment:

[0069] Use 1000 mesh sandpaper to derust the surface of the steel plate, put it into 80% ethanol solution for ultrasonic cleaning, remove the surface grease, dust and other impurities, take it out and dry it naturally, and keep it for later use.

[0070] (2) Coating preparation:

[0071] Add 70 parts of polyphenylene sulfide, 30 parts of silicone resin and 3 parts of cysteine into 200 parts of ethanol and ball mill for 5 hours to form suspension A;

[0072] Add 3 parts of carbon fiber and 0.1 part of mica powder to 110 parts of ethanol solution containing 20 parts of KH560 and 20 parts of water and ultrasonically treat it for 30 minutes, then stir it magnetically for 24 hours at room temperature to obtain solution B;

[0073] Mix A and B according to the ratio of 1:1 to get spray coating C.

[0074] (3) Preparation of polyphenylene sulfide coating:

[0075] The spr...

Embodiment 3

[0086] 1. Preparation of polyphenylene sulfide coating

[0087] (1) Metal substrate surface pretreatment:

[0088] Use sandblasting technology and chemical etching to derust the surface of the steel plate, put it into 80% ethanol solution for ultrasonic cleaning, remove the surface grease, dust and other impurities, take it out and dry it naturally, and keep it for later use.

[0089] (2) Coating preparation:

[0090] Add 87 parts of polyphenylene sulfide, 5 parts of silicone resin and 0.1 part of cysteine into 300 parts of ethanol and ball mill for 5 hours to form suspension A;

[0091] Add 0.5 parts of silicon carbide whiskers, 1 part of molybdenum disulfide, and 5 parts of graphene into 110 parts of ethanol solution containing 20 parts of polycysteine solution and 20 parts of water, sonicate for 30 min, and stir magnetically for 24 h at room temperature. ; Obtain solution B;

[0092] Mix A and B according to the ratio of 1:1 to get spray coating C.

[0093] (3) Prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com