Super hydrophobic aluminium alloy surface with wear resistance and heat resistance and preparation method thereof

An aluminum alloy surface, super-hydrophobic technology, applied in metal processing equipment, abrasives, manufacturing tools, etc., can solve problems such as poor durability, achieve good hydrophobic performance, improve heat resistance, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing a superhydrophobic metal aluminum alloy surface, the preparation method steps are as follows:

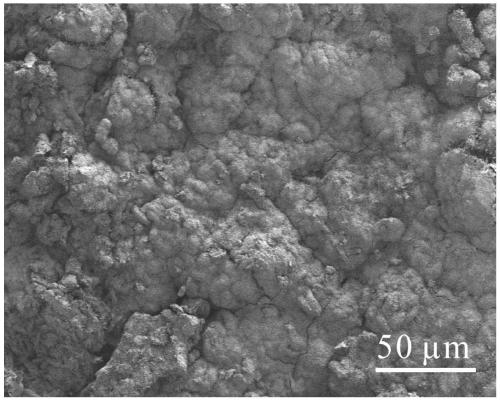

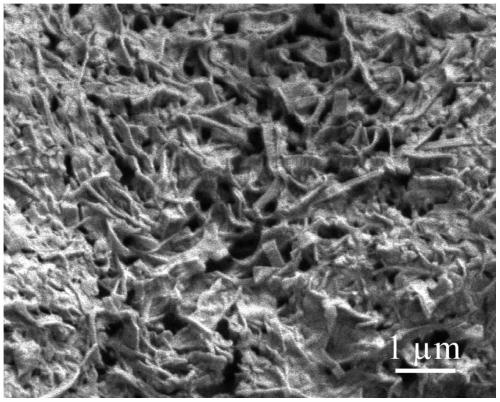

[0035] (1) Aluminum alloy surface pretreatment: sandblasting the aluminum alloy with a size of 20×20×1cm, and the size of the gravel is 24 mesh, put the sandblasted samples into acetone and ethanol solutions for ultrasonic cleaning, The time is 10 minutes.

[0036] (2) Soaking: immerse the cleaned aluminum alloy block in 0.01 mol of perfluorooctanoic acid solution, the ambient temperature is 95° C., and the immersion time is 4 hours.

[0037] (3) Take out the sample after immersion, and dry it in an oven for 1 hour to obtain a superhydrophobic aluminum alloy surface.

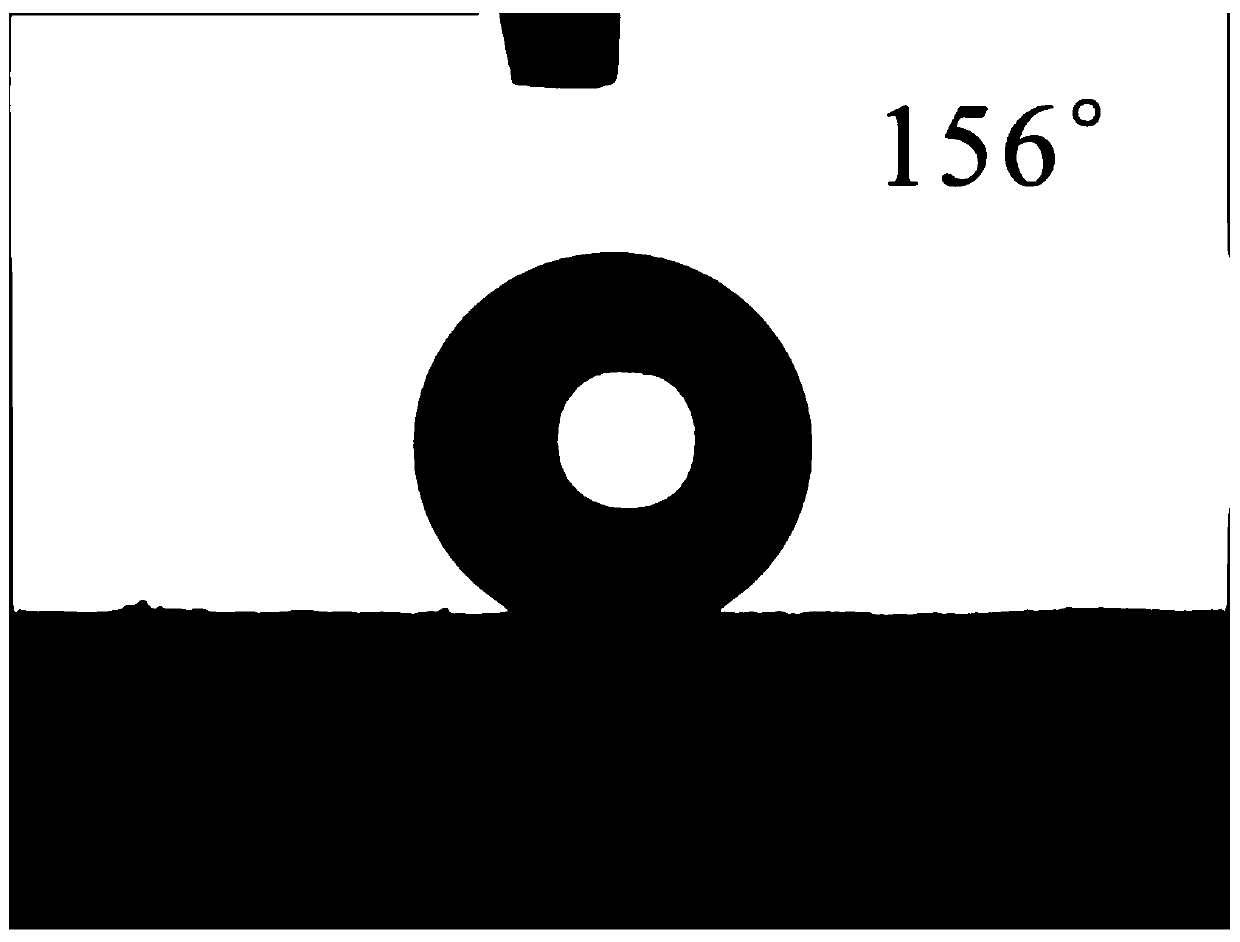

[0038] The SL200B contact angle measuring instrument was used to measure the contact angle on the surface of the above-mentioned superhydrophobic aluminum alloy, and 5 points were uniformly selected on the surface, and the average value of the measured contact an...

Embodiment 2

[0040] This embodiment provides a method for preparing a superhydrophobic metal aluminum alloy surface, the preparation method steps are as follows:

[0041] (1) Aluminum alloy surface pretreatment: sandblasting the aluminum alloy with a size of 20×20×1cm, and the size of the gravel is 24 mesh, put the sandblasted samples into acetone and ethanol solutions for ultrasonic cleaning, The time is 10 minutes.

[0042] (2) Soaking: Soak the etched aluminum alloy block into 0.01 mol of perfluorooctanoic acid solution, the ambient temperature is 95° C., and the soaking time is 6 hours.

[0043] (3) Take out the sample after immersion, and dry it in an oven for 1 hour to obtain a superhydrophobic aluminum alloy surface.

[0044] The SL200B contact angle measuring instrument was used to measure the contact angle on the surface of the above-mentioned superhydrophobic aluminum alloy, and 5 points were uniformly selected on the surface, and the average value of the measured contact angle ...

Embodiment 3

[0046] This embodiment provides a method for preparing a superhydrophobic metal aluminum alloy surface, the preparation method steps are as follows:

[0047] (1) Aluminum alloy surface pretreatment: sandblasting the aluminum alloy with a size of 20×20×1cm, and the size of the gravel is 24 mesh, put the sandblasted samples into acetone and ethanol solutions for ultrasonic cleaning, The time is 10 minutes.

[0048] (2) Soaking: Soak the etched aluminum alloy block into 0.01mol perfluorooctanoic acid solution, the ambient temperature is 95° C., and the soaking time is 8 hours.

[0049] (3) Take out the sample after immersion, and dry it in an oven for 1 hour to obtain a superhydrophobic aluminum alloy surface.

[0050]The SL200B contact angle measuring instrument was used to measure the contact angle on the surface of the above-mentioned superhydrophobic aluminum alloy, and 5 points were uniformly selected on the surface, and the average value of the measured contact angle is sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com