Preparation method of high-wear-resistance self-repairing super-hydrophobic coating

A super-hydrophobic coating and self-repairing technology, which is applied in coatings and other directions, can solve the problems of loss of surface functionality and uneven chemical properties of super-hydrophobic surfaces, etc., and achieve the effect of simple method, super-hydrophobic recovery and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

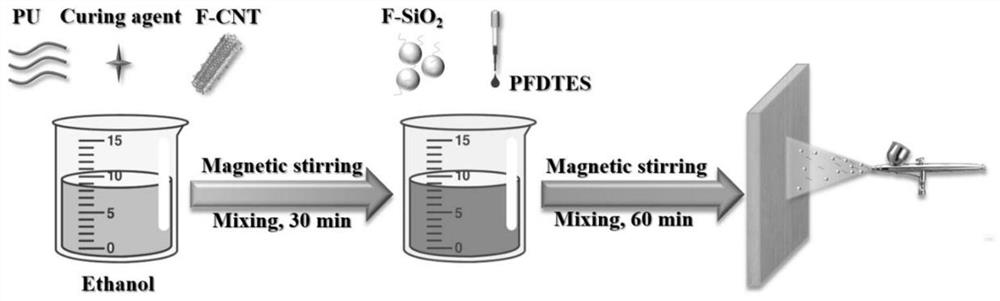

[0029] This embodiment relates to a preparation method of a highly wear-resistant self-repairing superhydrophobic coating, see attached figure 1 and Figure 5 Shown: Include the following steps:

[0030] Step 1: Add 0.6 mL of PFDTES into 60 mL of absolute ethanol, then disperse 2 mL of acetic acid in the PFDTES solution, and stir magnetically at room temperature for 2 h. Mix 4 mL of deionized water with 40 mL of ethanol, add 3 g of SiO 2 (20nm) particles and 3gCNT (30μm) were filled into ethanol aqueous solution, ultrasonically dispersed for 10min, then slowly dropped into the treated PFDTES solution and magnetically stirred at 50°C for 24h. The precipitate was centrifuged at 10,000 rpm for 10 minutes, then the modified filler was washed once with ethanol, and dried at 80°C for 12 hours to obtain superhydrophobic F-CNT and F-SiO 2 filler;

[0031] Step 2: Add 0.3g F-CNT, 2g HAR and IPDI (the mass ratio of HAR to IPDI is 4) into 4ml ethanol solution respectively. After ult...

Embodiment 2

[0033] This embodiment relates to a method for preparing a highly wear-resistant self-repairing superhydrophobic coating, comprising the following steps:

[0034] Step 1: Add 0.6 mL of PFDTES into 60 mL of absolute ethanol, then disperse 2 mL of acetic acid in the PFDTES solution, and stir magnetically at room temperature for 2 h. Mix 4 mL of deionized water with 40 mL of ethanol, add 3 g of SiO 2 (20nm) particles and 3g of CNT (20μm) were filled into ethanol aqueous solution, ultrasonically dispersed for 10min, then slowly dropped into the treated PFDTES solution and magnetically stirred at 50°C for 24h. The precipitate was centrifuged at 10,000 rpm for 10 minutes, then the modified filler was washed once with ethanol, and dried at 80°C for 12 hours to obtain superhydrophobic F-CNT and F-SiO 2 filler;

[0035] Step 2: Add 0.3g F-CNT, 2g HAR and IPDI (the mass ratio of HAR to IPDI is 4) into 4ml ethanol solution respectively. After ultrasonic treatment for 30 min, 0.3 g of ...

Embodiment 3

[0037] This embodiment relates to a method for preparing a highly wear-resistant self-repairing superhydrophobic coating, comprising the following steps:

[0038] Step 1: Add 0.6 mL of PFDTES into 60 mL of absolute ethanol, then disperse 2 mL of acetic acid in the PFDTES solution, and stir magnetically at room temperature for 2 h. Mix 4 mL of deionized water with 40 mL of ethanol, add 3 g of SiO 2 (20nm) particles and 3g of CNT (30μm) were filled into ethanol aqueous solution, ultrasonically dispersed for 10min, then slowly dropped into the treated PFDTES solution and magnetically stirred at 50°C for 24h. The precipitate was centrifuged at 10,000 rpm for 10 minutes, then the modified filler was washed once with ethanol, and dried at 80°C for 12 hours to obtain superhydrophobic F-CNT and F-SiO 2 filler;

[0039]Step 2, 0.4g F-CNT, 2g HAR and IPDI (the mass ratio of HAR to IPDI is 4) were added into 4ml ethanol solution respectively. After ultrasonic treatment for 30 min, 0.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com