Chemically cross-linked modified alginate fiber and preparation method thereof

A technology of alginate fiber and chemical cross-linking, which is applied in the direction of alginate artificial filament, etc., can solve the problem of low strength of alginate fiber, and achieve the effects of low processing energy consumption, simple process and obvious reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This example discloses a chemically cross-linked modified alginate fiber prepared by the following method:

[0028] Dissolve 2g of sodium alginate and 0.2g of polyethylene glycol diglycidyl ether in 100ml of water with a pH value of 10 (adjust the pH with NaOH solution), react in a water bath at 60°C for 1 hour, and let it stand for defoaming after the reaction is completed. The fiber is extruded into a 3% calcium chloride aqueous solution through a spinning machine, and the fiber is taken out after being solidified and shaped, drawn and dried to obtain a chemically cross-linked modified alginate fiber. The breaking strength of the chemically cross-linked modified alginate fiber was 2.13cN / dtex.

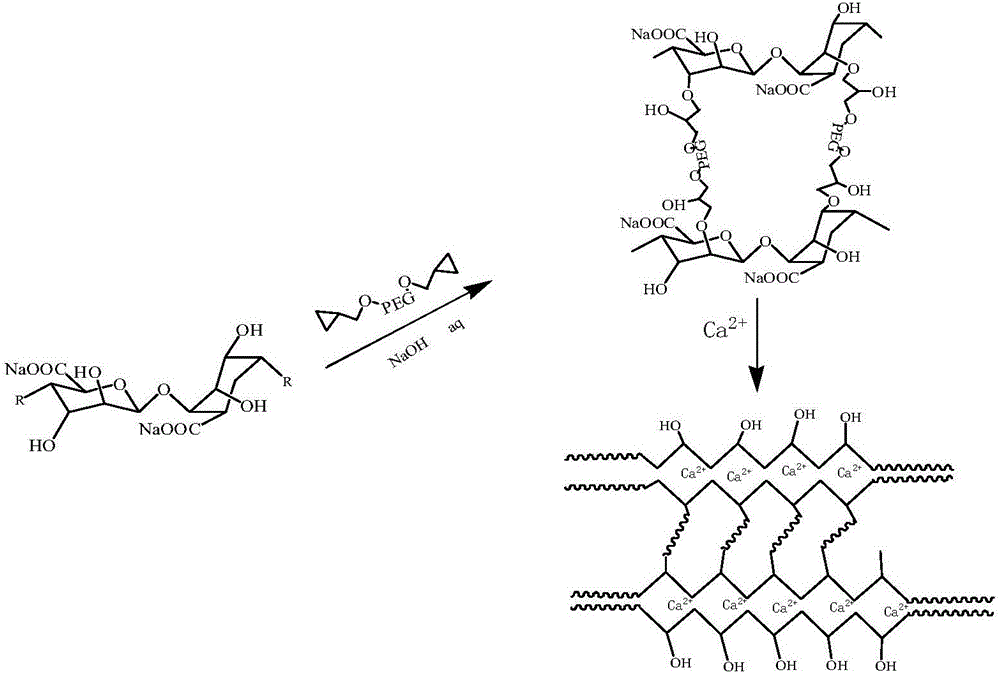

[0029] The structure and preparation process of the chemically cross-linked modified alginate fiber in this example are as follows: figure 1 As shown, the preparation process of chemically cross-linked modified alginate fibers in this example is: the epoxy groups at both ends...

Embodiment 2

[0032] This embodiment discloses a double network reinforced calcium alginate fiber, which is prepared by the following method:

[0033] Dissolve 2g of sodium alginate and 0.4g of polyethylene glycol diglycidyl ether in 100ml of water with a pH value of 10 (adjust the pH with NaOH solution), react in a water bath at 60°C for 1 hour, and let it stand for defoaming after the reaction is completed. The fiber is extruded into a 3% calcium chloride aqueous solution through a spinning machine, and the fiber is taken out after being solidified and shaped, drawn and dried to obtain a chemically cross-linked modified alginate fiber. The breaking strength of the chemically cross-linked modified alginate fiber was 2.16cN / dtex.

Embodiment 3

[0035] This embodiment discloses a double network reinforced calcium alginate fiber, which is prepared by the following method:

[0036] Dissolve 2g of sodium alginate and 0.6g of polyethylene glycol diglycidyl ether in 100ml of water with a pH value of 10 (adjust the pH with NaOH solution), react in a water bath at 60°C for 1 hour, and let it stand for defoaming after the reaction is completed. The fiber is extruded into a 3% calcium chloride aqueous solution through a spinning machine, and the fiber is taken out after being solidified and shaped, drawn and dried to obtain a chemically cross-linked modified alginate fiber. The breaking strength of the chemically cross-linked modified alginate fiber was 2.47cN / dtex.

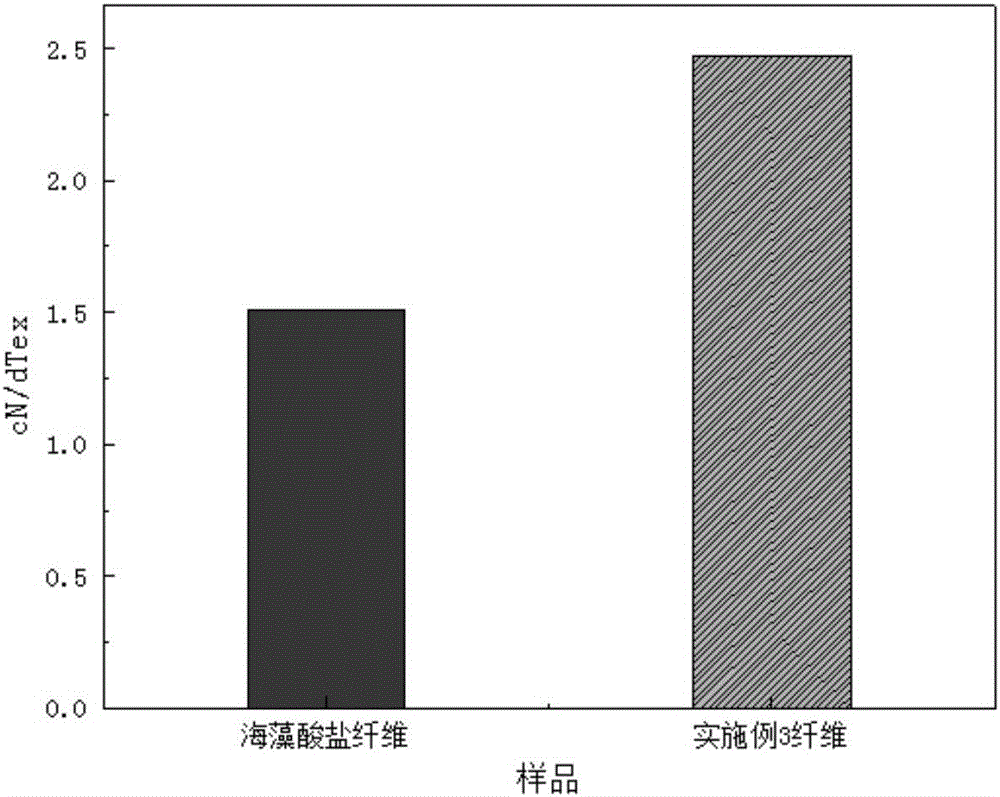

[0037] The breaking strength analysis of the cross-linked modified alginate fiber in this embodiment is as follows: image 3 As shown, both the pure alginate fiber and the chemically cross-linked modified alginate fiber are prepared from sodium alginate with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com