A kind of preparation method of high-performance ni-nb amorphous coating

An amorphous coating, high-performance technology, applied in the coating, metal material coating process, etc., to achieve the effect of strong controllability, improved corrosion resistance, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of Ni-Nb Amorphous Coating

[0031](1) After the substrate GH3039 has been cut, pre-grinded, cleaned and polished, a Ni-Nb composite coating (Ni at.62%, Nb at.38%, purity 99.9Wt% ), the thickness is 20μm; according to the technical requirements of mechanical coating equipment, the mass ratio of ball to material is 10:1, the speed is 250r / min, the time is 3h, and the coating thickness is 20μm.

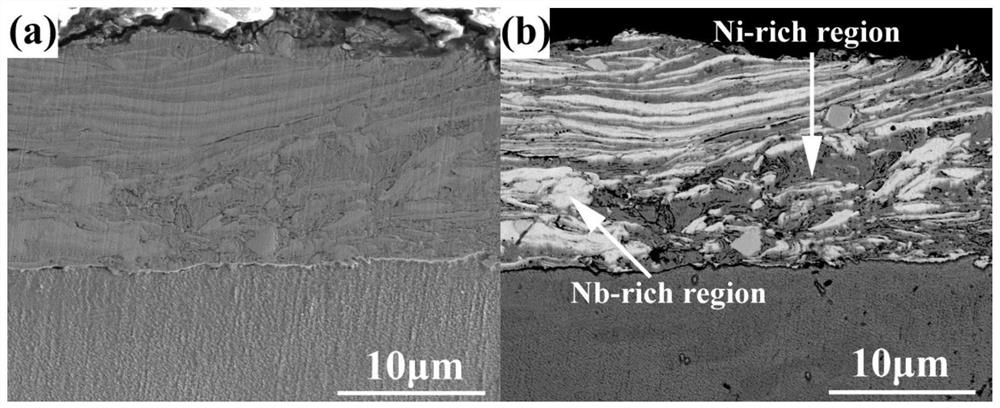

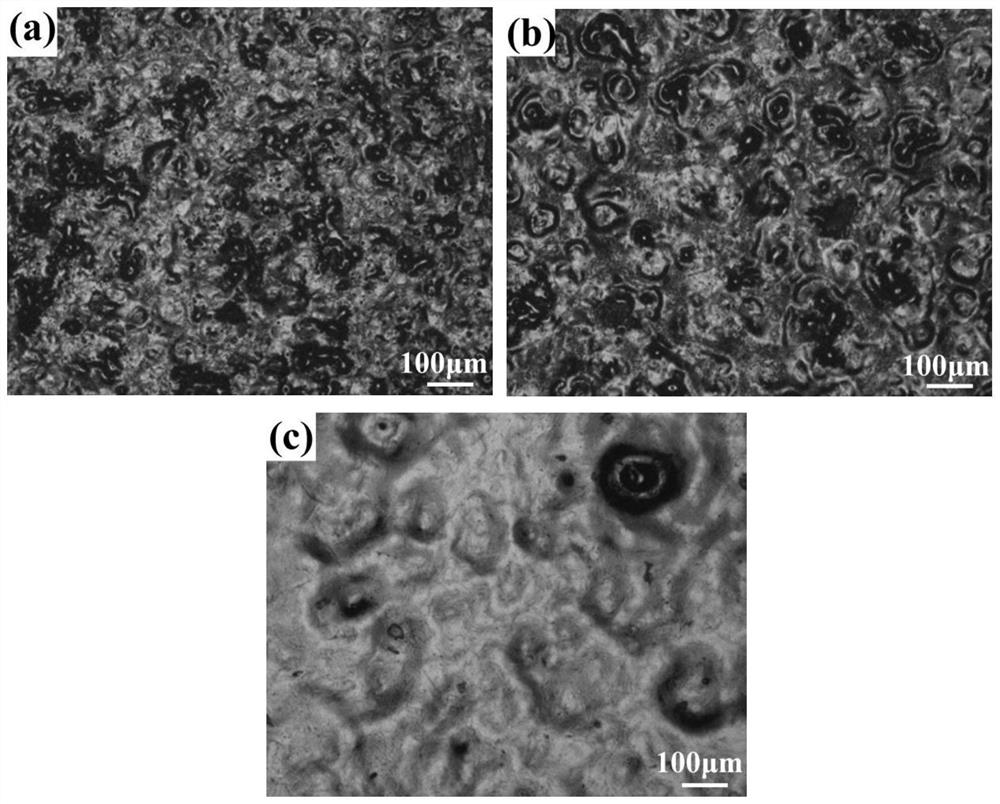

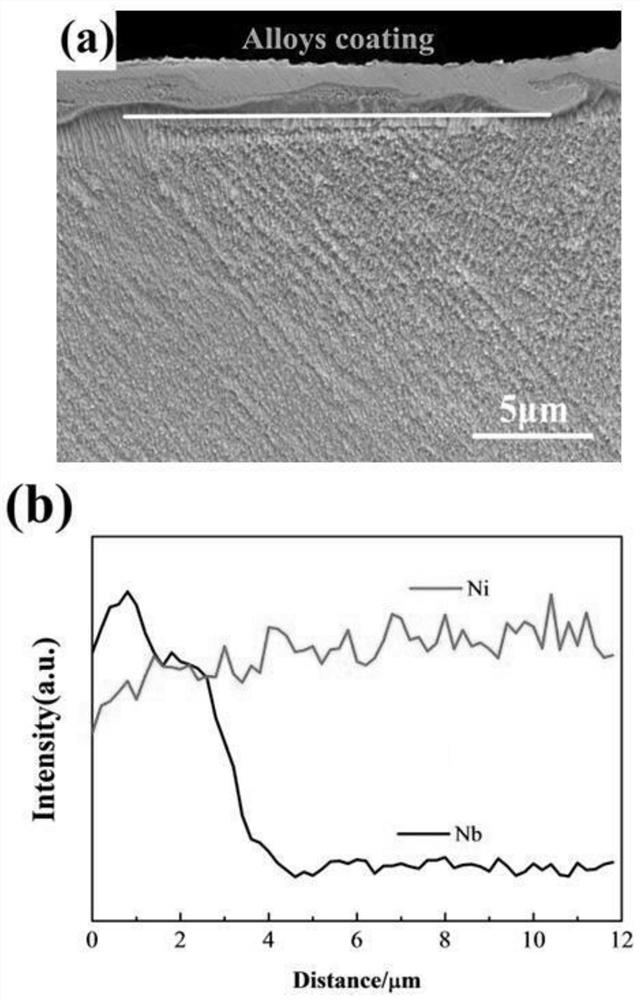

[0032] (2) The sample is irradiated with a high-current pulsed electron beam. The sample to be irradiated is fixed on the stage, and the coating surface is irradiated vertically by the "HOPE-II" high-current pulsed electron beam device, and then the Ni-Nb amorphous coating is obtained on the surface of the nickel-based alloy sample. Among them, the technical parameters of high-current pulsed electron beam irradiation are: the energy of the electron beam is 24KeV, and the energy density is 2.7J / cm 2 , the target source distance is 15cm, the pulse width is 1.5μs, and ...

Embodiment 2

[0039] Preparation of Ni-Nb Amorphous Coating

[0040] (1) After the substrate GH3039 has been cut, pre-grinded, cleaned and polished, a Ni-Nb coating (Ni at.62%, Nb at.38%, purity 99.9Wt%) is deposited on the surface by mechanical coating technology , the thickness is 20um; according to the technical requirements of the mechanical coating equipment, the mass ratio of ball to material is 10:1, the speed is 250r / min, the time is 3h, and the coating thickness is 20μm.

[0041] (2) The sample is irradiated with a high-current pulsed electron beam. The sample to be irradiated is fixed on the stage, and the coating surface is irradiated vertically by the "HOPE-II" high-current pulsed electron beam device, and then the Ni-Nb amorphous coating is obtained on the surface of the nickel-based alloy sample. Among them, the technical parameters of high-current pulsed electron beam irradiation are: the energy of the electron beam is 24KeV, and the energy density is 2.7J / cm 2 , the target...

Embodiment 3

[0048] Preparation of NiNb amorphous coating

[0049] (1) After the substrate GH3039 has been cut, pre-grinded, cleaned and polished, a nickel-niobium coating (Ni at.62%, Nb at.38%, purity 99.9Wt%) is deposited on the surface by mechanical coating technology, The thickness is 20μm; according to the technical requirements of the mechanical coating equipment, the mass ratio of the ball to material is 10:1, the rotation speed is 250r / min, the time is 3h, and the coating thickness is 20μm.

[0050] (2) The sample is irradiated with a high-current pulsed electron beam. The sample to be irradiated is fixed on the stage, and the coating surface is irradiated vertically by the "HOPE-II" high-current pulsed electron beam device, and then the Ni-Nb amorphous coating is obtained on the surface of the nickel-based alloy sample. Among them, the technical parameters of high-current pulsed electron beam irradiation are: the energy of the electron beam is 24KeV, and the energy density is 2.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com