Device and method for preparing metal composite material with coating structure through bidirectional extrusion

A metal composite material and cladding structure technology, applied in the direction of metal extrusion dies, etc., can solve the problems of long production process, large energy consumption, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

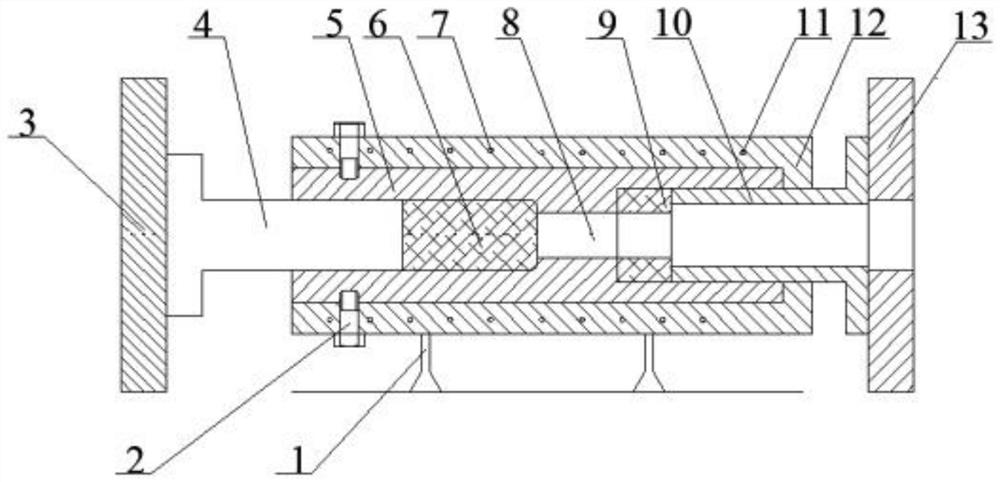

[0031]A bidirectional extrusion prepared a film-covered metal composite material comprising: a fixed bracket 1, a composite extrusion mold 5, an extrusion, an extruder 10, a forward extrusion device 3, and a reverse extrusion device. 13. The composite extrusion mold 5 is disposed between the forward extrusion device 3 and the reverse extrusion device 13.

[0032]The forward extrusion device 3 and the reverse pressing device 13 provide an extrusion driving force.

[0033]The outer sleeve of the composite extrusion mold 5 is provided with a mounting base 12, and the mounting base 12 is fixed to the fixed bracket 1.

[0034]Wherein, the mounting base 12 is fixed to the composite extrusion mold 5 by fastening screw 2.

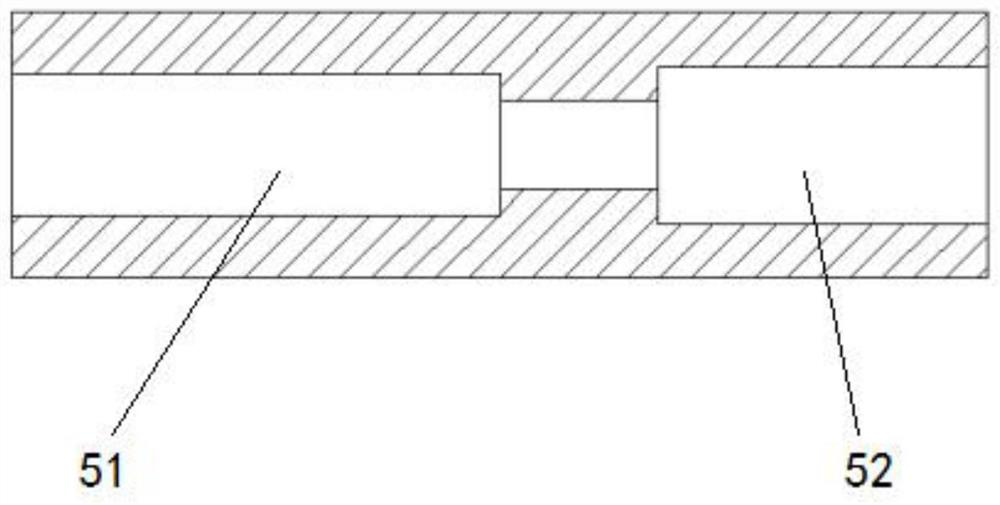

[0035]One end of the composite extrusion mold 5 is provided with a forward extrusion die 51, and the other end is provided with a reverse extrusion die 52, and the forward extrusion die 51 and the reverse extrusion die 52 are connected by a connection passage 8. Wherein, the mountin...

Embodiment 2

[0042]A method of preparing a coated metal composite material in a two-way extrusion, the method comprising the two-way extrusion provided in Example 1, and the method comprising the steps of:

[0043]S10, the inner layer blank 6, the outer hollow blank 9 is placed in the forward extrusion die 51, and in reverse extrusion die 52;

[0044]S20, start the first heating device 7 and the second heating device 11;

[0045]S30, the reverse extrusion device 13 operates by pressing the outer hollow blank 9 when it is pressed backwards after pressing the extruded punch 4;

[0046]S40, use the first extrusion convex, starting to work to the extrudation device 3, and the inner layer blank 6 is squeezed into the outer hollow blank 9;

[0047]When the inner layer blank 6 extrudes the outer hollow blank 9, the reverse pressing device 13 moves in the direction of the extruded convex mold 4, and maintains the forward extrusion blank extrusion speed and the reverse extruded blank extrusion speed phase. Match, extru...

Embodiment 3

[0051]In this example, an aluminum-clad magnesium composite bar having a diameter of magnesium alloy is prepared, an outer layer of aluminum alloy thickness of 5 mm: AZ31 magnesium alloy inner layer blank 6 has an outer diameter of 90 mm, an inner diameter hole 30mm, an outer diameter of 60 mm 7050 aluminum alloy Outer hollow blank 9.

[0052]S10, an AZ31 magnesium alloy inner layer of an outer diameter of 60 mm, a 7050 aluminum alloy outer layer blank having an outer diameter of 60 mm, an outer diameter of 60 mm, and a forward extrusion die 51 in a composite extrusion die, Inside the extruded die 52;

[0053]S20, the first heating device 7 is activated to 400 ° C; the second heating device 11 is activated, the temperature is warmed to 420 ° C, and heat the temperature for 30 minutes;

[0054]S30, the reverse extrusion device 13 operates by pressing the 7050 aluminum outer layer blank after pressing the extrusion convex mode after pressing the extruder 10;

[0055]S40, use the first extrusion c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com