Method to promote protein crystallization with bioglass

A technology of protein crystallization and biological glass, which is applied to the preparation method of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of loss, large particles, inconvenient and other problems, and achieve uniform dispersion, strong surface binding, and non-toxicity. easy precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (Example 1, the method of promoting protein crystallization with bioglass)

[0034] The bioglass suspension in this embodiment is a mixture formed by suspending small bioglass particles in deionized water. The small bioglass particles are ultrafine bioglass particles with a particle size of less than 200 nm. In the bioglass suspension, the concentration of the bioglass small particles is 2-50 / μL, and the concentration in this embodiment is 30 / μL.

[0035] The method that biological glass suspension impels protein crystallization comprises the steps:

[0036] ①Preparation of bioglass: P 2 o 5 :CaO:MgO:SiO 2 =1:3:1:5, weigh the corresponding P 2 o 5 , Ca(NO 3 ) 2 , Mg(NO3) 2 , tetraethyl orthosilicate, and then each compound was mixed with absolute ethanol and heated to reflux to dissolve in ethanol to obtain uniform P 2 o 5 ethanol solution, Ca(NO 3 ) 2 ethanol solution, Mg(NO3) 2 The ethanol solution and the ethanol solution of ethyl orthosilicate; the mol...

Embodiment 2

[0049] (Example 2, the method of promoting protein crystallization with bioglass)

[0050] In this example, the rest of the biological glass suspension obtained in step ② is the same as in Example 1, except that the suspension also includes 20 mg / mL of chloroform, 2.5 mg / mL of the porogen polyethylene glycol Alcohol 3350 and 5 mg / mL active sulfated oil. That is to say, the liquid solvent for increasing the surface activity of bioglass in this embodiment is deionized water, and the solute includes chloroform with a concentration of 20 mg / mL, 2.5 mg / mL porogen polyethylene glycol 3350 and 5 mg / mL active agent sulfated oil . The sulfated oil used in this embodiment is the sulfonated oil obtained by the action of castor oil and sulfuric acid, and the molecular formula is C 18 Na 2 o 6 S, CAS Registry No. 8002-33-3.

[0051] The biological glass suspension of the present embodiment promotes the remainder of the method for protein crystallization to be the same as in Example 1,...

Embodiment 3

[0055] (Example 3, the method for promoting protein crystallization with bioglass)

[0056] The rest of this embodiment is the same as embodiment 2, the difference is:

[0057] In step ③, when the protein crystallization is promoted by the bioglass suspension, the bioglass suspension promotes protein crystallization in the microfluidic protein crystallization plate.

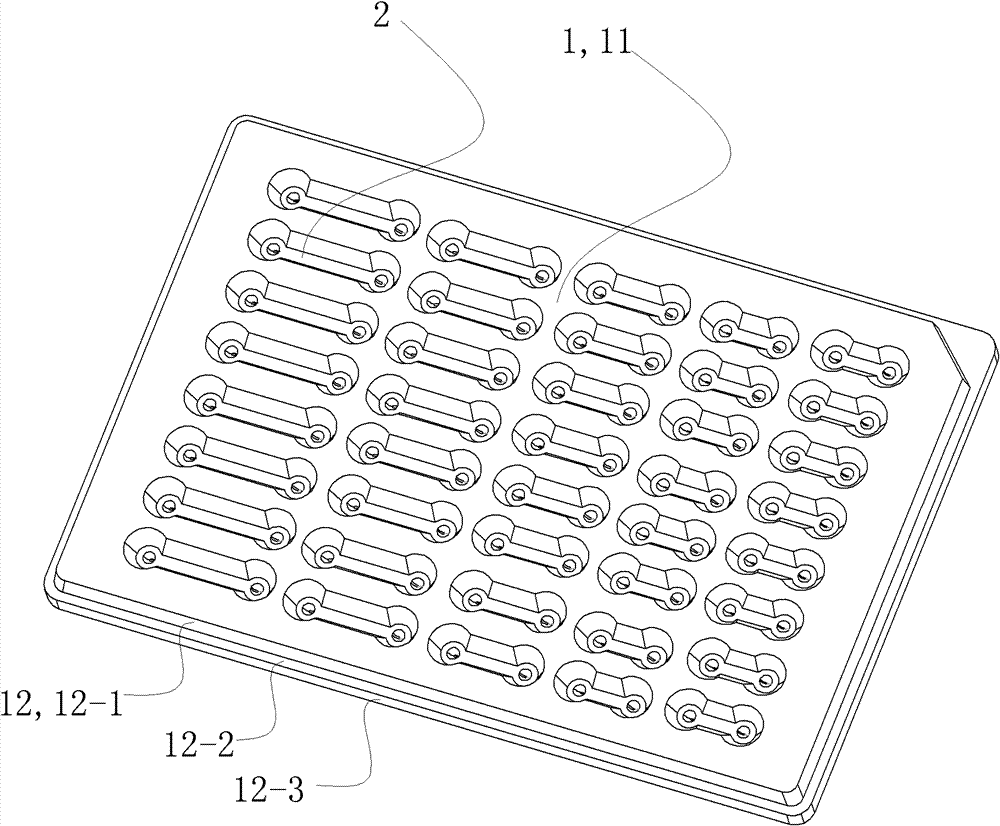

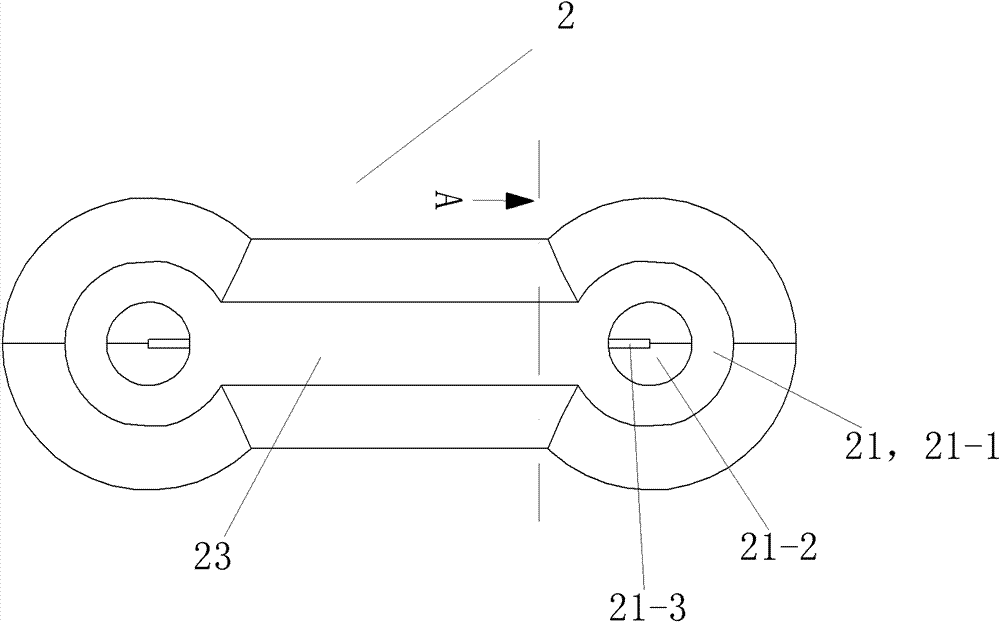

[0058] See figure 2 , the microfluidic protein crystallization plate used in this embodiment is an injection-molded integral piece, including a support structure part 1 and crystallization units 2 connected to the support structure part 1 and distributed in an array.

[0059] The supporting structure part 1 is composed of a panel 11 and a supporting part 12 supported on the periphery of the panel 11 . The overall shape of the panel 11 is a rectangle with one corner missing, and the triangular notch is used as a mark of the placement position during use, and the panel 11 is provided with a cross-sectional shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com