Vertical casting and extruding composite preparation device and method of coating structure metal composite material

A metal composite material and coating structure technology, applied in the field of metal processing, can solve the problems of high energy consumption, high cost, and difficulty in ensuring strength, and achieve the effects of excellent mechanical properties of materials, strong surface bonding, and elimination of blank defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

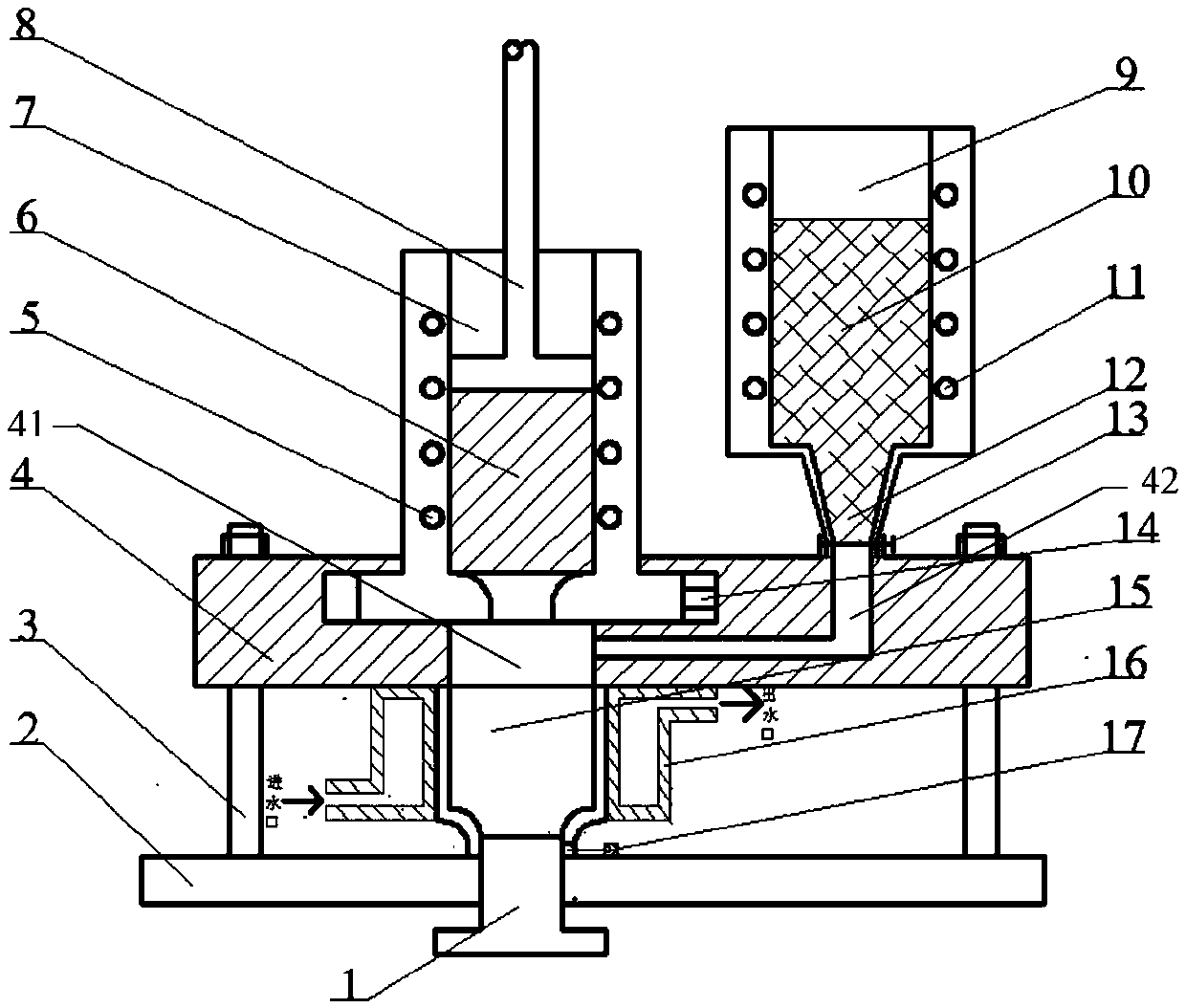

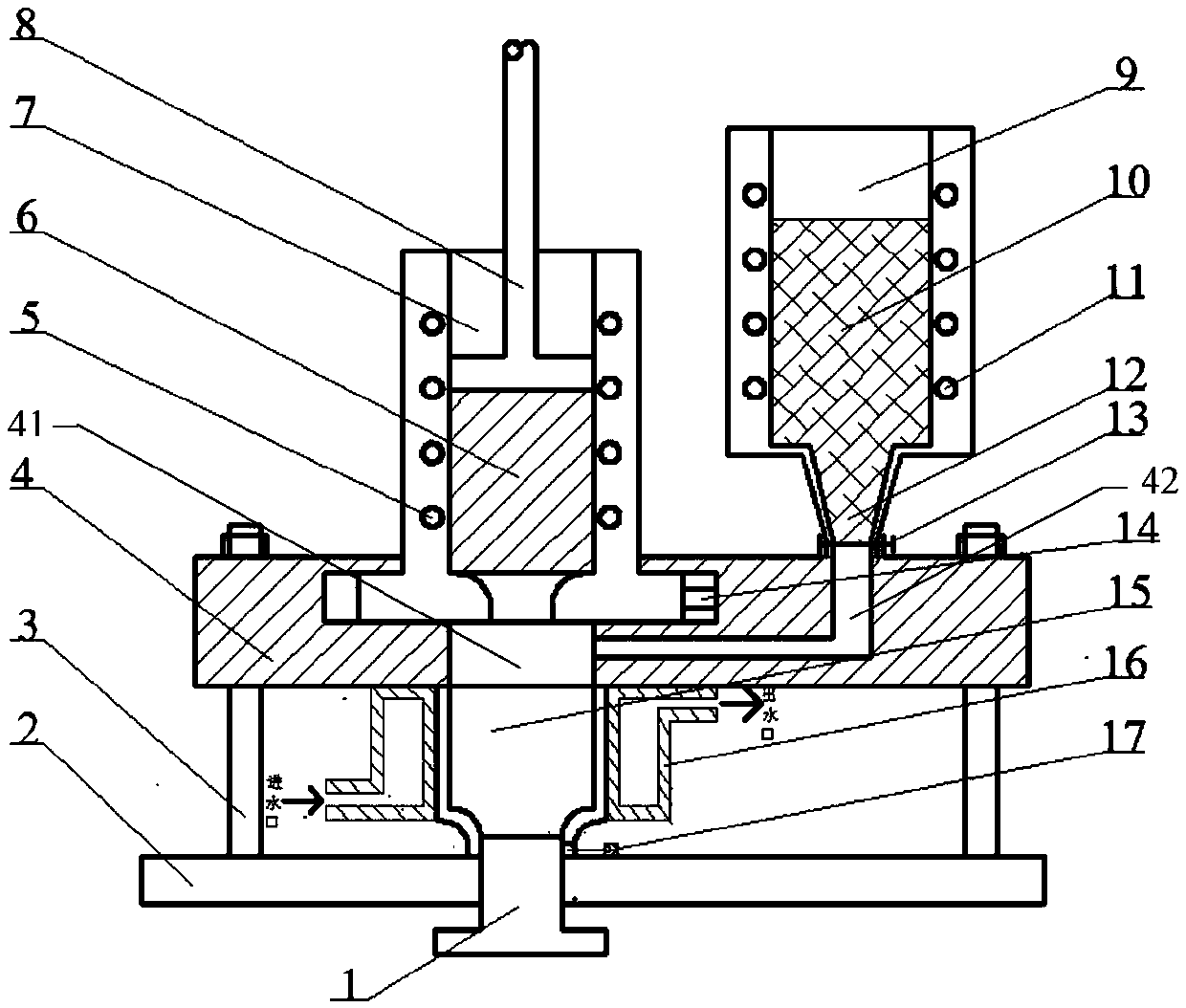

Method used

Image

Examples

Embodiment 1

[0027] Taking copper-clad steel as an example, the steel is made of ordinary carbon steel Q235, and the copper is made of No. 1 copper T1, which includes the following steps:

[0028] 1) The front and rear extrusion dies 7 are locked and fixed by the locking device 14 .

[0029] 2) Place the blank of carbon steel Q235 in the extrusion die 7, add liquid No. 1 copper into the casting die; and turn on the extrusion heating device 5 and the casting heating device 11.

[0030] 3) Extrude the carbon steel Q235 billet through the extrusion punch 8, and stop the extrusion when the carbon steel Q235 billet touches the starting block.

[0031] 4) Turn on the casting channel switch 13, squeeze the liquid No. 1 copper into the extrusion compound cylinder 15 through the casting punch 8, and the cooling device 16 starts to work.

[0032] 5) Take out the block 1 for initial use, continue to extrude with the extrusion punch 8, and realize the extrusion compounding of the composite material a...

Embodiment 2

[0035] Taking aluminum-clad magnesium as an example, the aluminum is made of 1050 aluminum, and the magnesium is made of AZ31 magnesium alloy, including the following steps:

[0036] 1) The front and rear extrusion dies 7 are locked and fixed by the locking device 14 .

[0037] 2) Place the magnesium alloy billet in the extrusion die 7, add liquid 1050 aluminum into the casting die; and turn on the extrusion heating device 5 and the casting heating device 11.

[0038] 3) The magnesium alloy billet is extruded through the extrusion punch 8 , and the extrusion is stopped when the magnesium alloy billet touches the starting block 1 .

[0039] 4) Turn on the casting channel switch 13, extrude the liquid 1050 aluminum into the extrusion composite cylinder 15 through the casting punch 8, and the cooling device 16 starts to work.

[0040] 5) Take out the block 1 for initial use, continue to extrude with the extrusion punch 8, and realize the extrusion compounding of the composite ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com