Modified epoxy resin-based copper clad laminate and preparation method thereof

An epoxy resin modification technology, applied in chemical instruments and methods, flat products, and other household appliances, etc., can solve the problems of high water absorption, low dielectric constant, low heat and humidity resistance, and insufficient curing, so as to weaken the reaction performance, improving density, and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

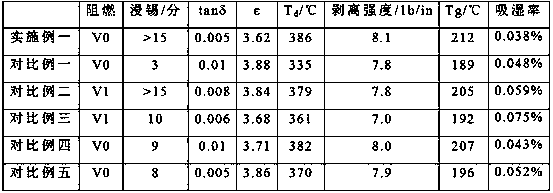

Examples

Embodiment 1

[0047] (1) Disperse nano-silica foam in toluene, then add vinyl propionate, tert-butyl diazoacetate and tert-butyl nitrite; stir at 80°C for 15 minutes; then add tetramethylethylenediamine After dispersing evenly, add dibutylzinc dilaurate, reflux for 7 hours, and finally add acetone to obtain a modified silica foam system with a solid content of 25%;

[0048] (2) At room temperature, mix 3,3'-dithiodipropionic acid, dichloromethane, and acetone; then add pyridinium m-nitrobenzenesulfonate and manganese acetate, stir for 30 minutes, and then add methyl butynol ( Completed in 20 minutes), after stirring for 3 hours, add 2,3-epoxycyclopentyl cyclopentyl ether, after stirring for 50 minutes, add methylcyclohexene tetracarboxylic dianhydride, continue stirring for 20 minutes; then add N , Nʹ-dicyclohexylcarbodiimide, and continued to stir for 10 minutes to obtain a monofunctional epoxy system;

[0049] (3) Mix graphene oxide and isomeric undecyl alcohol polyoxyethylene ether for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com