Semi-curing sheet for high dielectric property copper clad laminate and preparation method thereof

A technology of prepregs and copper clad laminates, which is applied in the field of prepregs for high dielectric performance copper clad laminates and its preparation, can solve the problems of high water absorption, low dielectric constant, low moisture and heat resistance, and insufficient curing, so as to achieve good fluidity and improve Compatibility, the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Disperse 2-methylpentanal in ethanol, then add the hexane solution of the catalyst (the mass concentration of the catalyst in the hexane solution of the catalyst is 1%), stir at room temperature for 15 minutes; then add allylboronic acid, Continue to stir for 5 minutes, then add dibutylzinc dilaurate, continue to stir for 1 hour, finally add N-benzylidene aniline, 2,3-epoxycyclopentyl cyclopentyl ether, and stir at 60°C for 30 minutes to obtain Modified epoxy systems; 2-methylpentanal, ethanol, catalyst in hexane, allylboronic acid, dibutylzinc dilaurate, N-benzylidene aniline, 2,3-epoxycyclopentyl The mass ratio of cyclopentyl ether is 5: 20: 1: 4: 0.002: 8: 100;

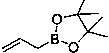

[0037] The chemical structural formula of described catalyst is:

[0038]

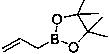

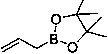

[0039] The chemical structural formula of described allyl boronic acid is:

[0040]

[0041] (2) Add mesoporous silica to concentrated sulfuric acid, ultrasonically treat (power 400W, frequency 20KHz) for 10 minutes and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com