High-frequency electronic medium material

An electronic medium and high frequency technology, applied in the field of new electronic composite materials, can solve the problems of leakage current flow and conductivity loss, and achieve the effects of excellent heat resistance, uniform density and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

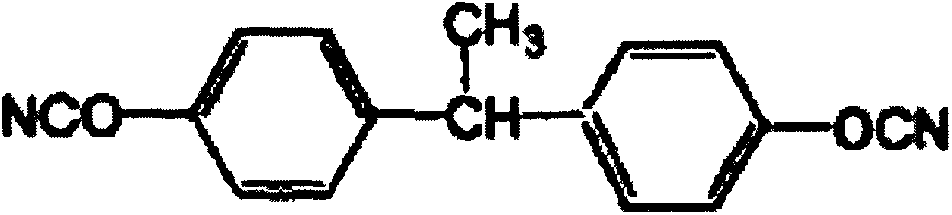

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment one filler

[0030] Disperse 1Kg of triphenylchlorosilane in deionized water, then add 500g of diethylmagnesium and 2092-ethyl-1-hexanol titanium; then conduct a hydrothermal reaction at 120°C for 3 hours; then filter the reaction solution and bake the filter cake After drying, calcinate at 600°C for 1 hour, cool naturally and then sinter at 950°C for 2 hours, add the obtained powder into ethanol, disperse evenly, then add 10g of polyoxyethylene sorbitan monooleate, and stir at 60°C for 2 hours , and finally dried to obtain a filler (particle size of 450nm to 680nm); 1000g of the filler was added to 1.6Kg of diglycidyl phthalate, and stirred at 125°C for 1 hour to obtain an active filler.

Embodiment 2

[0032] According to the composition of Table 1 and Table 2, proceed according to the following steps, mix cyclopentadienyl iron tricarbonyl and cyanate monomer, stir at 95°C for 10 minutes, then add amino compound and aliphatic glycidyl ether in turn, at 120 Stir for 1 hour at ℃, then add dipropylene phthalate, stir at 120°C for 0.5 hours, and obtain a resin prepolymer after cooling; then add the resin prepolymer to methyl ethyl ketone and stir for 1 hour; add active filler and propylene Nitrile; then add PMA and diallyl diphenyl ether, and continue to stir for 2.5 hours to obtain glue.

[0033] Table 1 raw material composition (g)

[0034]

[0035] Table 2 raw material composition (g)

[0036]

[0037] Acrylonitrile

Embodiment 3

[0038] Example 3 Preparation of high-frequency electronic dielectric material

[0039] Coat the above glue with electronic grade glass cloth and bake in an oven at 170°C for 2 minutes to prepare a prepreg; cut off the burrs of the prepreg; take 5 pieces of lamination and cover both sides with a release film, The high-frequency electronic dielectric material can be obtained by hot pressing.

[0040] The conditions of hot pressing adopt the method of gradually increasing temperature and increasing pressure. The temperature is raised from 50°C to 180°C for 10 minutes, kept for 60 minutes, then raised to 200°C for 10 minutes, kept for 90 minutes, then raised to 230°C for 5 minutes, kept for 90 minutes, and finally cooled to 50°C for 180 minutes. ; 1min pressure from 0Kg / cm 2 Rise to 15Kg / cm 2 , then keep the pressure for 45min, then rise to 20Kg / cm in 1min 2 Keep the pressure for 50 minutes, and rise to 35Kg / cm in the last 1 minute 2 , keep the pressure for 200min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com