Preparation method of polypropylene rod and post-processing equipment used in the method

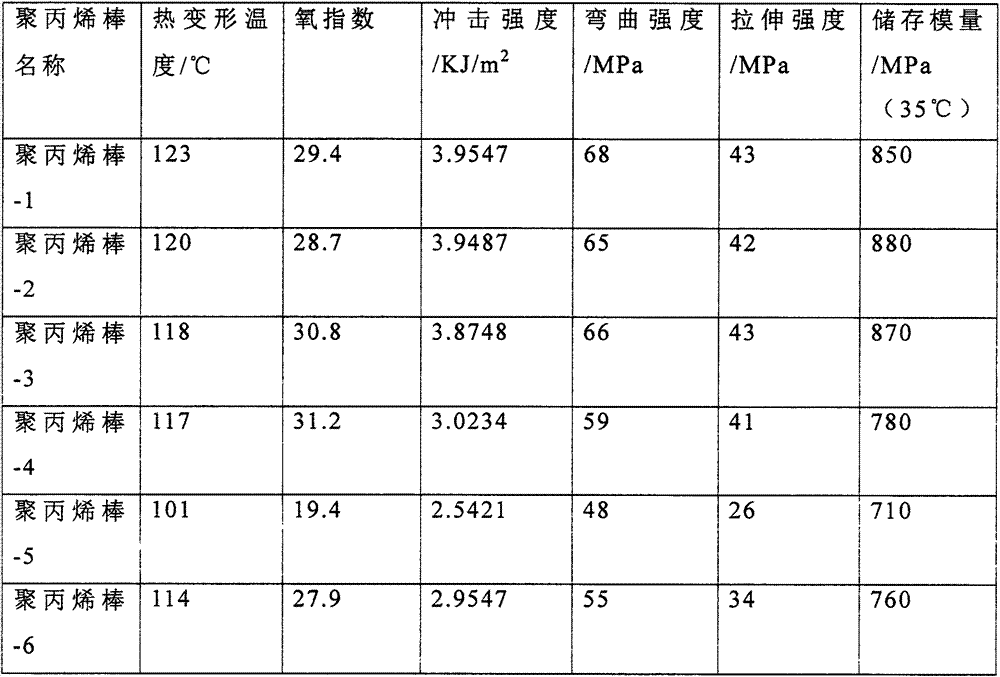

A polypropylene post-processing technology, which is applied in the field of polymer preparation, can solve the problems of reducing the impact performance of polypropylene rods, the reduction of material fracture absorption capacity, the reduction of crystallinity and storage modulus, etc., to achieve increased performance stability and excellent mechanical properties. Performance, effect of good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

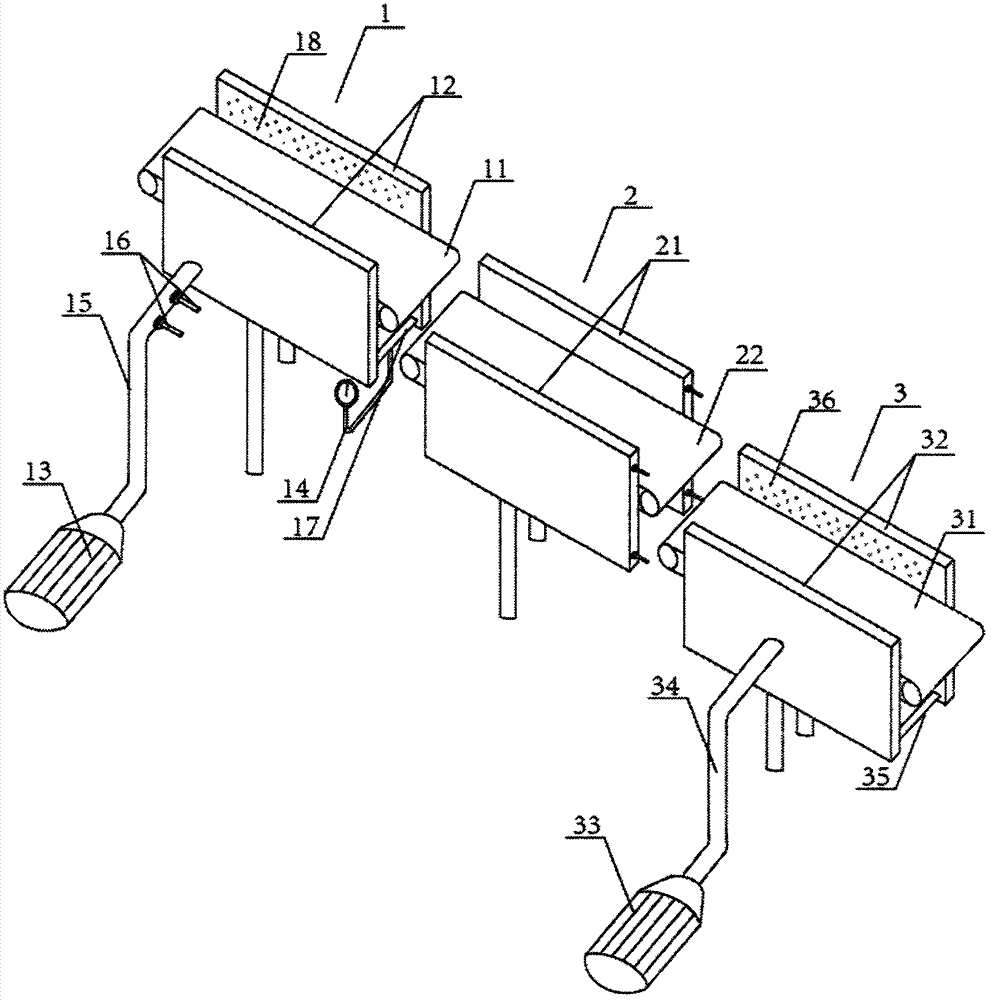

Image

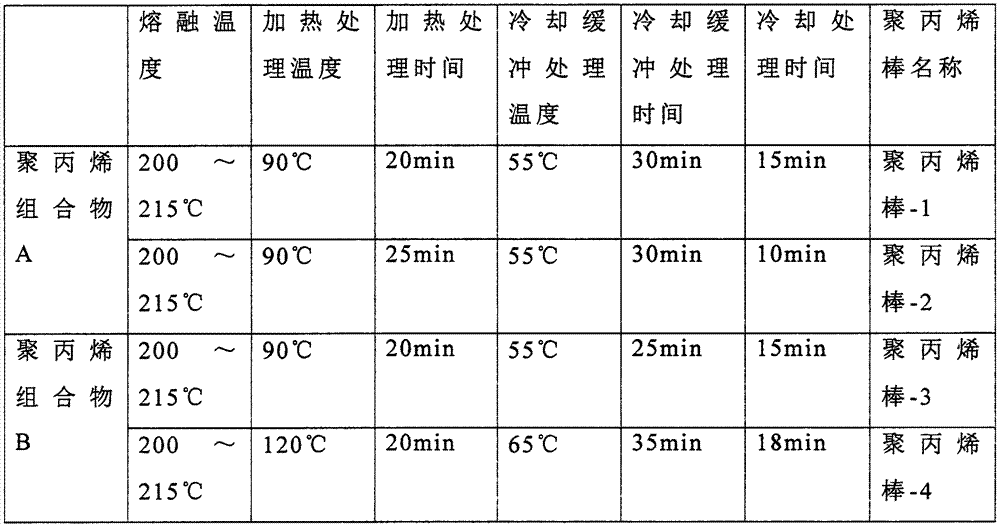

Examples

Embodiment 1

[0031] Embodiment one: the synthesis of thiocyanate-1-(2-aminophenyl)ethanone

[0032] With 2-aminophenylacetic acid, potassium thiocyanate as raw material, copper phthalocyanine as catalyst, its reaction is as follows:

[0033] (1) Add 5 grams of 2-aminophenylacetic acid, 1.02 grams of potassium thiocyanate, 0.01 g of copper phthalocyanine and 4 milliliters of toluene into the reactor, and react at 55° C. under nitrogen;

[0034] (2) TLC tracking reaction until complete completion;

[0035] (3) The crude product obtained after the reaction was separated by column chromatography (petroleum ether:ethyl acetate=10:1) to obtain the target product thiocyanato-1-(2-aminophenyl)ethanone.

Embodiment 2

[0036] Example 2: Preparation of Flame Retardant Filler

[0037] Prepared by:

[0038] Add expandable graphite to the ethanol solution of 0.08M tetraphenylphosphine bromide so that the molar ratio of phosphorus to expandable graphite is 0.05:1, stir and fully mix and then put it into a container and seal it. The filling degree is 70%. The container was heated at 100°C for 4 hours, cooled naturally to room temperature, and the resulting product was freeze-dried, and then sintered in a muffle furnace at 800°C for 110 minutes under a nitrogen atmosphere to obtain a solid; then the solid was crushed and passed through a 150-mesh sieve to obtain The undersize is added to a mixture of vinyl glycol ether and acetone to form a reaction solution, and the reaction solution is suction filtered after reflux for 30 minutes, and the obtained filter cake is a flame-retardant filler after drying; the undersize, vinyl ethyl The mass ratio of glycol ether to acetone is 100:50:130.

Embodiment 3

[0039] Embodiment three: preparation of auxiliary filler

[0040] Prepared by:

[0041] Mix silicon dioxide, aluminum phosphate, and white clay uniformly in a mass ratio of 100:50:8, and sinter in a muffle furnace at 800°C for 4 hours to obtain a solid; then crush the solid and pass it through a 150-mesh sieve, and take the The bottom is the auxiliary filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com