A preparation method of composite hard sheet for tropical blister packaging

A technology of blister packaging and composite hard sheet, applied in the field of pharmaceutical packaging, can solve the problems of high cross-linking density, low production efficiency, easy contamination of finished products, etc., and achieve good mechanical properties, good curing effect and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

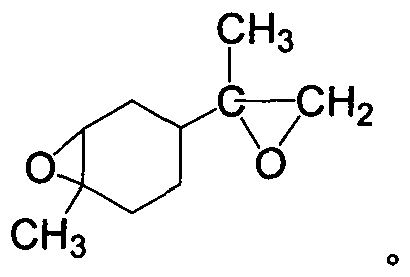

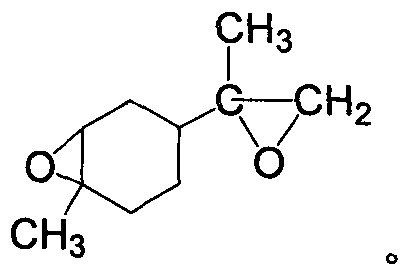

Image

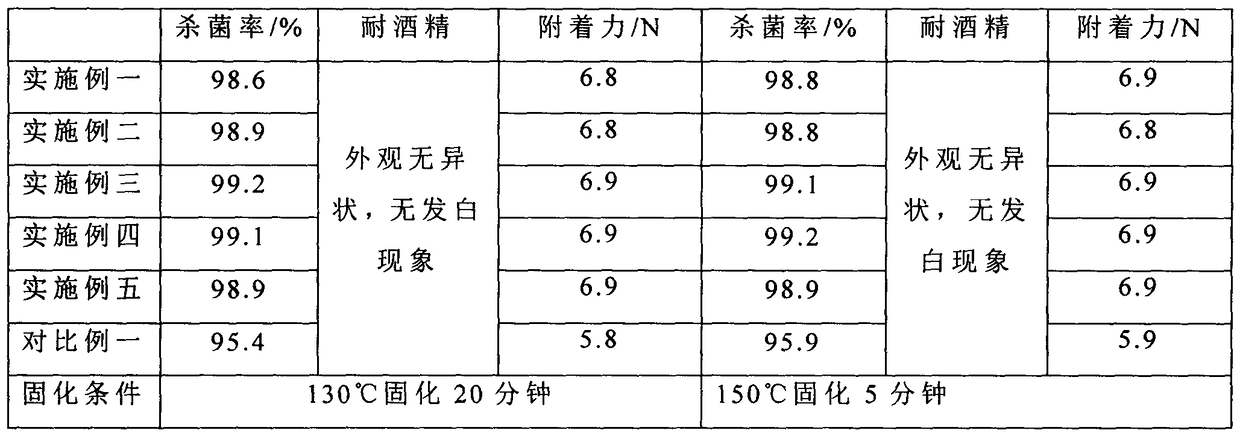

Examples

Embodiment 1

[0024] Mix 40g of di-n-hexylamine and 100g of filler for 1 hour, then add 10g of N-formylmorpholine, 90g of diethyl phosphinate and 20g of benzimidazole, and mix for 2 hours to obtain a mixture; Add oxide, 30g polyamide wax, 80g ethoxylated trimethylolpropane triacrylate to the mixture, stir at 170°C for 5 minutes to obtain a compound; put the compound into the extruder; then corona treat the surface The finished polyester film passes through the extruder, and the compound is coated on the treated polyester film by the extrusion die, and then heat-baked to prepare a composite polyester film; the composite polyester film and aluminum foil are laminated by hot pressing, The aluminum-plastic material is obtained; the aluminum-plastic material is passed through an extruder, and the compound is coated on the aluminum surface of the aluminum-plastic material by an extrusion die, and then heat-baked to prepare a composite hard sheet for tropical blister packaging. It can be cut and p...

Embodiment 2

[0026] Mix 60g of di-n-hexylamine and 150g of filler for 1 hour, then add 13g of N-formylmorpholine, 160g of diethyl phosphinate and 18g of benzimidazole, and mix for 2 hours to obtain a mixture; Add oxide, 50g polyamide wax, 80g ethoxylated trimethylolpropane triacrylate into the mixture, stir at 170°C for 5 minutes to obtain a compound; put the compound into the extruder; then corona treat the surface The finished polyester film passes through the extruder, and the compound is coated on the treated polyester film by the extrusion die, and then heat-baked to prepare a composite polyester film; the composite polyester film and aluminum foil are laminated by hot pressing, The aluminum-plastic material is obtained; the aluminum-plastic material is passed through an extruder, and the compound is coated on the aluminum surface of the aluminum-plastic material by an extrusion die, and then heat-baked to prepare a composite hard sheet for tropical blister packaging. It can be cut an...

Embodiment 3

[0028] Mix 50g of di-n-hexylamine and 110g of filler for 1 hour, then add 12g of N-formylmorpholine, 140g of diethyl phosphinate and 19g of benzimidazole, and mix for 2 hours to obtain a mixture; Add oxide, 40g polyamide wax, 70g ethoxylated trimethylolpropane triacrylate to the mixture, stir at 170°C for 5 minutes to obtain a compound; put the compound into the extruder; then corona treat the surface The finished polyester film passes through the extruder, and the compound is coated on the treated polyester film by the extrusion die, and then heat-baked to prepare a composite polyester film; the composite polyester film and aluminum foil are laminated by hot pressing, The aluminum-plastic material is obtained; the aluminum-plastic material is passed through an extruder, and the compound is coated on the aluminum surface of the aluminum-plastic material by an extrusion die, and then heat-baked to prepare a composite hard sheet for tropical blister packaging. It can be cut and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com