A kind of mid-wave infrared anti-reflection film on silicon substrate and preparation method thereof

A technology of infrared anti-reflection coating and silicon substrate, which is applied in optical components, instruments, optics, etc., can solve the problems of unsuitability and low transmittance of anti-reflection coating, reduce reflection loss, enhance signal strength, and improve detector The effect of response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings.

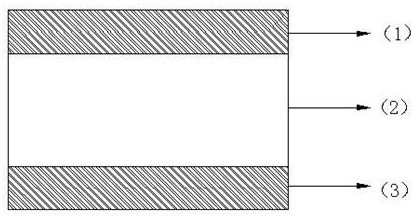

[0019] see figure 1 , the mid-wave infrared anti-reflection coating of the present invention includes a silicon substrate and optical films on both sides. In the figure (1) is the front film system, (2) is the silicon substrate, and (3) is the back film system.

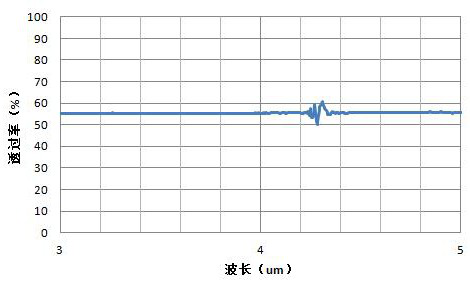

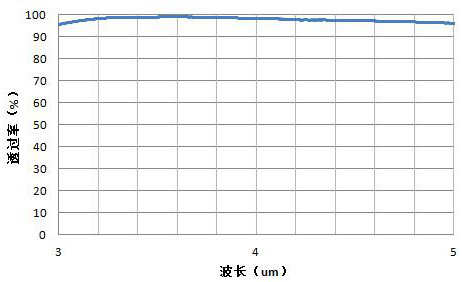

[0020] The spectral anti-reflection area of the mid-wave infrared anti-reflection coating of the present invention is 3-5 μm. Select suitable optical thin film materials in the required spectral range, Ge as high refractive index coating materials, ZnS and YbF3 as low refractive index coating materials.

[0021] The mid-wave infrared anti-reflection film of the present invention adopts a multi-layer irregular film structure. The coating process uses a quartz crystal oscillator to monitor the material deposition thickness in real time. The central wavelength is selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com