Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

788 results about "Evaporation (deposition)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Evaporation is a common method of thin-film deposition. The source material is evaporated in a vacuum. The vacuum allows vapor particles to travel directly to the target object (substrate), where they condense back to a solid state. Evaporation is used in microfabrication, and to make macro-scale products such as metallized plastic film.

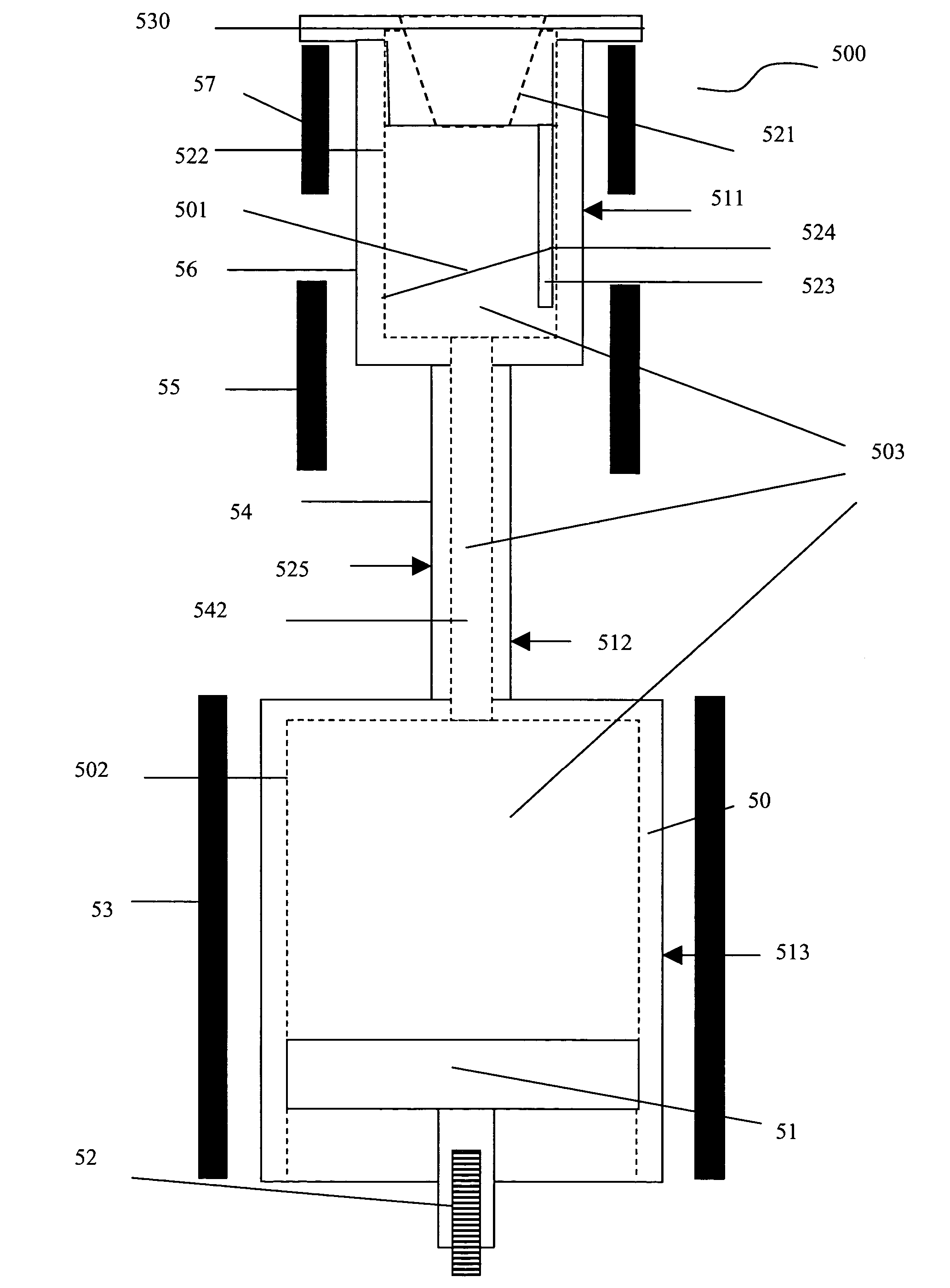

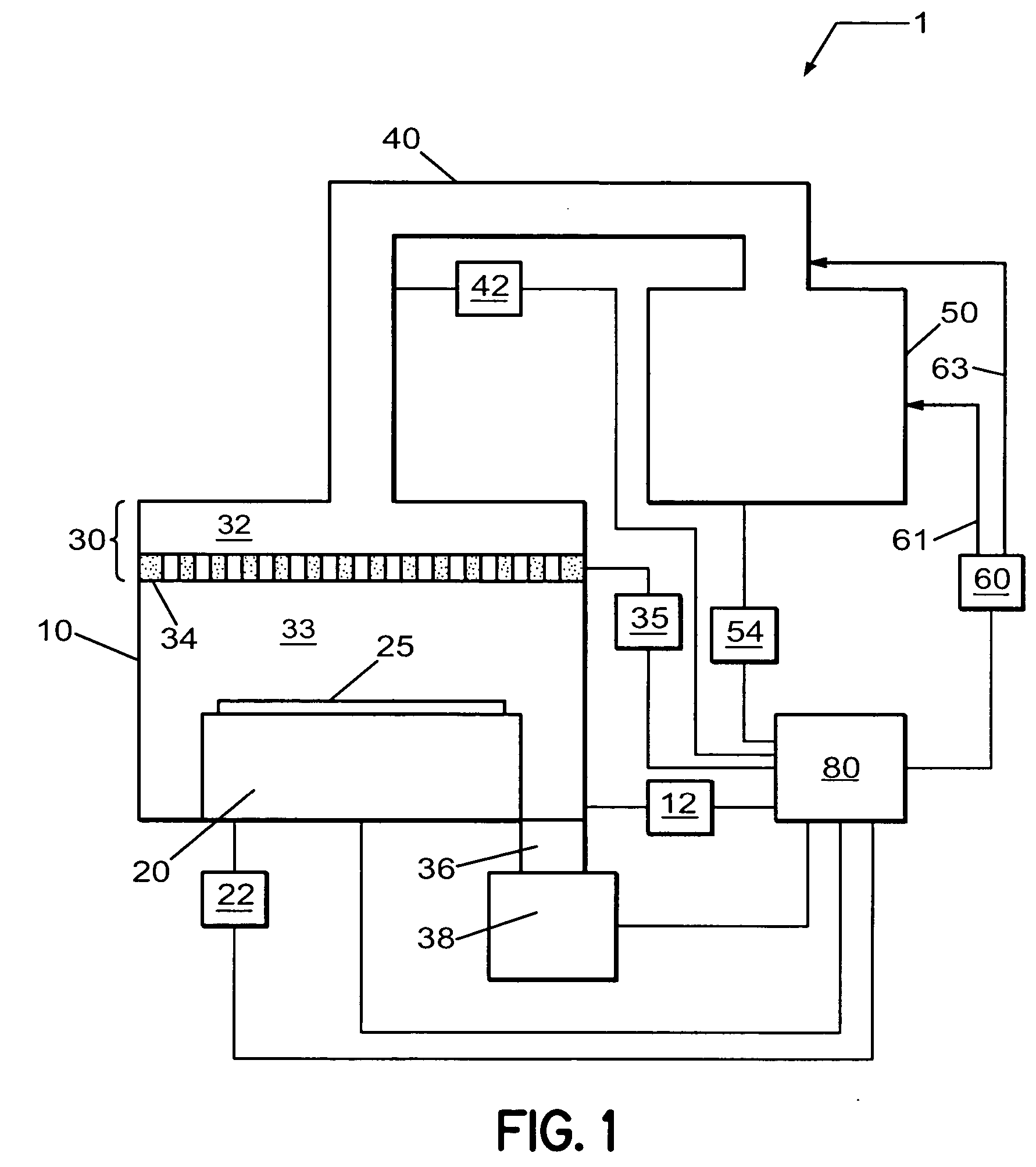

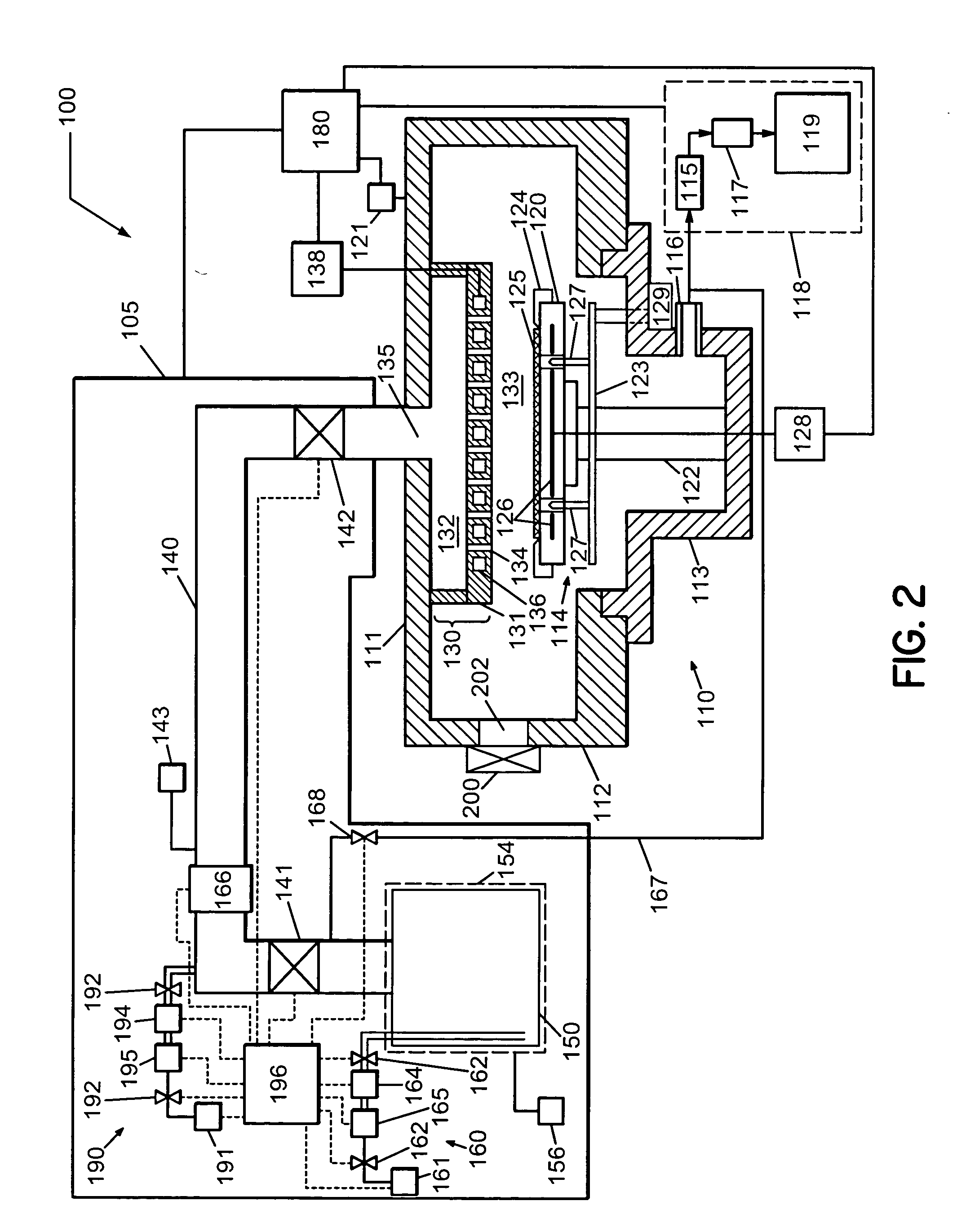

Method and apparatus for reducing particle formation in a vapor distribution system

InactiveUS20070218200A1Reduce particle pollutionChemical vapor deposition coatingDistribution systemEvaporation

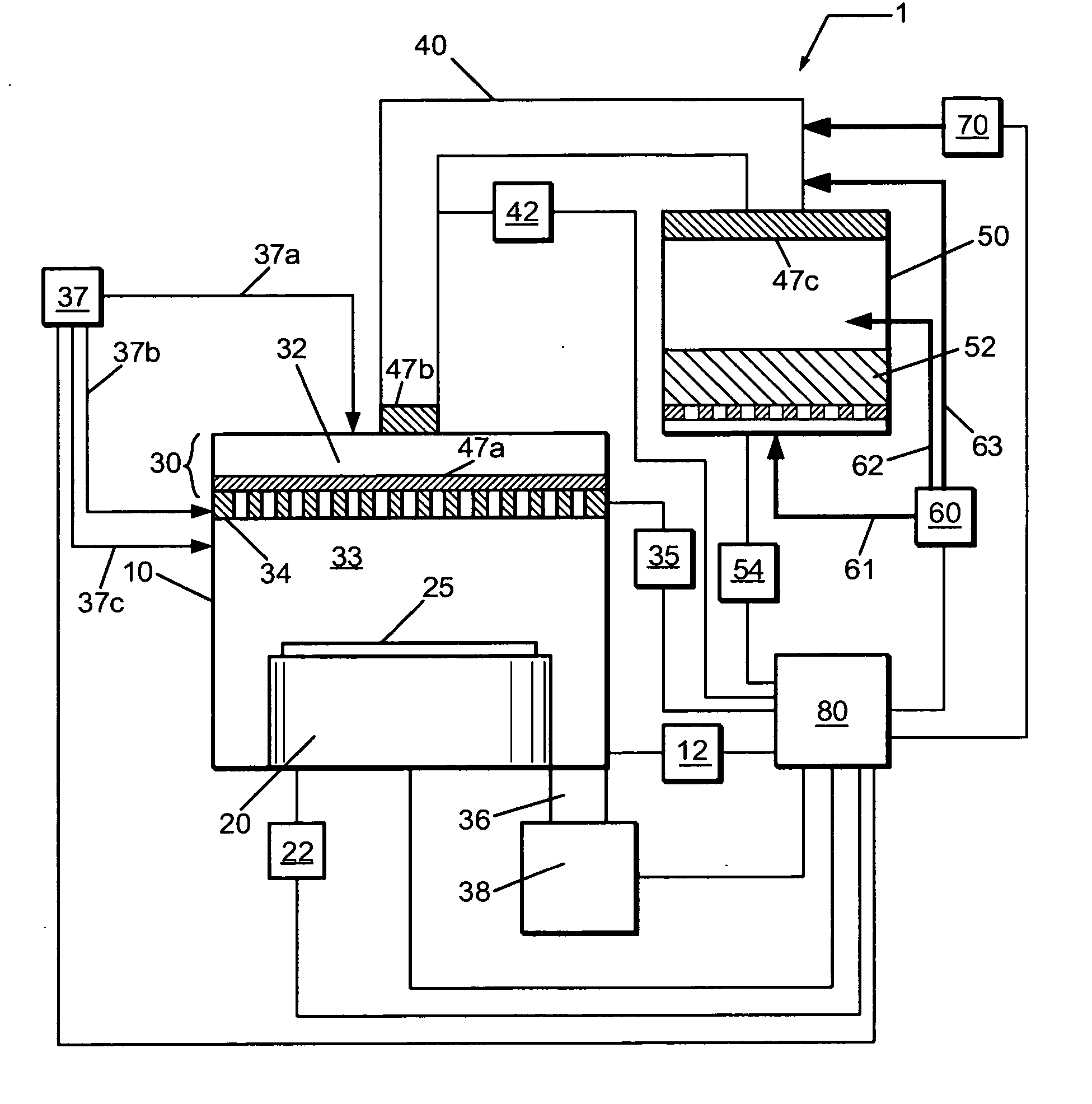

A method and system is described for reducing particle contamination in a vapor distribution system. The vapor distribution system comprises a housing and a vapor distribution head comprising a plurality of openings configured to introduce a film precursor vapor to a deposition system. The housing and vapor distribution head define a plenum coupled to a film precursor evaporation system, and configured to receive the film precursor vapor from the evaporation system and distribute the film precursor vapor within the deposition system through the plurality of openings. In order to reduce particle contamination, the vapor distribution system is designed to reduce the difference, or ratio, between the pressure in the plenum and the pressure in the deposition system. For example, the plenum pressure can be less than twice the pressure in the process space, or can be less than 50 mTorr, 30 mTorr or even 20 mTorr than the pressure in the process space.

Owner:TOKYO ELECTRON LTD

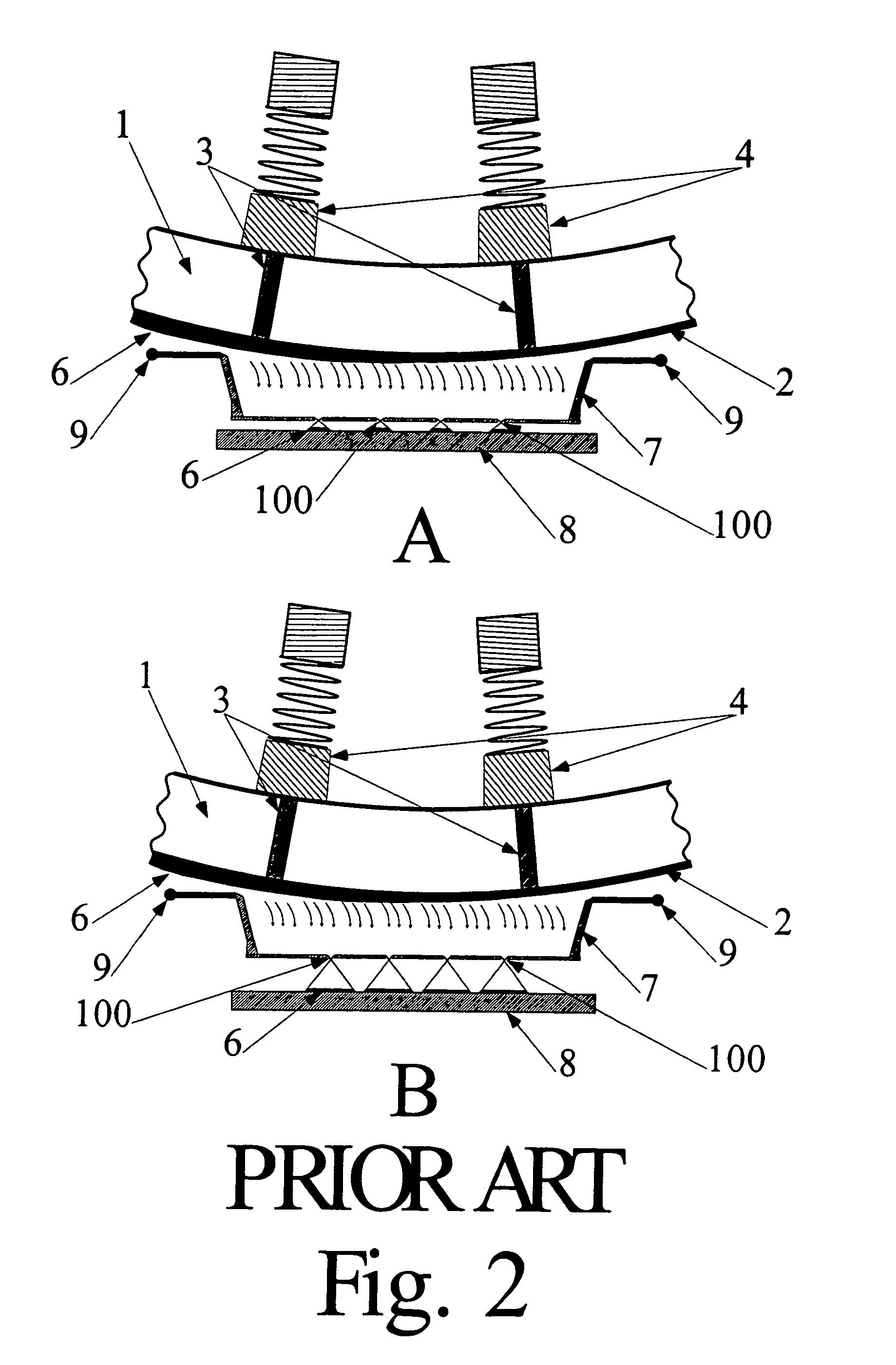

Apparatus for depositing an organic layer and method for controlling a heating unit thereof

InactiveUS20070077358A1Improve heating efficiencyMinimize timeVacuum evaporation coatingSputtering coatingCrucibleEvaporation

An apparatus for depositing an organic layer and a method for controlling the heating unit thereof are provided. The apparatus includes a crucible positioned in a deposition chamber and containing materials for evaporation. The apparatus also includes a heating unit having first and second heat sources for heating the crucible. A housing isolates the heat emitted from the heating unit and an outer wall anchors the crucible. A nozzle sprays the materials evaporated from the crucible. The first and second heat sources are positioned on first and second sides of the crucible, respectively, and are independently controlled to minimize the time required to stabilize the deposition rate.

Owner:SAMSUNG DISPLAY CO LTD

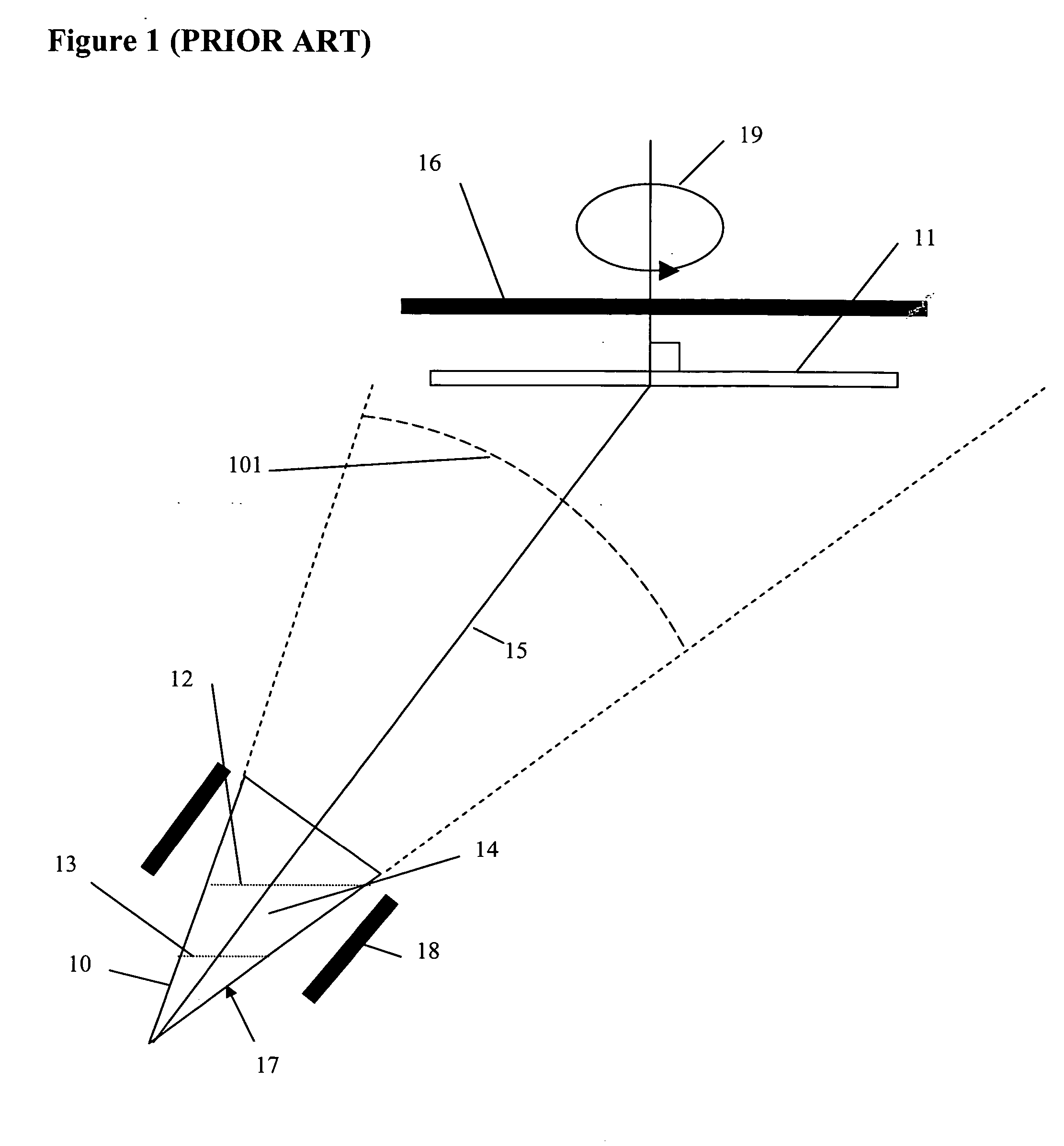

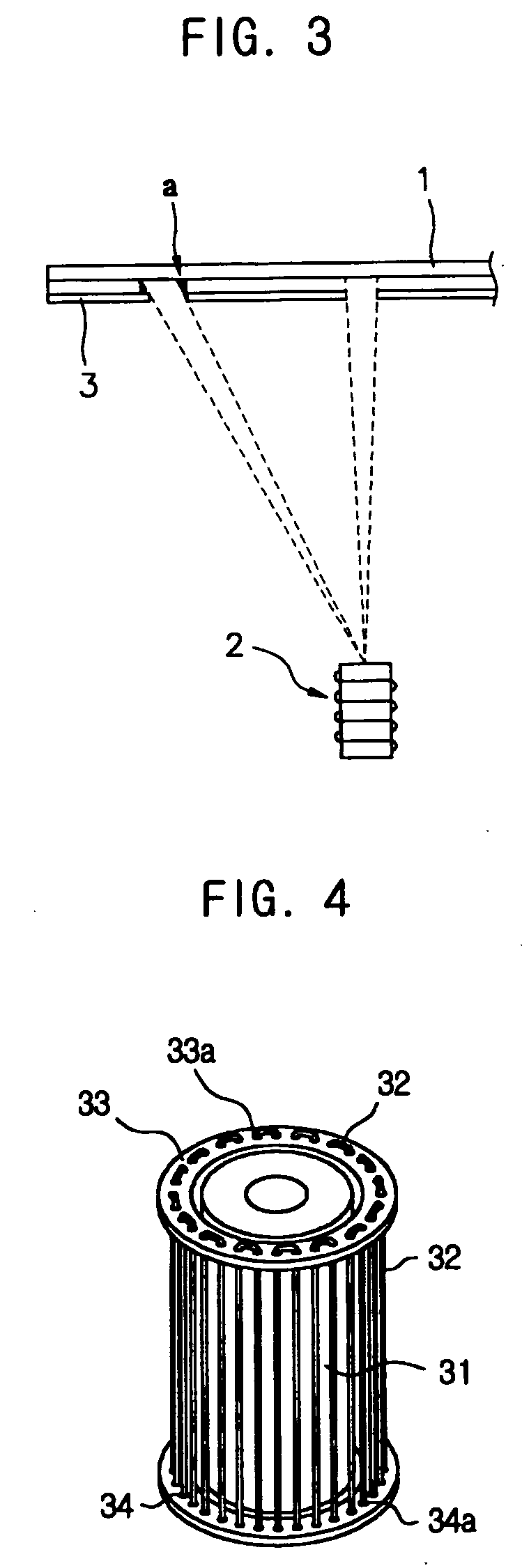

Patterned thin-film deposition using collimating heated masked assembly

InactiveUS20050183670A1Accurate timingUndesired heatingVacuum evaporation coatingSolid-state devicesEvaporationElectrical and Electronics engineering

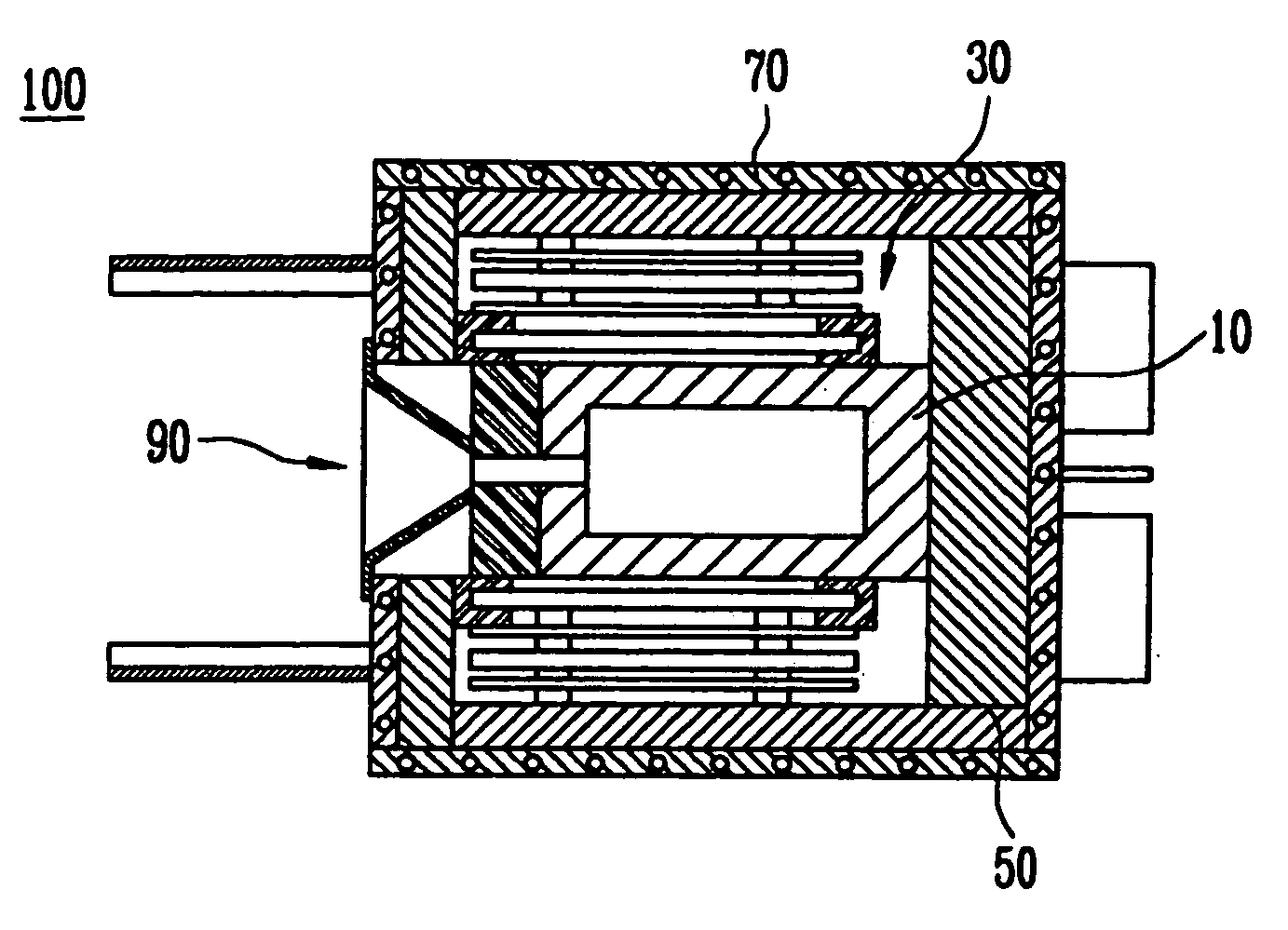

Scanning localized evaporation and deposition of an evaporant on a substrate utilizes a mask assembly comprised of a series of mask elements with openings thereon and spaced apart in a stack. The openings are aligned so as to direct the evaporant therethrough onto the substrate. The mask elements are heated and the stack may include a movable shutter element to block openings in adjacent mask elements. The evaporant streams are usually vertical but some may be oblique to the substrate, and they may be of different materials.

Owner:OPTOELECTRONICS SYST

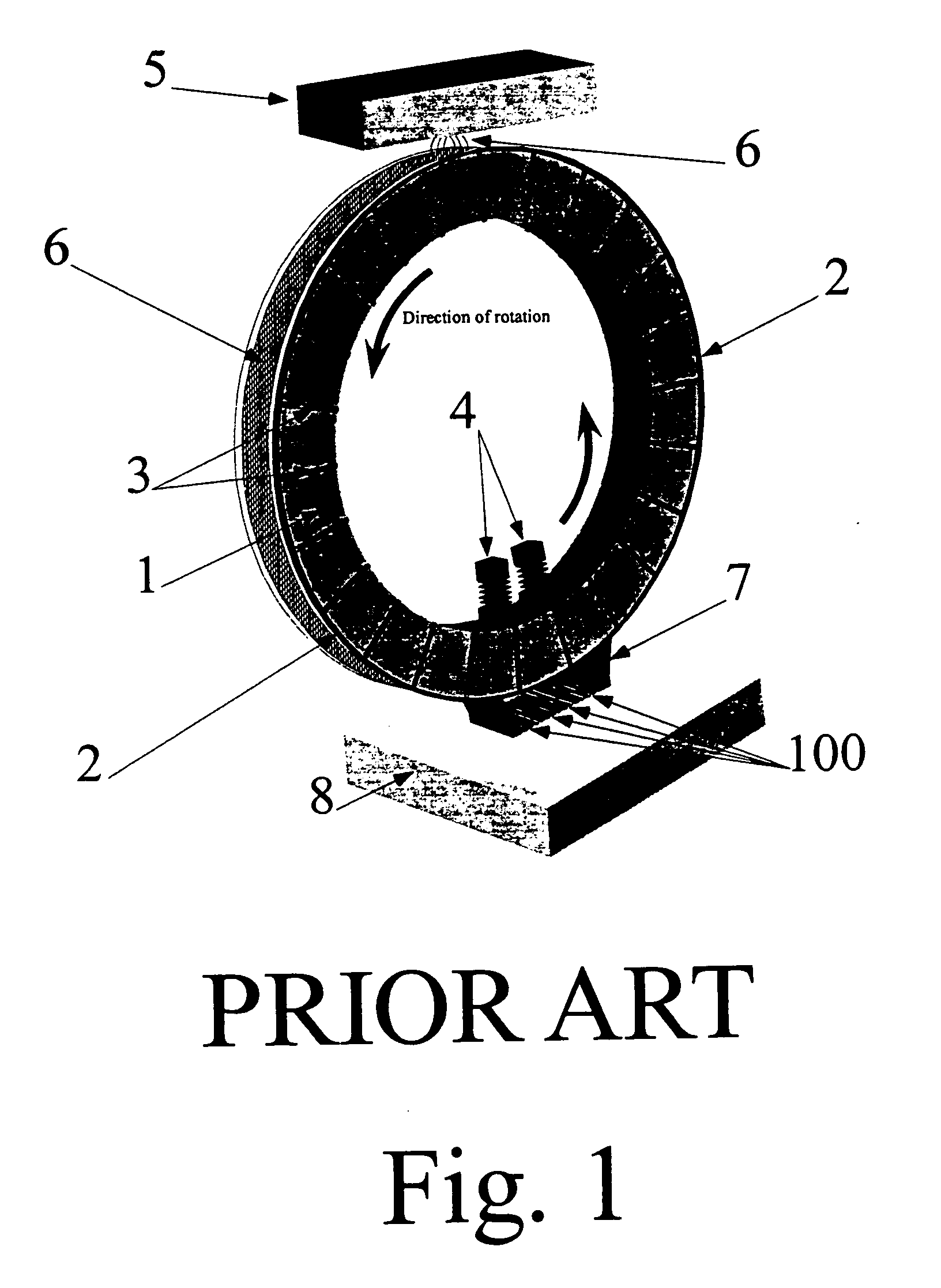

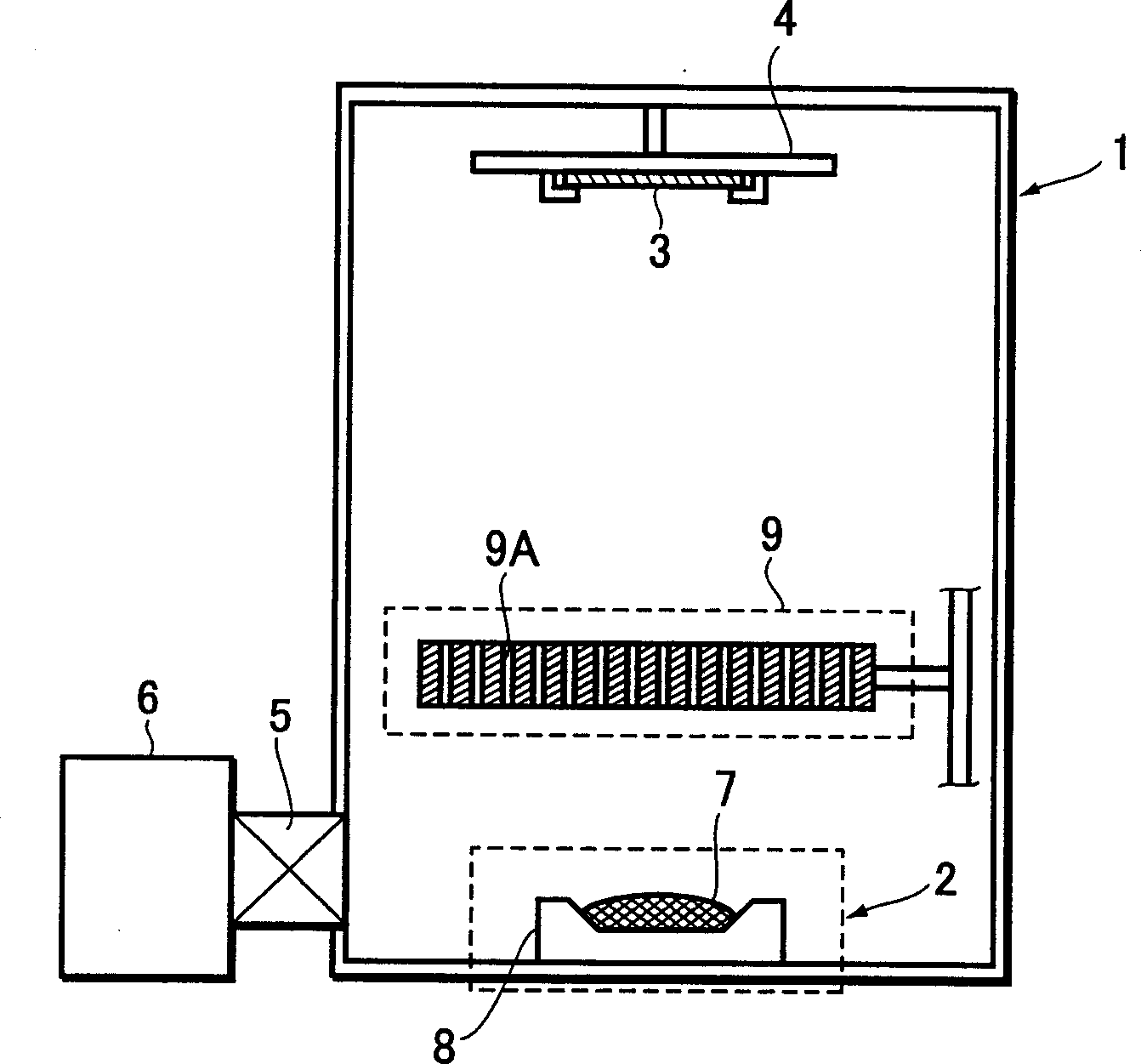

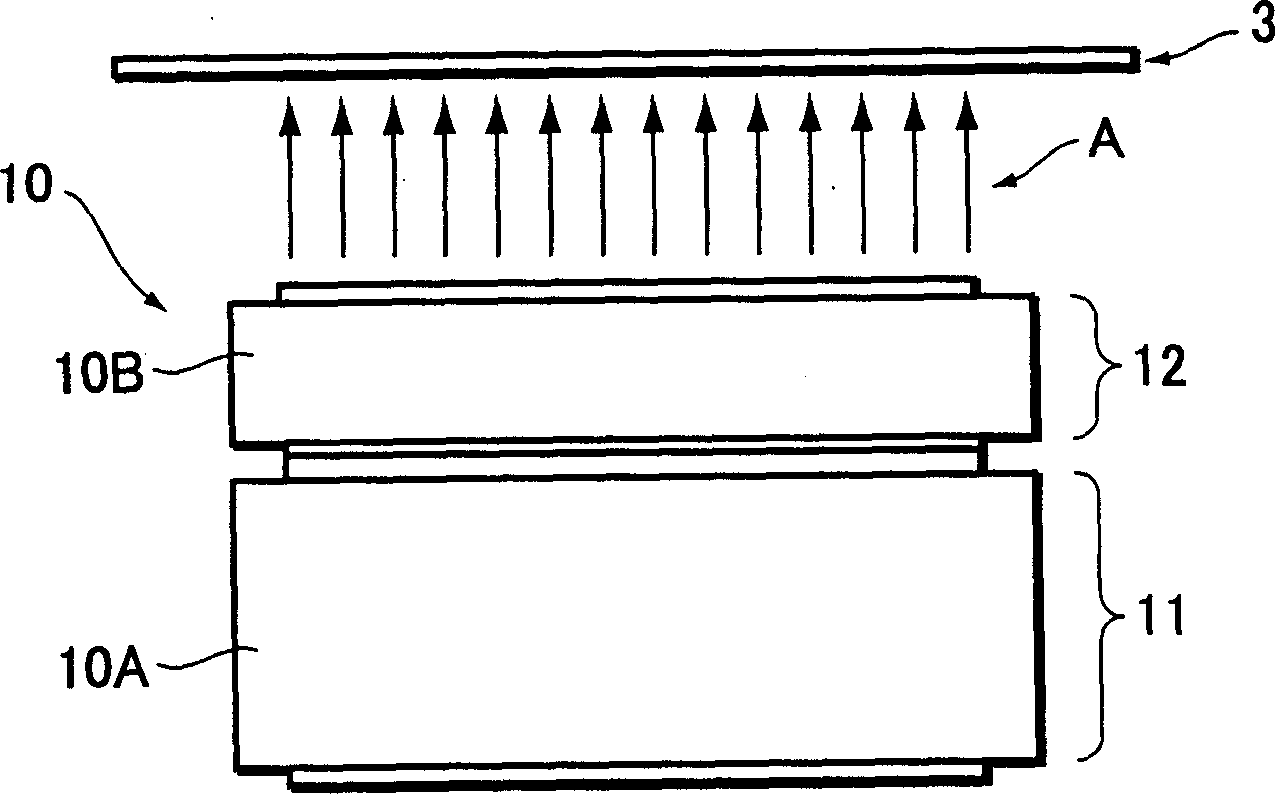

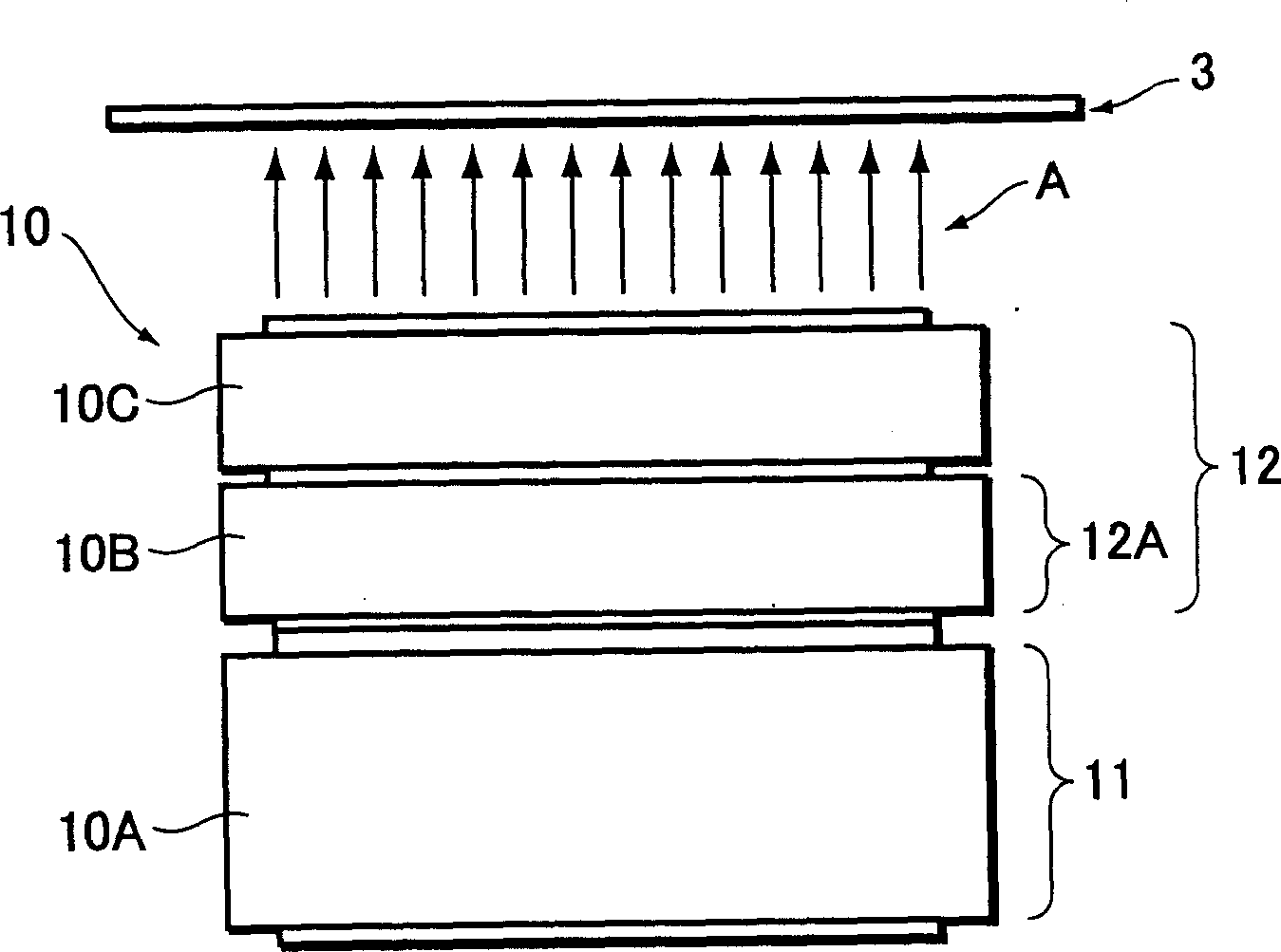

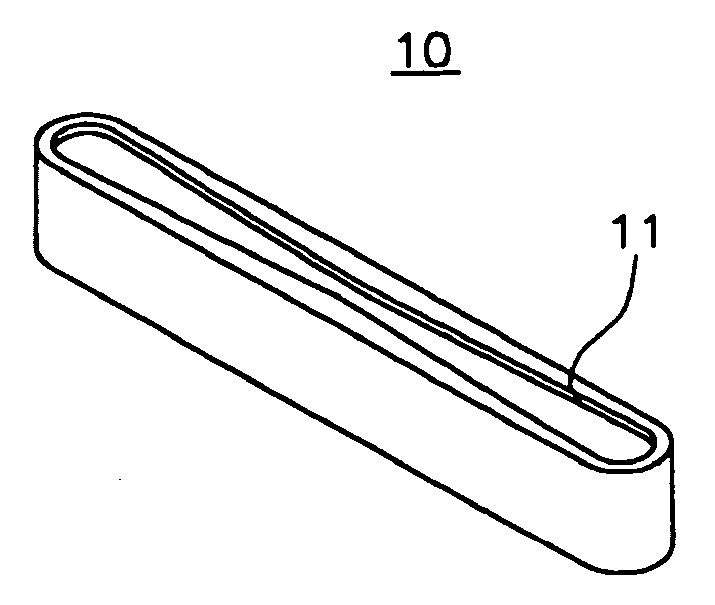

Vacuum evaporator and method for manufacturing organic el display panel using the same

InactiveCN1500904AUniform qualityImprove qualityElectroluminescent light sourcesSolid-state devicesEvaporationElectrode

There is provided a vacuum evaporator comprising an evaporation source (10) formed out of a stacked frame structure (10A, 10B), in which the bottom frame (10A) serves as a heating part (11) and another frame (10B) serves as an evaporation flow controller (12). This vacuum evaporator causes an improvement in utilization efficiency of a deposition material (B), an enhancement in qualities of a thin film and a uniform deposition on a larger-area substrate.

Owner:NIPPON STEEL CHEMICAL CO LTD

Means and method for a liquid metal evaporation source with integral level sensor and external reservoir

InactiveUS20050229856A1Long operating timeReduce hydrostatic pressureVacuum evaporation coatingSputtering coatingEvaporation (deposition)Engineering

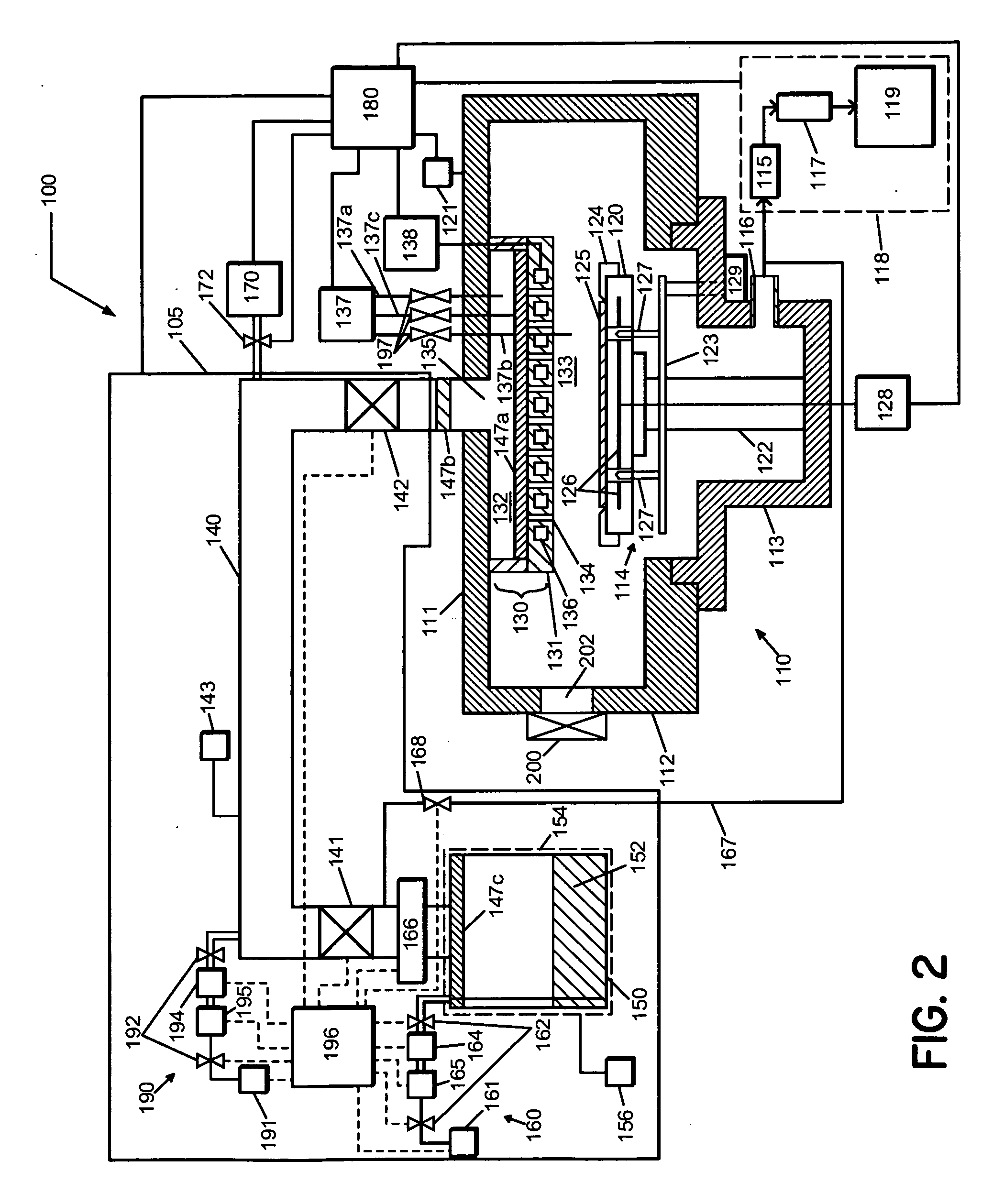

A liquid metal evaporation source for use in Molecular Beam Epitaxy and related metal vacuum deposition techniques. An evaporator is maintained at a high temperature to evaporate a liquid metal, a reservoir for holding the liquid metal source is maintained at a temperature above the melting point of the metal but below the temperature in the evaporator, and a hollow transport tube connecting the evaporator and reservoir is maintained at a temperature between these temperatures. The reservoir is in the shape of a hollow cylinder with a close-fitting cylindrical piston which is used to force the liquid metal through the hollow transport tube into the evaporator. The liquid metal will not flow past the piston seal if a suitably small gap is formed between the piston and the reservoir walls wherein the surface tension of the liquid metal will exceed its hydrostatic pressure against the piston thus forming a leak-tight seal.

Owner:RJM SEMICON

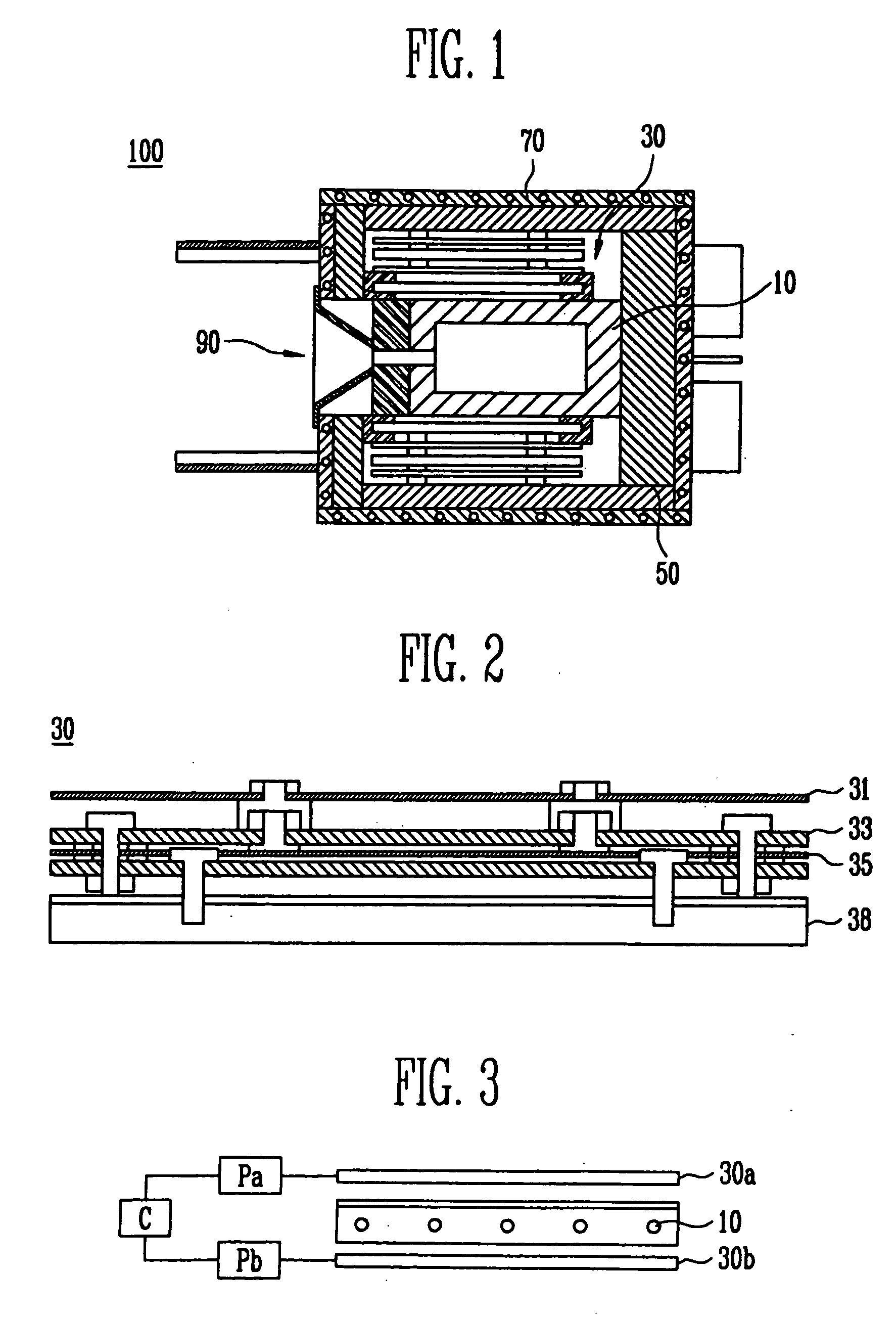

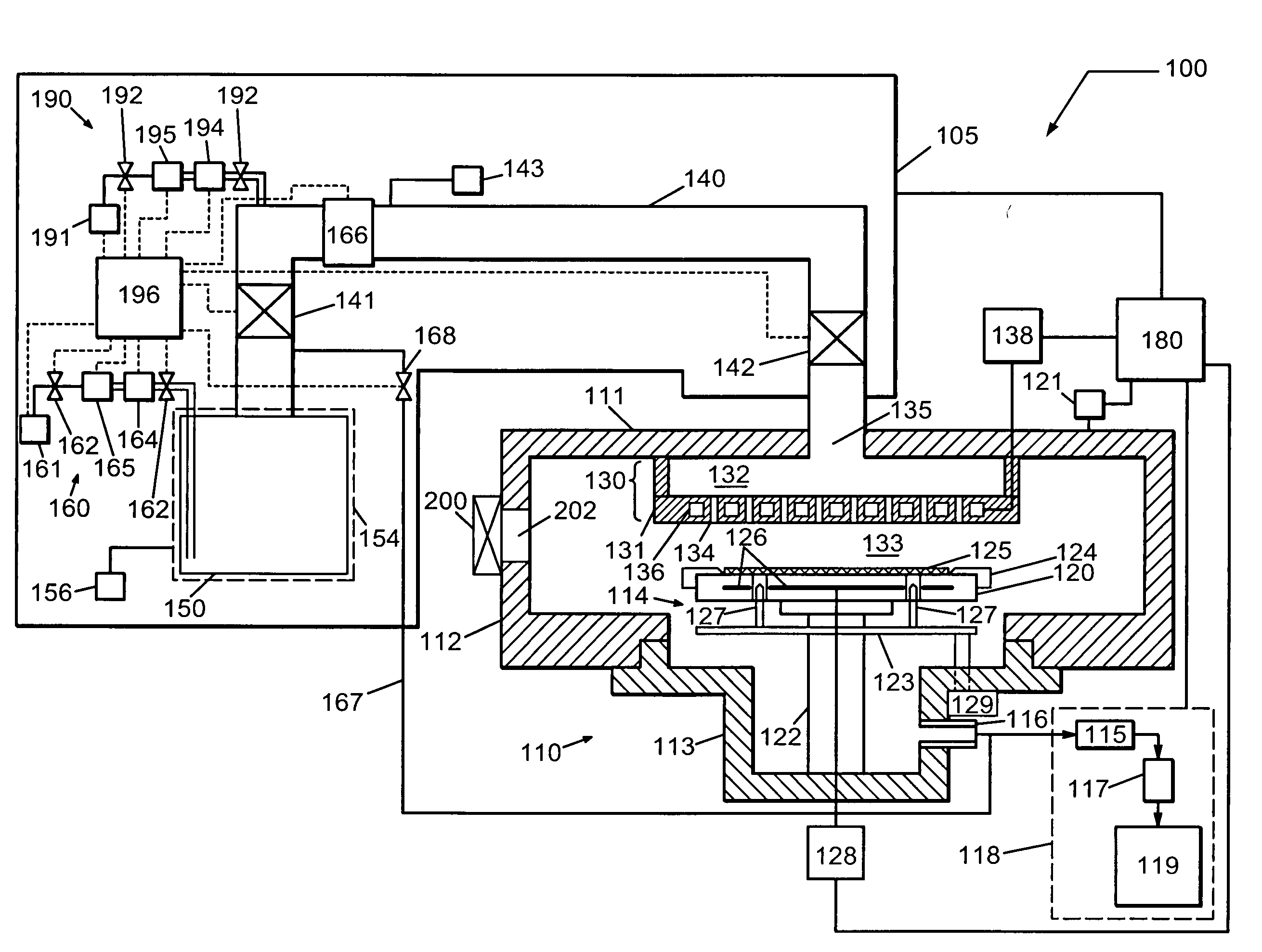

Multi-tray film precursor evaporation system and thin film deposition system incorporating same

ActiveUS20060112882A1Increase chanceVacuum evaporation coatingSemiconductor/solid-state device manufacturingEvaporation (deposition)Thin membrane

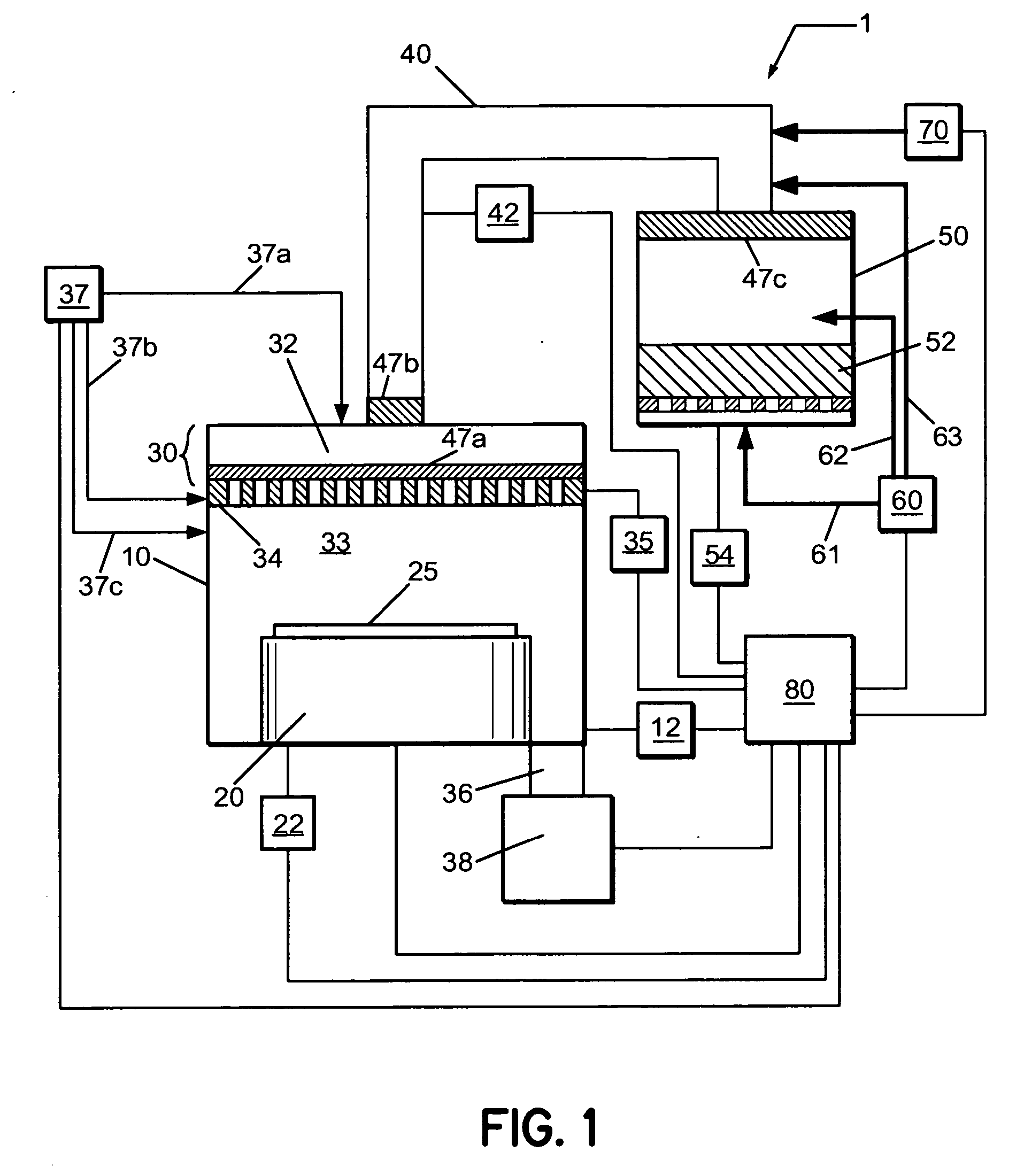

A high conductance, multi-tray solid precursor evaporation system coupled with a high conductance vapor delivery system is described for increasing deposition rate by increasing exposed surface area of solid precursor. The multi-tray solid precursor evaporation system includes a base tray with one or more upper trays. Each tray is configured to support and retain film precursor in, for example, solid powder form or solid tablet form. Additionally, each tray is configured to provide for a high conductance flow of carrier gas over the film precursor while the film precursor is heated. For example, the carrier gas flows inward over the film precursor, and vertically upward through a flow channel within the stackable trays and through an outlet in the solid precursor evaporation system.

Owner:TOKYO ELECTRON LTD

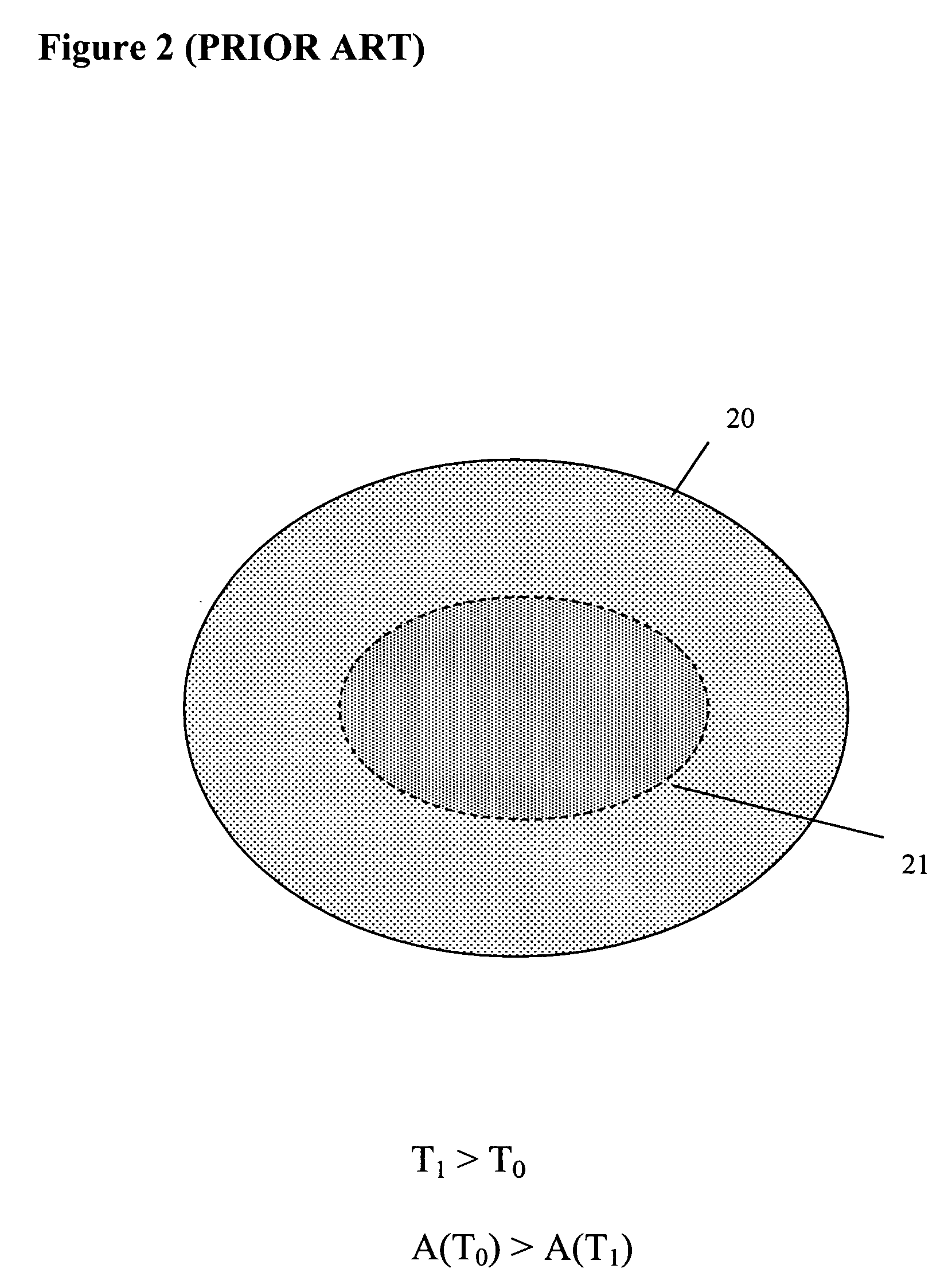

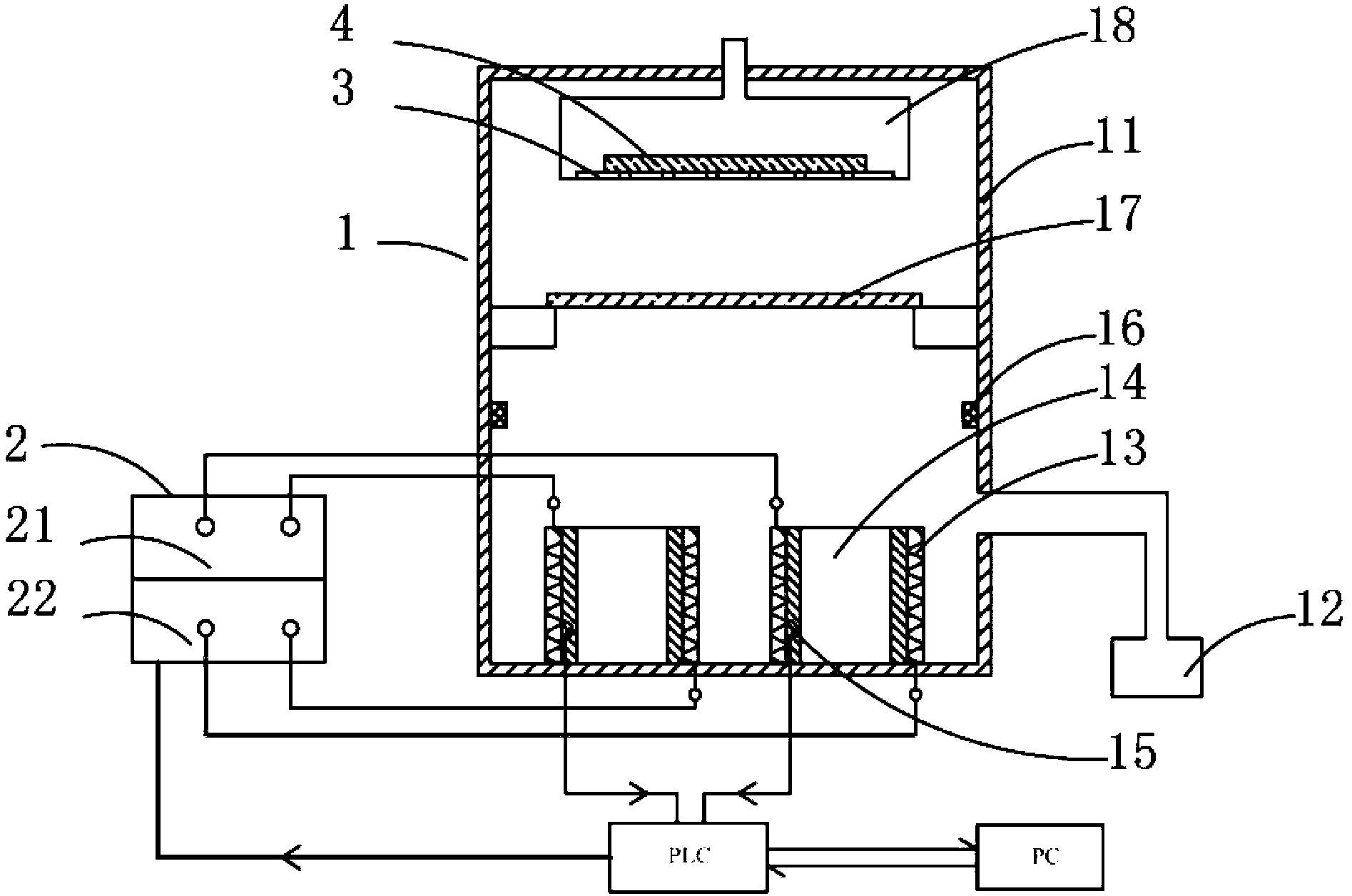

Temperature control system-based evaporation temperature control method for OLED (Organic Light Emitting Diode) organic layer

InactiveCN103305803AIncrease profitImprove uniformityVacuum evaporation coatingSolid-state devicesTemperature controlControl system

The invention discloses a temperature control system-based evaporation temperature control method for an OLED (Organic Light Emitting Diode) organic layer. The evaporation temperature control method comprises a preheating process and an evaporation process, wherein the preheating process is divided into three temperature-rise processes with temperature gradients; the evaporation process comprises a step of controlling the temperature of an evaporation source by controlling the power of an evaporation power supply on the basis of an actually-measured deposition rate curve. According to the temperature control system-based evaporation temperature control method for the OLED organic layer, the stabilization time of the temperature of the evaporation source and the deposition rate is shortened, the use ratios of the organic materials of the evaporation source are improved, meanwhile, the degradation, the degeneration and the like of the organic materials caused when the temperature rise is too fast or the risen temperature is too high are avoided, and the production cost is lowered; by utilizing a characteristic that the evaporation rate is changed by 20-30% when the evaporation temperature is changed by 1%, the accuracy of the temperature control is improved, the stability of evaporation temperature is maintained, and the uniformity of evaporated films is improved.

Owner:SICHUAN CCO DISPLAY TECH

Method for manufacturing optical member having water-repellent thin film

InactiveUS20030003227A1Rapidly vapor depositVacuum evaporation coatingSputtering coatingGas phaseEvaporation

A method for manufacturing an optical member by vapor depositing an antireflective film on a plastic optical member and vapor depositing a water-repellent thin film over the antireflective film. The vapor deposition of the water-repellent thin film is conducted by evaporating a fluorine-containing organic silicon compound in which the plastic optical member does not exceed the maximum temperature during the vapor deposition of antireflective film. The heating for evaporation comprises a first stage where the temperature is raised from an ordinary temperature to the prescribed temperature (1) not exceeding the starting temperature of vapor deposition of said compound, and the second stage where the temperature is raised from said prescribed temperature (1) to the prescribed temperature (2) equal to or higher than said starting temperature of vapor deposition. The rate of raising temperature of the first stage of raising temperature is higher than that of the second stage.

Owner:HOYA CORP

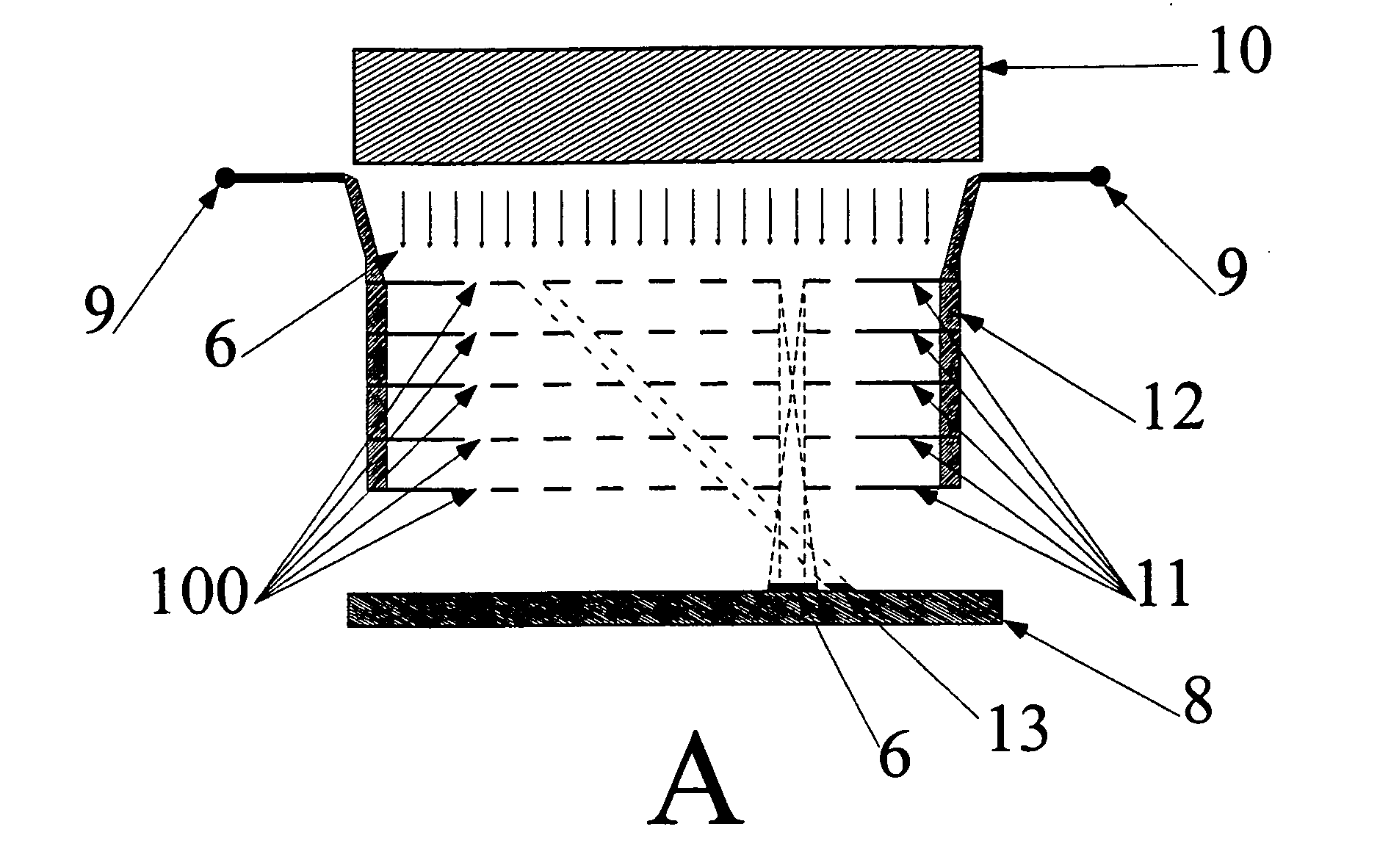

Evaporation source for deposition process and insulation fixing plate, and heating wire winding plate and method for fixing heating wire

InactiveUS20050034672A1Low use rateImprove shadow effectVacuum evaporation coatingSputtering coatingCrucibleEngineering

Disclosed is a linear evaporation source used for forming a thin film for an organic semiconductor device, the linear evaporation source comprising a crucible having a receiving space formed therein, for accommodating an evaporation material and an opening section formed at one side of the crucible in a length direction, wherein the opening section becomes narrow as it travels from both ends to a center portion thereof. If the thin film is formed using the linear evaporation source, a low material use rate of the vacuum evaporation source for the formation of the thin film is improved, thickness uniformity of the deposited thin film throughout the whole area is secured, and shadow effect due to the shadow mask is improved.

Owner:INNOVEX

Grating preparation method through pattern transfer based on nano-imprint

InactiveCN105487151ASimple preparation processReduce manufacturing costPhotomechanical apparatusDiffraction gratingsEvaporation (deposition)Organic solvent

The invention belongs to the technical field of optical thin-film micro-nano structures, and provides a grating preparation method through pattern transfer based on nano-imprint. The grating preparation method through pattern transfer based on nano-imprint is characterized by comprising the following steps that 1) polymers are coated on a substrate; 2) a pressing mould template is prepared; 3) the imprint process is performed: the substrate on which the polymers are coated and the pressing mould template are installed on the two imprint discs of an imprint machine, and pressurization is performed when temperature is close to polymer glassy phase change point temperature through heating so that the polymers are enabled to be fully filled with pressing mould patterns and then cooling is performed; and the pressing mould template and the substrate are separated when temperature is close to the phase change point through cooling so that a polymer mask film slot profile is obtained; and 4) micro-nano pattern transfer is performed: required grating ridge material fills in the polymer mask film slot profile by directly using an electron beam evaporation method, deposition thickness is monitored by utilizing the film thickness optical control technology, and then grating structures complementary with the mask film are formed by dissolving the polymer patterns through an organic solvent so that the gratings prepared through pattern transfer based on nano-imprint are obtained. The method is simple in the preparation technology and low in production cost.

Owner:WUHAN UNIV OF TECH

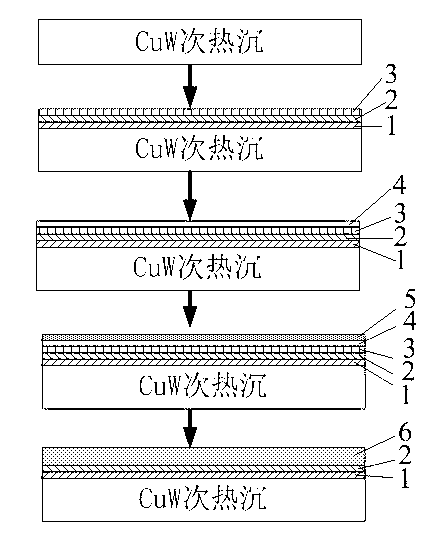

Preparation method for gold-tin eutectic solder

ActiveCN103170765AEnsure consistencyFast deposition rateVacuum evaporation coatingSputtering coatingAdditive ingredientEvaporation

The invention discloses a preparation method for gold-tin eutectic solder. According to the method, various metal films deposit on a CuW secondary heat sink by using the Au target and Sn target layering magnetron sputtering technique, and the gold-tin eutectic solder is formed by sintering of high temperature alloy. Compared with the prior art, the preparation method for the gold-tin eutectic solder has the advantages that the deposition rate is high, uniformity of deposited layer thicknesses can be guaranteed through rotation of a base plate in deposition, and the shortcomings that use ratios are low, plating reactions are difficult to control and thicknesses and ingredients are difficult to accurately control due to a traditional method of electron beam evaporation or layered plating are overcome.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Hot filament and heat evaporation vapor deposition membrane equipment

InactiveCN101397654ASolve the problem that the thermal evaporation treatment process cannot be carried out at the same timeFunctionalChemical vapor deposition coatingMaterials preparationGas phase

The invention discloses a hot filament and thermal evaporation vapor deposition thin film device for material preparation. The device consists of a hot filament chemical vapor deposition activation part for activating a source gas to deposit the material and forms a combination with a thermal evaporation part. A substrate bracket does combined movement relative to the hot filament or the thermal evaporation wire or the hot filament and the thermal evaporation wire.

Owner:MINNAN NORMAL UNIV

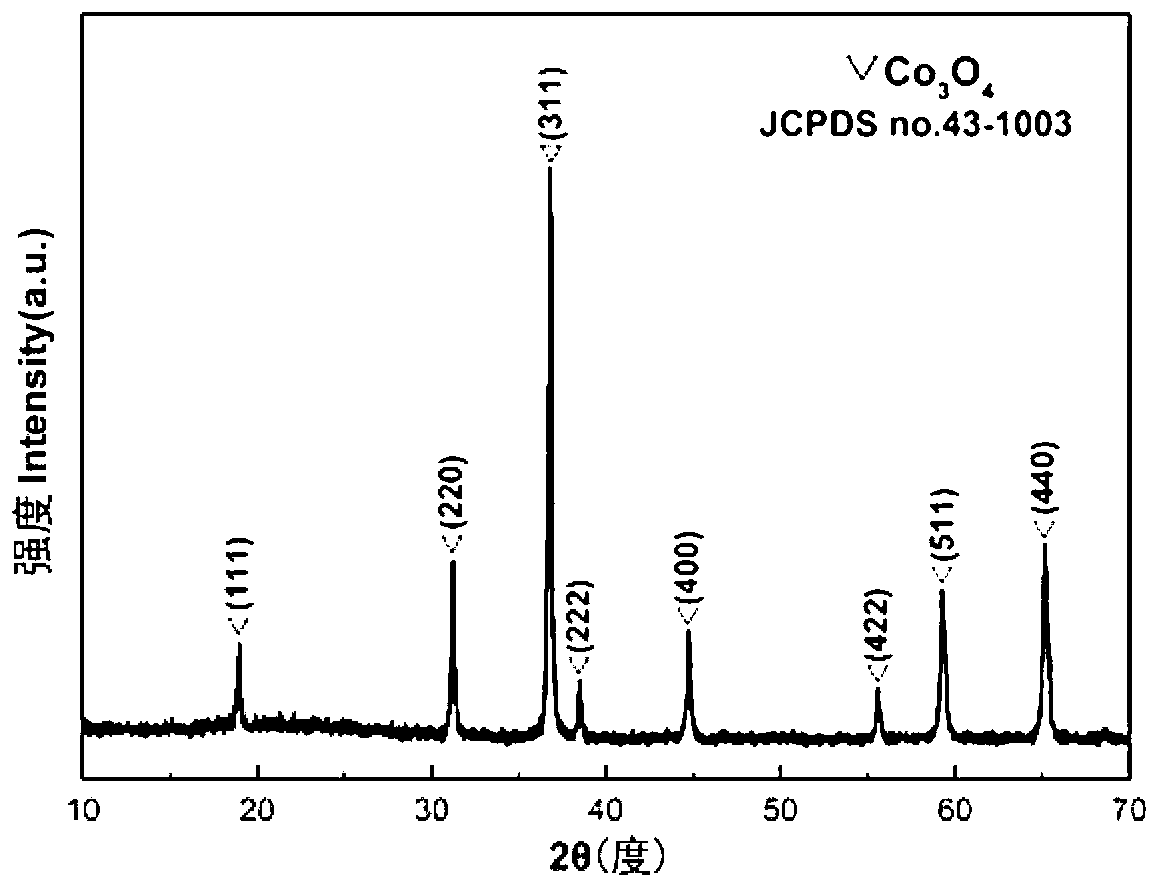

Cobaltosic oxide nanowire array based alcohol gas sensor and preparation method thereof

InactiveCN103217460AImprove performanceImprove adsorption capacityMaterial resistanceEvaporation (deposition)Alcohol

The invention discloses a cobaltosic oxide nanowire array based alcohol gas sensor. The alcohol gas sensor includes an insulating substrate, an electrode layer and a sensing electric conductor. The sensing electric conductor is composed of a cobaltosic oxide nano-array grows on the insulating substrate directly by a hydrothermal method. The invention also provides a preparation method of the alcohol gas sensor. The method includes: first employing the well-known thermal evaporation, sputtering or chemical evaporation deposition coating technology to deposit an electrode layer material on both ends of the insulating substrate, and controlling the thickness; and then making use of the hydrothermal method to let the cobaltosic oxide nano-array grow on the insulating substrate directly to serve as the sensing electric conductor of the gas sensor. The preparation process can generate the product with good crystallinity, has a short production period and no pollution, and avoids the difficulty of dispersing or manipulating a nano-material, thus being convenient for industrialized production. And the obtained gas sensor has excellent sensitivity to alcohol detection, and shows good selectivity, stability and repeatability.

Owner:ZHEJIANG UNIV

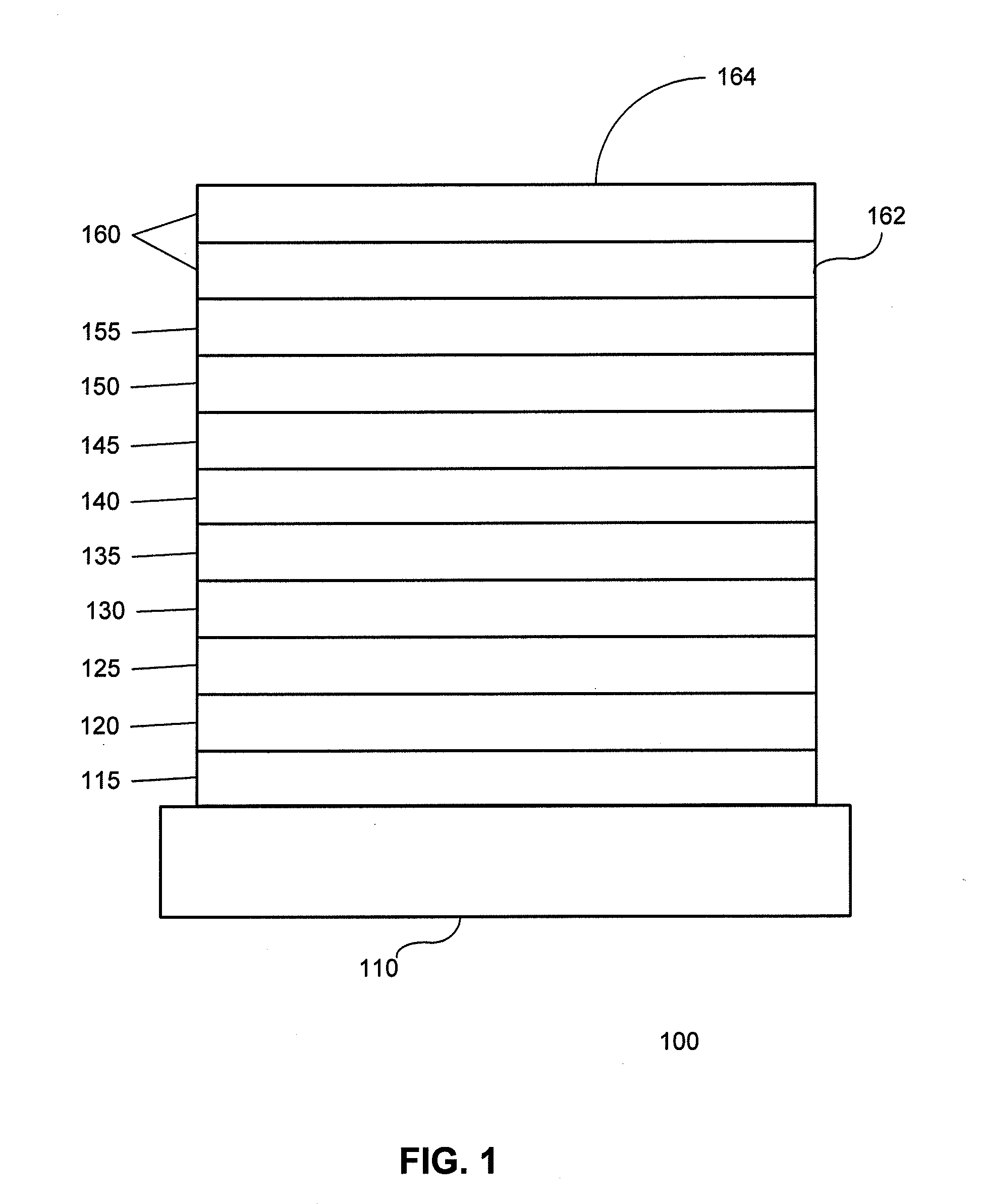

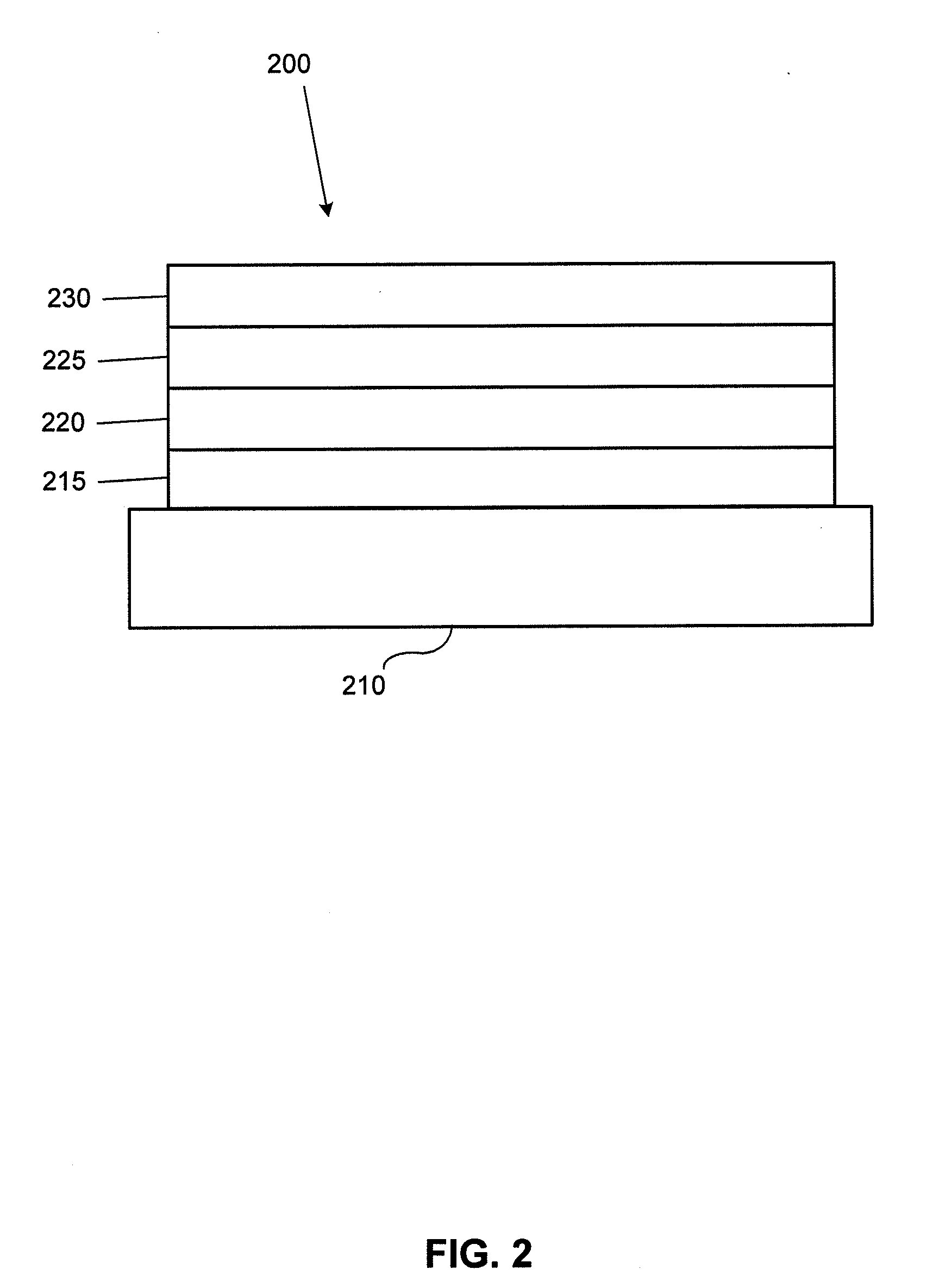

Materials and methods for OLED microcavities and buffer layers

InactiveCN103620807AGood colorImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingCharge injectionEvaporation (deposition)

The present teachings provide methods for forming organic layers for an organic light-emitting device (OLED) using an inkjet printing or thermal printing process. The method can further use one or more additional processes, such as vacuum thermal evaporation (VTE), to create an OLED stack. OLED stack structures are also provided wherein at least one of the charge injection or charge transport layers is formed by an inkjet printing or thermal printing method at a high deposition rate. The structure of the organic layer can be amorphous, crystalline, porous, dense, smooth, rough, or a combination thereof, depending on deposition parameters and post-treatment conditions. An OLED microcavity is also provided and can be formed by one of more of the methods.

Owner:KATEEVA

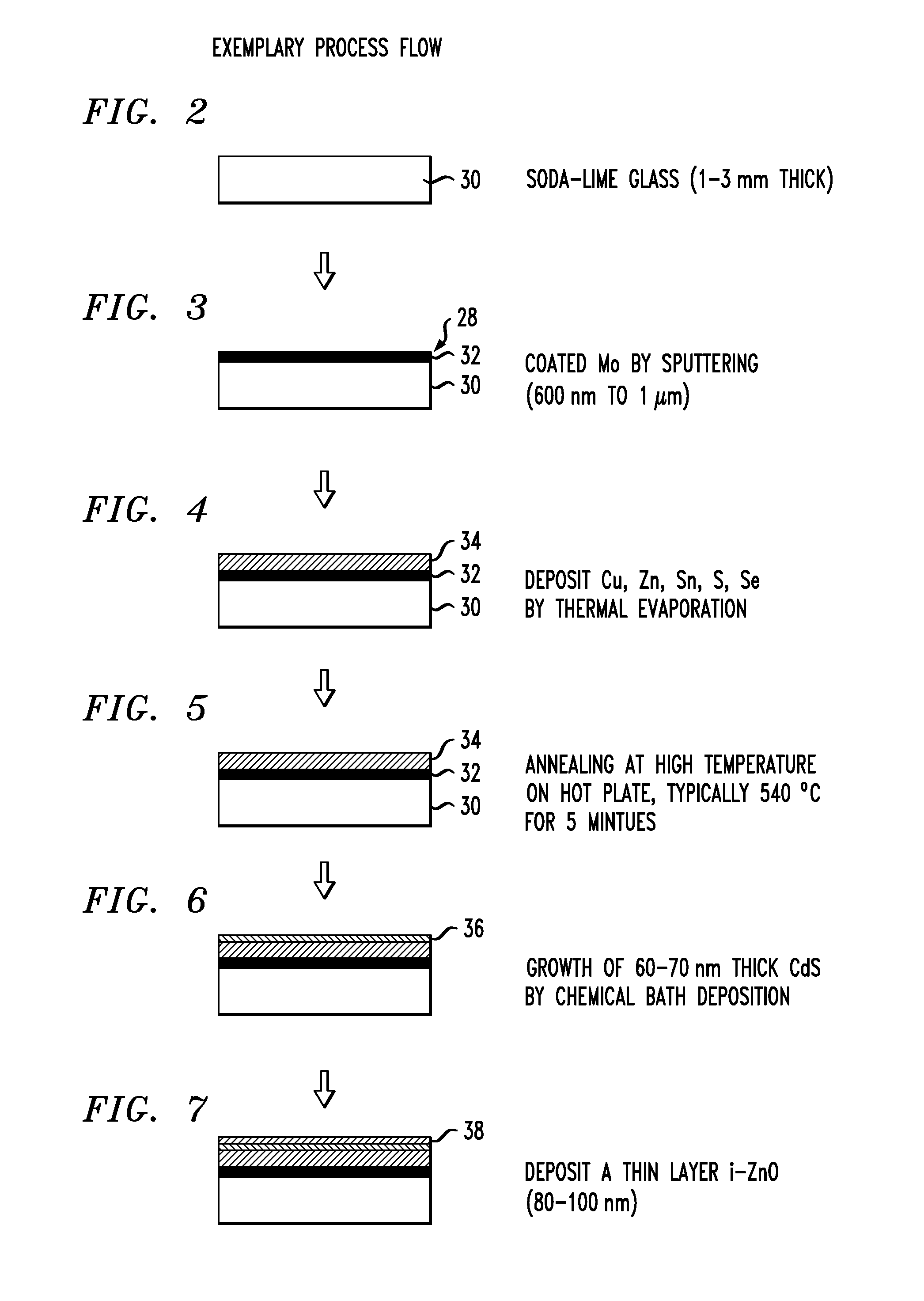

Fabricating kesterite solar cells and parts thereof

ActiveUS20120100664A1Precise compositionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationDeposition processVacuum deposition

A Kesterite film is vacuum deposited and annealed on a substrate. Deposition is conducted at low temperature to provide good composition control and efficient use of metals. Annealing is conducted at a high temperature for a short period of time. Thermal evaporation, E-beam evaporation or sputtering in a high vacuum environment may be employed as part of a deposition process.

Owner:GLOBALFOUNDRIES US INC

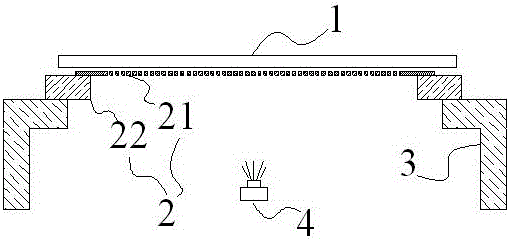

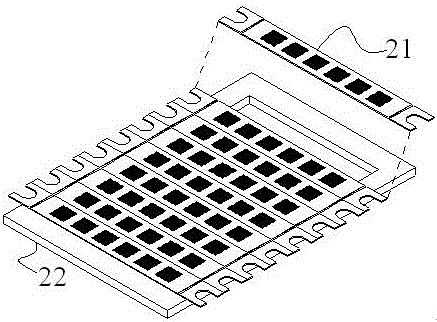

Mask plate assembly for high-precision evaporation

InactiveCN105821373AHigh positioning accuracyImprove performanceSolid-state devicesVacuum evaporation coatingEvaporation (deposition)Engineering

The invention provides a mask plate assembly for high-precision evaporation. The mask plate assembly comprises a mask frame and at least one set of mask units arranged on the mask frame. Each mask unit is formed by two layers of structures including a mask appearance layer and a mask opening layer; and through the reasonable arrangement of the structure of the two layers of structures including the mask appearance layers and the mask opening layers, the mask plate assembly can have the higher position precision, deposition of follow-up OLED substrate surface organic materials can be well achieved, and the quality of OLED products is effectively improved.

Owner:KUN SHAN POWER STENCIL

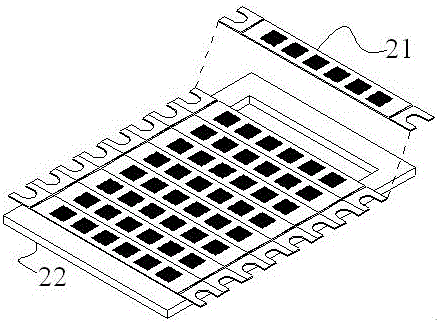

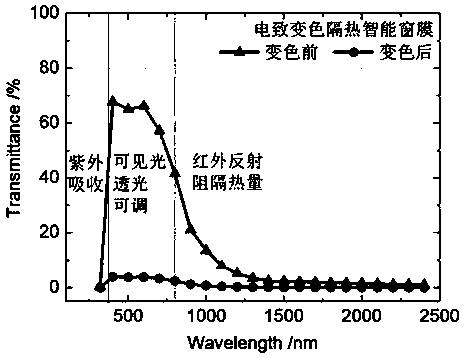

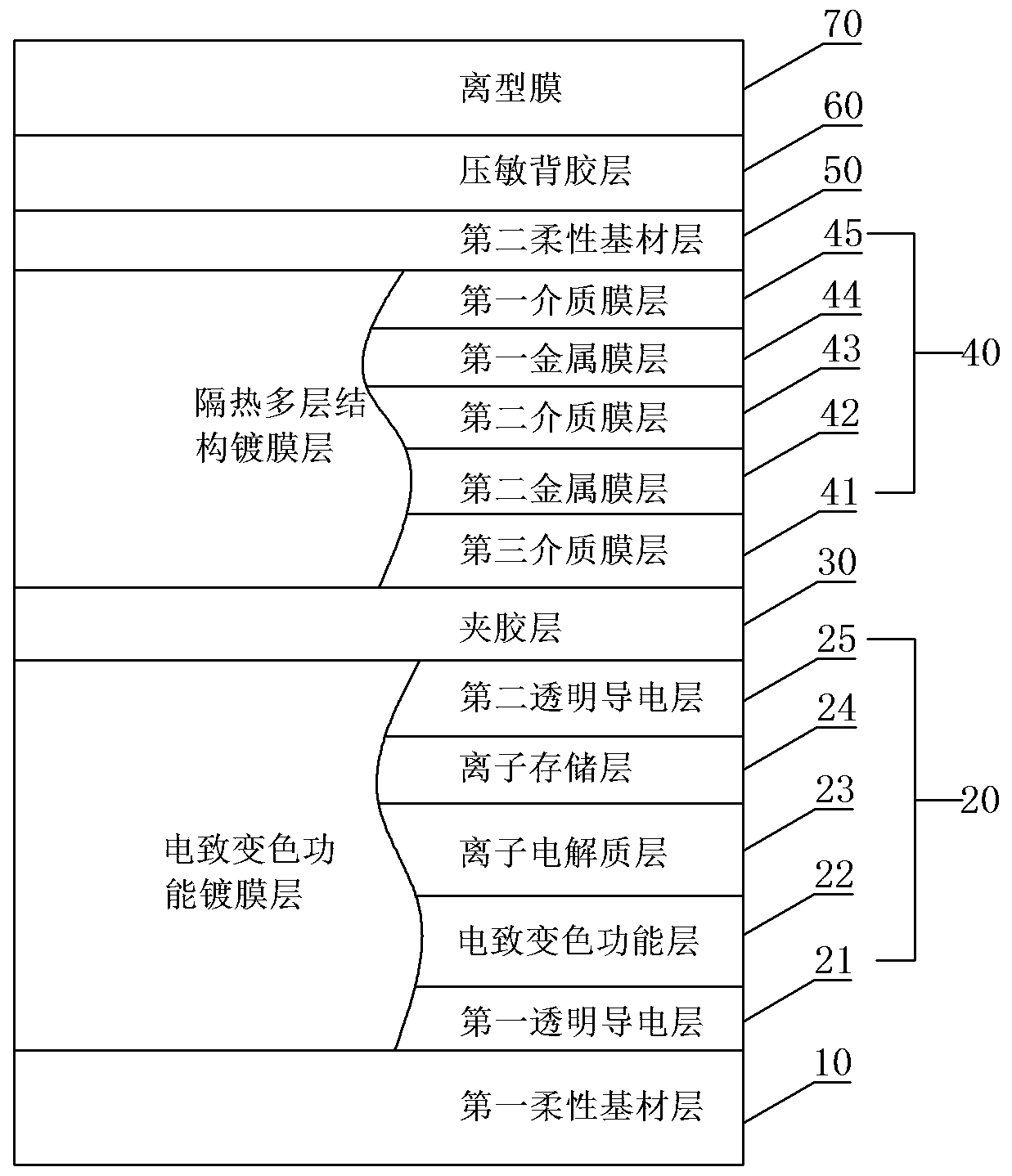

Flexible electrochromic thermal insulating intelligent window film and preparation technology thereof

PendingCN107765490AAchieve preparationImprove infrared heat radiation rejection rateNon-linear opticsIonLaminated composites

The invention discloses a flexible electrochromic thermal insulating intelligent window film and a preparation technology thereof. The window film is prepared by adopting a vacuum physical vapor deposition process such as reel-to-reel magnetron sputtering or evaporation; the surface of a flexible substrate such as PET (Polyethylene Terephthalate) is sequentially coated with a transparent conductive film layer, an electrochromic functional film layer, a solid film electrolyte layer, an ion storage film layer and a transparent conductive film layer to obtain a flexible electrochromic functionalwindow film; a silver-containing multilayer thermal insulating window film is prepared on the surface of the flexible substrate such as the PET by adopting a reel-to-reel magnetron sputtering continuous coating technology; further, the electrochromic window film is compounded with the thermal insulating window film by using a laminating process, and finally, the multi-functional intelligent windowfilm with the characteristics of electrochromic property, thermal insulation, energy saving as well as explosion resistance and splash resistance is otained. Compared with a traditional low radiationthermal insulating window film, the flexible electrochromic thermal insulating intelligent window disclosed by the invention has the advantage that energy consumption of windows can be further reduced by 50 percent or above; compared with existing electrochromic glass products, the flexible electrochromic thermal insulating intelligent window disclosed by the invention has the advantages of lowercost, greater convenience in installation and higher safety; compared with an existing research and development technology of the flexible electrochromic film, the preparation technology has the advantages of more excellent stability, more excellent energy-saving and thermal insulation characteristics, higher suitability for batch production of large-size window films and the like.

Owner:WEIFANG YITONG ELECTRONICS CO LTD

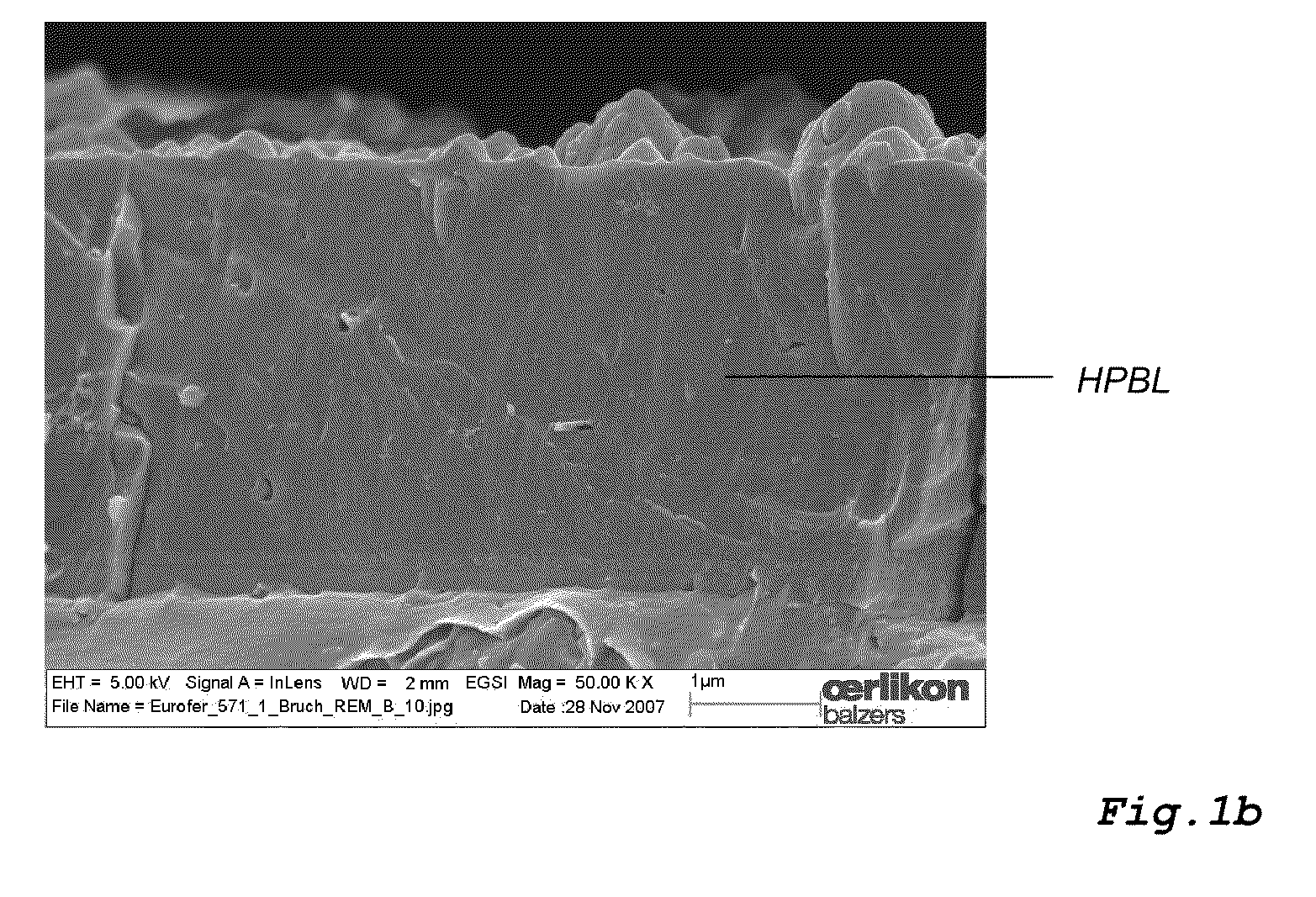

Permeation barrier layer

ActiveUS20090191417A1Improve wear resistanceReduce heat transferFinal product manufactureVacuum evaporation coatingGas phaseEvaporation

The method for manufacturing a hydrogen permeation barrier comprises the steps ofa) depositing on a substrate (SUB) a layer system (LS) comprising at least one layer (L1,L2,L3);characterized in that step a) comprises the step ofb) depositing at least one hydrogen barrier layer (HPBL) comprising an at least ternary oxide.The apparatus comprises a sealable volume and a wall forming at least a portion of a boundary limiting said volume, wherein said wall comprises a hydrogen permeation barrier comprising a layer system (LS) comprising at least one layer, wherein said layer system comprises at least one hydrogen barrier layer (HPBL) comprising an at least ternary oxide.Preferably, said at least ternary oxide is substantially composed of Al, Cr and O, and said depositing said at least one hydrogen barrier layer (HPBL) is carried out using a physical vapor deposition method, in particular a cathodic arc evaporation method.Preferably, step a) comprises depositing on said substrate at least one of: an adhesion layer (AdhL), a hydrogen storage layer (HStL), a protective layer (ProtL), in particular a thermal barrier layer (ThBL), a diffusion barrier layer (DBL), an oxidation barrier layer (OxBL), a chemical barrier layer (ChBL), a wear resistance layer (WRL).Excellent hydrogen permeation barrier properties can be achieved, and the layer system can be tailored as required by an envisaged application.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

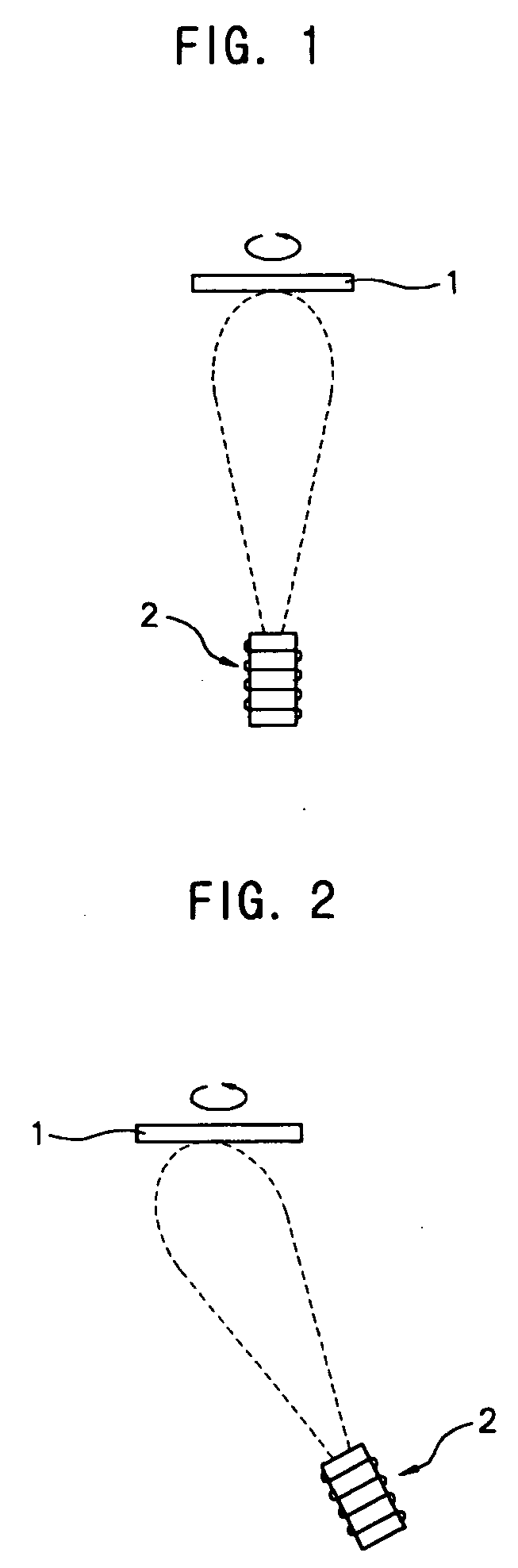

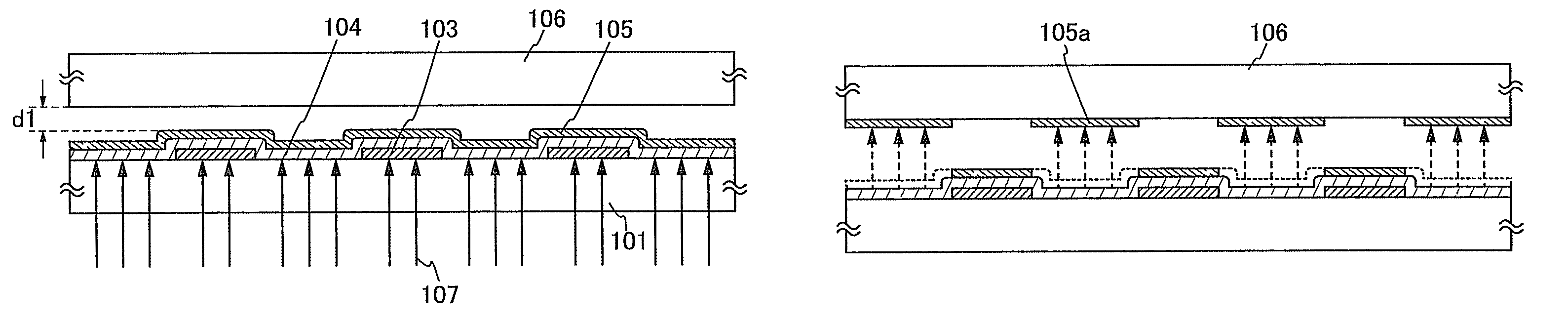

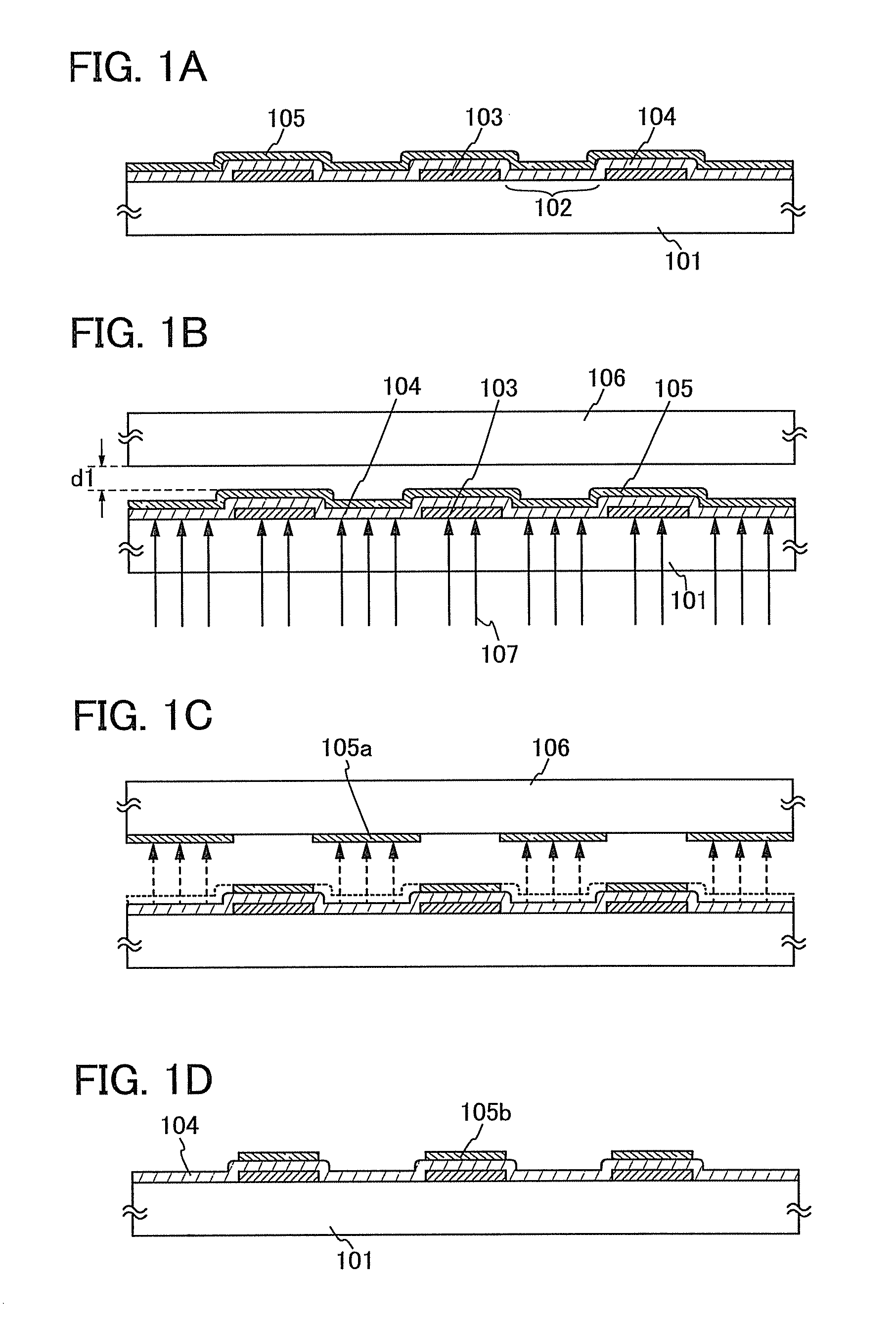

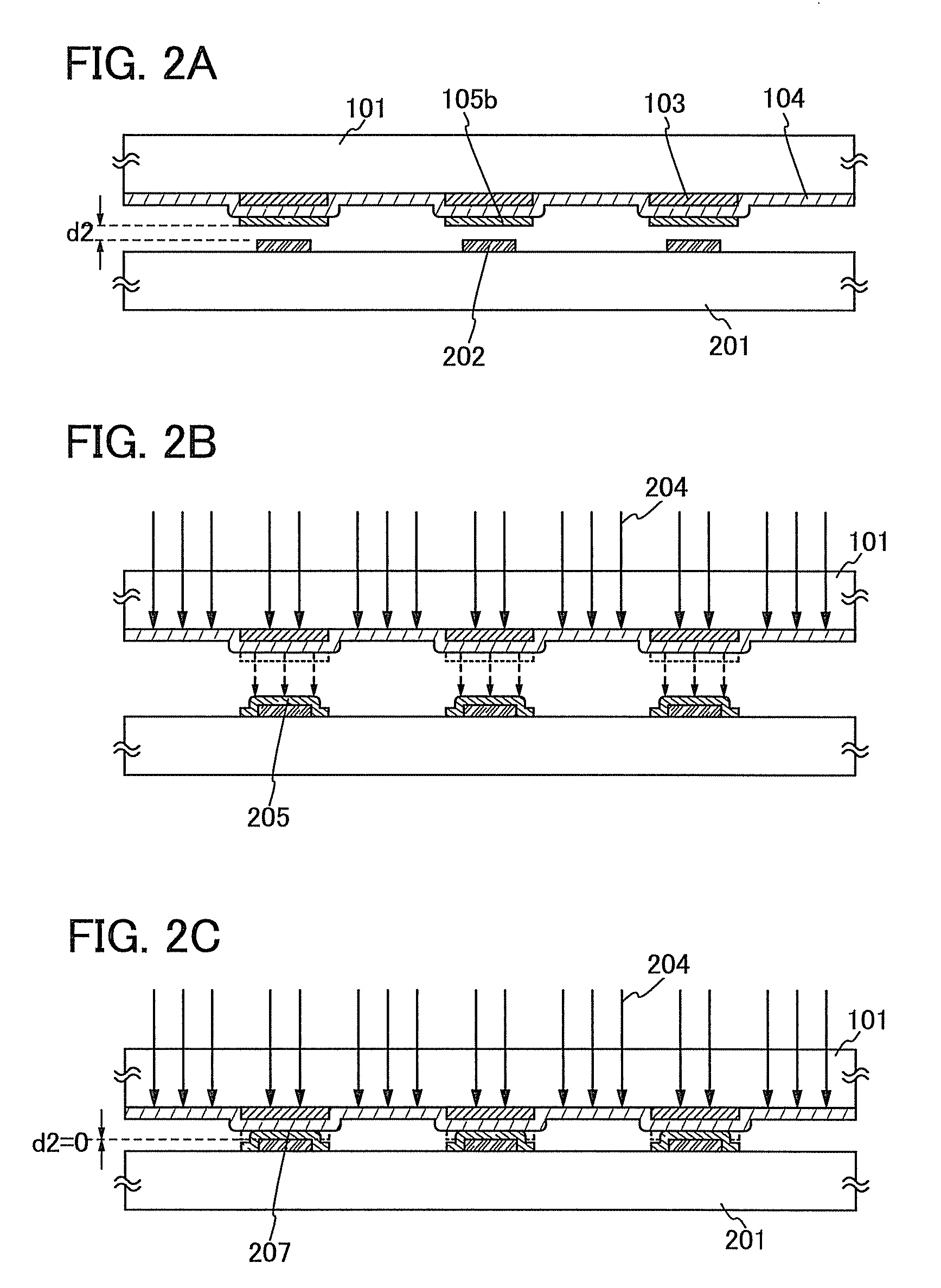

Method for manufacturing light-emitting device

InactiveUS7993945B2High definitionLong lastingElectroluminescent light sourcesSolid-state devicesEvaporationOptoelectronics

An object is to provide a method for manufacturing a light-emitting device with high definition, high light-emitting characteristics, and the long lifetime by employing a method in which a desired evaporation pattern can be formed and an excess evaporation of a material layer which is to be the transfer layer is prevented and in which deterioration of the material or the like is hard to occur in a transfer step. This is a method for manufacturing a light-emitting device, in which irradiation with first light is performed to pattern a material layer over a first substrate which is an evaporation donor substrate and irradiation with second light is performed to evaporate the material layer patterned onto a second substrate which is a deposition target substrate.

Owner:SEMICON ENERGY LAB CO LTD

A cleaning method of a metal film forming mask

InactiveCN104614933AEasy to cleanLow costOriginals for photomechanical treatmentEvaporation (deposition)Organic solvent

A cleaning method of a metal film forming mask is disclosed. The method includes following three steps: S1) forming an organic layer on the surface of a mask by evaporation deposition; S2) putting the mask with the organic layer obtained in the step S1 into a metal film forming cavity, and performing metal evaporation deposition; and S3) putting the mask obtained in the step S2) into an organic solution and cleaning. The method can allow the metal film forming mask to be cleaned in a cleaning machine applying organic solvents, effectively prevents inconvenience in transportation processes, and saves the cost of delivering the mask to outside to be cleaned.

Owner:TRULY HUIZHOU SMART DISPLAY

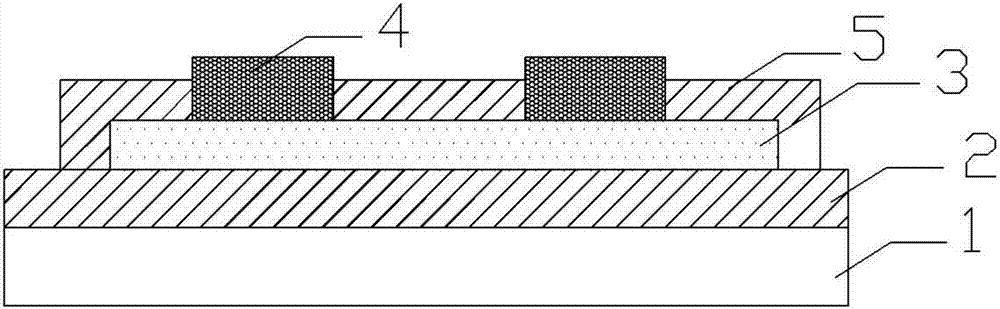

Mask plate assembly for evaporation of OLED

PendingCN105714247AHigh positioning accuracyAchieving opening position compensationVacuum evaporation coatingSputtering coatingEvaporation (deposition)Materials science

The invention provides a mask plate assembly for evaporation of an OLED. The mask plate assembly comprises a mask frame and at least one mask unit arranged on the mask frame, wherein each mask unit is composed of two layers of structures including a mask layer and a mask supporting layer. By reasonably arranging the two layers of structures including the mask layer and the mask supporting layer of each mask unit, the mask plate assembly provided by the invention has a relatively high position precision, deposition of an organic material on the surface of a follow-up OLED substrate can be better satisfied, and the quality of an OLED product is effectively improved.

Owner:KUN SHAN POWER STENCIL

Method of Treating Non-Refrigerated, Spectrally-Selective Lead Selenide Infrared Detectors

InactiveUS20080224046A1Improve the detection rateImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingGas analysisLinear matrix

The invention relates to a method of processing non-refrigerated lead selenide infrared detectors, consisting in: 1) selecting the substrate and preparing same; 2) delineating and depositing multilayer interference filters; and 3) treating polycrystalline lead selenide infrared detectors on the interference filters, comprising the following steps, namely 3a) metal deposition, 3b) delineation of the metal deposit, 3c) delineation of the sensor, 3d) PbSe deposition by means of thermal evaporation, 3f) processing of sensor, 3g) thermal treatment in order to sensitise the active material, and 3h) deposition of a passivator layer on the active material. The inventive method is unique in that it can be used to treat differently-shaped non-refrigerated infrared detectors on the same substrate, including discrete elements, multielements, linear matrices, two-dimensional matrices, etc., with the responses of each being modified by design by the corresponding interference filter. The invention is suitable for low-cost infrared detectors that are used for process control, gas analyses, temperature measurements, military applications, etc.

Owner:MINIO DE DEFENSA

Manufacturing method of carbon nano-tube micro-channel cooler system

InactiveCN102169838AImprove cooling effectNanostructure manufactureSemiconductor/solid-state device detailsEvaporation (deposition)Ptru catalyst

The invention discloses a manufacturing method of a carbon nano-tube micro-channel cooler system for a radiating chip in a very-large scale integrated circuit (VLSI), which comprises the following steps of: firstly, manufacturing a pattern with required fine scale through a photoetching and peeling process; meanwhile, adhering a catalyst film obtained through an evaporation method on a surface ofthe pattern; secondly, placing a silicon wafer with the catalyst film in a heating furnace of a carbon nano-tube growth machine, growing in a high-temperature chemical vapor deposition mode to obtainthe required carbon nano-tube cluster; finally, transferring the carbon nano-tube cluster on a surface of a heating chip by adopting a transferring process through a metal coating sprayed on the surface of the carbon nano-tube, heating a sealing cover, then finishing the manufacturing process of the carbon nano-tube micro-channel cooler; then radiating through the cooling liquid flowing through an entry guide to finish the manufacturing of the carbon nano-tube micro-channel cooler system. The radiating performance is obviously improved and a more efficient radiating method is provided for radiating the chip in the integrated circuit.

Owner:SHANGHAI UNIV

Groove and microstructure composite liquid absorption core and manufacturing method thereof

InactiveCN105091648ASmall capillary radiusIncrease capillary pressureIndirect heat exchangersEvaporation (deposition)Electroless deposition

The invention discloses a groove and microstructure composite liquid absorption core. The groove and microstructure composite liquid absorption core comprises a red copper basal body provided with a groove in the surface, wherein microstructure layers with thicknesses of 0.1-1000 microns are respectively arranged on the inner surface of the groove and the outer surface, provided with the groove, of the red copper basal body; and the microstructure layers mainly consist of fine copper particles with particle sizes within 0.1-20 microns. The invention further discloses a manufacturing method of the composite liquid core; and the method comprises the following steps: (1) the groove structure is machined on the red copper basal body by a broaching or planing process; (2) after the groove structure is cleaned, the microstructure is built on the surface of the groove as a cathode by an electrochemical deposition method; and (3) the interface bonding strength between the microstructure and the surface of the groove is improved through a sintering curing process. The composite liquid absorption core, provided by the invention, can provide excellent capillary force, is excellent in permeability, and facilitates to flow liquid on a condensation section back to an evaporation section; and the manufacturing method is simple, easy to be controlled, high in production efficiency and low in cost, and can be widely applied to such two-phase heat transfer devices as heat pipes, heat columns and soaking plates.

Owner:SOUTH CHINA UNIV OF TECH

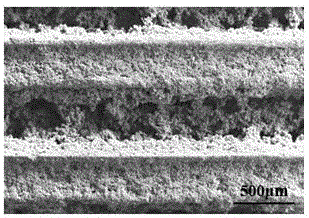

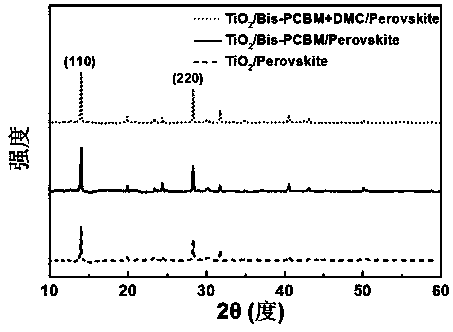

Preparation method of perovskite battery with n-type doped electron transport layer and TiO2 layer

ActiveCN108091766AIncrease short circuit currentImprove photoelectric conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEvaporation (deposition)Electrical battery

The invention provides a preparation method of a perovskite battery with an n-type doped electron transport layer and a TiO2 layer. The method comprises the following steps of: (1) FTO transparent conductive glass substrate cleaning and TiO2 thin film preparation: an upper TiO2 layer is deposited on a treated FTO transparent conductive glass substrate, and the FTO transparent conductive glass substrate with the deposited upper TiO2 layer is arranged in a drying oven for later use; (2) Bis-PCBM and DMC composite film preparation; (3) spin coating treatment on the FTO transparent conductive glass substrate with the deposited upper TiO2 layer; (4) perovskite film preparation; (5) Spiro-OMeTAD thin film preparation: a Spiro-OMeTAD solution is spin coated on the FTO transparent conductive glass substrate in step (4); and (6) MoO3 and Ag electrode preparation: an MoO3 electrode and Ag electrode are formed on a Spiro-OMeTAD thin film through evaporation. With the method of the invention adopted, the electron mobility and conductivity of a thin film can be improved; the photoelectric conversion efficiency of a device can be improved; the surface of the thin film is smoother, so that the thin film can be used as a good substrate for the deposition and growth of a perovskite layer in subsequent processes; and the degradation process of the perovskite layer can be slowed down, and the stability of the device can be improved.

Owner:SUZHOU UNIV

Graphene doping material, and preparation method and application of graphene doping material

ActiveCN103400632AReduce square resistanceThickness is easy to controlCarbon-silicon compound conductorsCable/conductor manufactureSputteringDopant

The invention relates to a graphene doping agent, a graphene doping process and the application of a doped graphene material. A doping process can be completed by using processes such as a dry process (including thermal evaporation and sputtering) or a wet process (including spinning, electrochemical deposition and solution soaking). By virtue of the graphene doping agent, the sheet resistance of a graphene film with a substrate is reduced from about 830 ohms to about 530 ohms on the premise that the transmittance of graphene in a visible light range is not influenced, the conductivity is improved, and the stability is high. By the adoption of the wet process or the dry process for doping, the advantages of controllability in plating thickness, controllability in doping amount, high uniformity and the like are achieved; and by the adoption of an annealing process, the doping agent is more compactly combined with the graphene, the doped graphene material is unlikely to be influenced by the environment when being subsequently used.

Owner:2D CARBON CHANGZHOU TECH INC

Self-powered photodetector based on Cs3Cu2I5 perovskite and preparation method thereof

ActiveCN110459640AStable structureGood light responseFinal product manufactureSemiconductor devicesHeterojunctionGas phase

The invention belongs to the technical field of semiconductor photodetection, and particularly relates to a self-powered photodetector based on Cs3Cu2I5 perovskite and a preparation method thereof. The self-powered photodetector includes an insulating transparent substrate, the upper end of the substrate is provided with a carrier transport layer, a Cs3Cu2I5 light absorption layer and a first contact electrode sequentially from bottom to top, and a second contact electrode is arranged on the carrier transport layer. According to the preparation method, the carrier transport layer is prepared by adopting a magnetron sputtering or metal organic chemical vapor deposition method, the Cs3Cu2I5 light absorption layer is prepared by adopting a solution or vapor phase co-evaporation method, staggered energy band arrangement is ensured to be formed between the carrier transport layer and the Cs3Cu2I5 light absorption layer, the formation of a built-in electric field at the interface of a heterojunction is used to enable photogenerated carriers to be separated, and the detector can thus work under zero volt. The preparation method is simple, each functional layer is environment-friendly, theprepared device has a high detection rate for ultraviolet light, the ultraviolet-visible light suppression ratio exceeds 10 of the fourth power, and the application prospect is good.

Owner:ZHENGZHOU UNIV

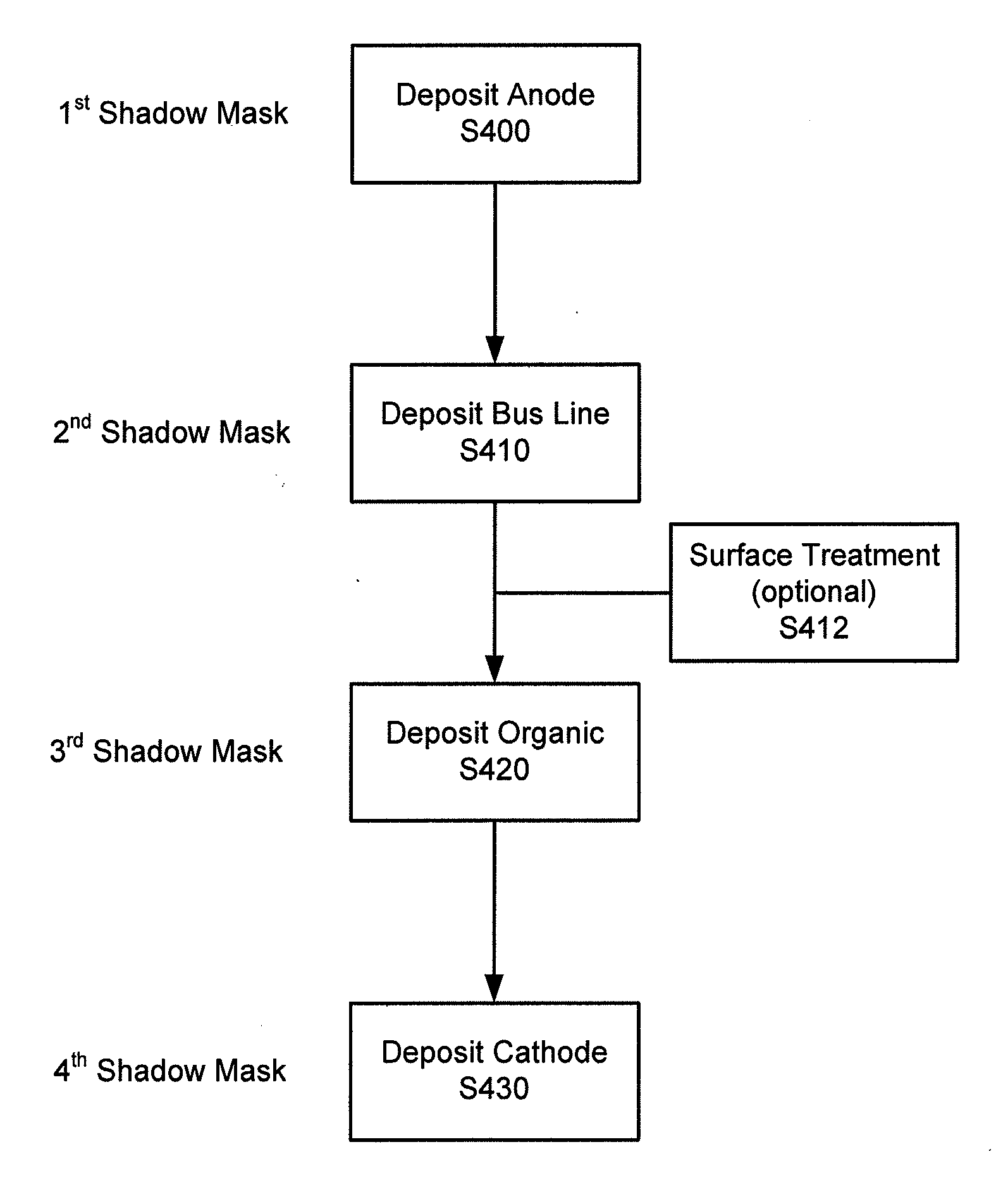

Process For Fabricating OLED Lighting Panels

ActiveUS20120286650A1Reduce probabilityIncrease the areaDischarge tube luminescnet screensElectroluminescent light sourcesElectricityGas phase

Systems and methods for the design and fabrication of OLEDs, including high-performance large-area OLEDs, are provided. Variously described fabrication processes may be used to deposit and pattern bus lines and / or insulators using vapor deposition such as vacuum thermal evaporation (YTE) through a shadow mask, and may avoid multiple photolithography steps. Bus lines and / or insulators may be formed with a smooth profile and a gradual sidewall transition. Such smooth profiles may, for example, reduce the probability of electrical shorting at the bus lines. Other vapor deposition systems and methods may include, among others, sputter deposition, e-beam evaporation and chemical vapor deposition (CVD). A final profile of the bus line and / or insulator may substantially correspond to the profile as deposited. A single OILED devices may also be formed with relatively large dimension.

Owner:UNIVERSAL DISPLAY

Black phosphorene-containing graphene flexible resistive random access memory and preparation method thereof

InactiveCN106876584ALarge specific surface areaImprove migration speedElectrical apparatusEvaporation (deposition)Graphite

The invention provides a black phosphorene-containing graphene flexible resistive random access memory and a preparation method thereof. The preparation method of the resistive random access memory comprises the steps of cleaning a Al2O3 substrate; depositing a Ni / Au composite thin film by an electron beam evaporation technology to obtain a bottom electrode layer; transferring a black phosphorene-containing graphene composite thin film material on the bottom electrode layer by a transfer method to obtain a resistive changing functional layer; forming a top electrode pattern by a photoresist patterning process, depositing a Ag, Cu or Ni thin film by the electron beam evaporation technology to form a top electrode layer, and removing and stripping photoresist to form a memory unit; and forming a coating layer pattern by the photoresist patterning process, depositing the Al2O3 thin film again by an atomic layer deposition technology to form a coating layer, and removing and striping the photoresist to form the black phosphorene-containing graphene flexible resistive random access memory. The resistive random access memory prepared according to the method is simple in structure, fast in erasure speed and small in operation voltage, non-destructive readout is achieved, and the resistive random access memory can be used for fabricating a large-area flexible device.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

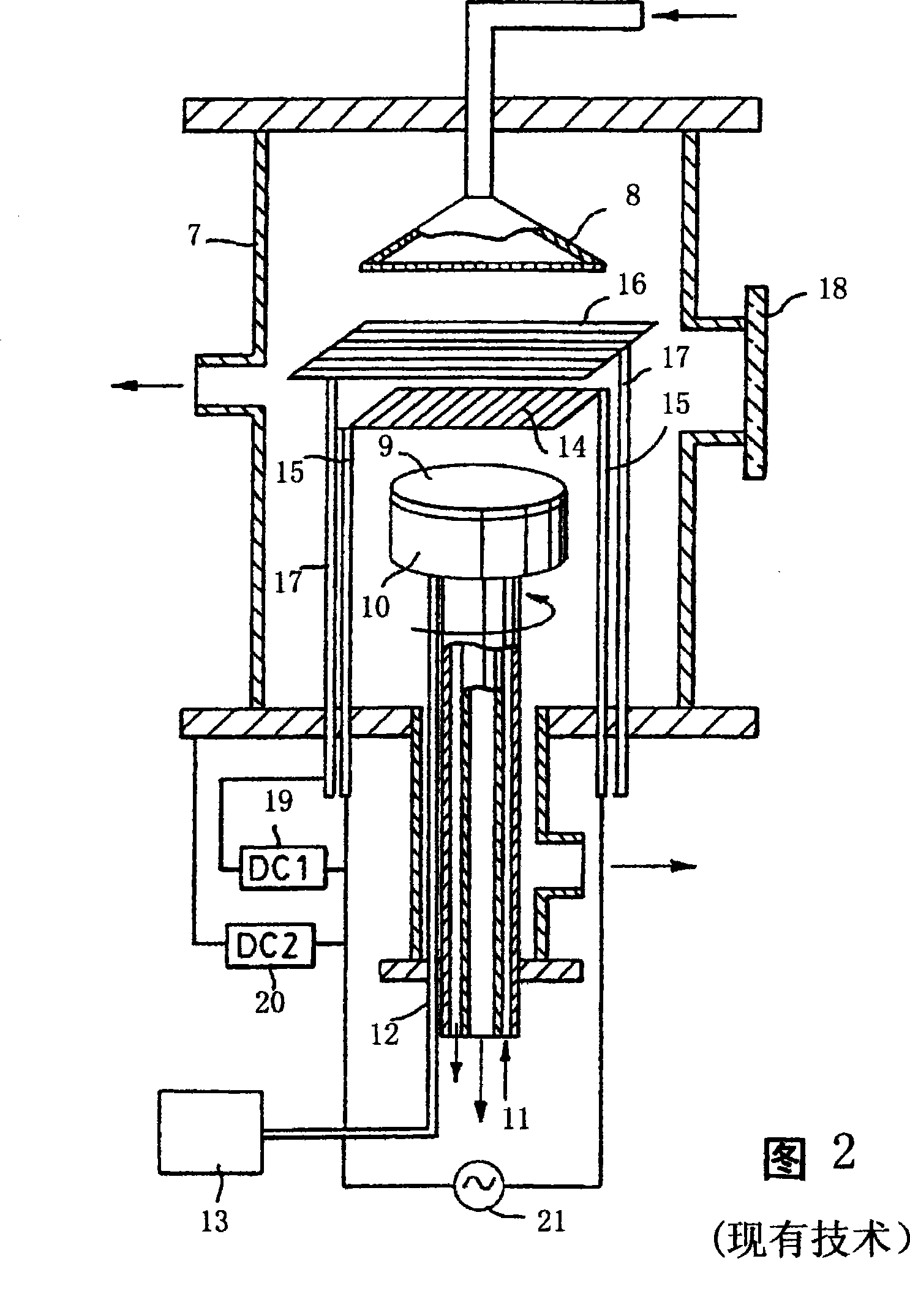

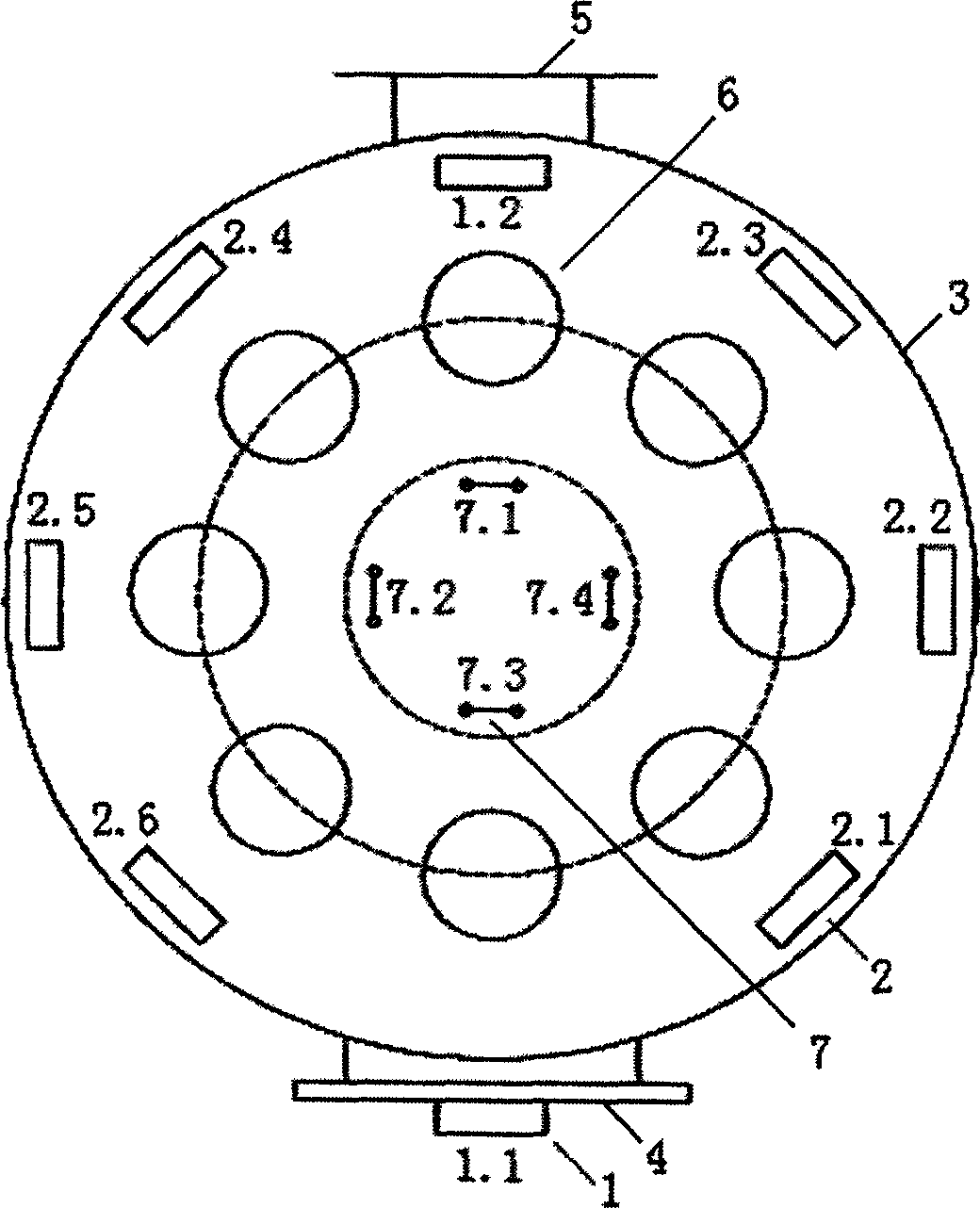

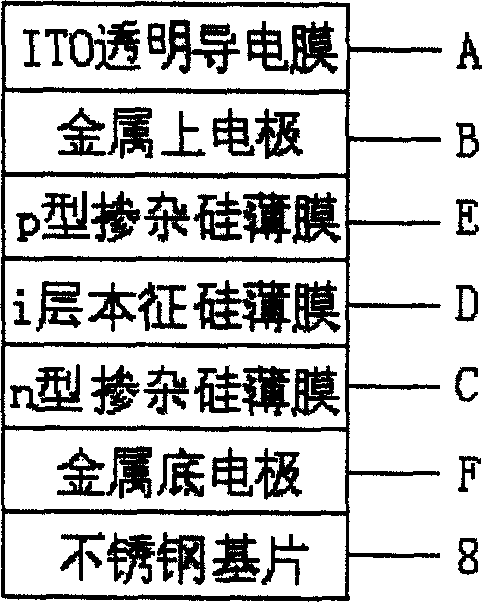

Physical vapor deposition device and method for Nano silicon-crystal thin film of solar battery

InactiveCN1760405AEliminate light decayHigh energy stateVacuum evaporation coatingSputtering coatingGas phaseSilicon solar cell

A physical evaporation deposition apparatus for preparing the nano-crystal silicon film of solar cell is based on the vacuum evaporation coating machine but has the physical evaporation deposit function. It method includes such steps as designing the figuration of vacuum evaporation coating machine, using ion beam method to deposit nano-crystal silicon film, and gas-phase doping to prepare the PIN structure of solar cell. Its advantage is high photoelectric conversion efficiency.

Owner:吴大维

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com