Vacuum evaporator and method for manufacturing organic el display panel using the same

An evaporation and vacuum technology, which is applied in the fields of vacuum evaporation coating, lighting device, semiconductor/solid-state device manufacturing, etc. It can solve the problems of reduced quality of formed film and inability to uniformly evaporate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

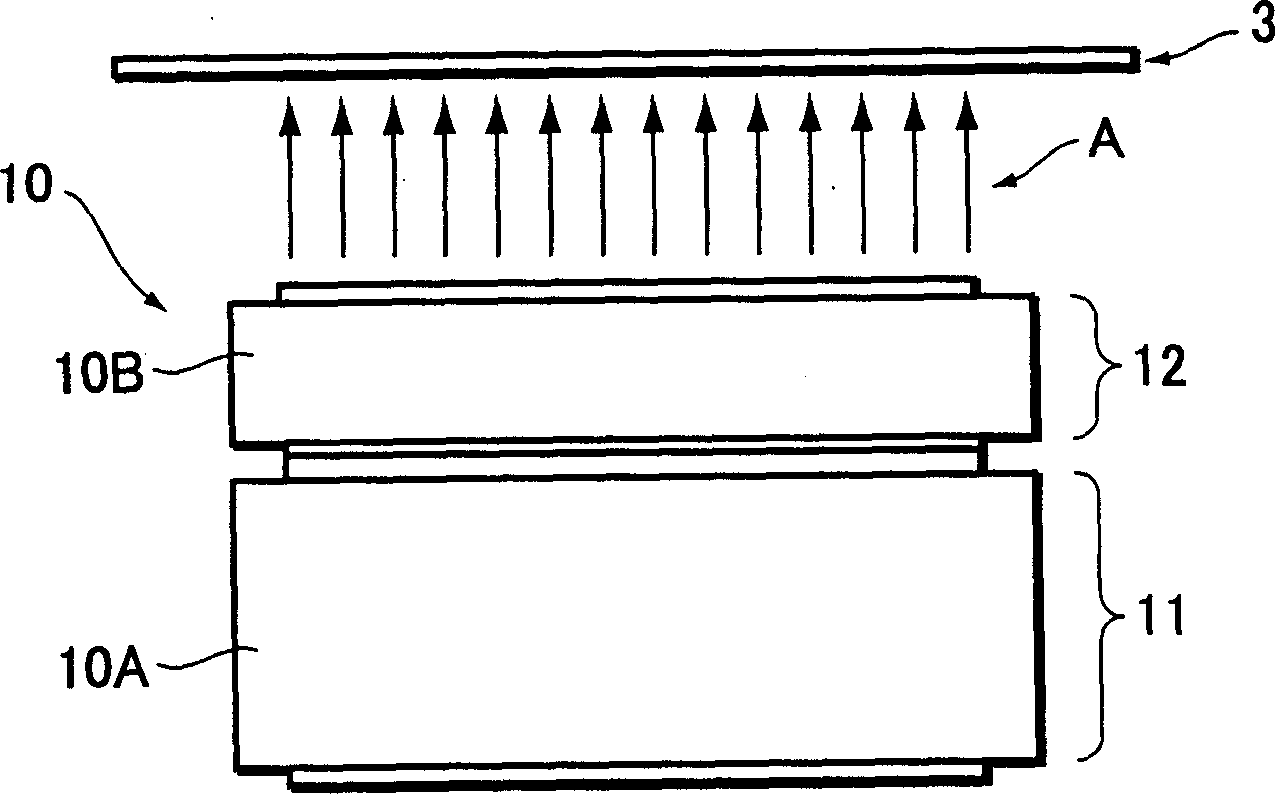

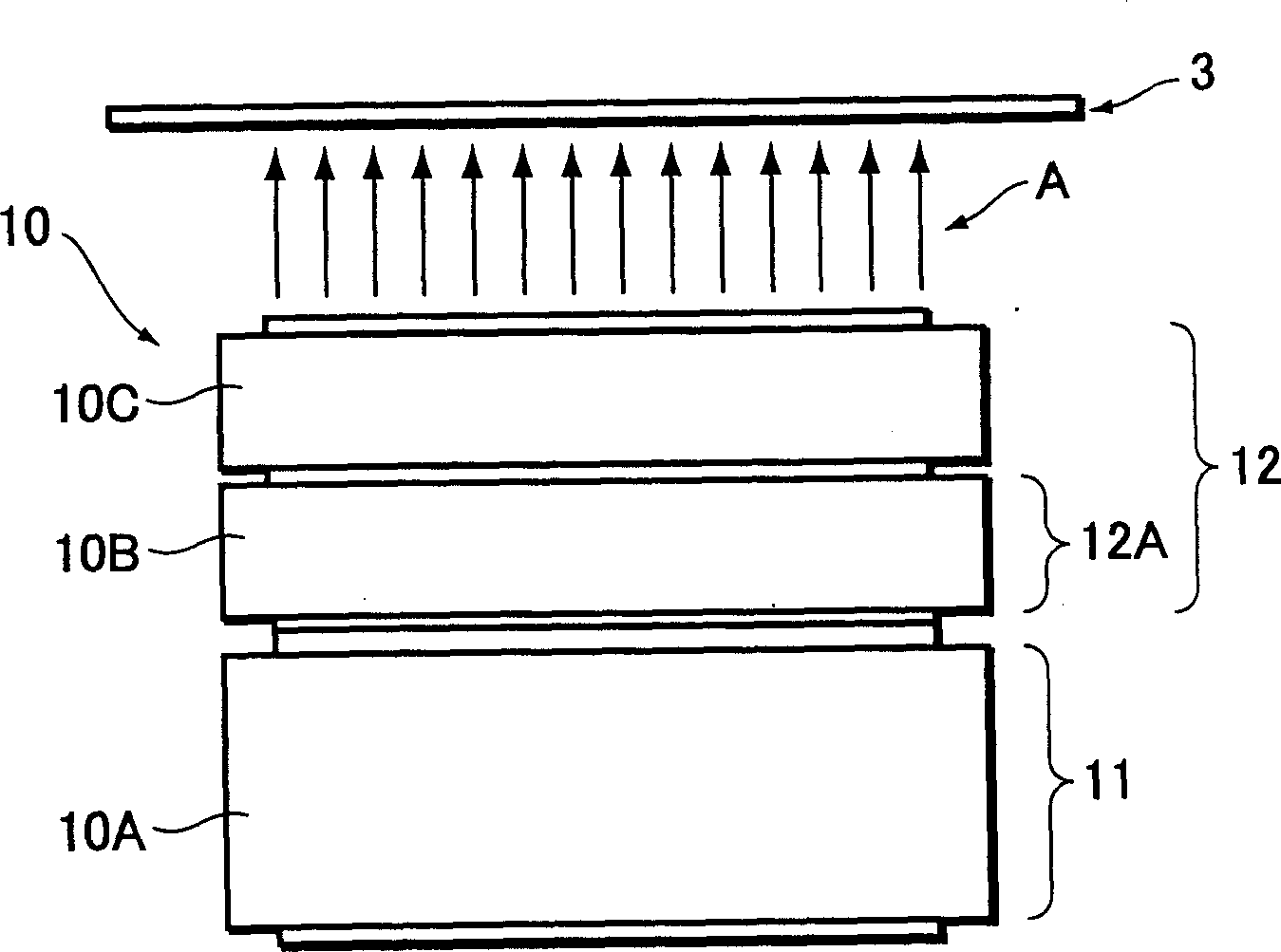

[0026] Such as figure 2 As shown, the evaporation source 10 is composed of laminated frames 10A and 10B, and the frame 10A at the lowest layer forms a heating part 11, and the heating part 11 contains an organic material and heats and evaporates the organic material, while the other layer The frame body 10B forms the vapor deposition flow control part 12, and controls the direction of the vapor deposition flow from the heating part 11 toward the vapor deposition object (substrate 3).

[0027] The direction of the vapor deposition flow of the organic material vaporized by the heating unit 11 is controlled by the vapor deposition flow control unit 12 , so that only the vapor deposition flow A passing there flows toward the substrate 3 . At this time, the organic material that has not passed through the vapor deposition flow control unit 12 does not escape from the stacked frames 10A, 10B, so it is all recovered in the frame 10A at the lowest level, and the organic material of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com