Black phosphorene-containing graphene flexible resistive random access memory and preparation method thereof

A technology of resistive memory and black phosphorene, which is applied in electrical components and other directions, can solve the problems of rare memory applications, and achieve the effects of simple structure, good flexibility, and stable operating voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

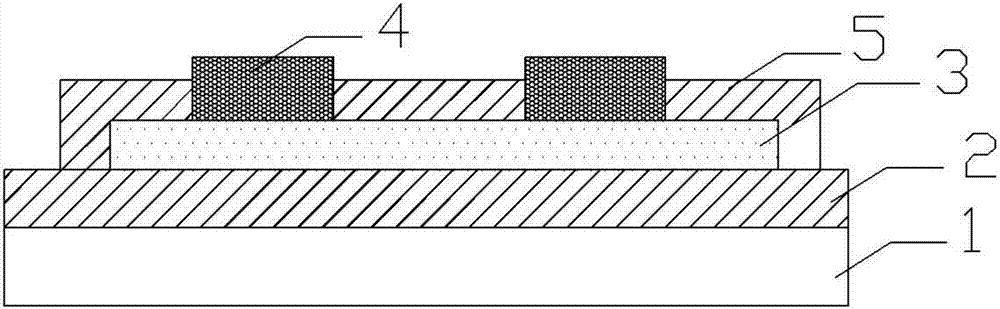

Embodiment 1

[0030] (1) Cleaning Al 2 O 3 Substrate: Al 2 O 3 The surface of the substrate is wiped clean with ethanol cotton balls, boiled in a mixture solution of sulfuric acid and phosphoric acid with a volume ratio of 3:1, rinsed with ethanol and deionized water, and dried with nitrogen.

[0031] (2) Using electron beam evaporation technology to deposit a Ni / Au composite film with a thickness of 80 nm on the substrate to obtain a bottom electrode layer.

[0032] (3) The black phosphorene quantum dots are added to the organic solvent dispersion containing graphene oxide, mixed in a water bath ultrasonically to form a dispersion, and electrophoretic deposition is used to obtain a black phosphorene-containing graphene oxide film under a nitrogen atmosphere The black phosphorene-containing graphene composite film material is obtained by high-temperature reduction, and the black phosphorene-containing graphene composite film material with a thickness of 7.5 nm is transferred on the bottom electro...

Embodiment 2

[0036] (1) Cleaning Al 2 O 3 Substrate: Al 2 O 3 The surface of the substrate is wiped clean with ethanol cotton balls, boiled in a mixture solution of sulfuric acid and phosphoric acid with a volume ratio of 3:1, rinsed with ethanol and deionized water, and dried with nitrogen.

[0037] (2) Using electron beam evaporation technology to deposit a Ni / Au composite film with a thickness of 5 nm on the substrate to obtain a bottom electrode layer.

[0038] (3) The black phosphorene quantum dots are added to the organic solvent dispersion containing graphene oxide, mixed in a water bath ultrasonically to form a dispersion, and electrophoretic deposition is used to obtain a black phosphorene-containing graphene oxide film under a nitrogen atmosphere The black phosphorene-containing graphene composite film material is obtained by high-temperature reduction, and the black phosphorene-containing graphene composite film material with a thickness of 0.5 nm is transferred on the bottom electrod...

Embodiment 3

[0042] (1) Cleaning Al 2 O 3 Substrate: Al 2 O 3 The surface of the substrate is wiped clean with ethanol cotton balls, boiled in a mixture solution of sulfuric acid and phosphoric acid with a volume ratio of 3:1, rinsed with ethanol and deionized water, and dried with nitrogen.

[0043] (2) Using electron beam evaporation technology to deposit a 20nm thick Ni / Au composite film on the substrate to obtain a bottom electrode layer.

[0044] (3) The black phosphorene nanosheets are added to the organic solvent dispersion containing graphene oxide, and the dispersion is formed by ultrasonic mixing in a water bath. The electrophoretic deposition method is adopted to obtain the black phosphorene-containing graphene oxide film under a nitrogen atmosphere. The black phosphorene-containing graphene composite film material is obtained by high-temperature reduction, and the black phosphorene-containing graphene composite film material with a thickness of 5 nm is transferred on the bottom elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com