Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Fast transition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

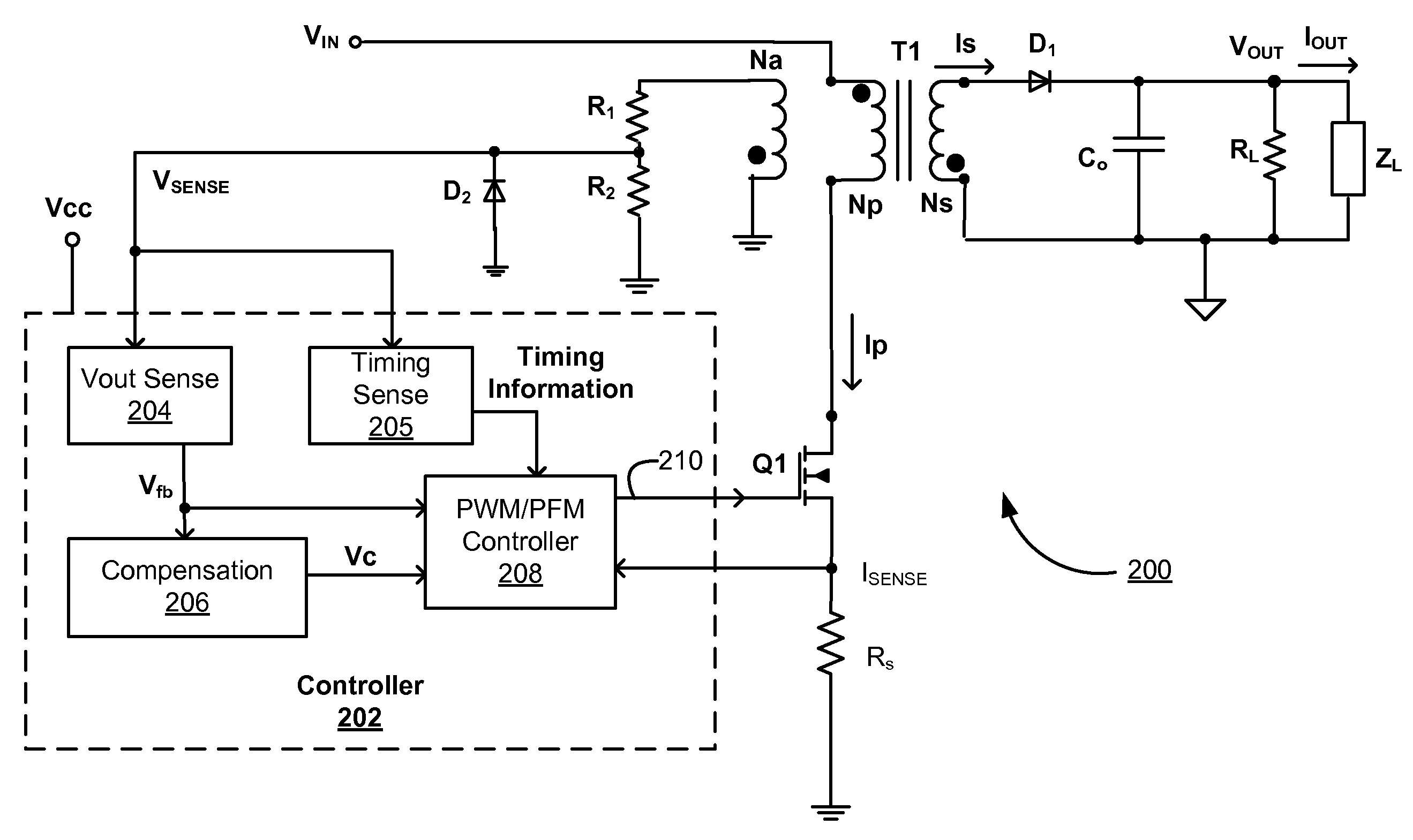

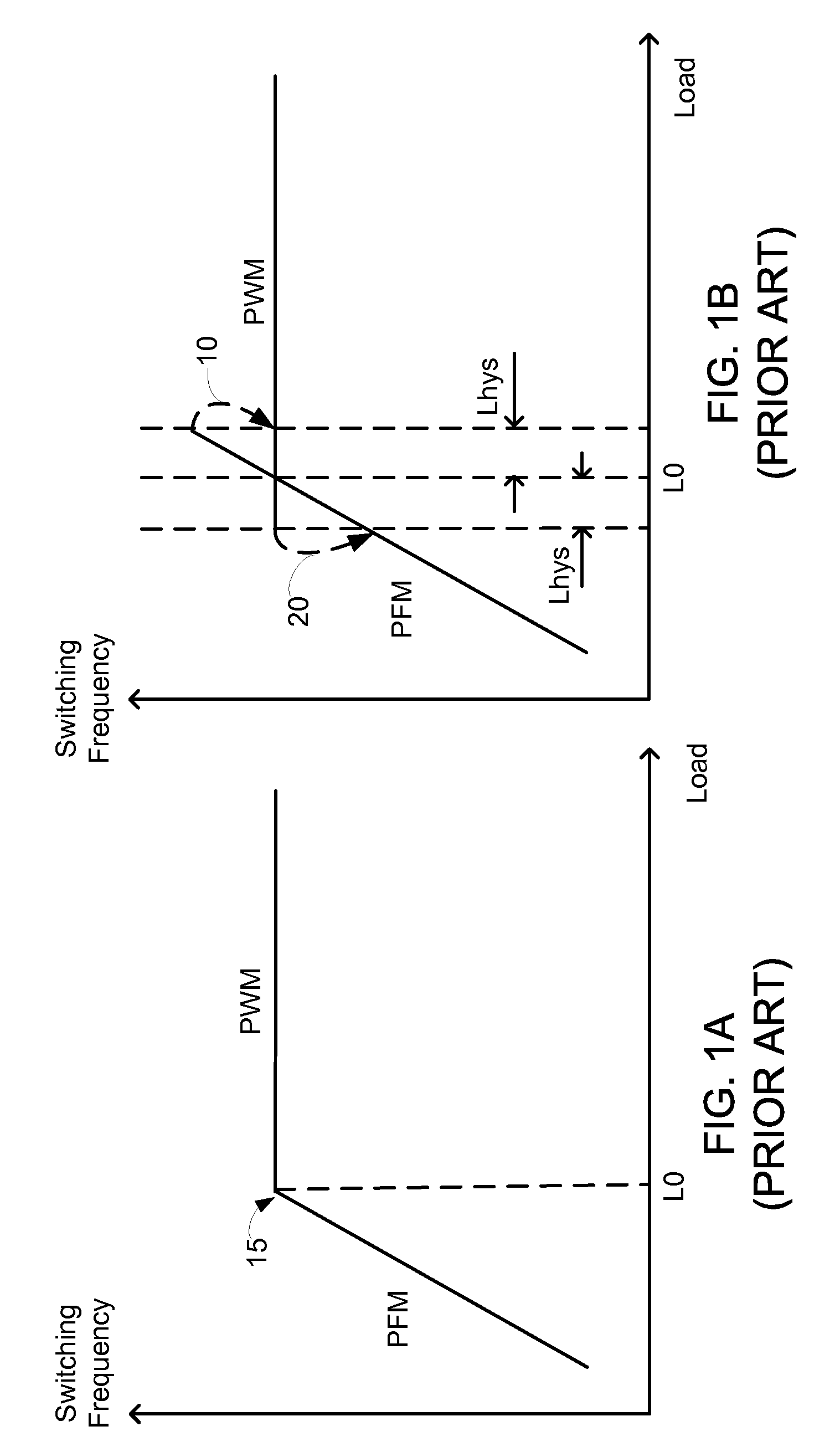

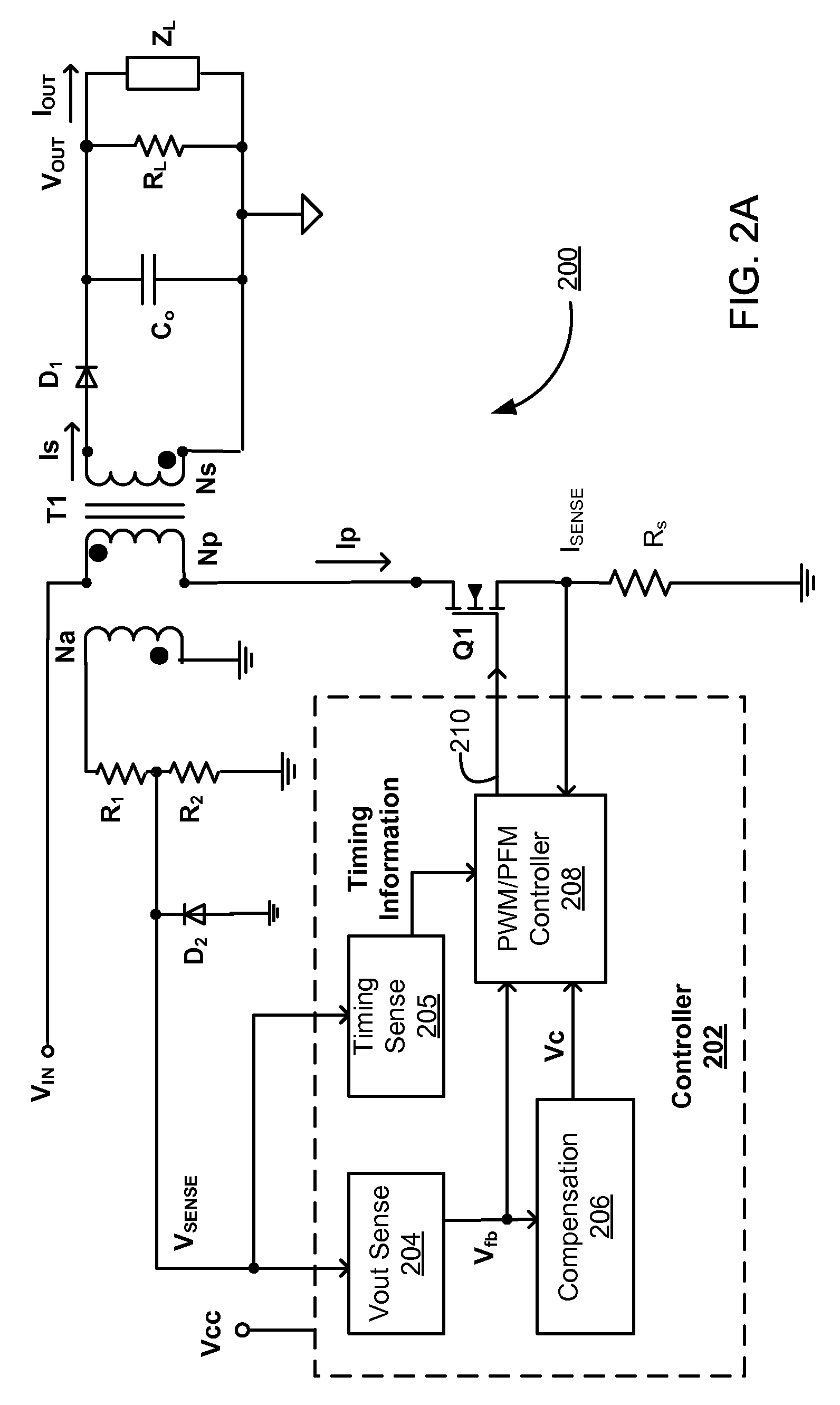

Adaptive control for transition between multiple modulation modes in a switching power converter

ActiveUS20100225293A1Fast transitionLow output rippleEfficient power electronics conversionDc-dc conversionVoltage rangeSelf adaptive

In a switching power converter, PWM mode and PFM mode are separated into two independent control sections with the control voltage range in each control section determined independently. Each of the PWM and PFM modulation modes cannot operate continuously beyond its boundaries, thereby forming a control gap between the two control sections within which no continuous operation is allowed. In order to supply a load condition within the control gap, the power supply operates at the two boundaries of the control gap. Transition between PWM and PFM modes occurs fast, with low output voltage ripple. No limitation needs to be imposed on the control voltage range in each of the PWM and PFM control sections, because the control parameters in the PWM and PFM control sections need not be matched to one another, due to separation of the PWM and PFM modes by the control gap.

Owner:DIALOG SEMICONDUCTOR

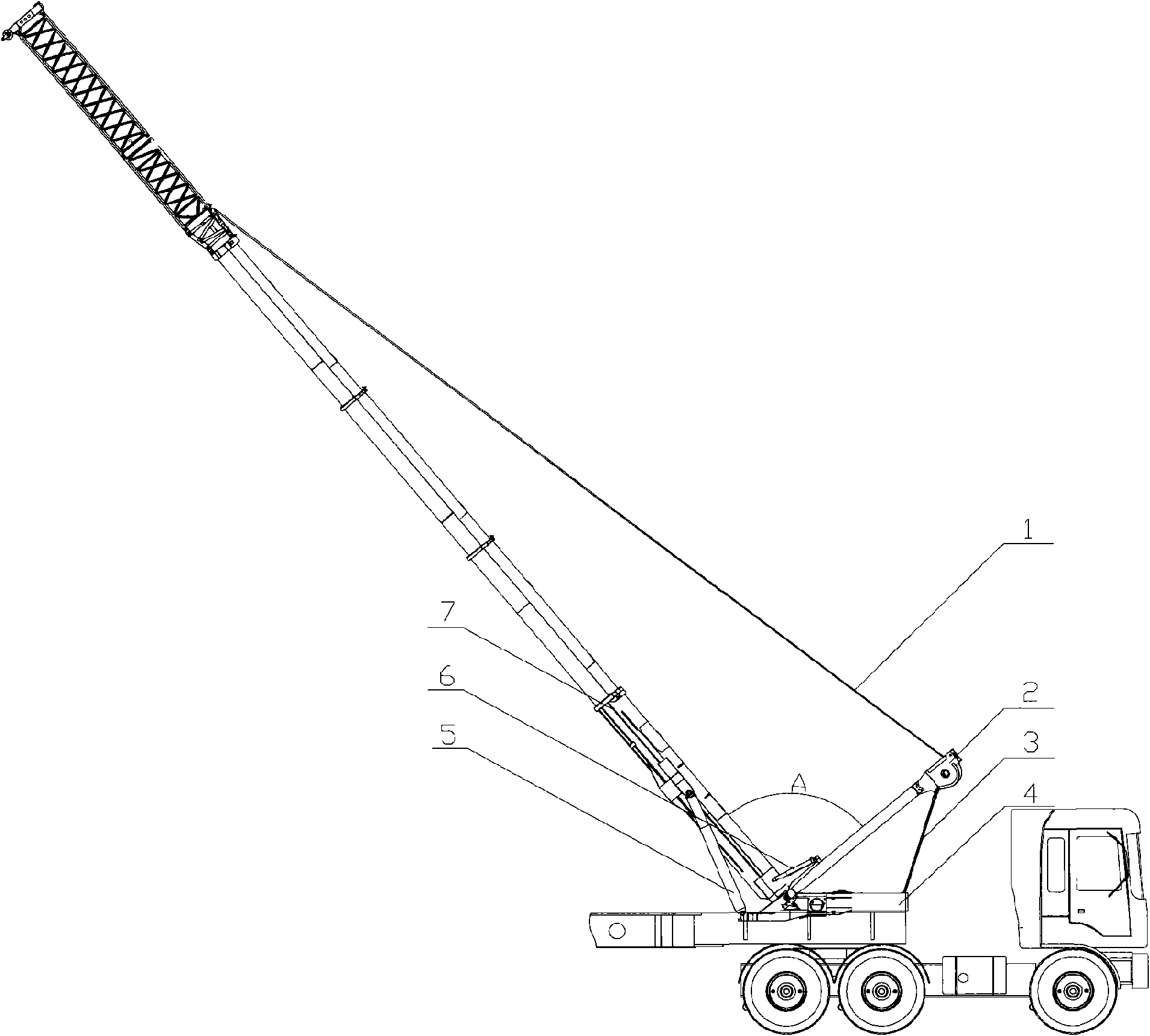

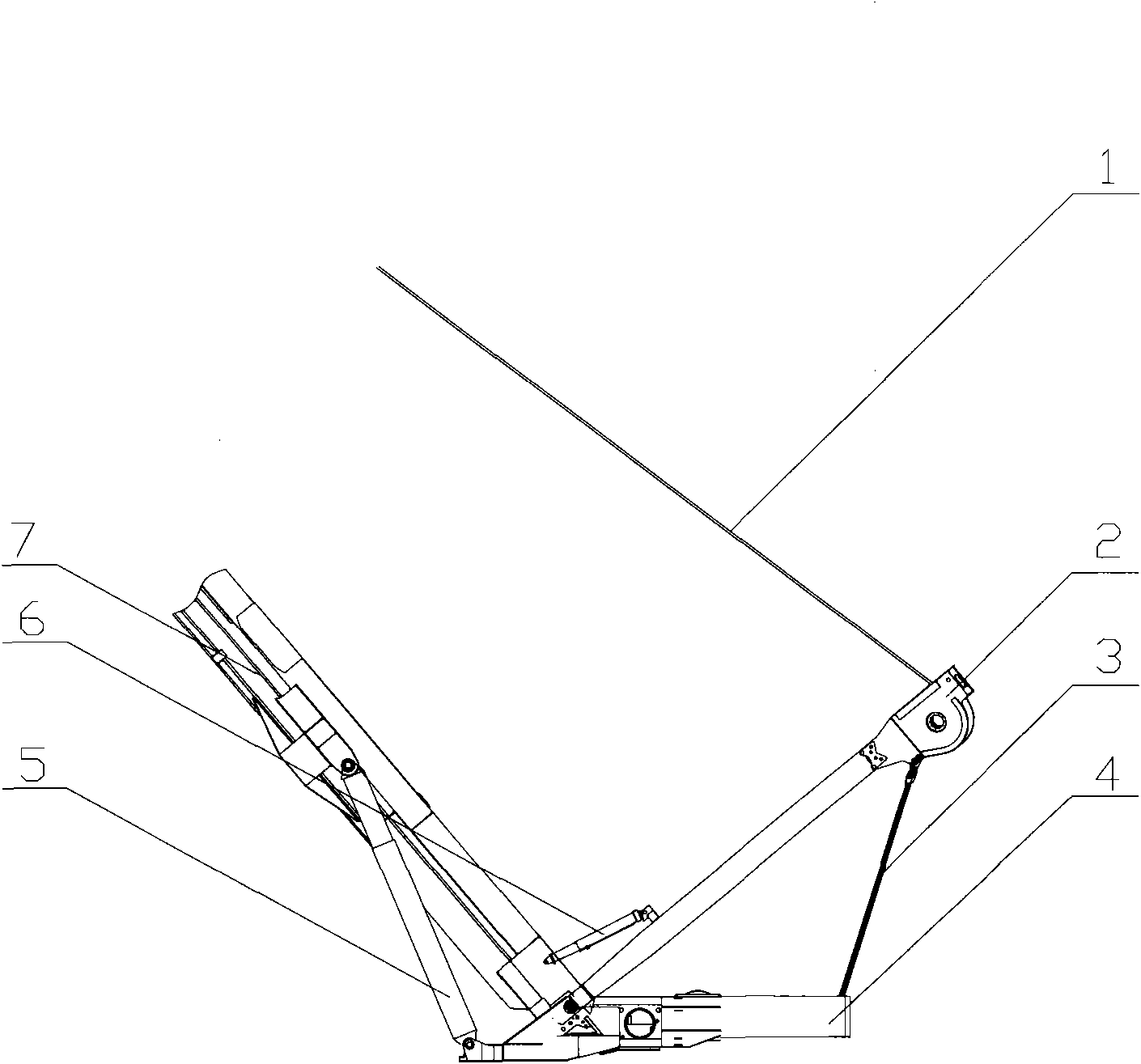

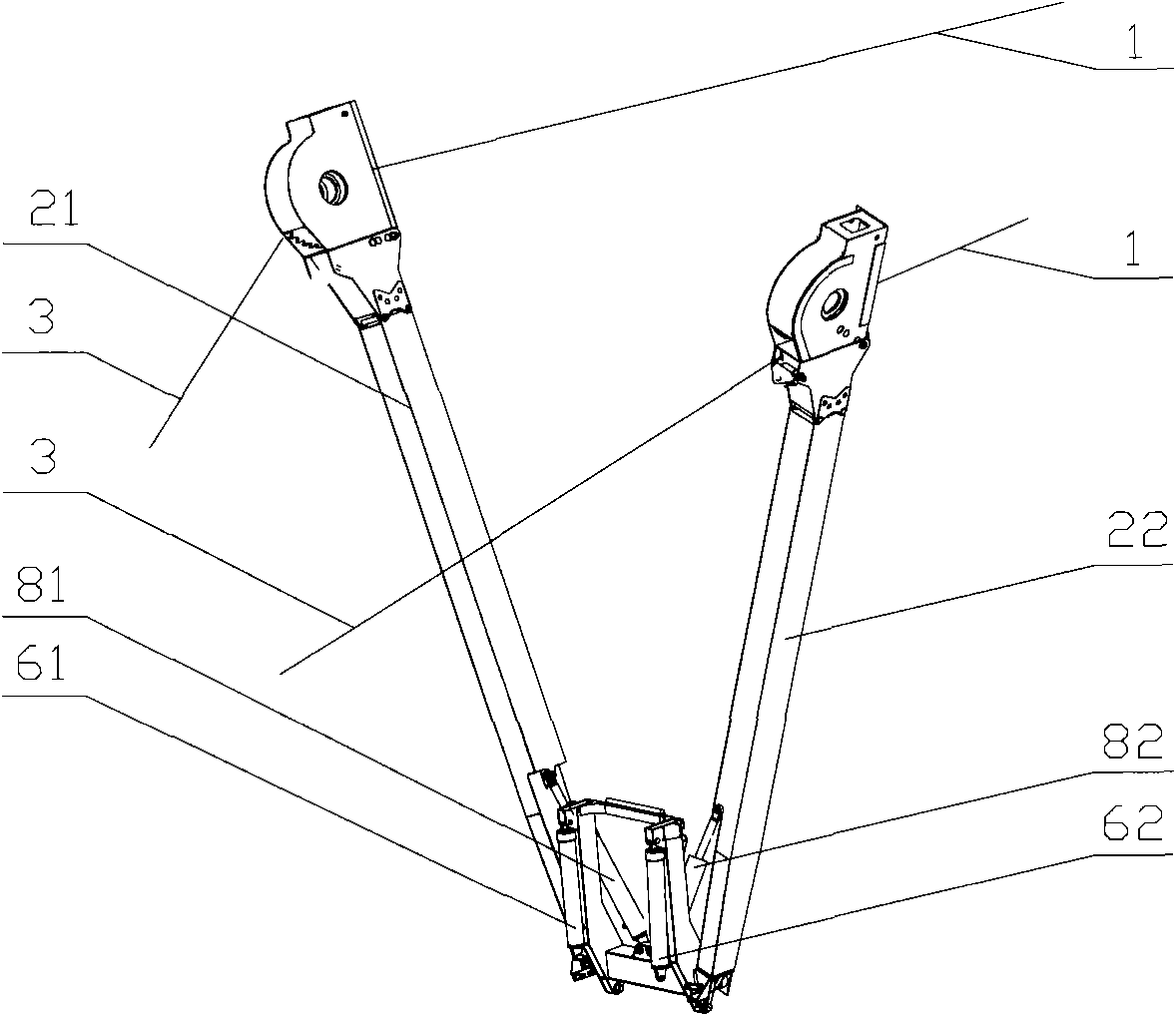

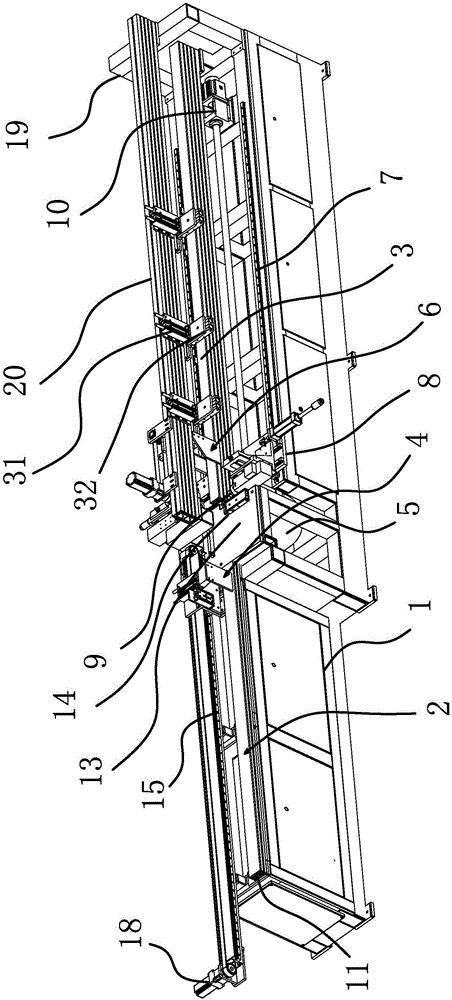

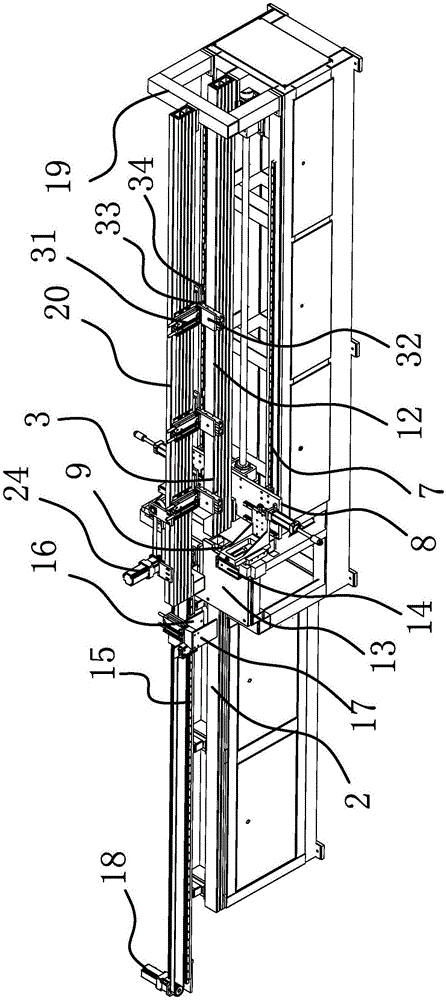

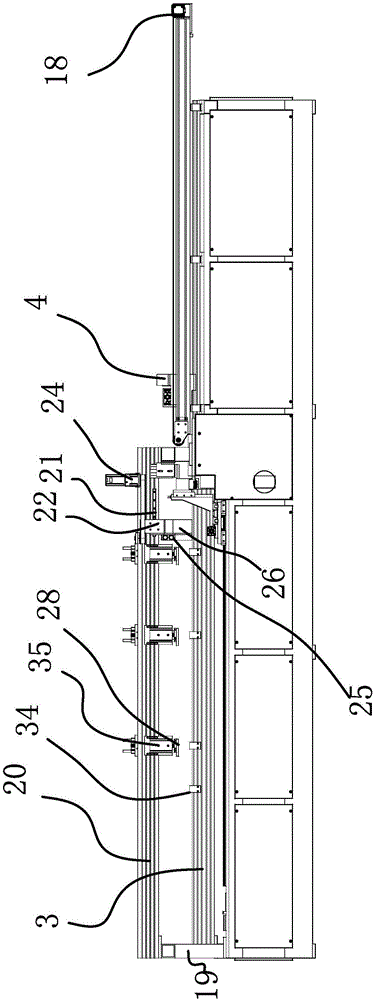

Lift and superlift device thereof

InactiveCN101659378AFast transitionCargo handling apparatusPassenger handling apparatusStress conditionsAxial force

The invention discloses a superlift device used for a lift. The superlift device comprises a superlift mast (2), a front tensioning mechanism (1) and a rear tensioning mechanism (3), wherein the innerend of the superlift mast (2) is articulated on a rotary table (4) or on the tail part of a lifting arm (7), one end of the rear tensioning mechanism is connected to the rotary table (4), and the other end thereof is connected with the outer end of the superlift mast (2). Therefore, when the lifting arm (7) bears load, the axial force of the superlift device along the direction of the superlift mast (2) acts on the rotary table (4) or the tail end of the lifting arm (7), so that the tensile force can be conducted onto the rotary table (4) or the tail part of the lifting arm (7), thereby further improving the stress condition of the lifting arm (7), and further improving the lifting performance and the bearing capacity of the lift as well as the stability of the complete lift during operation.

Owner:SANY AUTOMOBILE MFG CO LTD

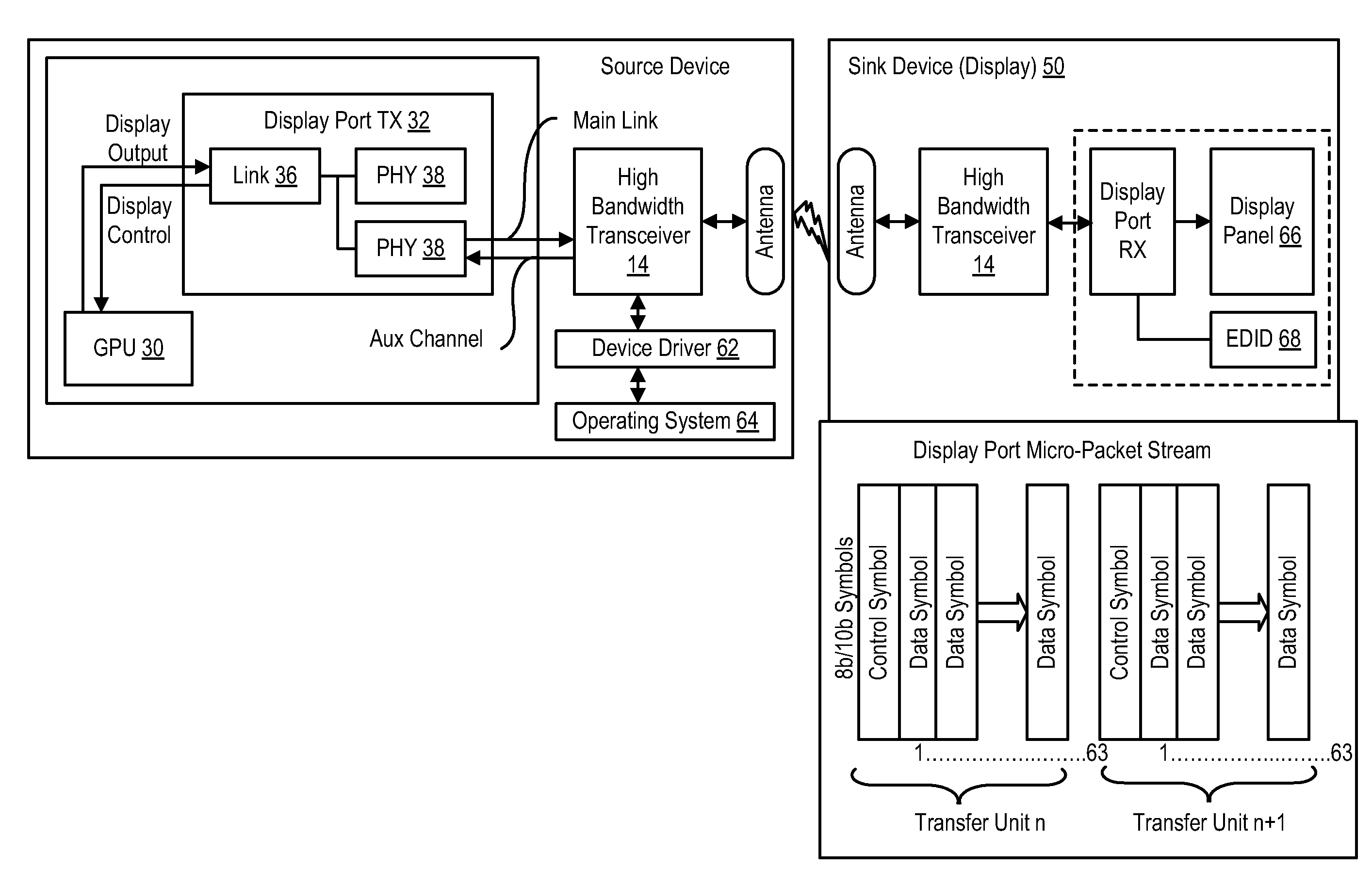

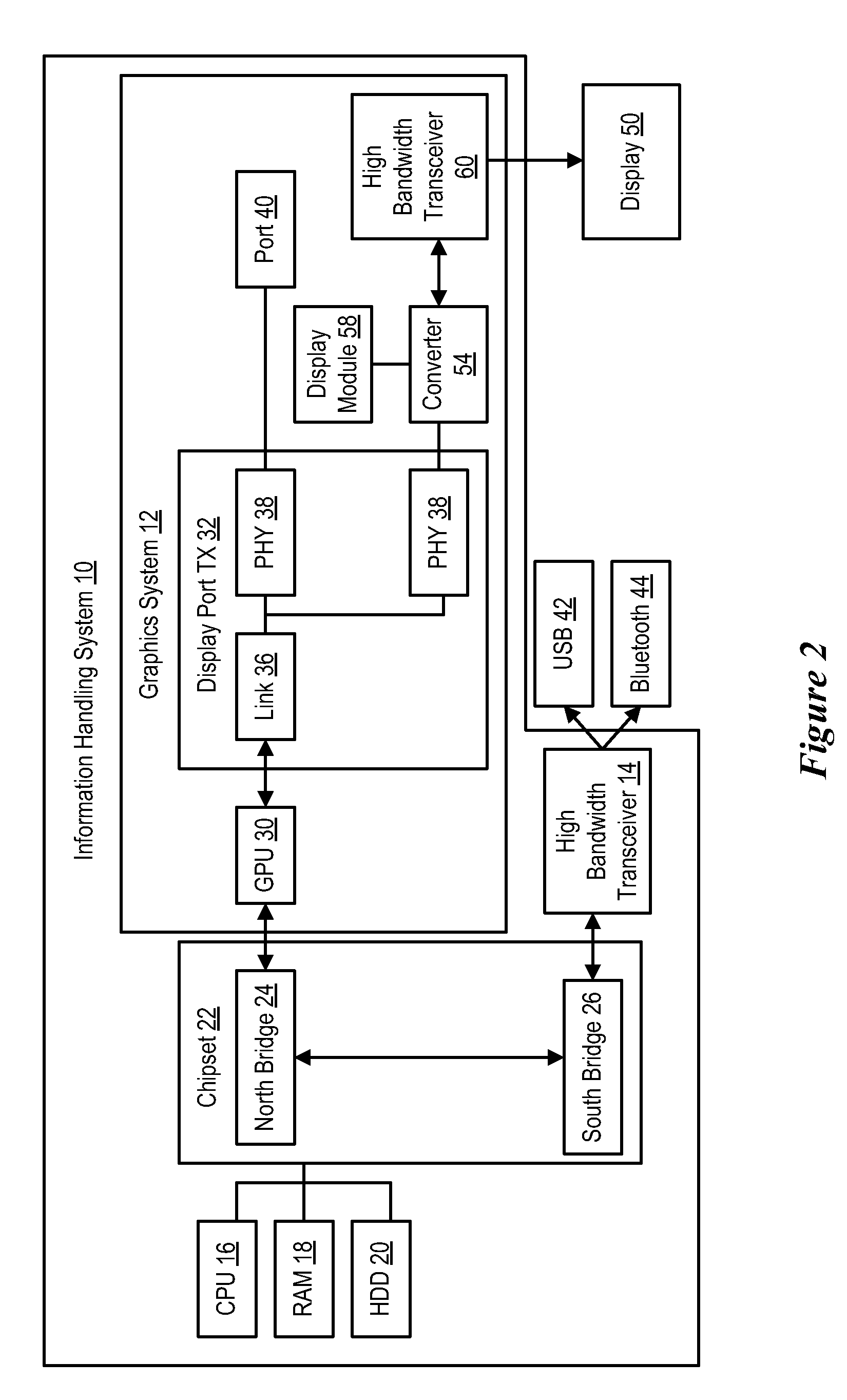

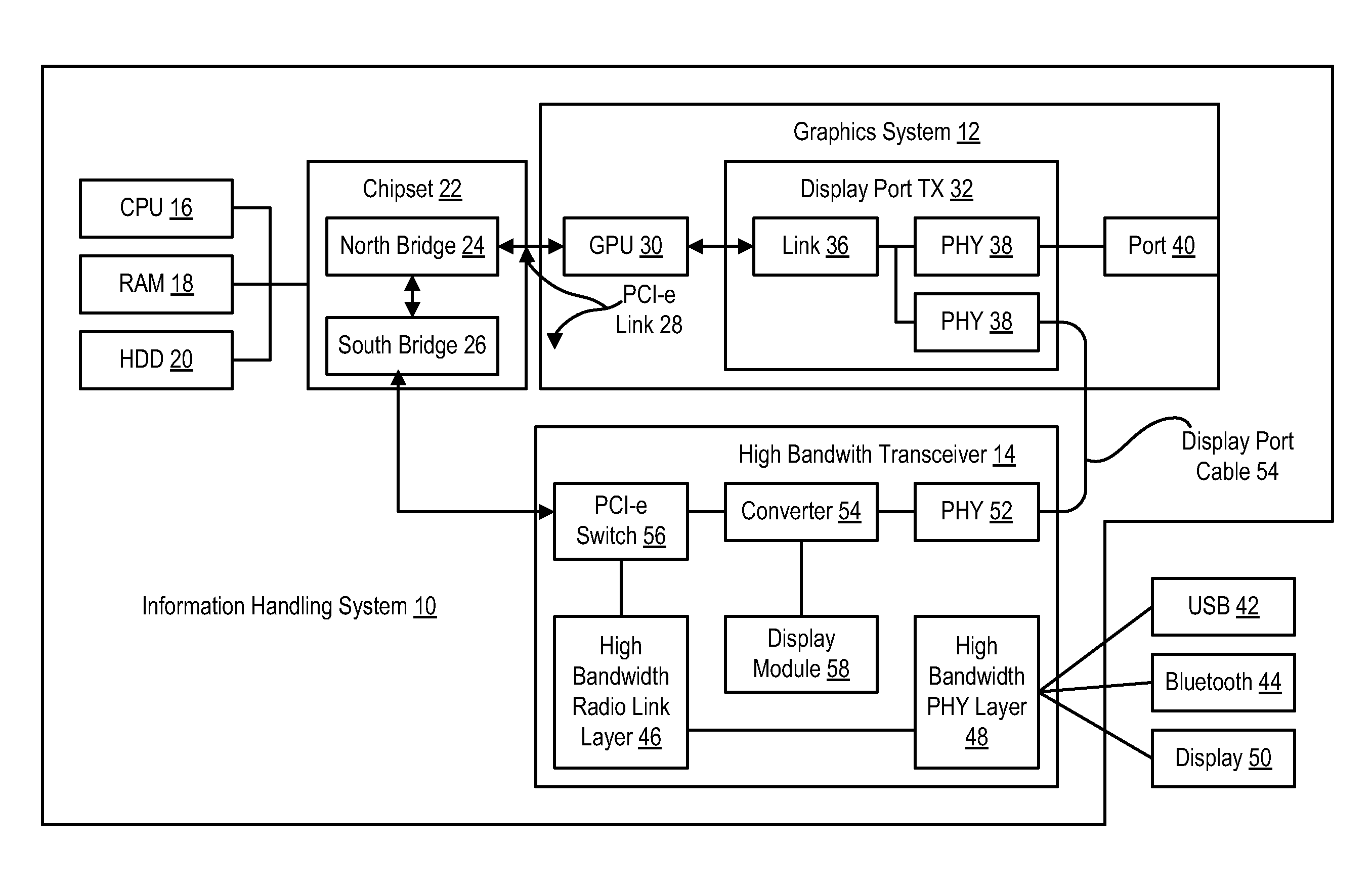

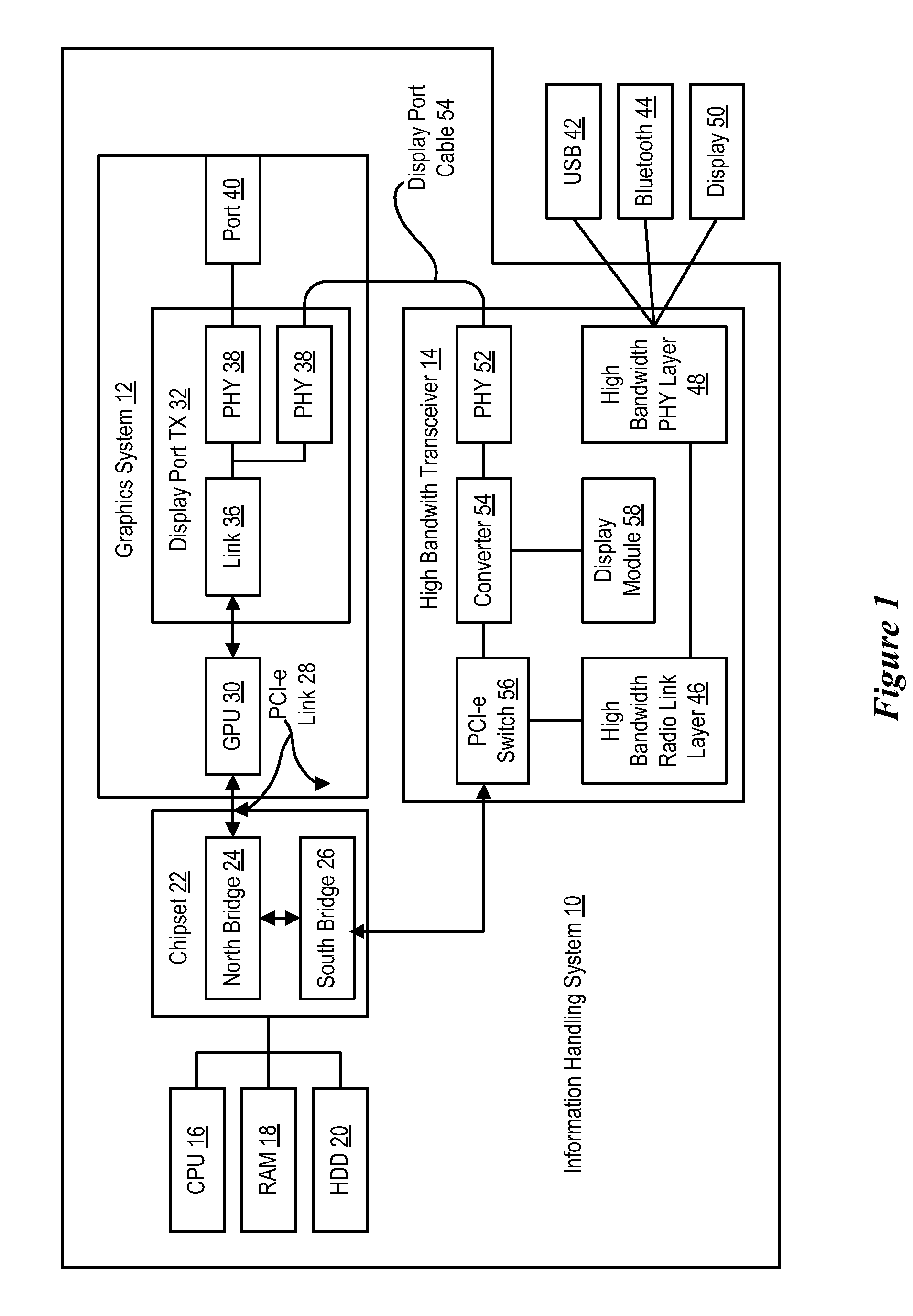

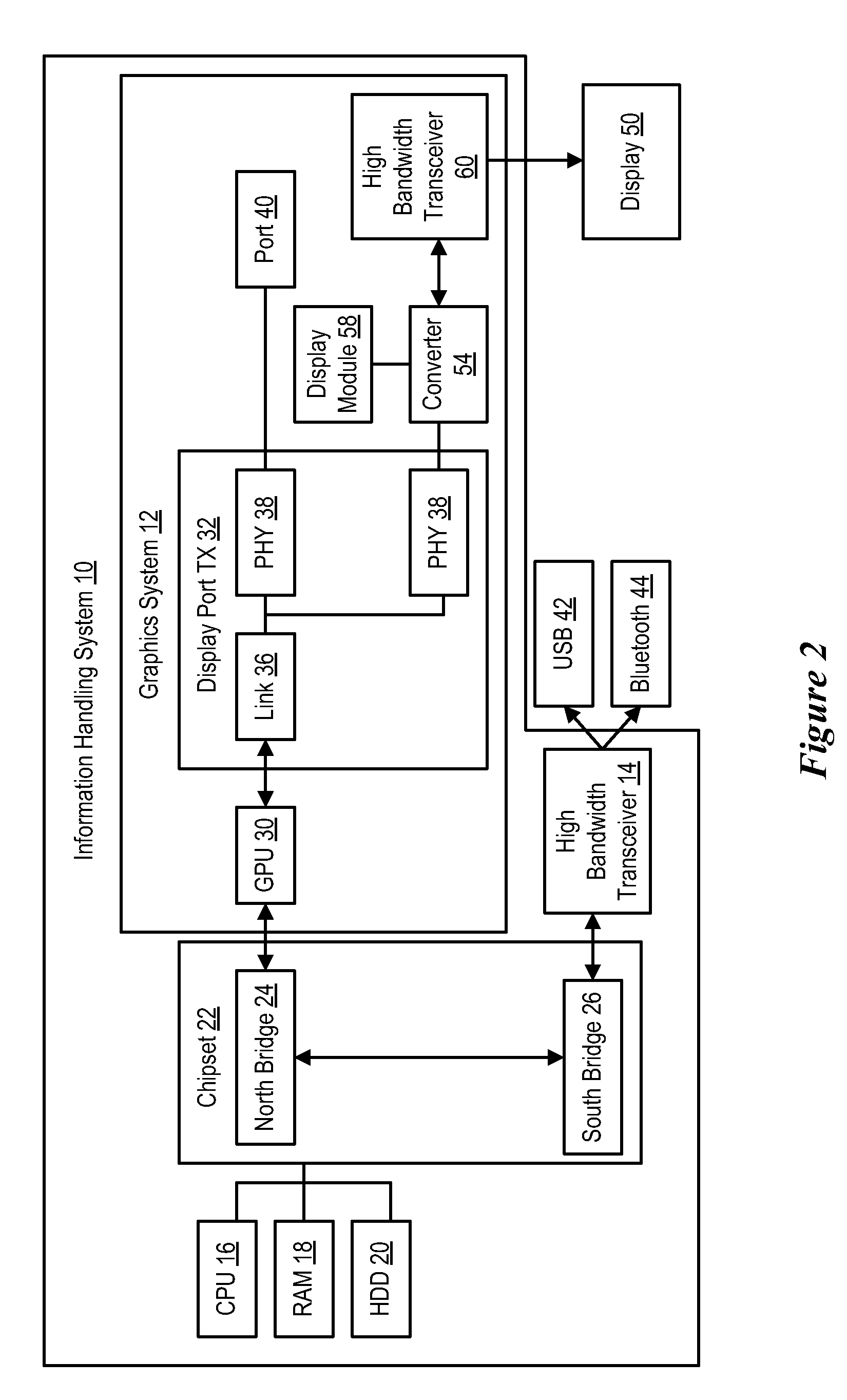

System and Method for Interfacing Graphical Information with an Information Handling System Wireless Transceiver

ActiveUS20080297520A1Fast transition timeHigh bandwidthDigital computer detailsCathode-ray tube indicatorsGraphicsTransceiver

Wireless communication of display information between an information handling system and display is supported by a direct connection between a graphics system of the information handling system and a transceiver of the information handling system. For example, the graphics system outputs pixel level display information through a cable directly to the transceiver. A converter on the transceiver converts the display information to network information, such as from a DisplayPort format to a PCI Express format, so the transceiver can send the display information through a wireless network, such as a personal area network, to the display. A display module located at the transceiver coordinates initiation of communication of display information from the graphics system to the display.

Owner:DELL PROD LP

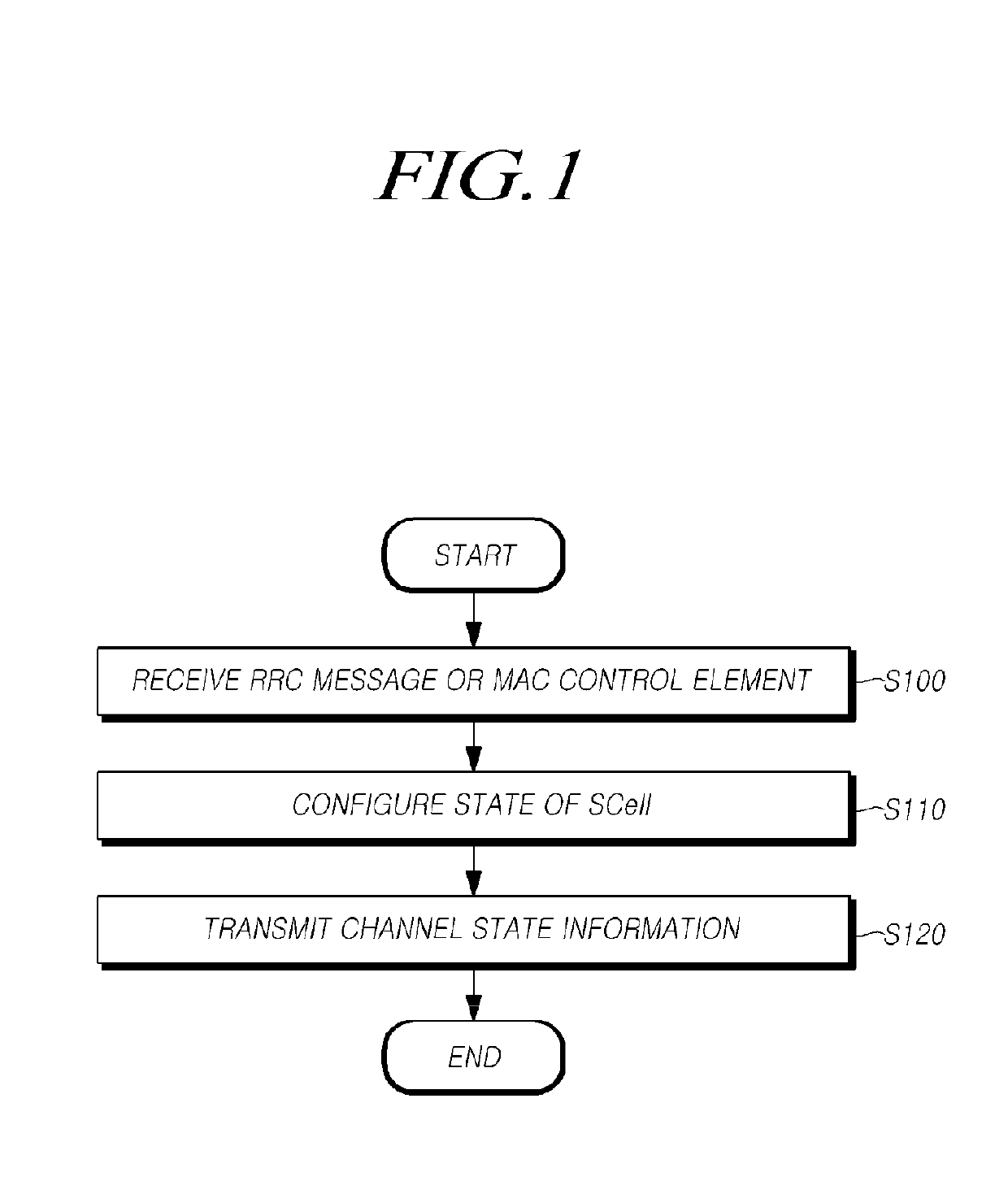

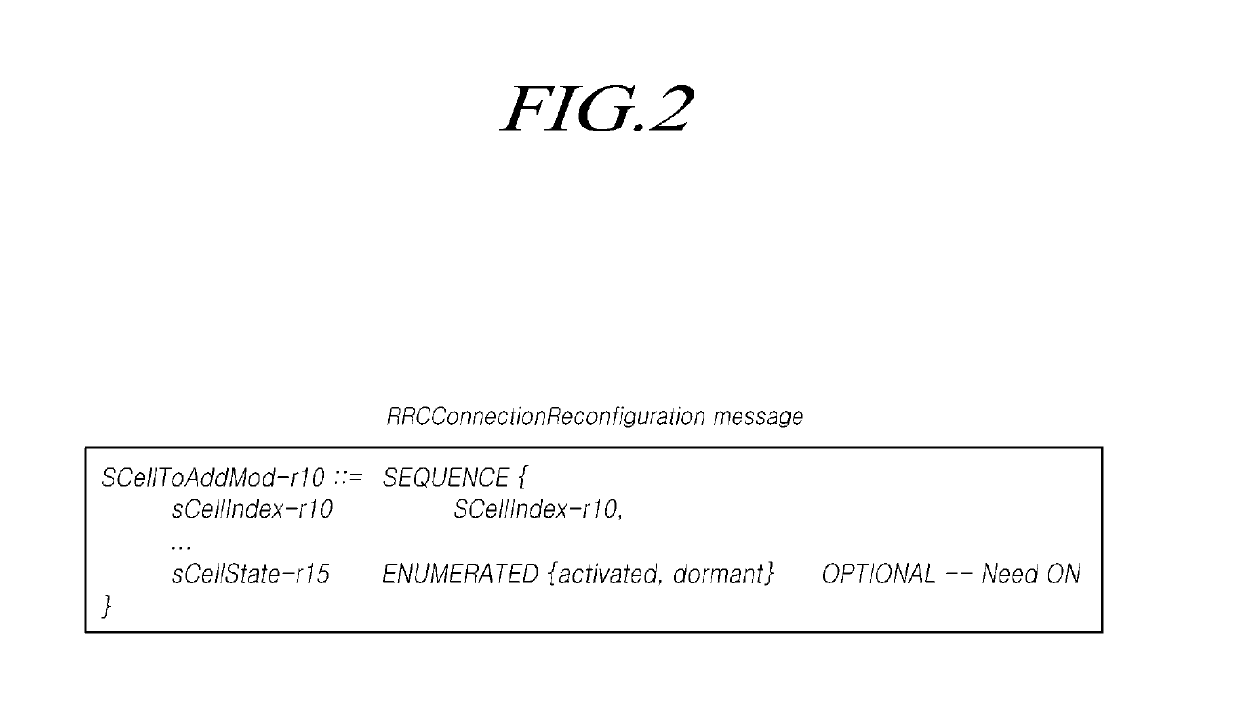

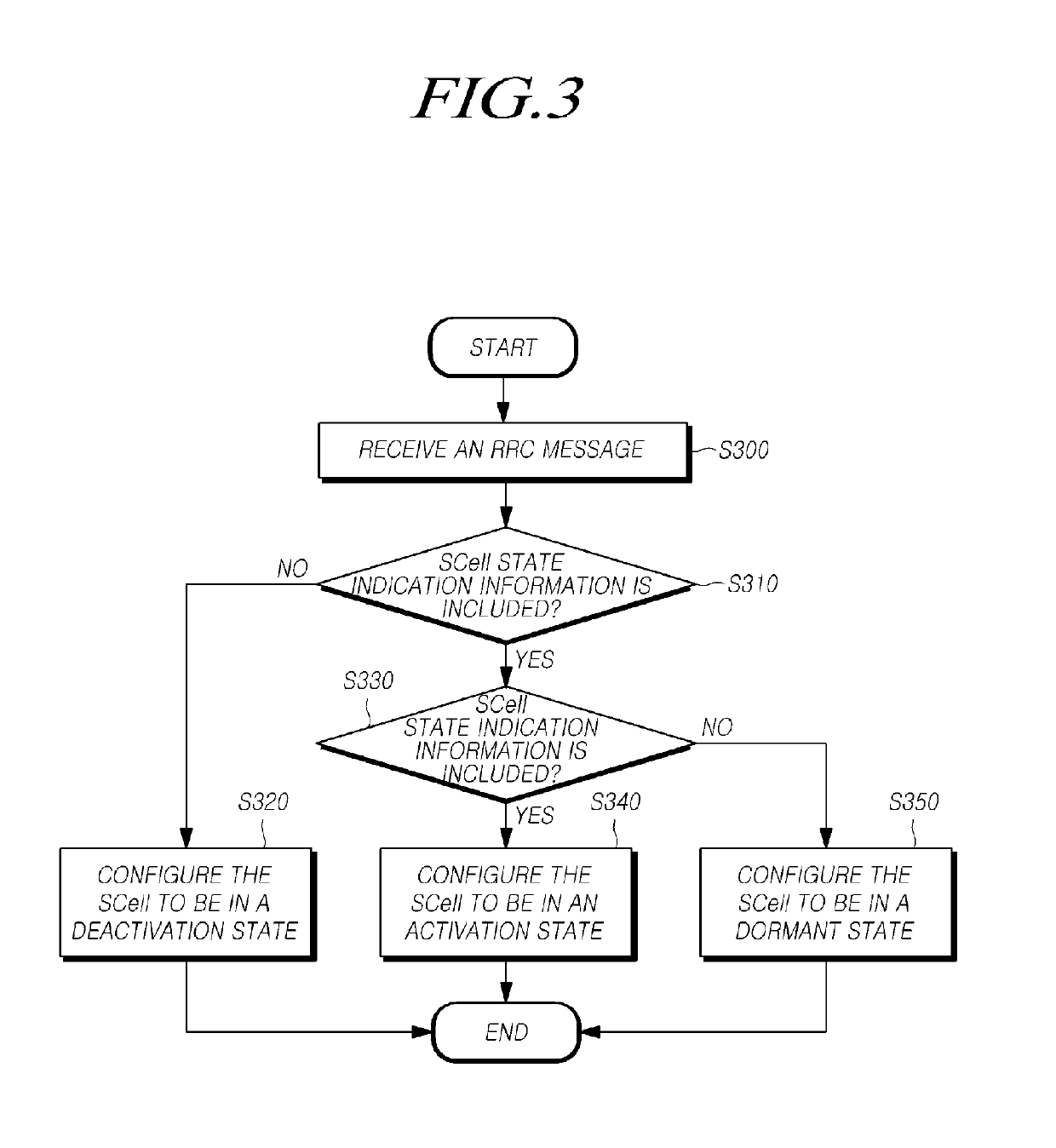

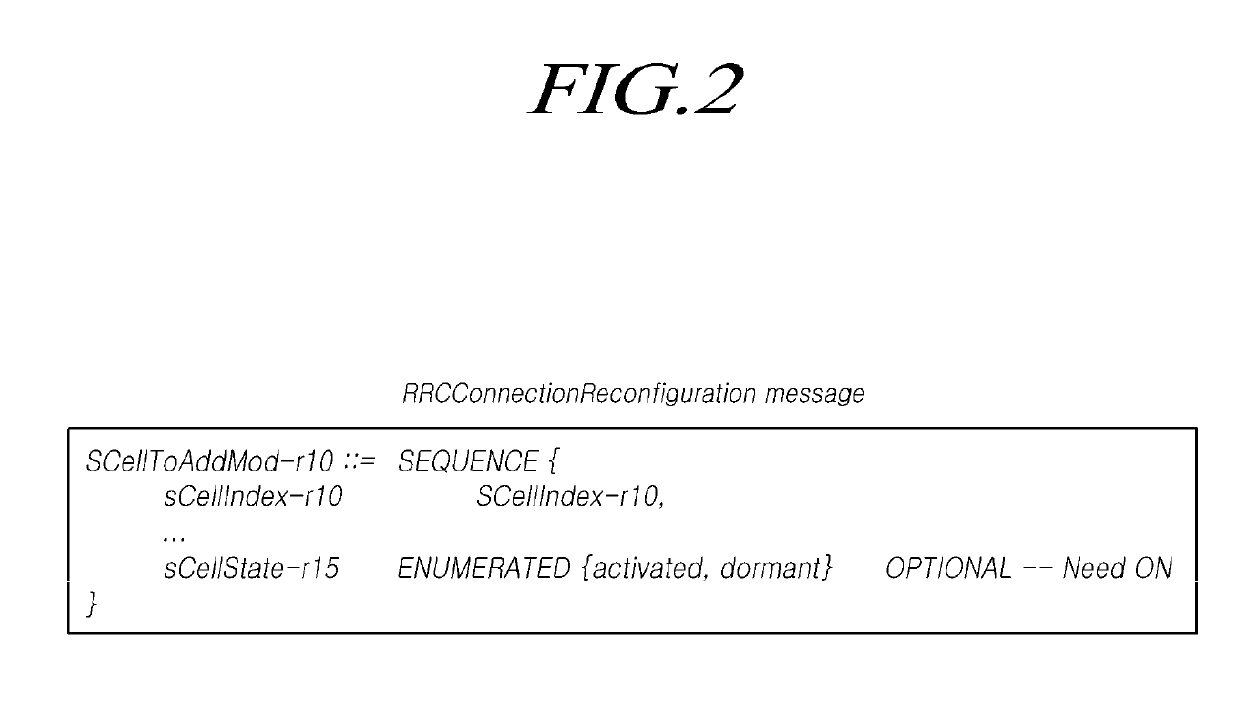

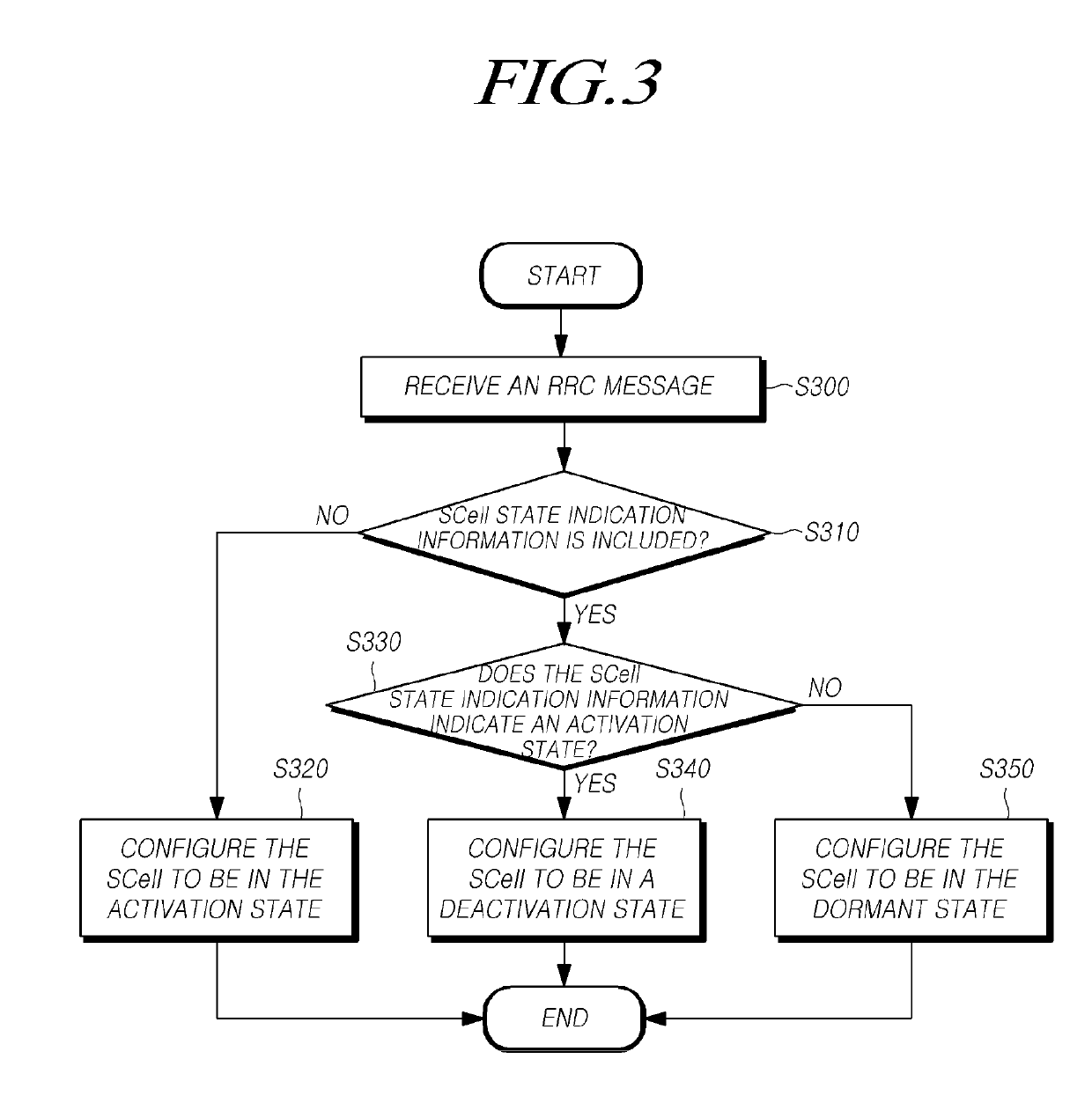

Methods for controlling scell state and apparatuses thereof

ActiveUS20190208429A1Remove unclearnessFast transitionTransmission path divisionNetwork topologiesChannel state informationComputer hardware

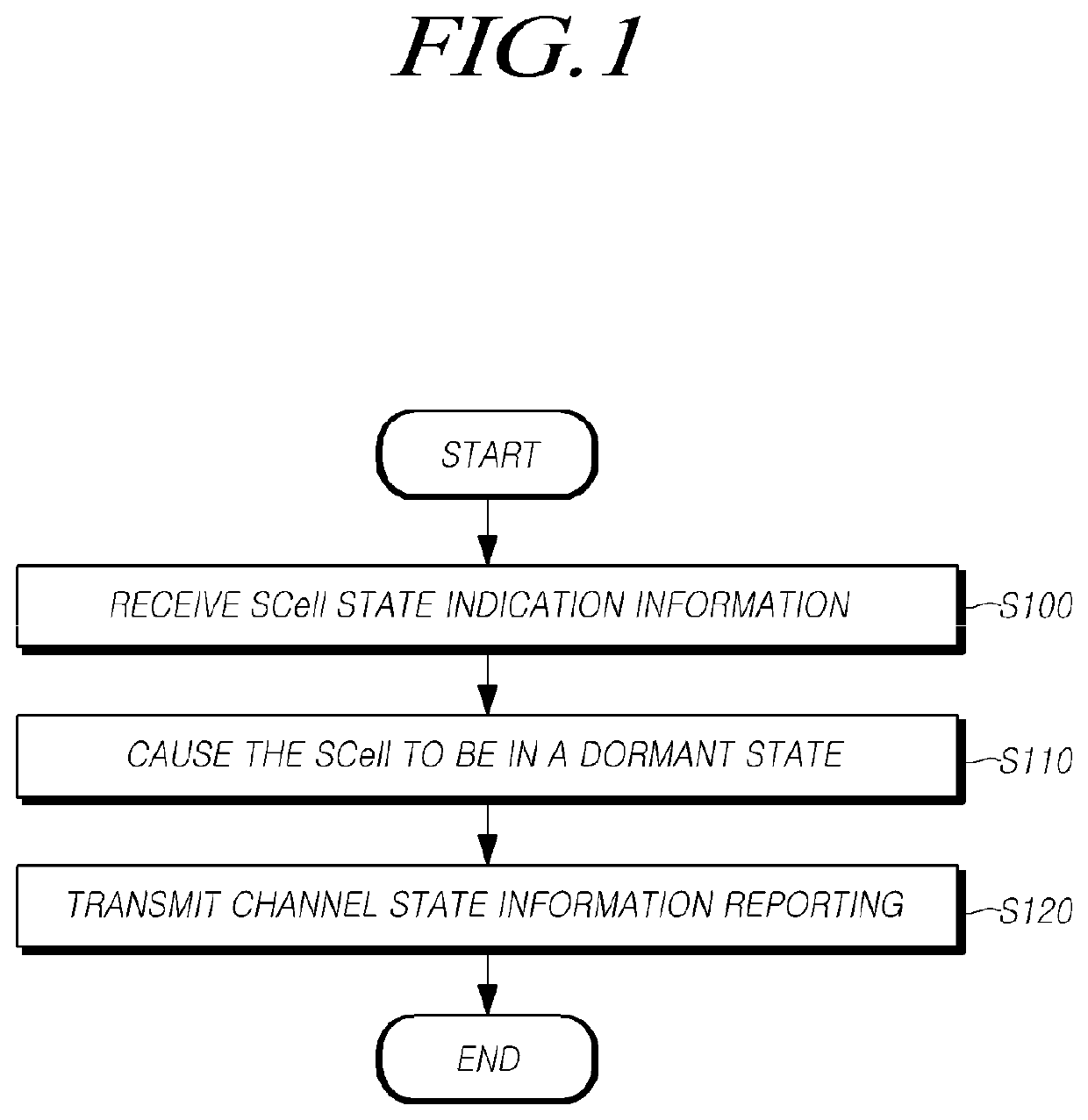

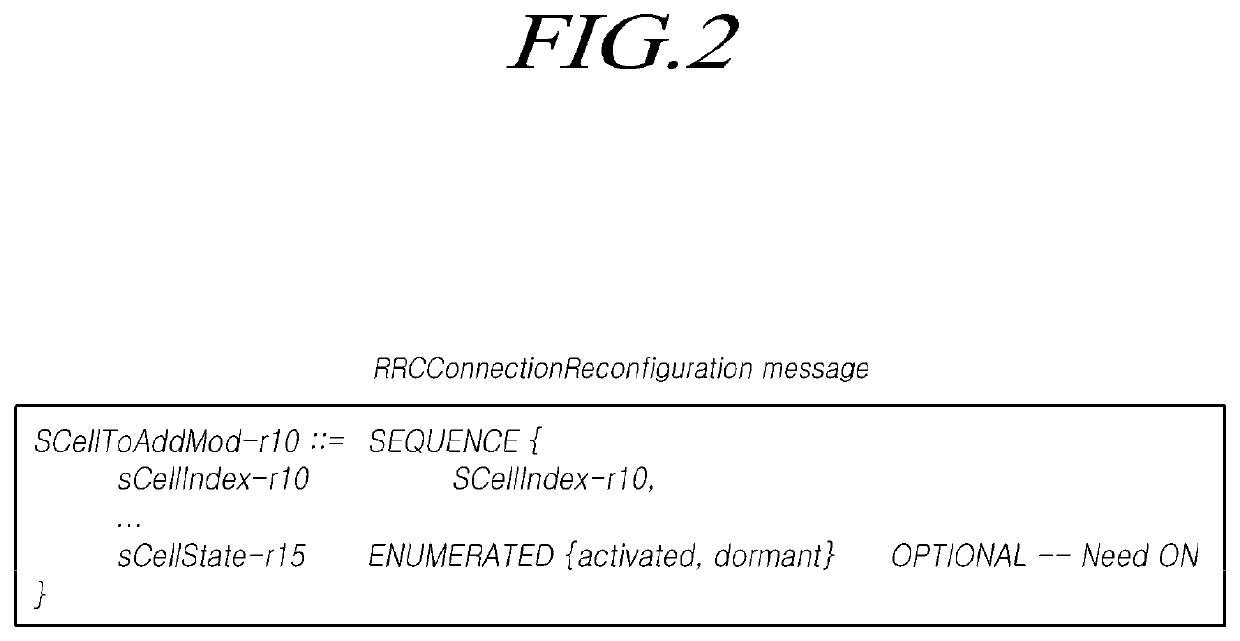

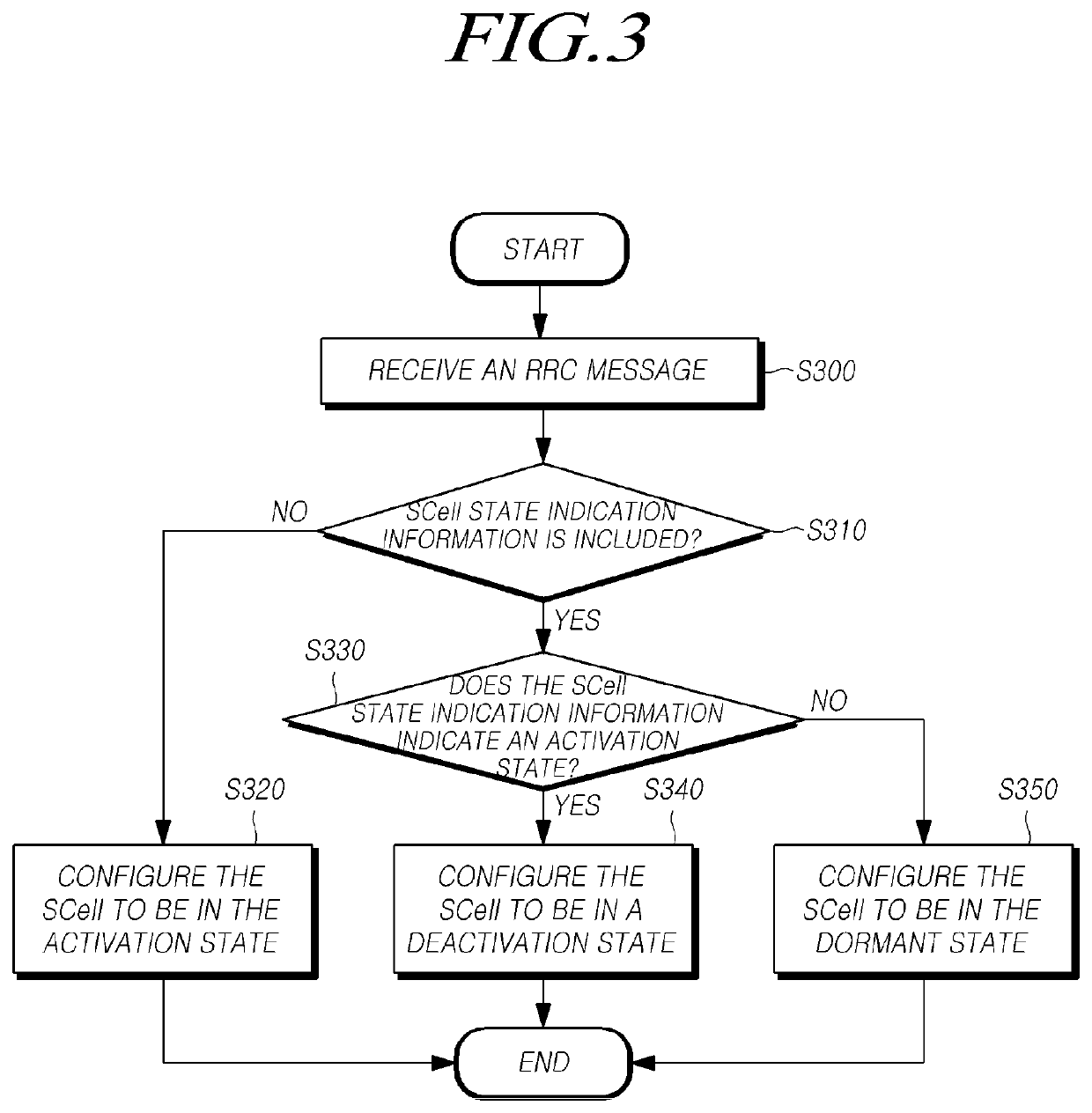

Provided is a method of controlling states of a secondary cell by a user equipment. The method may include receiving SCell state indication information indicating a state for the SCell from a base station through an RRC message or a MAC control element, configuring the state of the SCell in an activation state or a dormant state on the basis of the SCell state indication information, and transmitting channel state information for the SCell to the base station in accordance with CQI configuration information configured for the SCell.

Owner:KT CORP

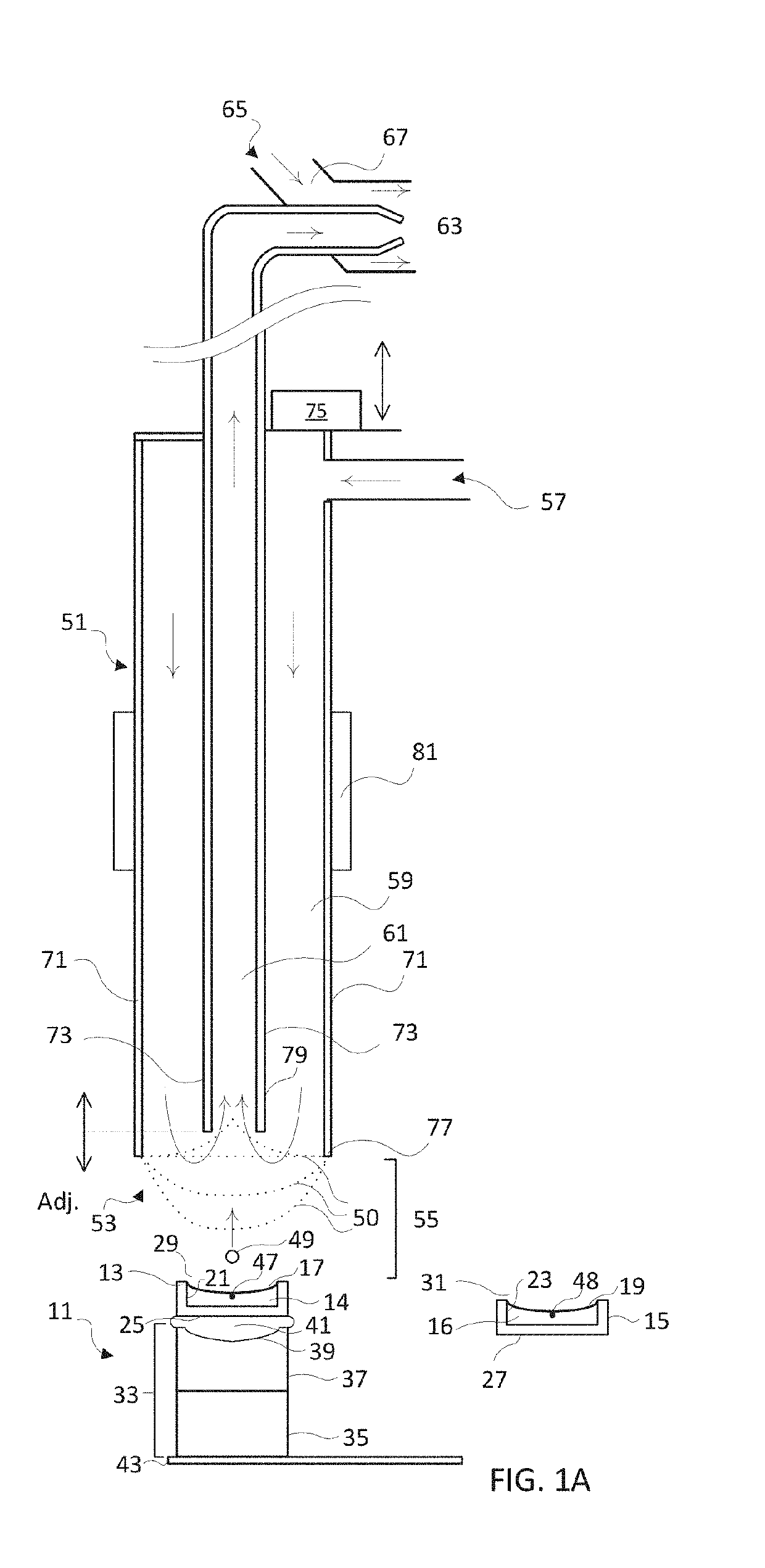

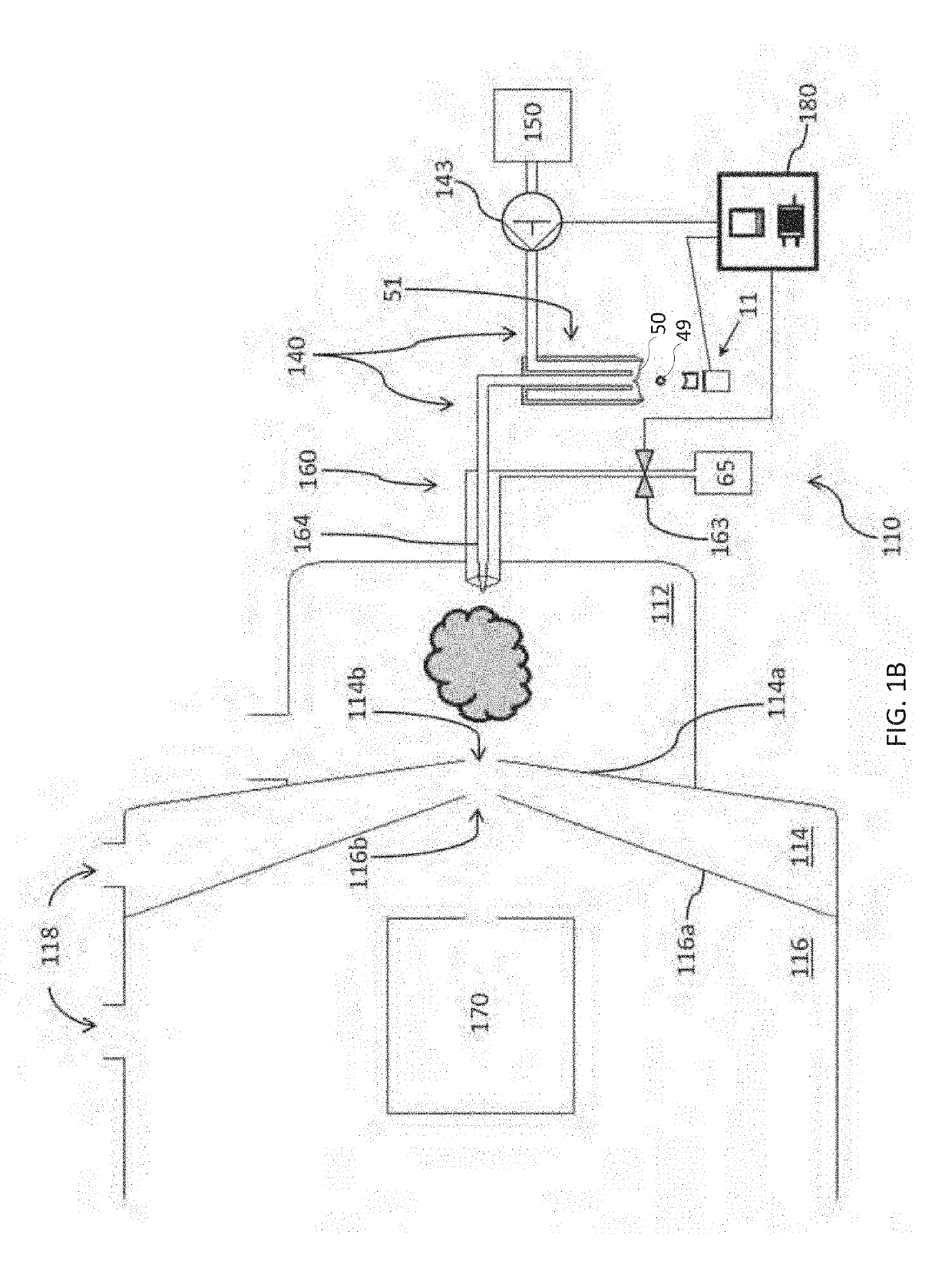

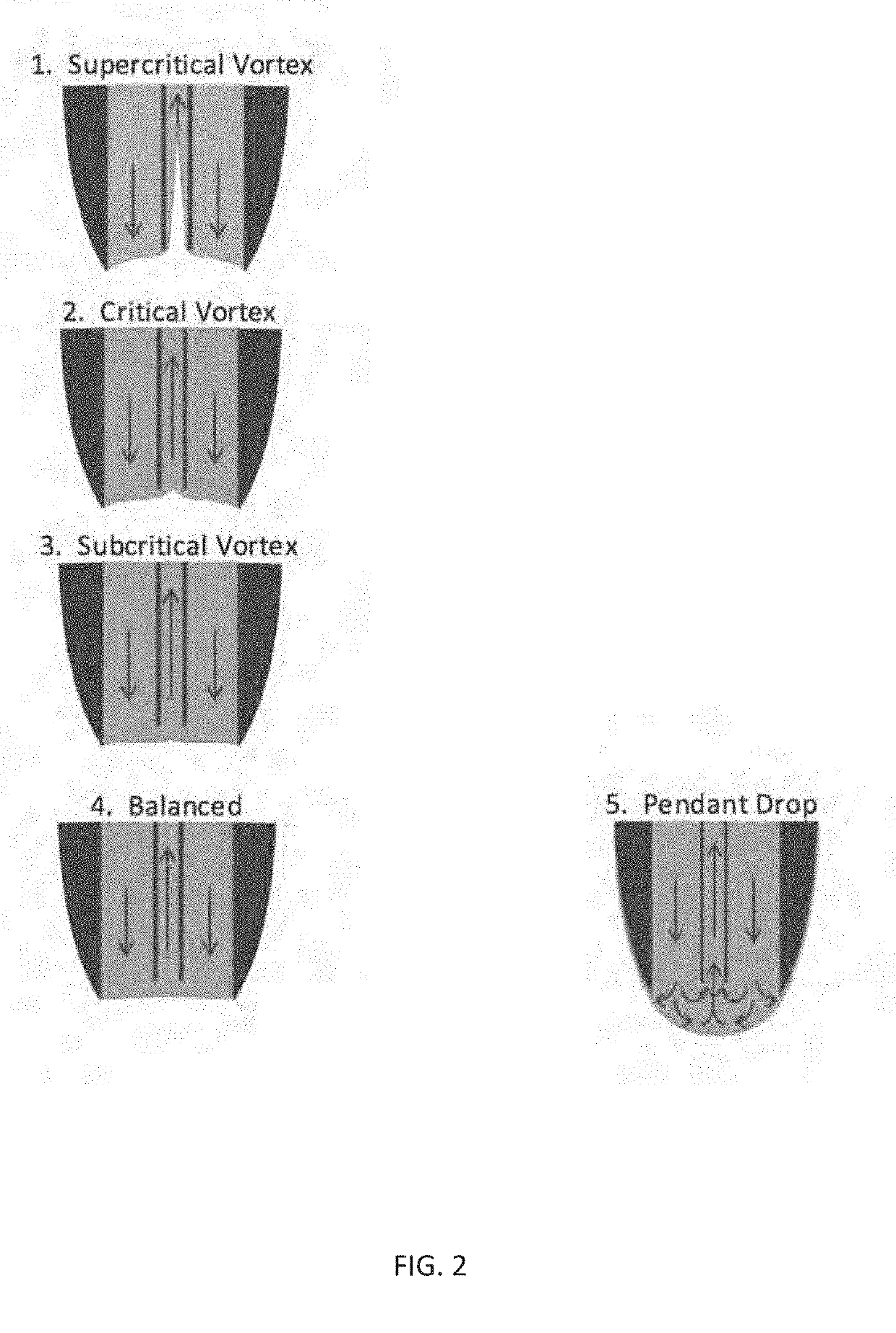

System and method for the acoustic loading of an analytical instrument using a continuous flow sampling probe

InactiveUS20190157061A1Rapid sample processingGenerate fastAnalysing fluids using sonic/ultrasonic/infrasonic wavesSamples introduction/extractionSmall dropletMass analyzer

A system and method are provided for loading a sample into an analytical instrument using acoustic droplet ejection (“ADE”) in combination with a continuous flow sampling probe. An acoustic droplet ejector is used to eject small droplets of a fluid sample containing an analyte into the sampling tip of a continuous flow sampling probe, where the acoustically ejected droplet combines with a continuous, circulating flow stream of solvent within the flow probe. Fluid circulation within the probe transports the sample through a sample transport capillary to an outlet that directs the analyte away from the probe to an analytical instrument, e.g., a device that detects the presence, concentration quantity, and / or identity of the analyte. When the analytical instrument is a mass spectrometer or other type of device requiring the analyte to be in ionized form, the exiting droplets pass through an ionization region, e.g., an electrospray ion source, prior to entering the mass spectrometer or other analytical instrument. The method employs active flow control and enables real-time kinetic measurements.

Owner:LABCYTE

Resistive random access memory based on organic/inorganic hybrid perovskite material and fabrication method of resistive random access memory

ActiveCN105789434ASimple structureImprove thermal stabilityElectrical apparatusStatic random-access memoryGas phase

The invention discloses a resistive random access memory based on an organic / inorganic hybrid perovskite material and a fabrication method of the resistive random access memory. The resistive random access memory comprises a bottom electrode, a top electrode and a resistance changing functional layer material, wherein the resistance changing functional layer material is arranged between the bottom electrode and the top electrode and comprises one layer or multiple layers of organic / inorganic hybrid perovskite thin film materials. The fabrication method comprises the following steps of (1) cleaning a substrate; (2) depositing the bottom electrode on the substrate by employing a physical vapor deposition technique; (3) forming the organic / inorganic hybrid perovskite thin film material on the bottom electrode as a resistance changing functional layer by techniques such as spin coating, dip coating and vacuum evaporation; and (4) depositing the top electrode on the resistance changing functional layer by employing the physical vapor deposition technique. According to the resistive random access memory, the structure is simple, and low-temperature and low-cost fabrication can be carried out; and the fabricated device has the technical advantages of large memory window, low conversion voltage, high conversion speed, multi-value storage capability, favorable thermal stability and device durability and the like.

Owner:GRIMAT ENG INST CO LTD

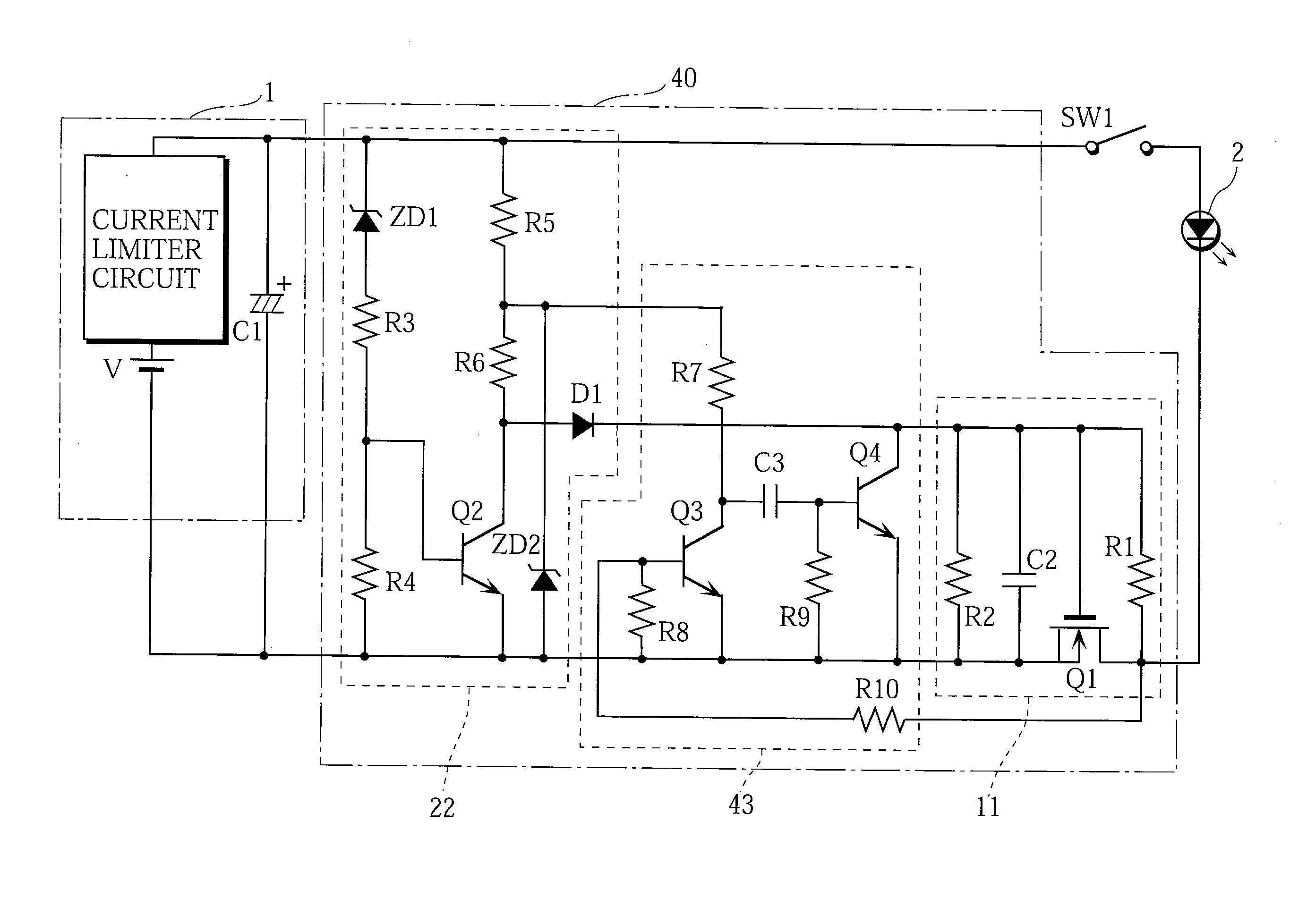

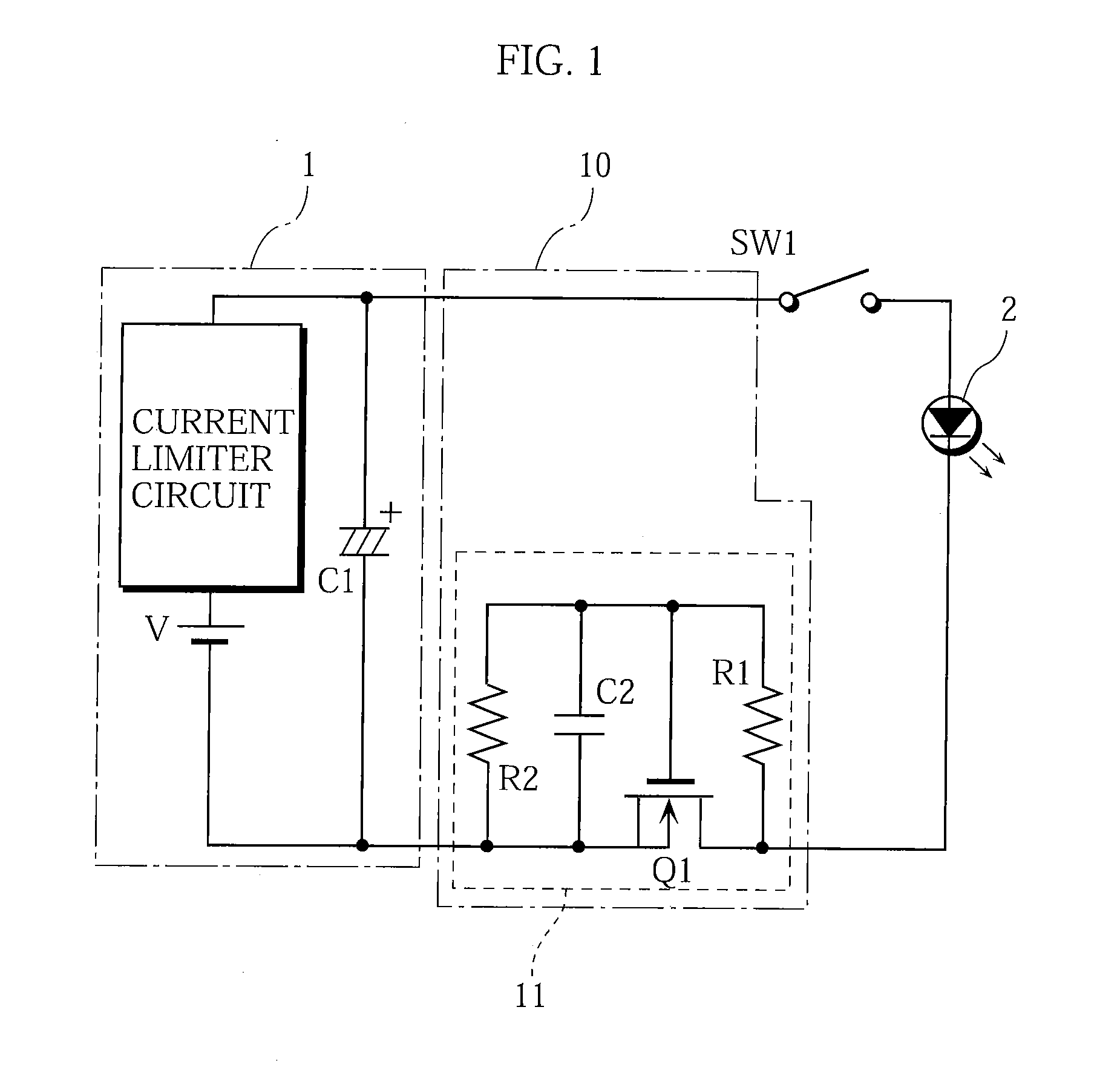

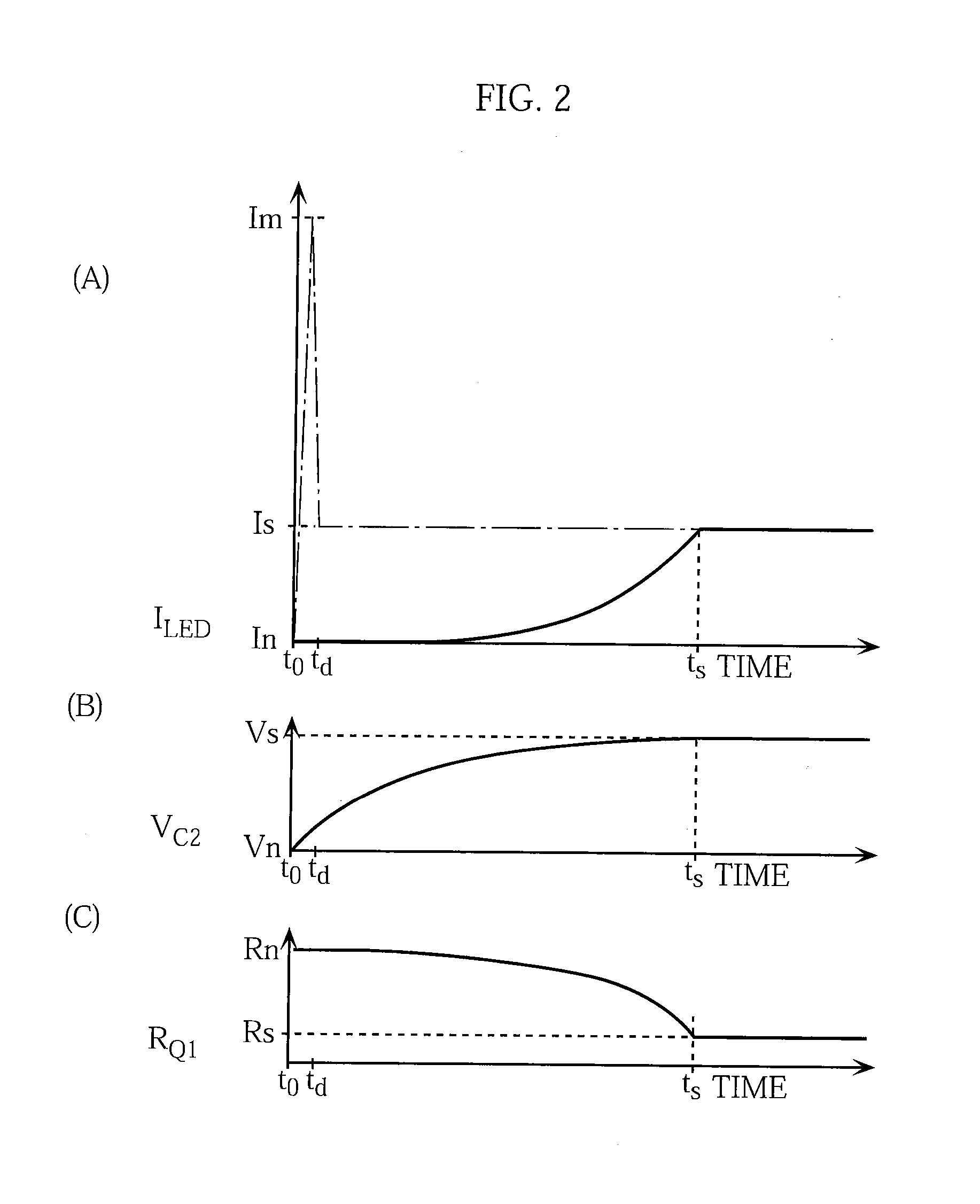

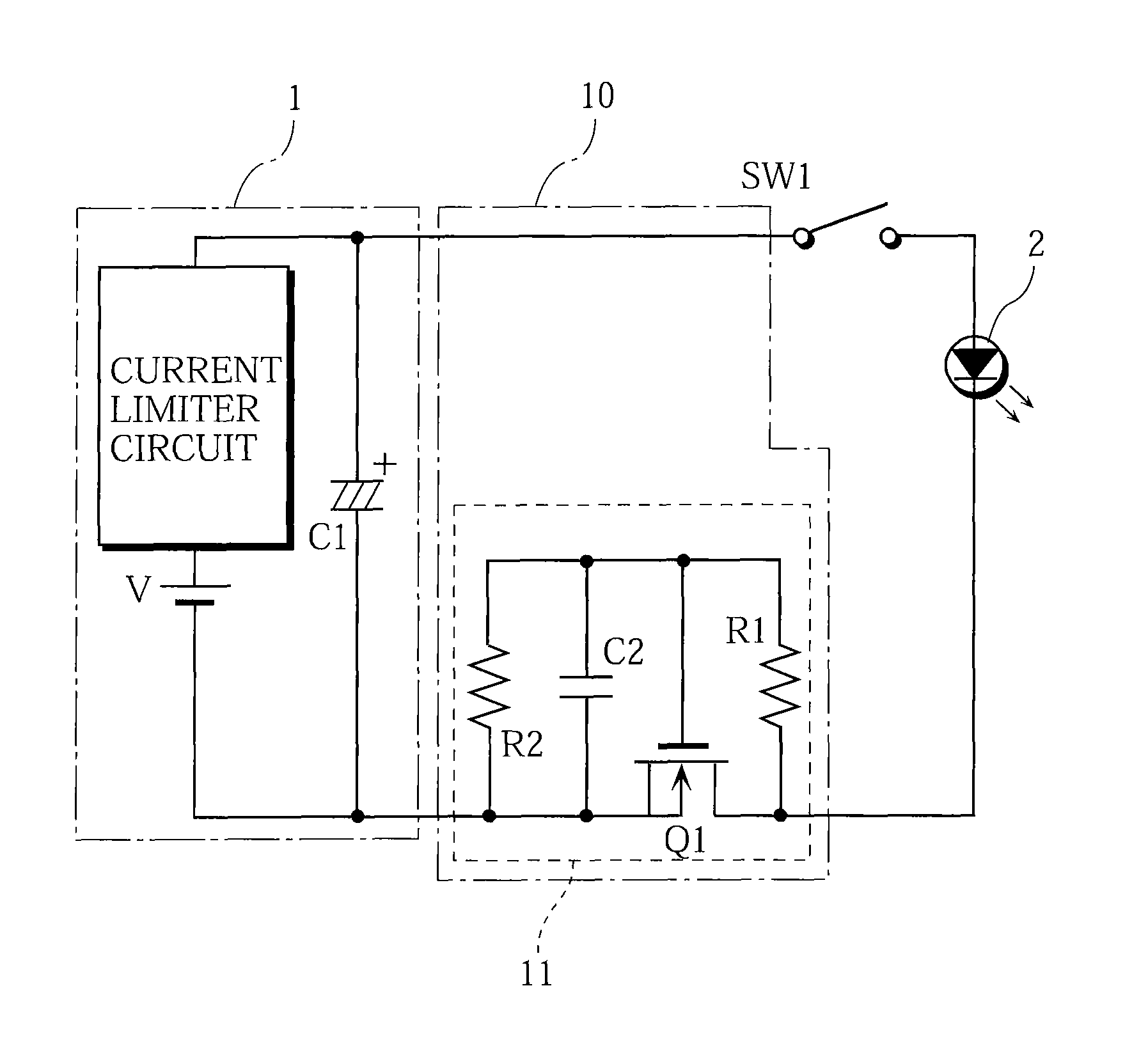

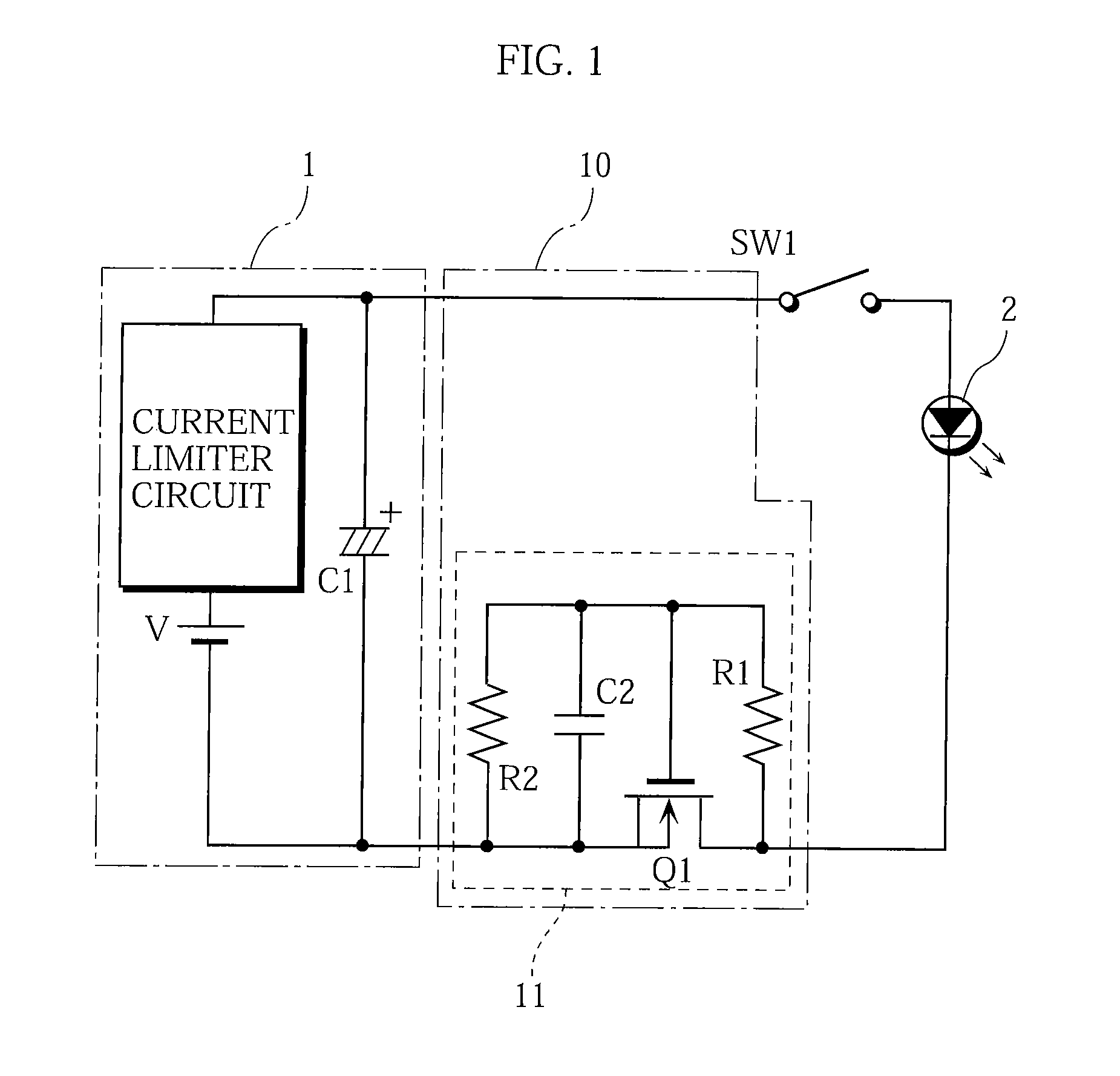

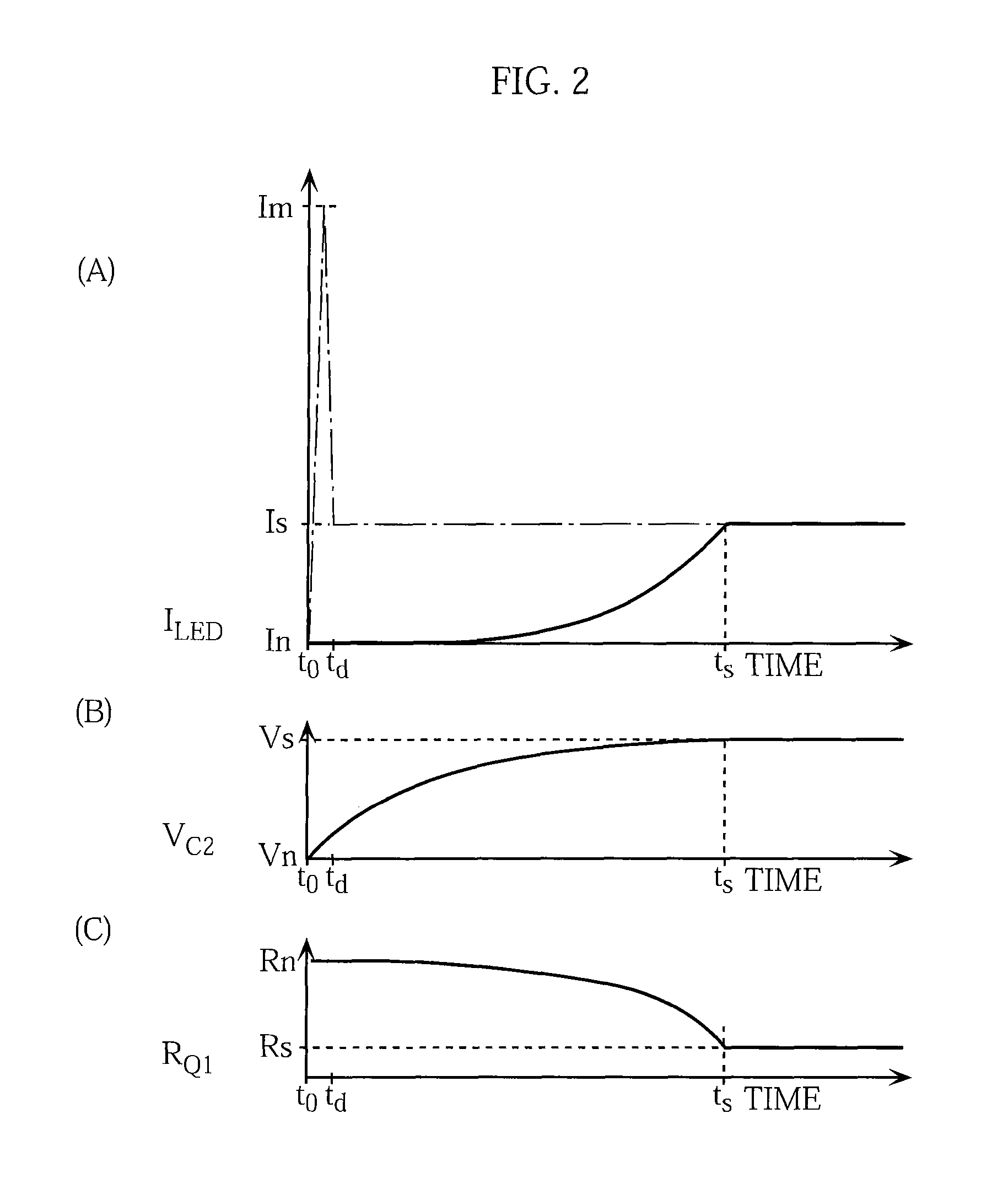

Electric circuit

InactiveUS20110002069A1Reduce energy lossFast transitionElectroluminescent light sourcesSemiconductor lamp usageElectricityCapacitance

A functional element is prevented from breakdown and deterioration because of mounting and demounting of the functional element immediately after cut-off of driving power from a constant-current power supply or during supply of the driving power.An electric circuit is configured to electrically connect a constant-current power supply 1 having a capacitance between an output terminal and a reference potential terminal and a detachable functional element 2 to each other. The electric circuit has an element breakdown prevention circuit 10 having a first circuit terminal connected to an output terminal of the constant-current power supply 1 through the functional element 2, and a second circuit terminal connected to the reference potential terminal of the constant-current power supply 1 through the functional element 2. The element breakdown prevention circuit 10 increases an impedance between the circuit terminals to a disconnected state impedance in response to a transition from a connected state, in which the functional element 2 is mounted, to a disconnected state, in which the functional element 2 is removed. The element breakdown prevention circuit 10 decreases the impedance between the circuit terminals to a connected-state impedance in response to a connection state transition.

Owner:IDEC CORPORATION

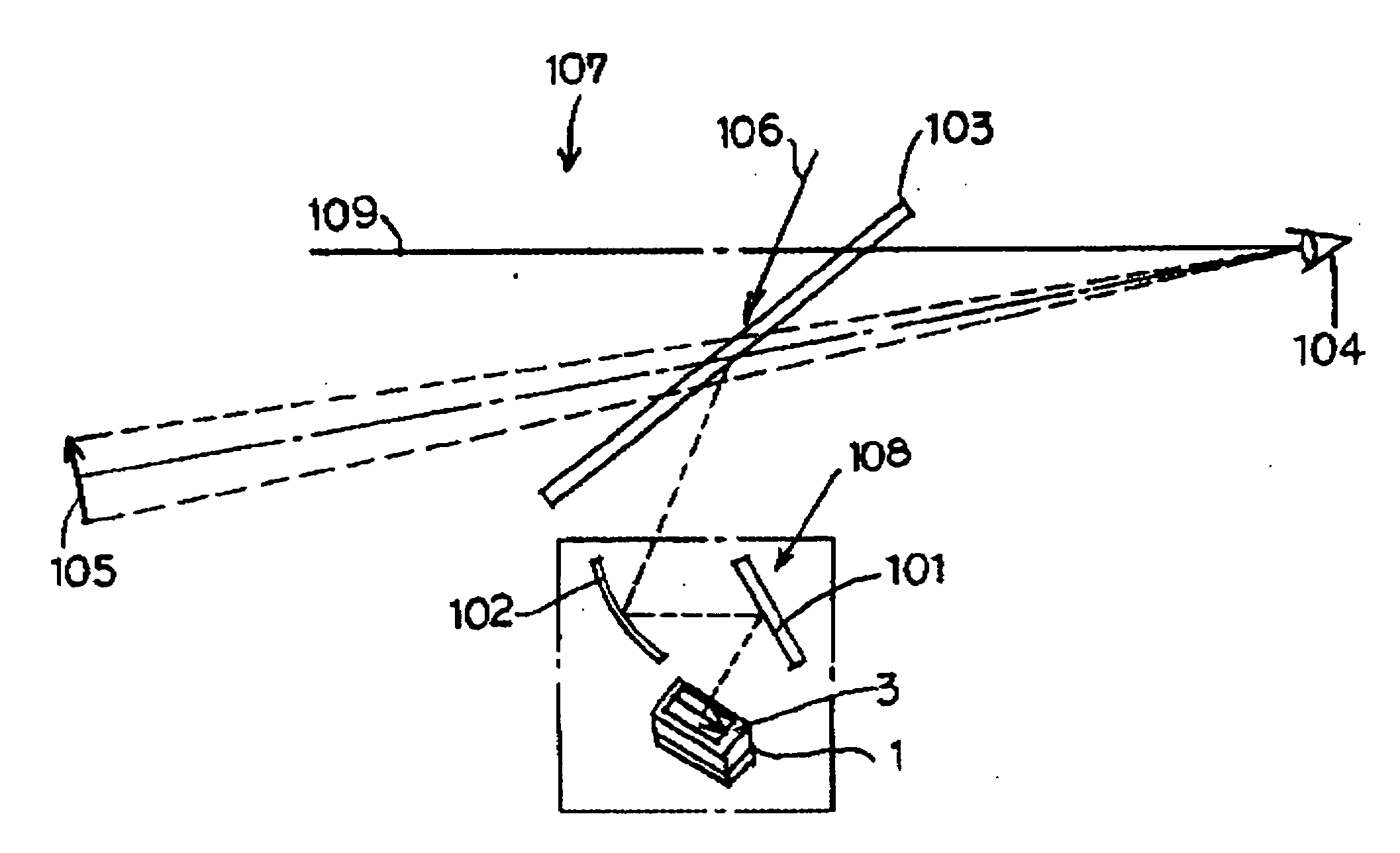

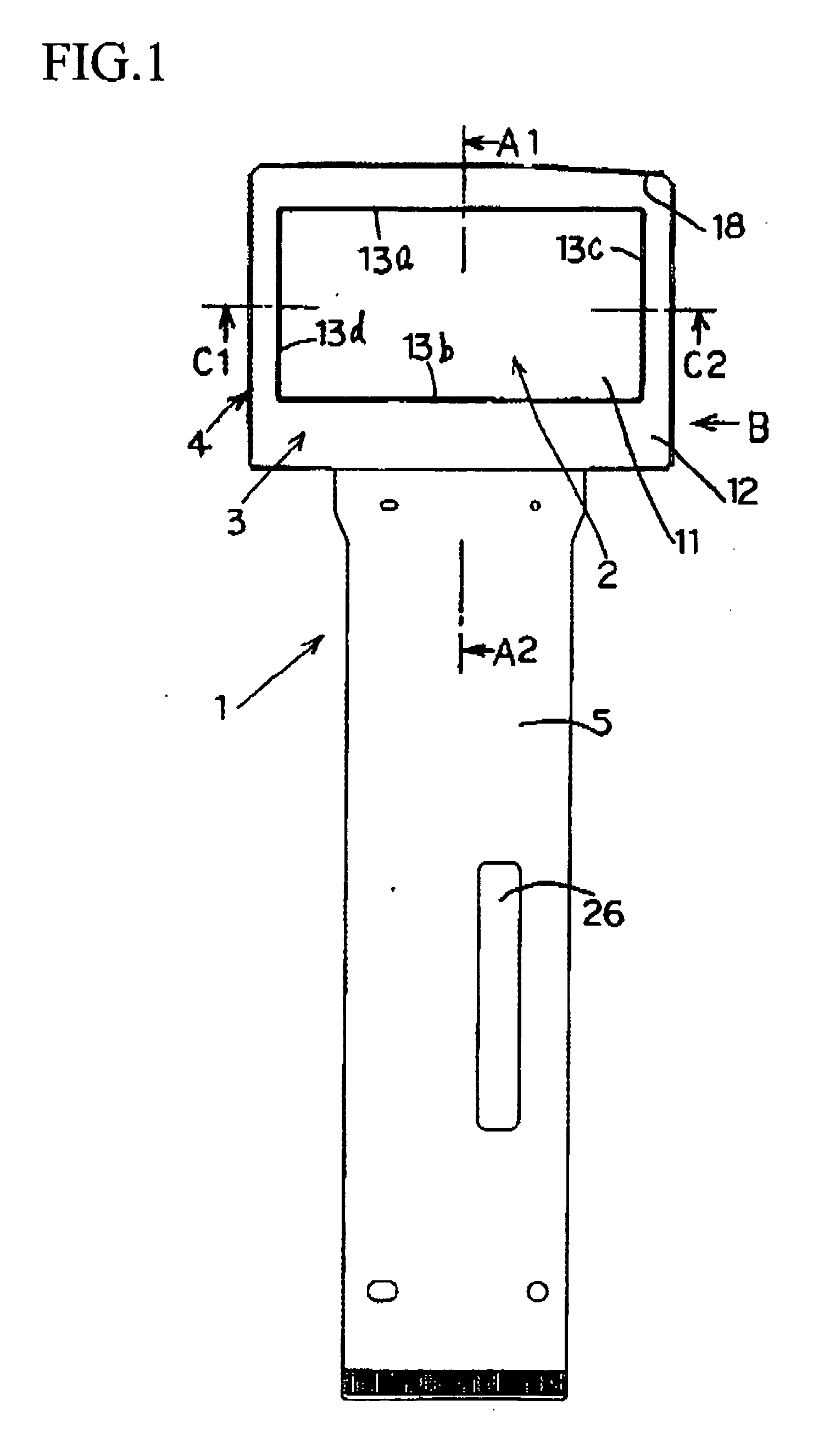

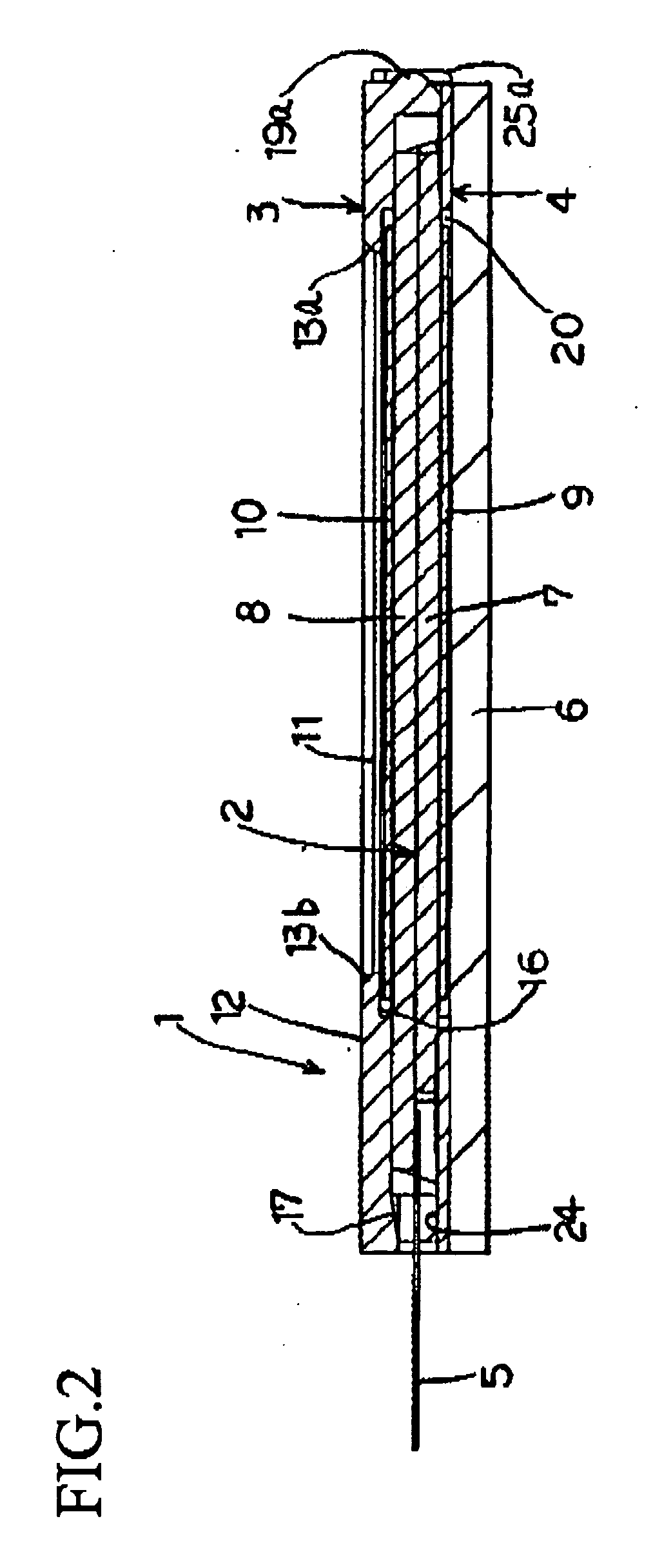

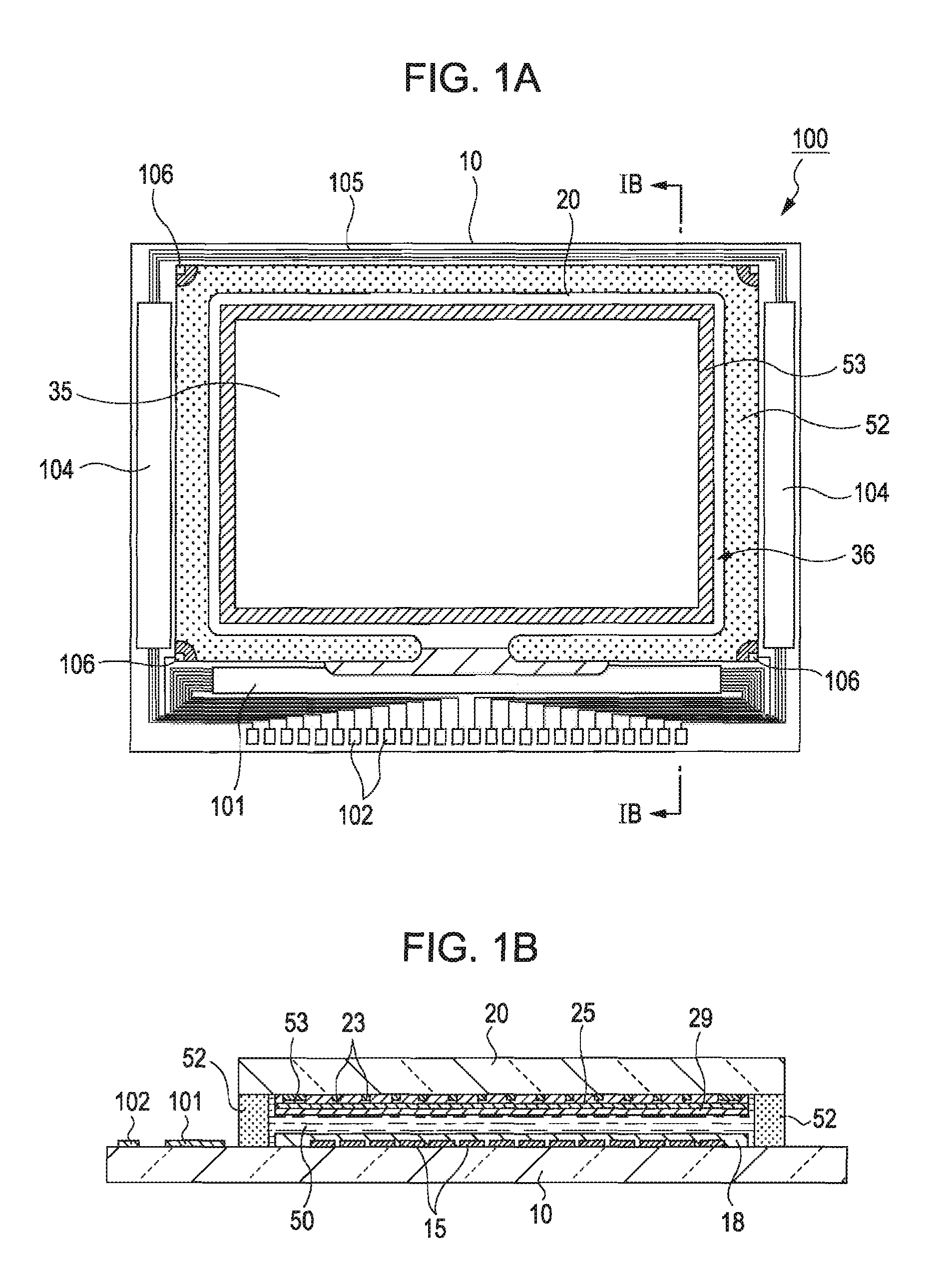

Liquid crystal display device and head-up display using it

InactiveUS20070164955A1Improve thermal conductivityFast heat conductionStatic indicating devicesDiffusing elementsHead-up displayMiniaturization

Provided is a liquid crystal display device that can be produced at low costs, can achieve miniaturization, and can offer clear virtual images. The liquid crystal display device is provided with: a frame body that is so disposed as to cover a top face of a liquid crystal cell, that has a first opening so formed as to face the top face of the liquid crystal cell, and that has a picture frame-shaped member formed around the first opening; a frame that is fixed to the frame body and that has a second opening so formed as to face a back face of the liquid crystal cell; and a light source that illuminates the liquid crystal cell via the second opening of the frame. Here, a top face of the picture frame-shaped member of the frame body is so designed that light is diffusely reflected therefrom.

Owner:EPSON IMAGING DEVICES CORP

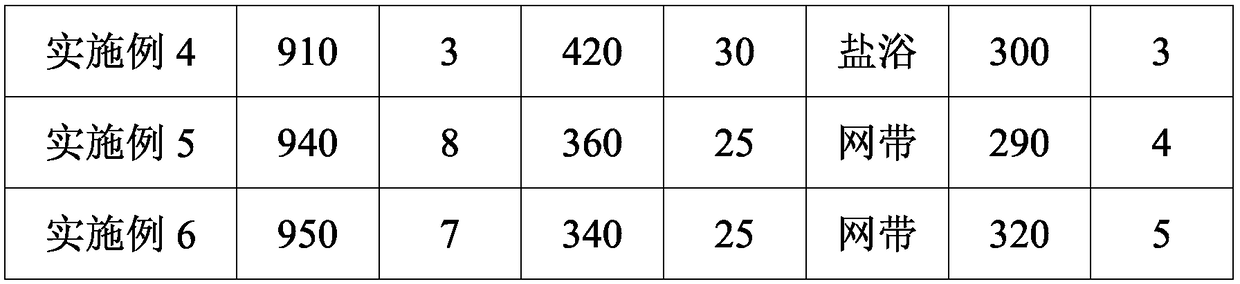

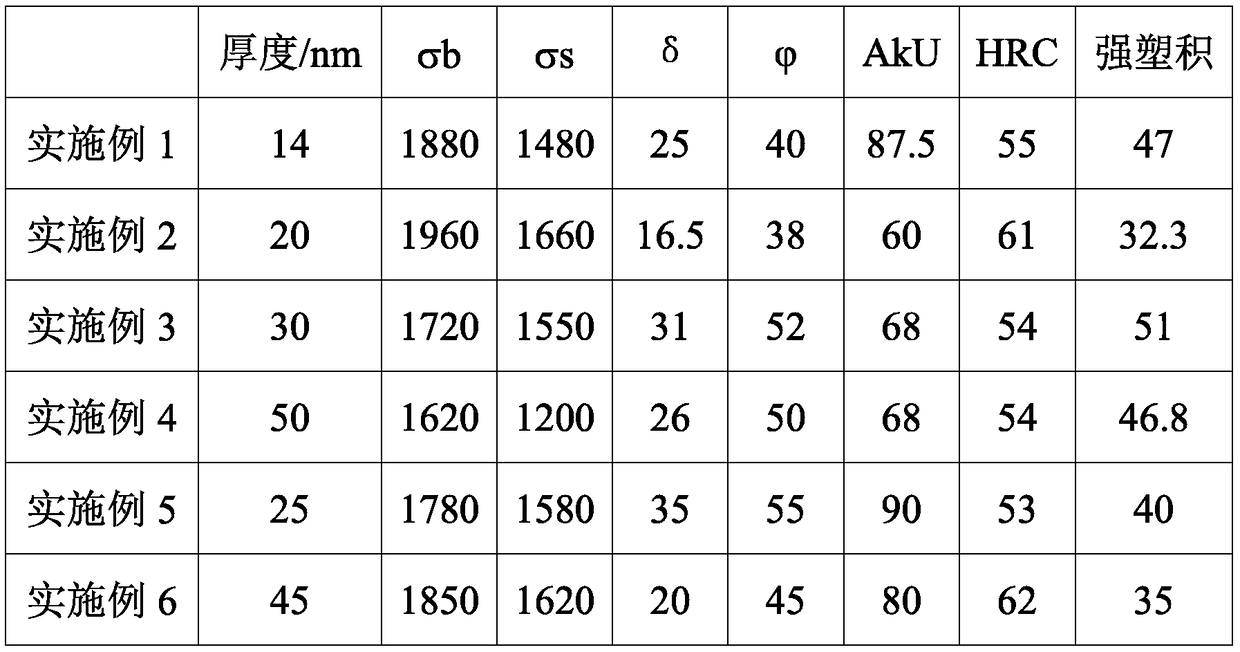

High performance cutting pick and manufacturing method thereof

InactiveCN108977631AOptimize chemical compositionHigh hardnessFurnace typesHeat treatment furnacesRaw materialMicrostructure

The invention provides a high performance cutting pick and a manufacturing method thereof, the high performance cutting pick comprises a tooth tip and a tooth body. The tooth body is high-strength, high-toughness and high-wear-resistance steel. The chemical components are as following by weight percent, 0.30 to 0.40 of C, 2.30 to 2.50 of Si, 2.20 to 2. 60 of Mn, 0.80 to 1.50 of Cr, 0.35 to 0.45 ofMo, 0.01 to 0.1 of Re, 0.02 to 0.04 of Nb, less than 0.01 of S, less than 0.01 of P, and the rest of Fe. After raw materials are refined and cast to obtain steel ingots or subjected to continuous casting to obtain continuous casting billets, after being rolled into round steel, cutting and annealing are conducted, and finally a cutting pick body is obtained by cold forging. The tooth tip is prepared from cemented carbide and welded to the tooth body by medium frequency induction heating. After cooling, austempering treatment is conducted, and finally discharging and air-cooling to room temperature are conducted. The finally obtained tooth body has tensile strength sigma b of 1700 to 2000MPa, yield strength sigma s of 1100 to 1520MPa, elongation delta of 16 to 35%, section shrinkage phi of45 to 55%, impact work Aku of 55 to 90 J, hardness HRC of 53 to 62, and strong plastic product of 32 to 51 GPa.%. The microstructure of the tooth body is a nano-carbide-free bainite-martensitic multiphase organization, and the thickness of a substructure slat is 10 to 50 nm.

Owner:鄂尔多斯市神东天隆矿山机械有限责任公司 +1

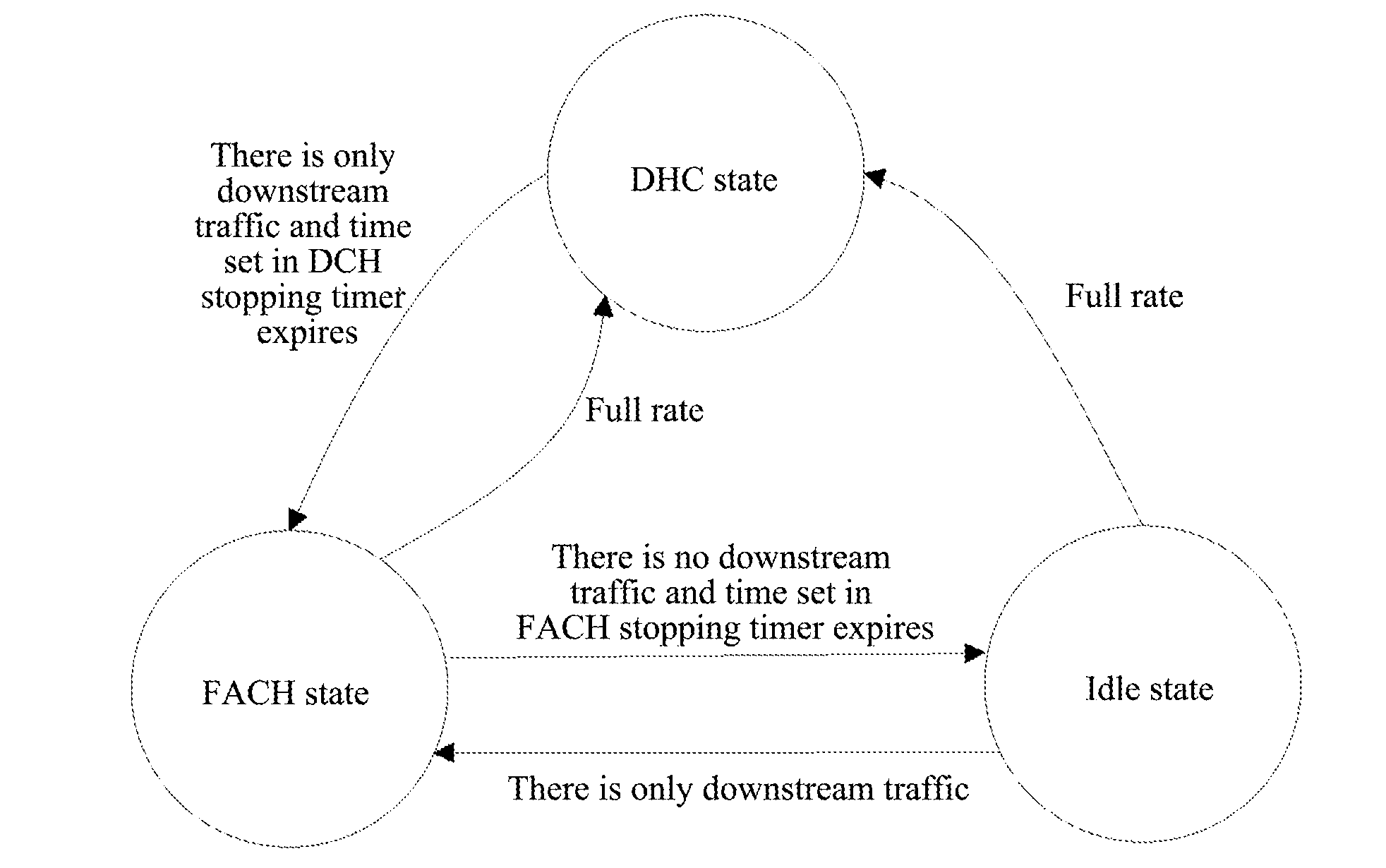

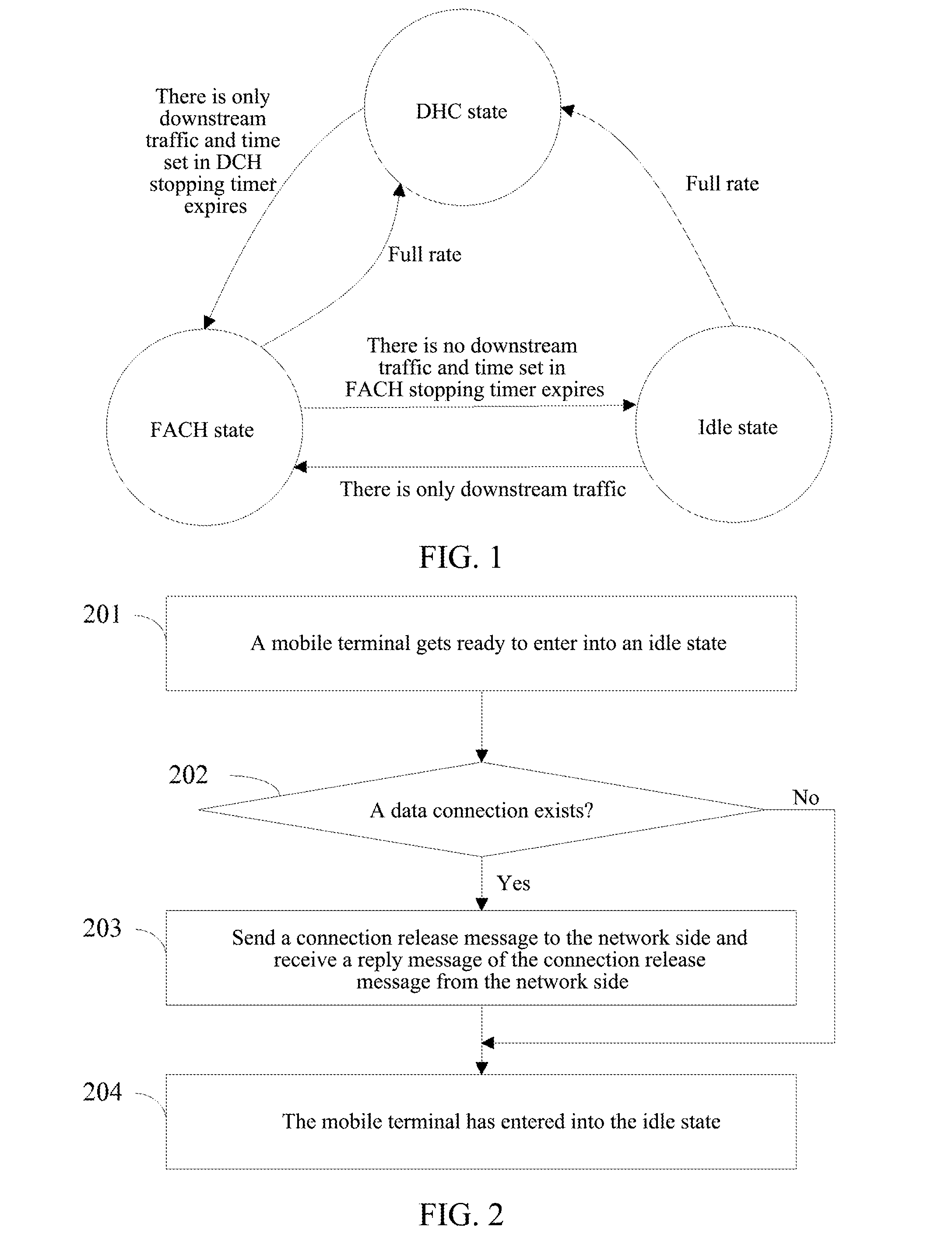

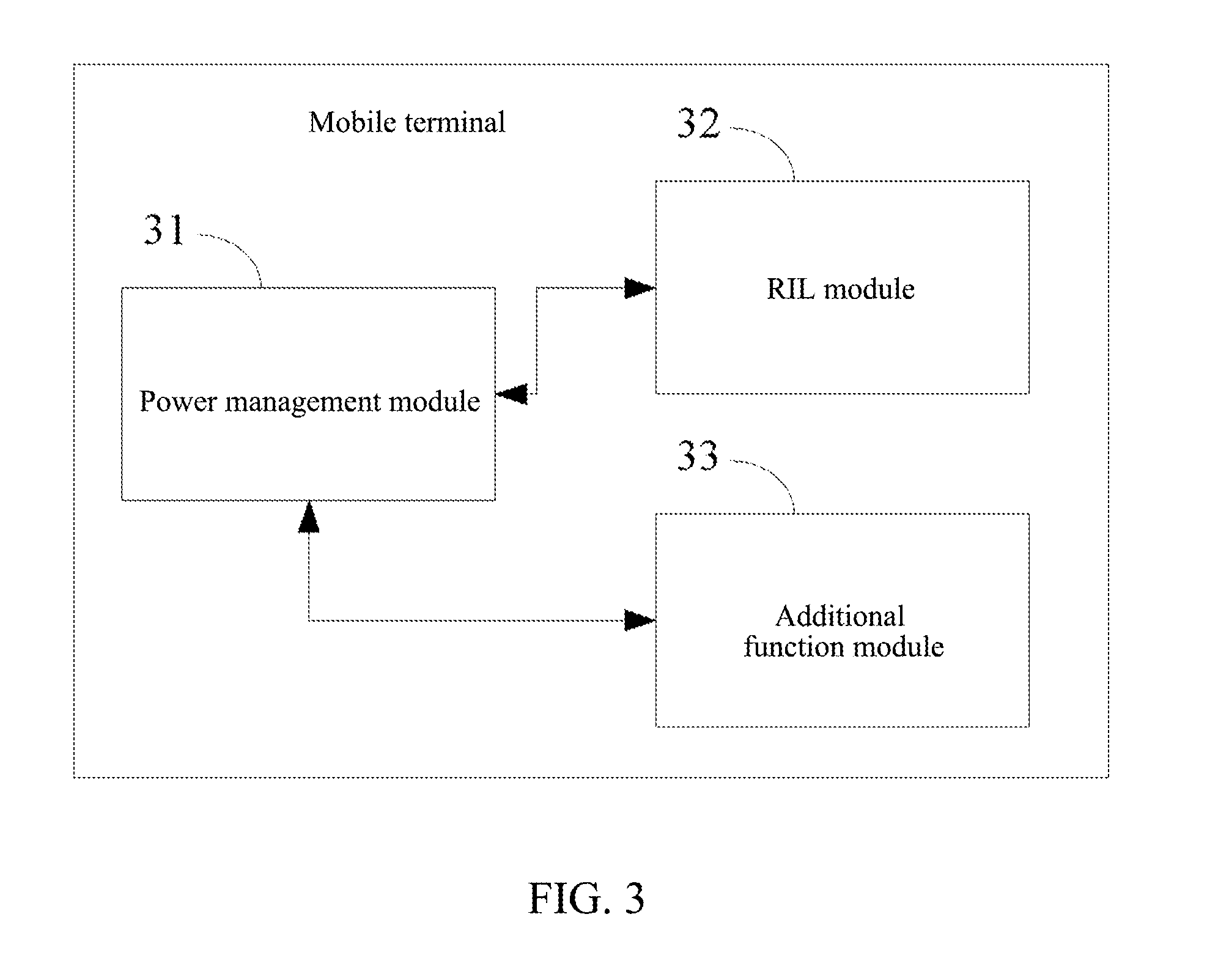

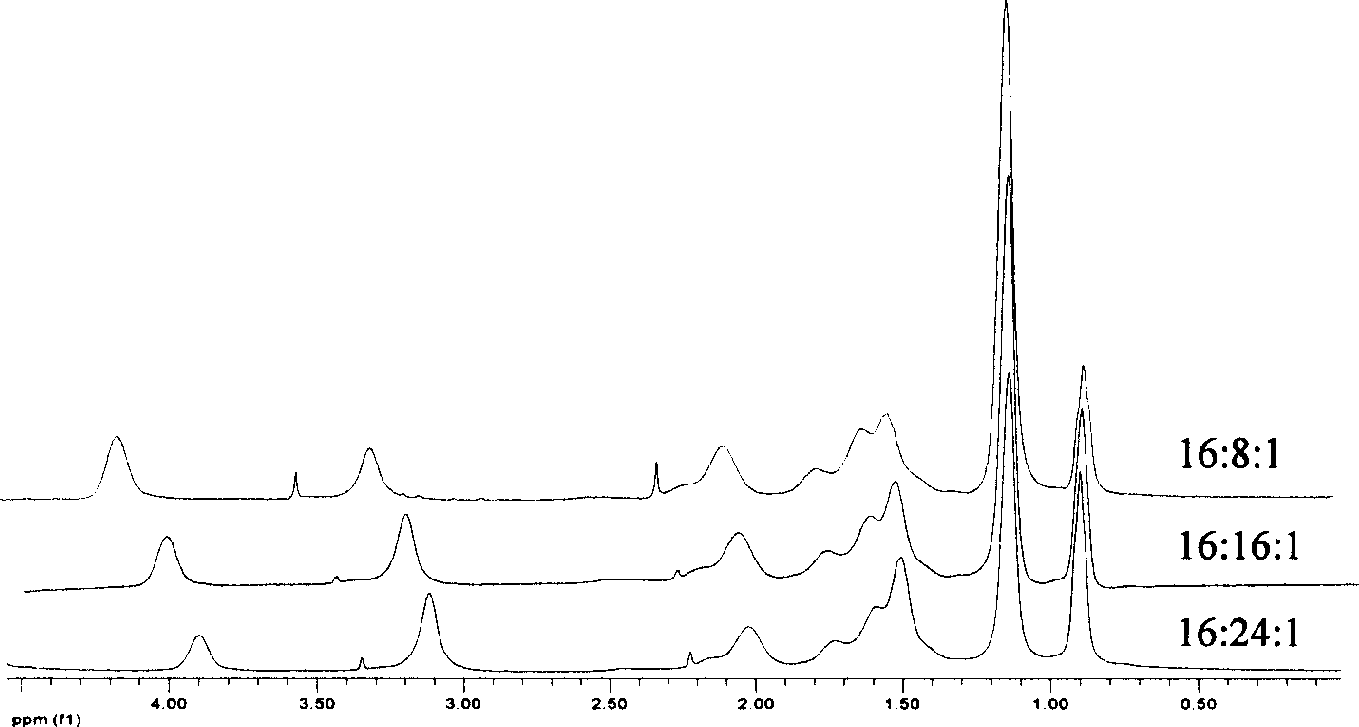

Method for entering idle mode and mobile terminal for implementing such method

InactiveUS20130138987A1Avoid wastingIncreased idle timePower managementConnection managementElectricityData connection

The present invention discloses a method for entering into an idle mode comprising: a mobile terminal getting ready to enter into an idle state; and determining whether a data connection exists currently, and if the data connection exists, sending a connection release message to a network side, and the mobile terminal entering into the idle state after receiving a reply message, if the data connection does not exist, the mobile terminal entering into the idle state directly. The present invention further discloses a mobile terminal to which the method is applied. Using the method and mobile terminal described above, the mobile terminal can enter into the idle state directly, thereby avoiding waste of electricity in the state transition process and extending the idle time of the mobile terminal.

Owner:ZTE CORP

Preparation and use of injectable isopropyl acrylamide tripolymer as thrombus material and its use

InactiveCN1679620AHigh strengthAvoid false boltsSuture equipmentsOrganic active ingredientsThrombusPropylamine

An injection of three-element isopropyl acrylamide material used as the vascular blocking material for treating the deformity of human cerebral artery and vein is prepared through reacting between propencyl chloride and n-propylamine to obtain propyl propenoyl chloride, synthesizing PNINAVP from ammonium persulfate and tetramethyl ethyldiamine in water, and dissolving iohexol in the solution of PNINAVP.

Owner:TIANJIN UNIV

Multiphase magnetic Fenton-photocatalyst and preparation method thereof and application

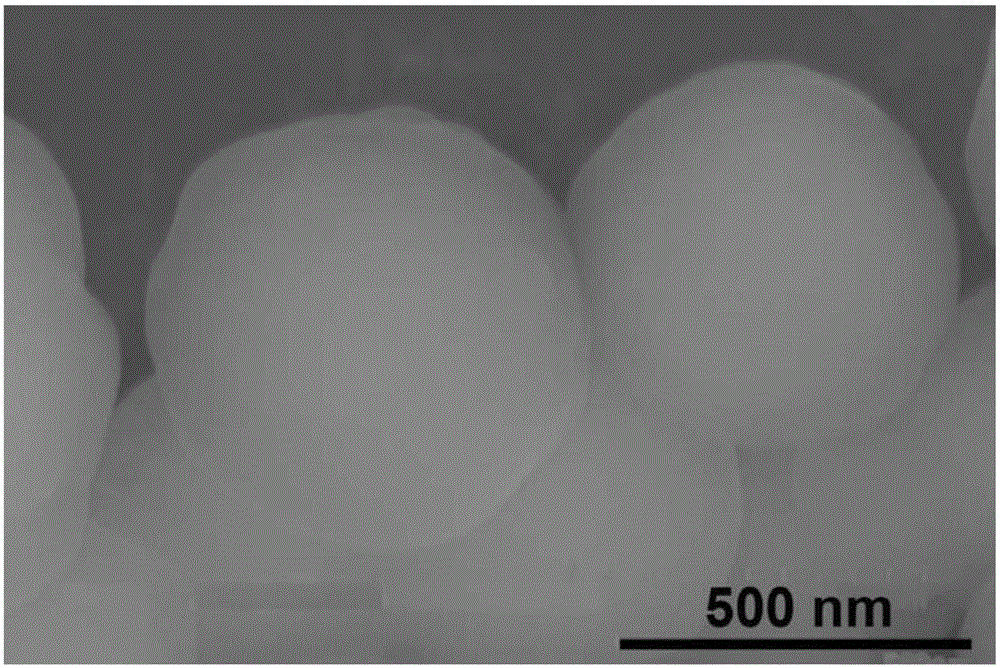

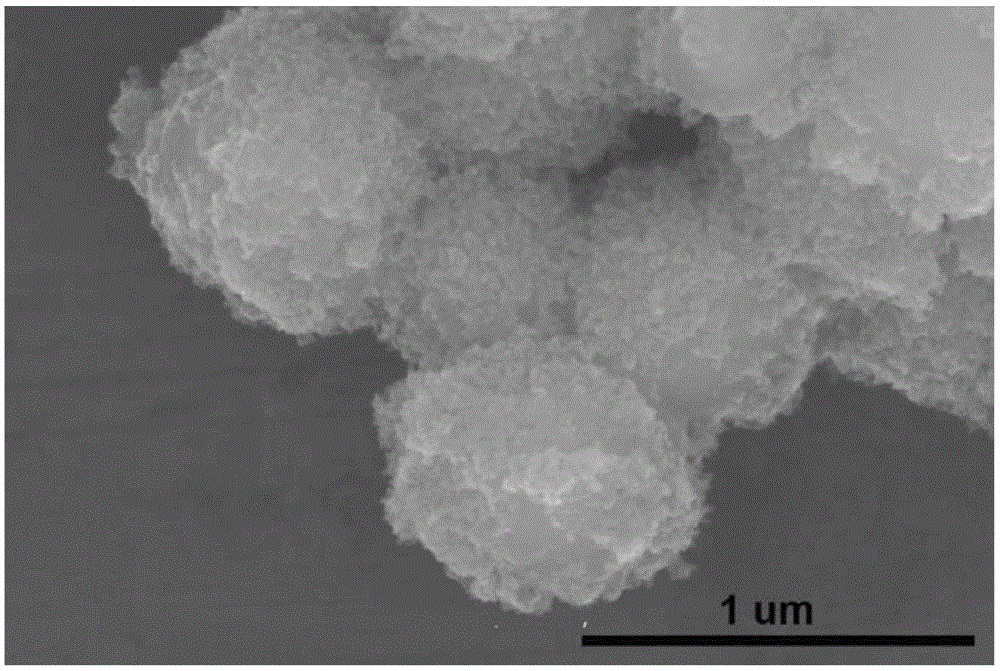

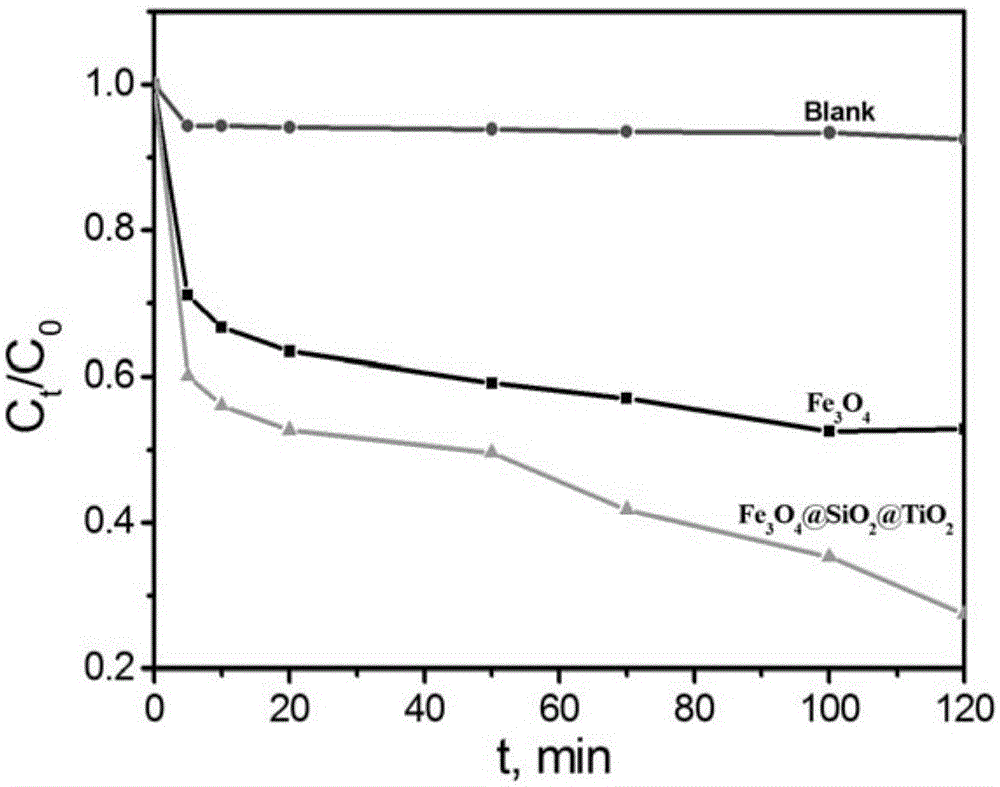

InactiveCN105032423AEasy to recycleGood superparamagneticMaterial nanotechnologyWater/sewage treatment by irradiationMicrosphereWastewater

The invention relates to a multiphase magnetic Fenton-photocatalyst which is core-shell type microsphere Fe3O4@TiO2 which is of a three-layer structure. A core Fe3O4 microsphere is formed by stacking nanometer small granules of 15-30 nm, the thickness of a transitional SiO2 layer is 50-150 nm, and the thickness of an outermost TiO2 is 100-300 nm. The prepared photocatalyst has good superparamagnetism, can be separated thoroughly in 30 s under the effect of an outside magnetic field, is easy to recycle, can be recycled, and is environmentally friendly. The multiphase magnetic Fenton-photocatalyst can catalyze hydrogen peroxide under visible light to degrade organic pollutants, a multi-channel reaction pathway is formed, and accordingly high catalytic activity is achieved. A composite microsphere is good in monodispersity and can maintain high activity of a catalyst in wastewater treatment and improve utilization rate.

Owner:张少旸

High-temperature phase-transitional temperature-sensitive fire-extinguishing gel and preparation method thereof

InactiveCN102188781ARaise the phase transition temperatureFast transitionFire extinguisherChemistryWater soluble

The invention relates to a high-temperature phase-transitional temperature-sensitive fire-extinguishing gel and a preparation method thereof. Through the physical crosslinking between polyacid with a hydrophilic backbone structure and polyamine with a hydrophobic backbone structure, the fire-extinguishing gel is in a soluble state at a low temperature and in a gel state at a high temperature. The fire-extinguishing agent is a low-viscosity aqueous solution at normal temperature; the viscosity is gradually increased as the temperature rises, and then the aquagel is formed and adhered on the surface of burning objects, thus the effect of fire-extinguishing is achieved and the fire behavior is blocked from spreading; after the temperature of the gel is lowered to a certain temperature, the gel is returned to the state of liquid, the residue can be cleaned by using water for flushing, thereby being efficient and environment-friendly. The fire-extinguishing agent provided by the invention has low viscosity, can be spouted by using the traditional squirt gun; meanwhile, other elements, such as fire-proofing agent, flame retardant, and the like, can be added to improve the fire-extinguishing performance of the fire-extinguishing agent.

Owner:SHANGHAI UNIV +1

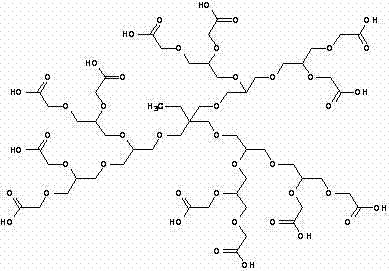

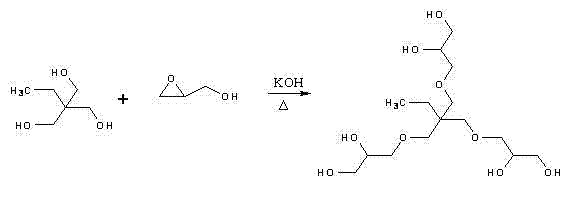

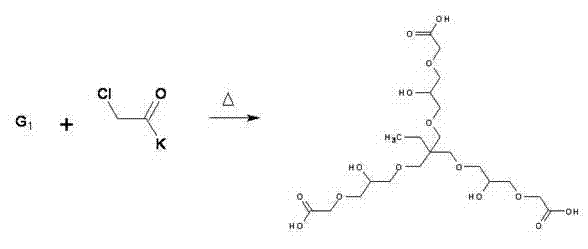

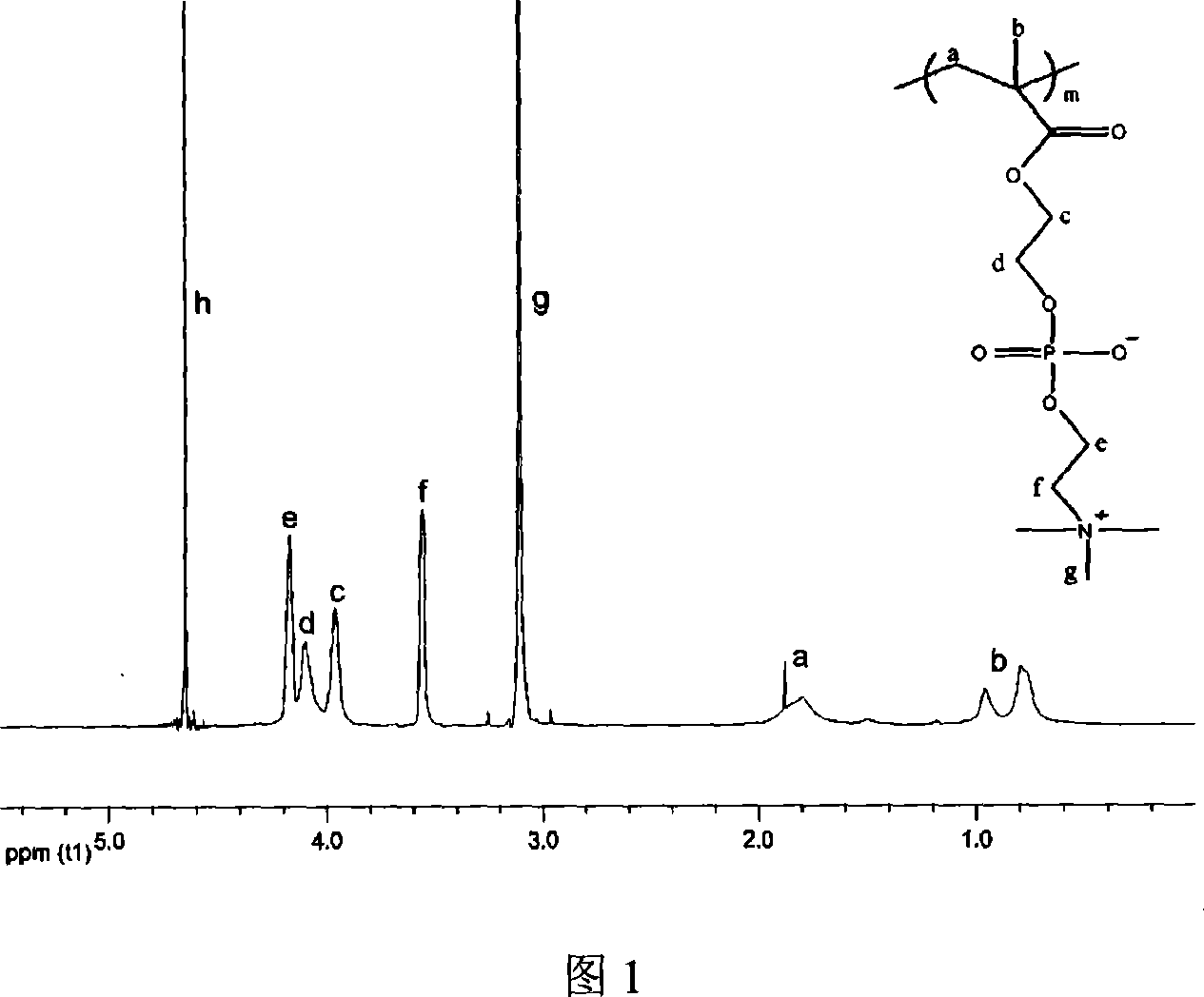

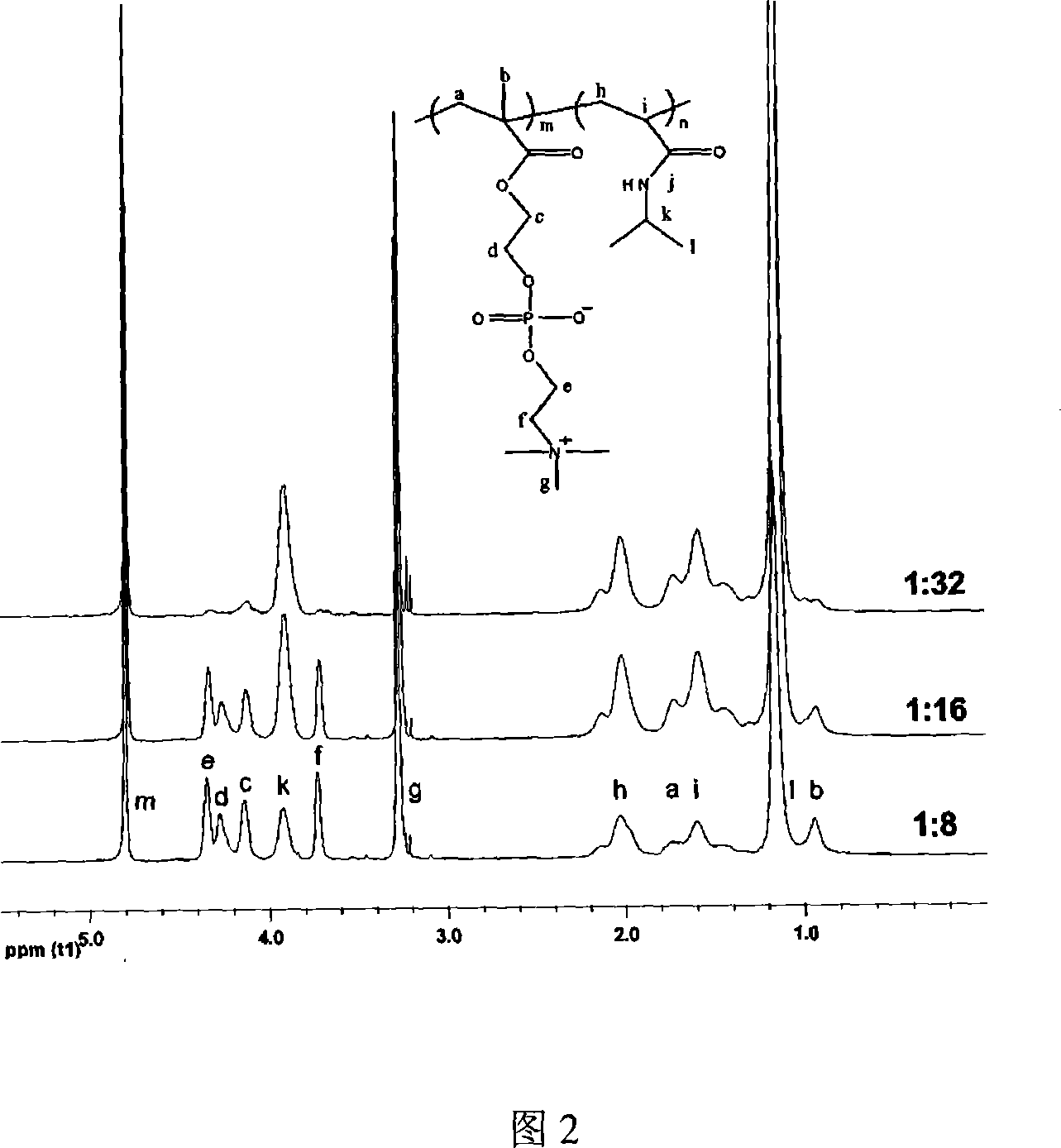

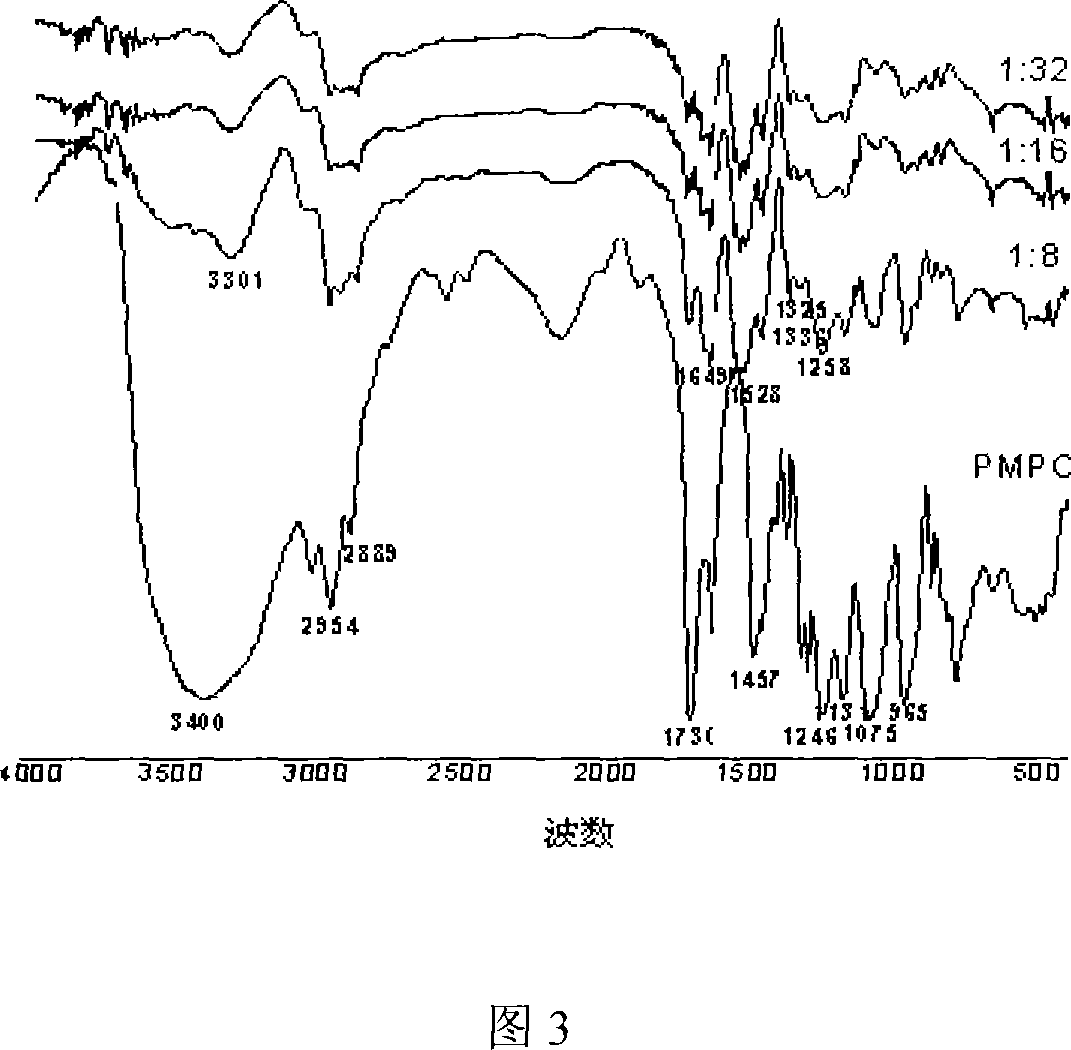

Temperature sensitive MPC-b-NIPAM biblock star type polymer for vessel embolism material and preparation method and application

InactiveCN101053681ARegular structureFast transitionCoatingsBiocompatibility TestingAqueous solution

The invention discloses a thermo sensitive MPC-b-NIPAM star-type diblock copolymer for blood vessel embolic materials, preparation method and application thereof, belongs to preparation technic of blood vessel embolic materials of biomedical engineering field. The copolymer formula is showed as formula 1. The preparation process comprises synthesis of TrisE, PMPC-Br, MPC-b-NIPAM. The copolymer aqueous solution is used for blood vessel embolic materials. The invention is characterized in that regular polymer molecule structure by means of ATRP, the copolymer LCST approaches to human body temperature, and has advantages of fast response function, good water-retention property and biocompatibility and so on.

Owner:TIANJIN UNIV

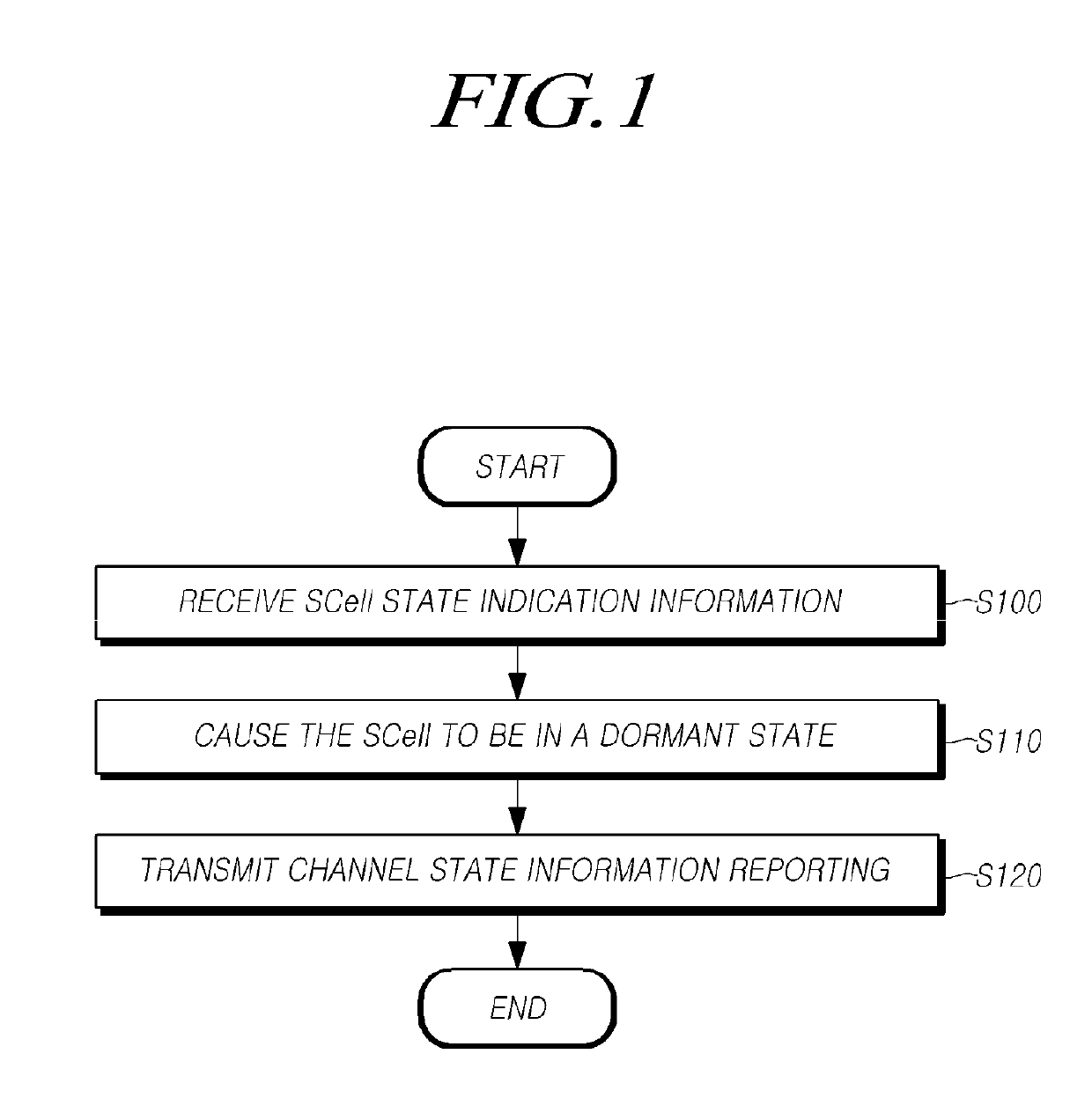

Method and apparatus for controlling scell state

ActiveUS20190200413A1Quickly perform operationReduce ambiguityPower managementTransmission path divisionChannel state informationComputer hardware

Provided is a method and an apparatus for changing or controlling a state of a secondary cell in carrier aggregation. The method includes receiving secondary cell (SCell) state indication information indicating a state for a SCell from a base station through an RRC message or an MAC control element, causing a state of the SCell to transition into a dormant state when the SCell state indication information indicates the dormant state, and transmitting channel state information reporting for the SCell in the dormant state according to an dormant state CQI report period parameter set separately from an activation state CQI report period parameter.

Owner:KT CORP

Self-propelled green hedge trimmer and use method

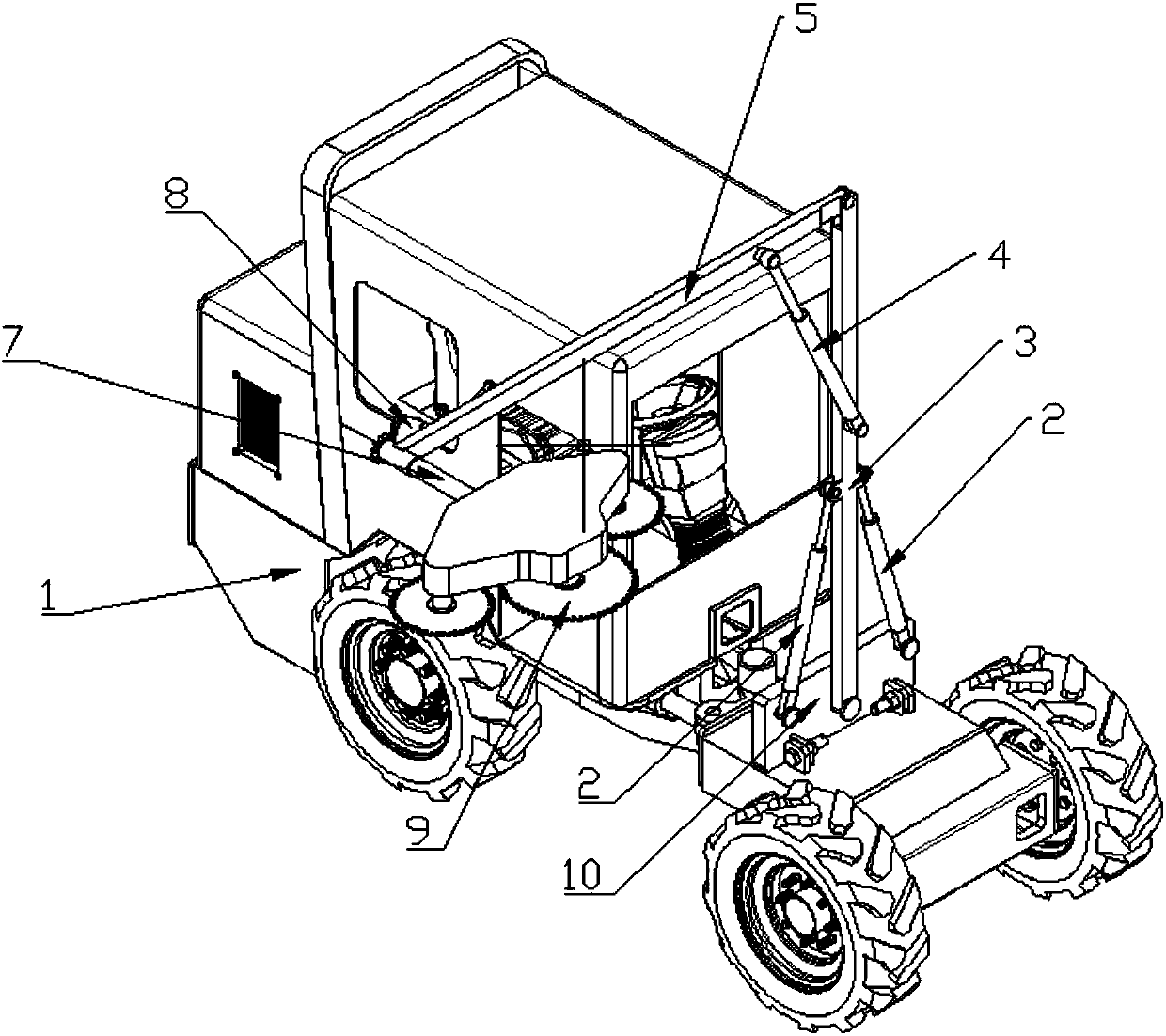

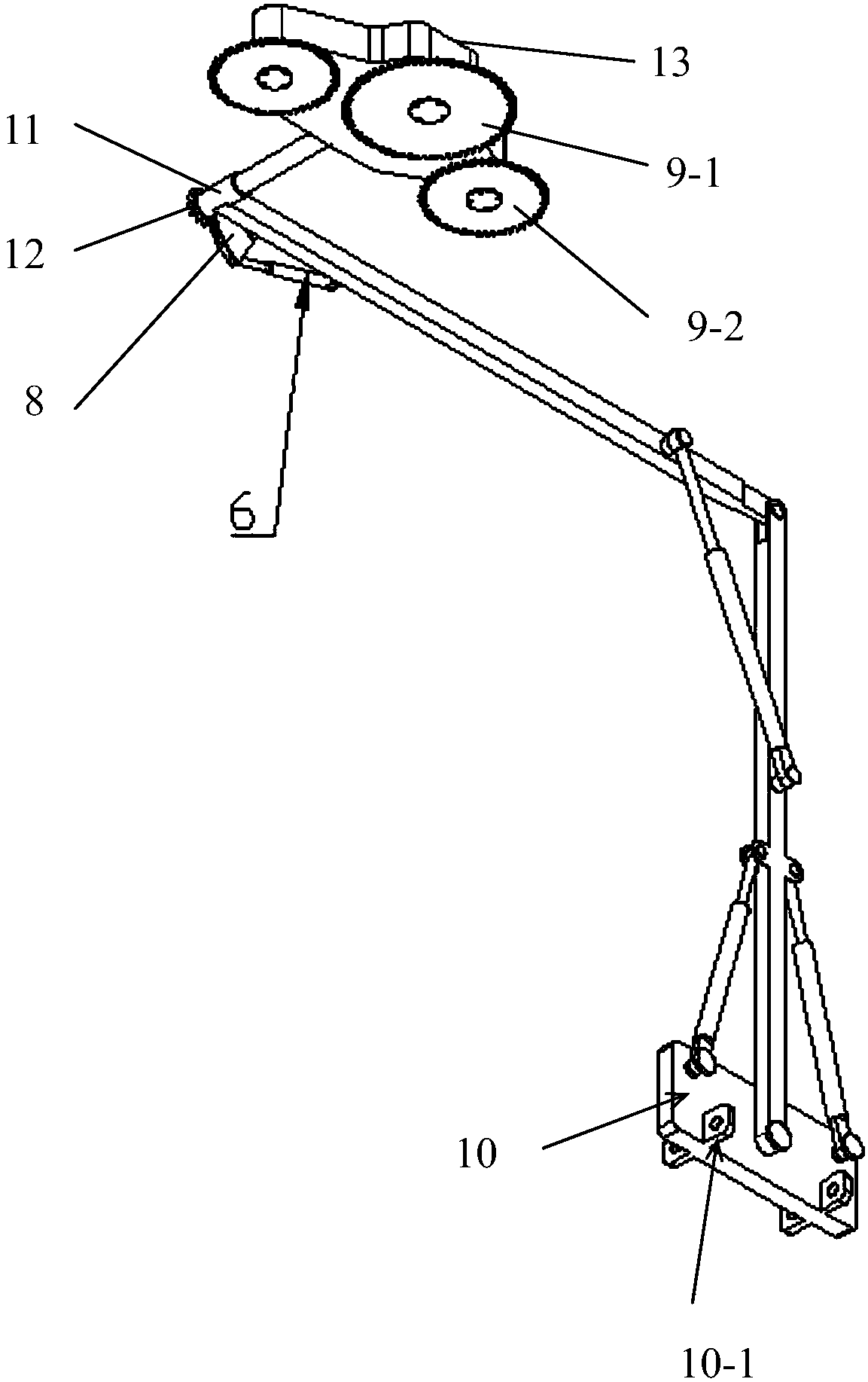

InactiveCN107810733AImprove pruning efficiencySave manpower and material costsHedge trimming apparatusCuttersLong armHydraulic cylinder

The invention relates to a self-propelled green hedge trimmer and a use method. The problems that an existing green hedge trimmer is not flexible in trimming knife operation angle adjustment and inconvenient to operate, and has difficulty in trimming beveled green hedges and landscape trees with certain height are solved. The angle, relative to the base, of a long arm rotating arm is adjusted through telescoping of the first stage hydraulic cylinder; the height and angle, relative to the long arm rotating arm, of a middle arm rotating arm is adjusted through telescoping of a second stage hydraulic cylinder; a sleeve is fixedly connected to the other end of the middle arm rotating arm, a fan-shaped gear is installed on the side wall of the middle arm rotating arm, the bottom of a cylinder body of a third stage hydraulic cylinder is hinged to the middle arm rotating arm, the tail end of a piston rod of the third hydraulic cylinder is hinged to the fan-shaped gear, the head end of a shortarm overturning arm is installed on the sleeve, and a saw blade is installed at the tail end of the short arm overturning arm; overturning of the short arm overturning arm is achieved through telescoping of the third stage hydraulic cylinder. Accordingly, the green hedge can be trimmed at different slopes and certain height.

Owner:HARBIN UNIV OF SCI & TECH

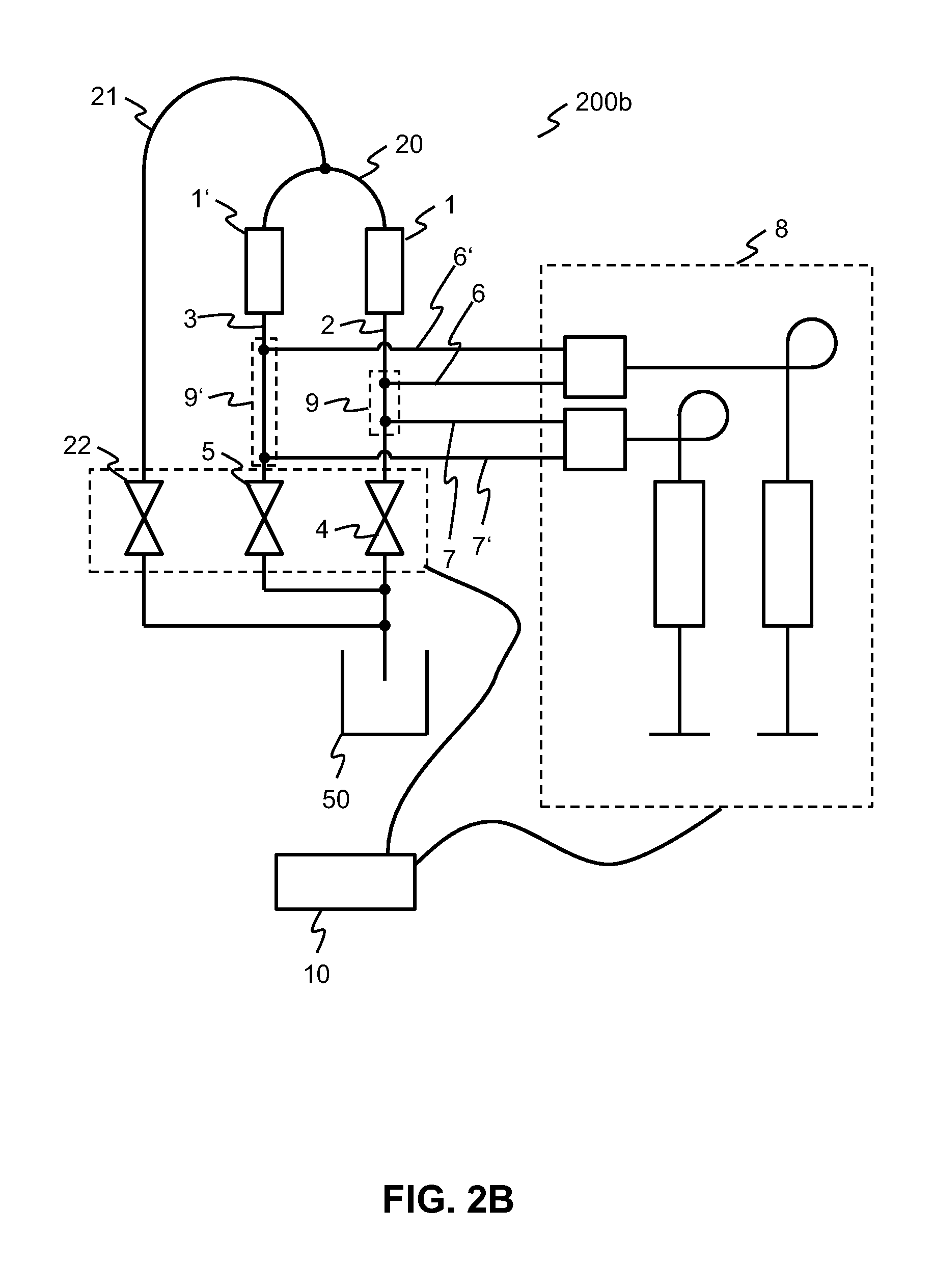

Flow conduit system for a biochemical sensor

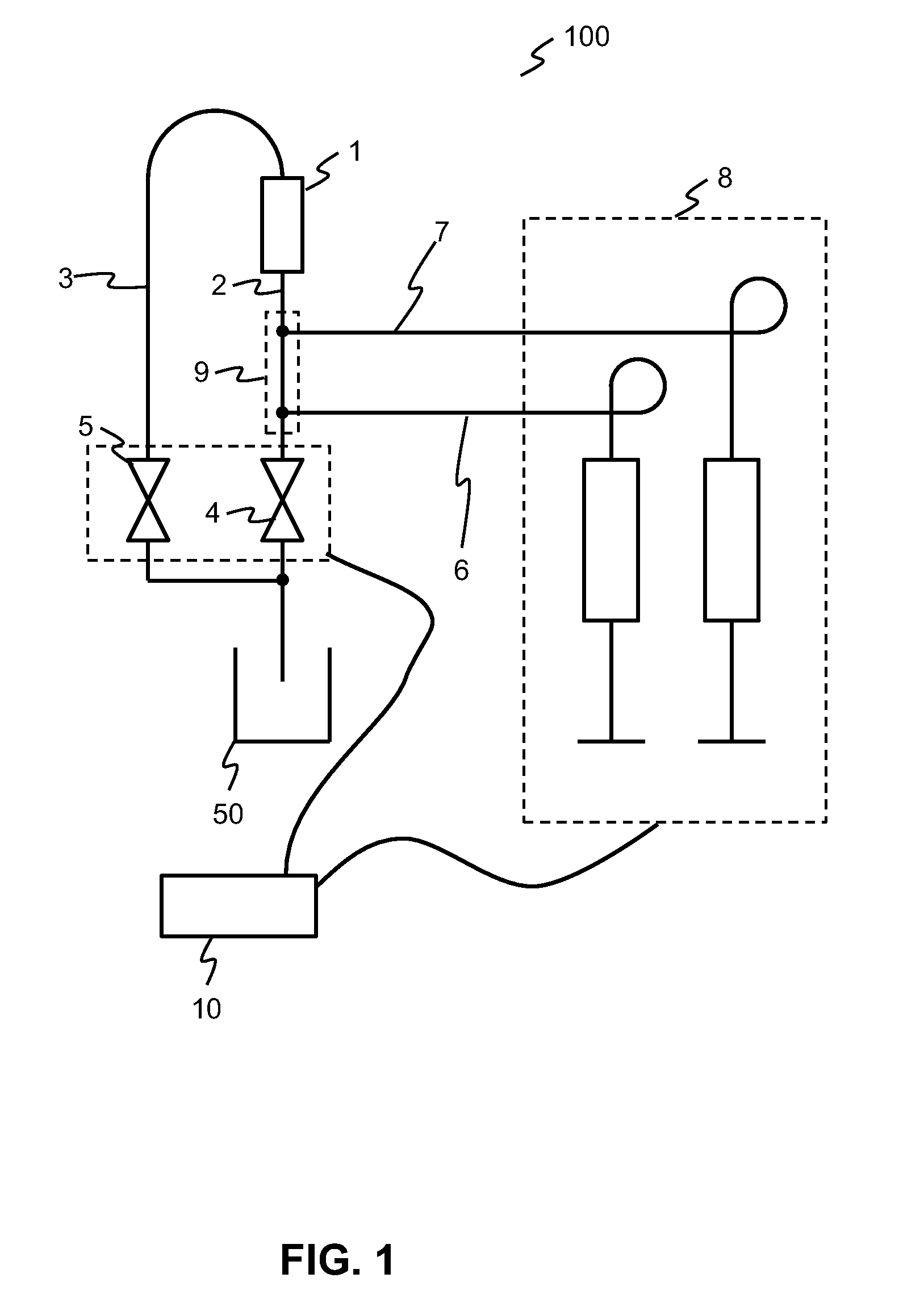

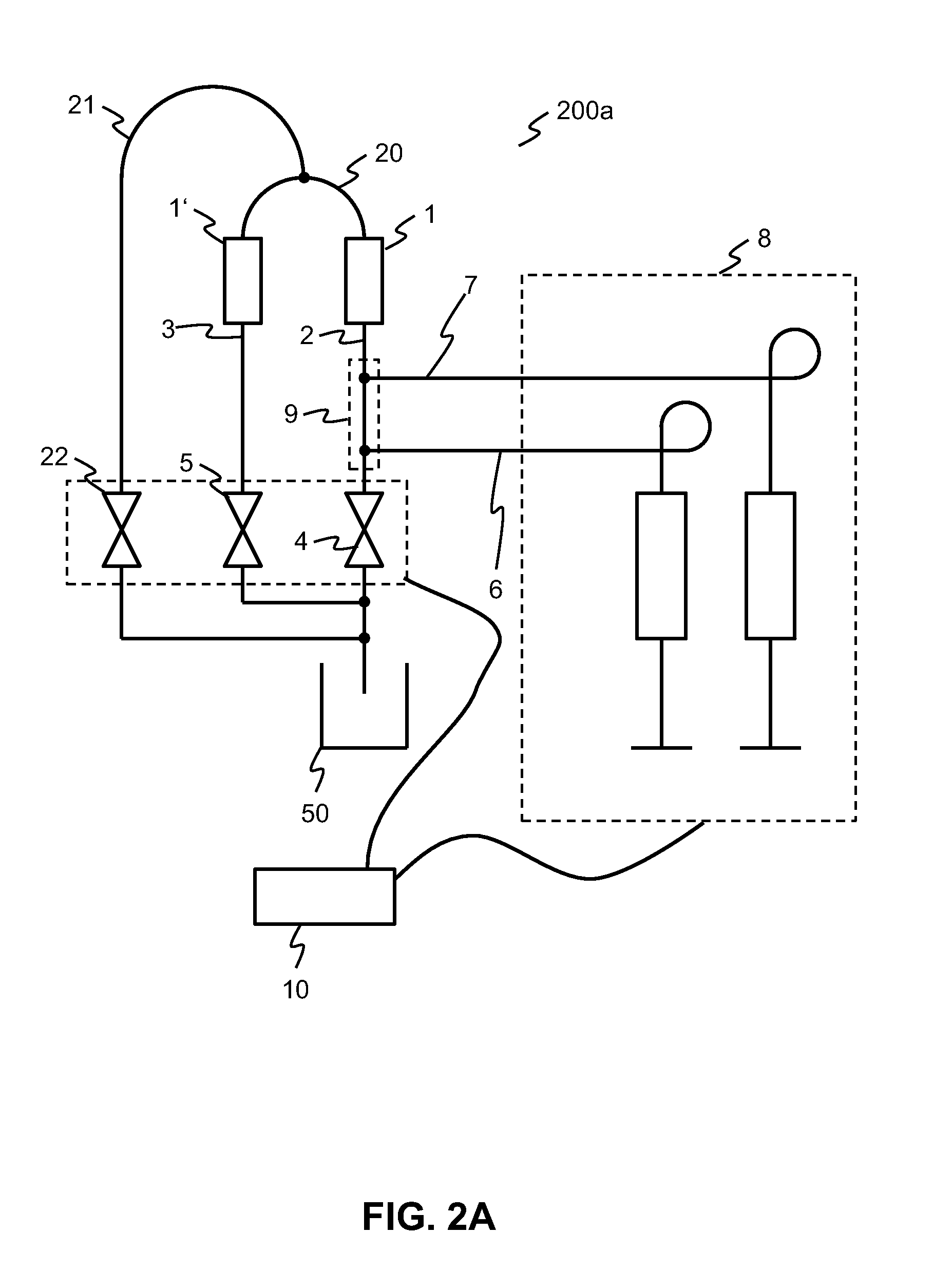

ActiveUS20150192574A1Fast transitionHigh sensitivityComponent separationBiological testingBiomedical engineeringStreamflow

A flow conduit system (100,200a,200b) suitable for biochemical sensing, the flow conduit system (100,200a,200b) comprising, a first flow cell conduit (1) comprising one or more sensing areas for biochemical sensing; a first selector valve (4); a first inlet / outlet conduit (2) which fluidly connects the first flow cell conduit (1) to the first selector valve (4); a first injection conduit (6) having a first end and a second end; a second injection conduit (7) having a first end and a second end; a fluid injecting means (8) fluidly connected to the second ends of each of the first and second injection conduits (6, 7) so that the fluid injecting means can selectively inject fluids into the first and / or second injection conduits (6,7); wherein the first injection conduit (6) is fluidly connected, at its first end, to the first inlet / outlet conduit (2) by a valveless junction (9), and the second injection conduits (6) is fluidly connected, at its first end, to the first inlet / outlet conduit (2) by a valveless junction (9).

Owner:CREOPTIX

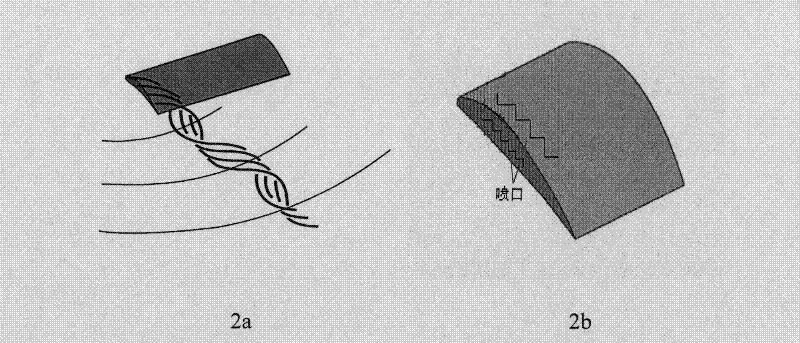

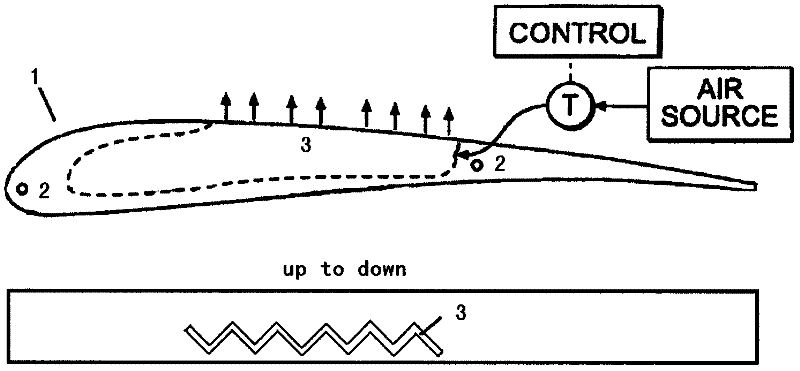

Wingtip noise control and device

InactiveCN102530242ANoise controlEasy to implementAir-flow influencersNoise controlDifferential pressure

The invention discloses a wingtip noise control and a device. The method comprises the following steps that: (1) a flow control device is installed at a wingtip of a wing or a wing flap and other elevating force sides of an aircraft; (2) when the aircraft flies at high incidence and takes off or lands, the flow control device is utilized to change or weaken a large-scale unsteady wingtip vortex structure which is generated due to the differential pressure between the upper and the lower surfaces of the elevating force side through adopting a jet flow mode; during a cruising period, the flow control device does not work; and the nozzle of the flow control device adopts a sawtooth structure, the included angle of sawtooth side lines is 60-130 degrees, the sawtooth height is 2-5cm, and the sawtooth length is 0.4-0.6 time that of the chord length.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

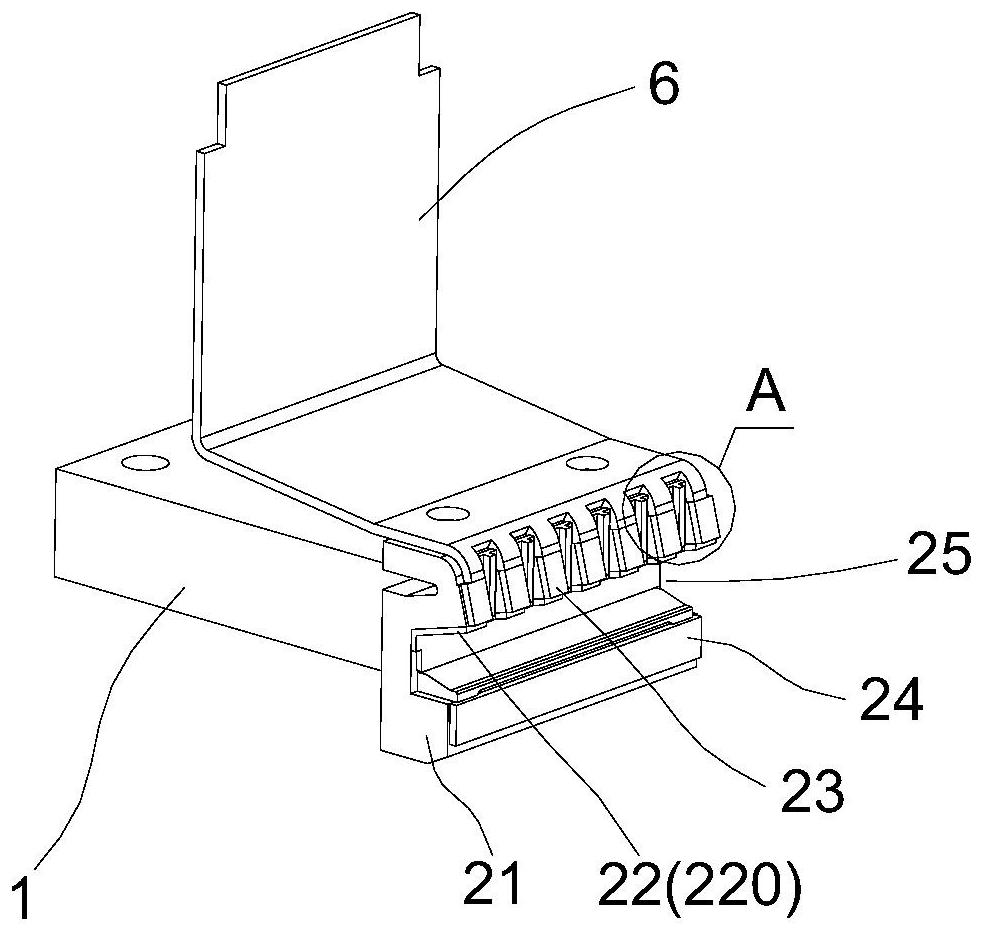

Woodworking cutting and punching all-in-one machine

ActiveCN106426423AIncrease productivityFast transitionMulti-purpose machinesTransfer mechanismEngineering

The invention provides a woodworking cutting and punching all-in-one machine, belongs to the technical field of machinery, and solves the technical problems of low production efficiency and the like due to that cutting and punching are realized on different equipment respectively in the prior art. The woodworking cutting and punching all-in-one machine comprises a rack, wherein an electric saw and a main guide rail are arranged on the rack; a main supporting plate is slidably connected to the main guide rail; an electric drill is arranged on the main supporting plate; a charge workbench is fixed on the rack; a transfer mechanism I is arranged on the rack; a punching workbench is further fixed on the rack; the electric saw is located between the charge workbench and the punching workbench; a transfer mechanism II is further arranged on the rack; the main guide rail is located at one side of the punching workbench and the slide direction of the main guide rail is the same as the left-right direction of the rack; and the charge workbench and the punching workbench are located at positions on the same straight line or located at parallel staggered positions or located at inclined positions. According to the woodworking cutting and punching all-in-one machine provided by the invention, cutting and punching for wood are combined on one piece of equipment, thus the production efficiency can be increased.

Owner:TAIZHOU EVOK MASCH CO LTD

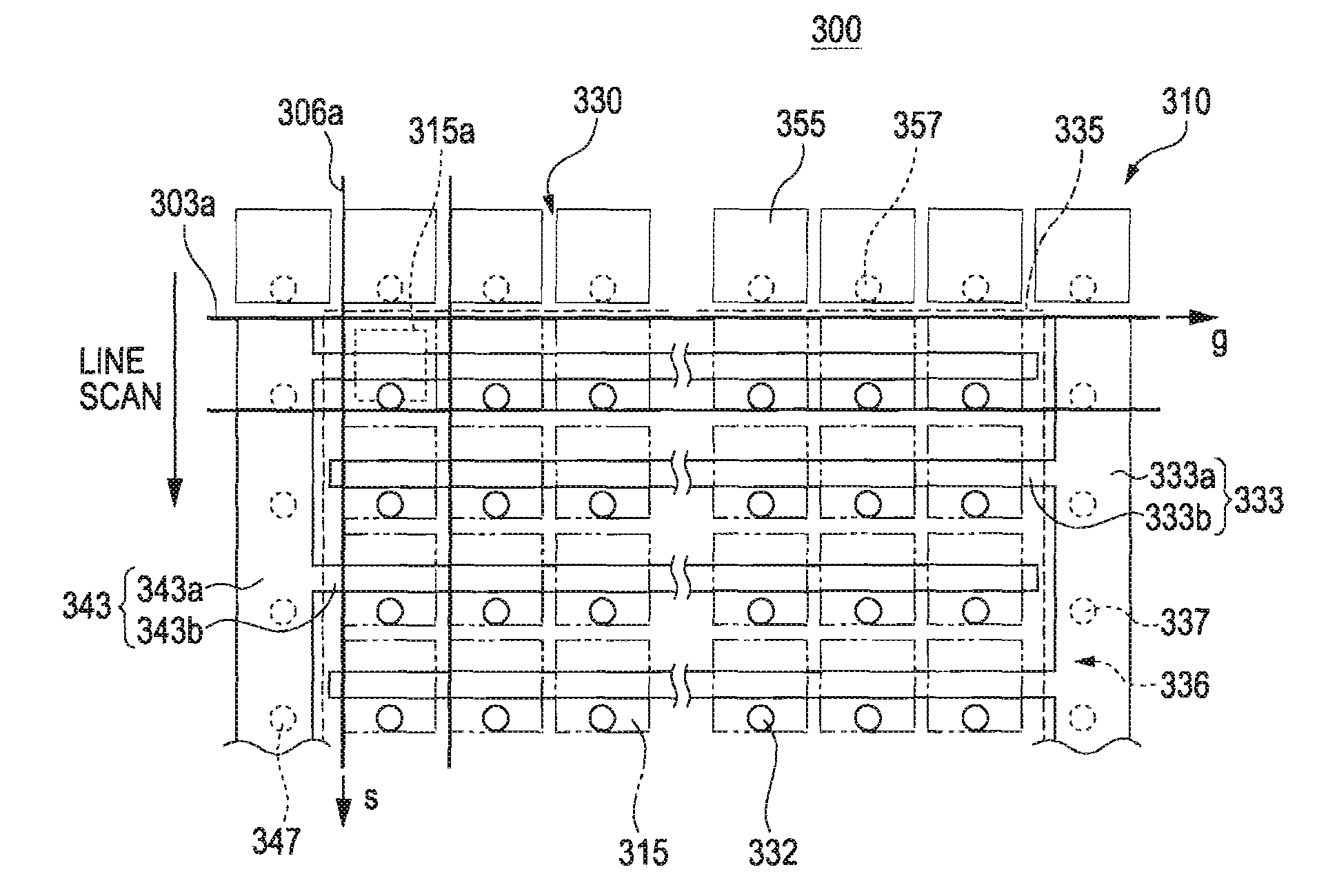

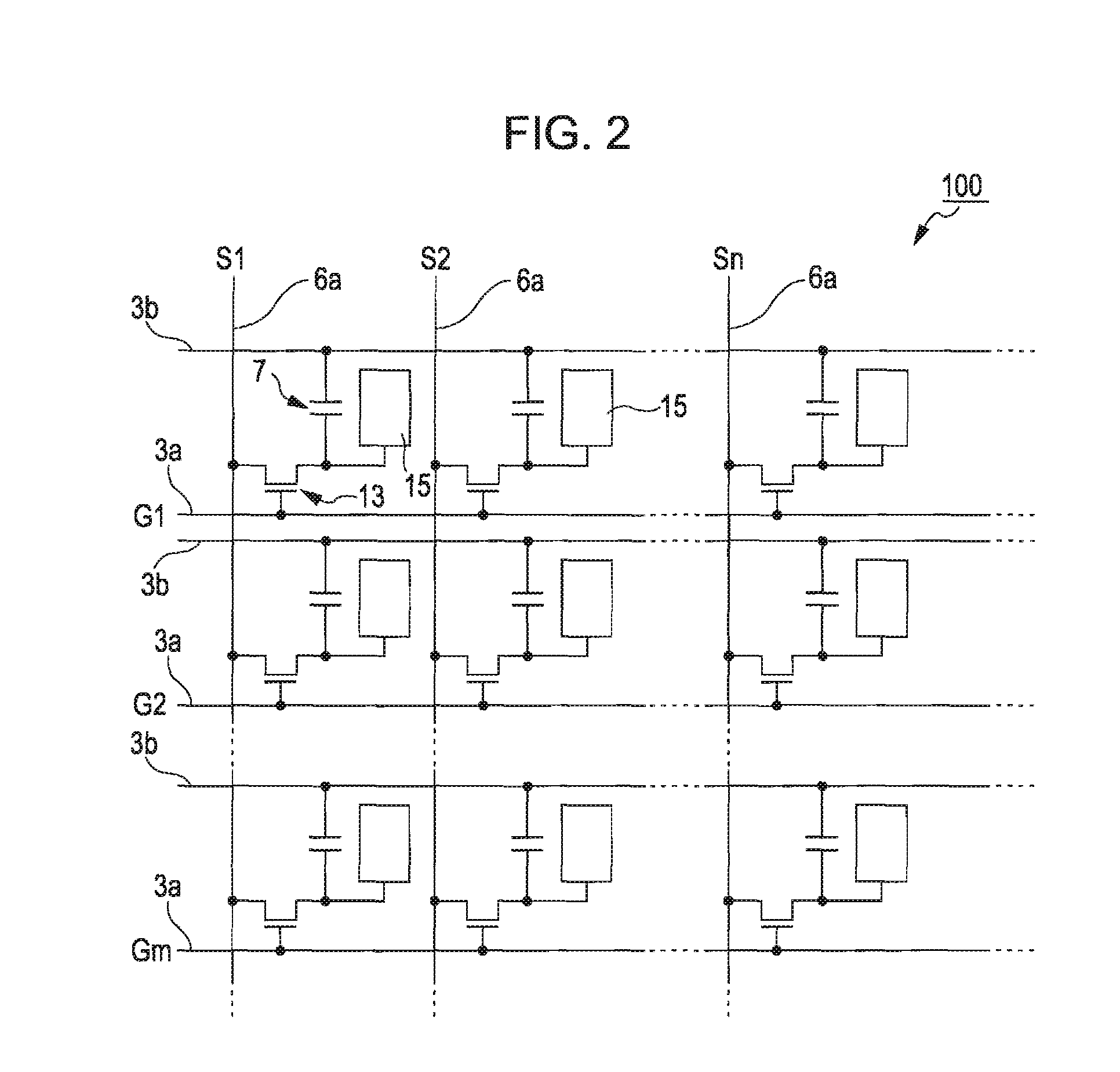

Liquid crystal device, projector, and electronic apparatus

InactiveUS20080122999A1Improve display characteristicsQuick responseStatic indicating devicesNon-linear opticsEngineeringConductive materials

A liquid crystal device has a pair of substrates arranged so as to face each other and a liquid crystal layer interposed between the pair of substrates and performs a display operation or an optical modulation operation by converting an alignment of liquid crystal molecules in the liquid crystal layer from a splay alignment to a bend alignment. The liquid crystal device includes a plurality of pixel electrodes disposed on either one of the pair of substrates so as to correspond to a plurality of pixels, and an auxiliary electrode formed in a layer disposed under the pixel electrodes in a manner such that at least part thereof overlaps the pixels in a plan view and made of a light-transmissible conductive material.

Owner:SEIKO EPSON CORP

Temperature-responsive supra-molecular copolymer hydrogel embolization material and preparation method thereof

InactiveCN107754025ASmooth entryFast transitionSurgeryTissue regenerationMolten statePolymer science

The invention discloses a temperature-responsive supra-molecular copolymer hydrogel embolization material and a preparation method thereof, wherein two monomers such as acrylamide and N-acryloyl chloride glycinamide are copolymerize under the action of an initiator to obtain a polymer gel PNAGA-PAAm, the polymer gel and iohexol are mixed at a high temperature to obtain a uniform mixture, the iohexol-containing hydrogel can be injected into renal artery through a microcatheter in a molten state at a temperature of slightly above the body temperature to embolize the kidney so as to be used for embolizing large arteries, the hydrogel mixture can undergo sol-gel transition at the temperature near body temperature, and the transition is fast. According to the present invention, the iohexol-containing polymer can be developed under X-rays, such that the embolization material can smoothly enter the target site, and the false embolization can be avoided.

Owner:TIANJIN UNIV

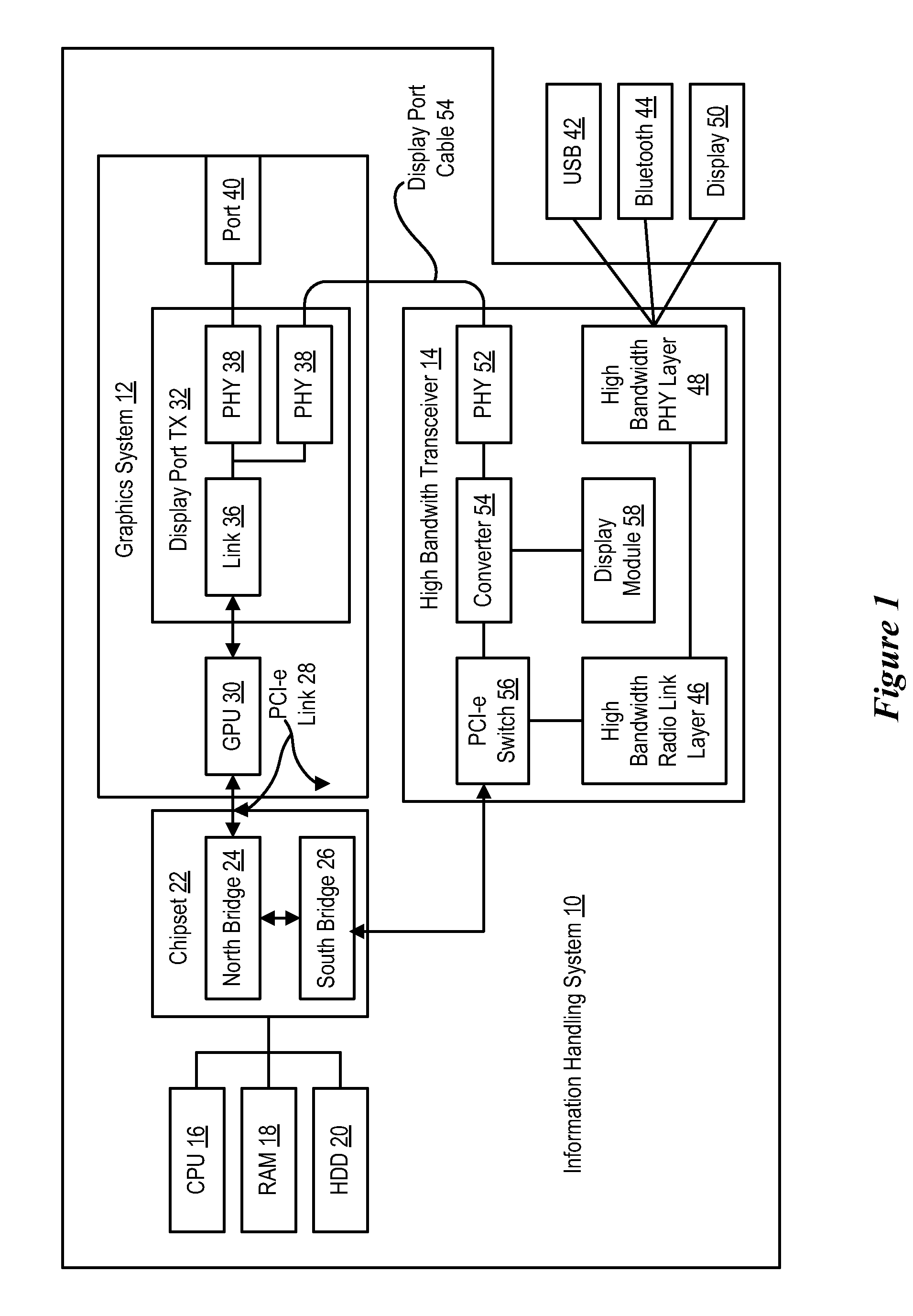

System and method for interfacing graphical information with an information handling system wireless transceiver

ActiveUS8031199B2Reduce disadvantagesReduce problemsDigital computer detailsCathode-ray tube indicatorsGraphicsTransceiver

Wireless communication of display information between an information handling system and display is supported by a direct connection between a graphics system of the information handling system and a transceiver of the information handling system. For example, the graphics system outputs pixel level display information through a cable directly to the transceiver. A converter on the transceiver converts the display information to network information, such as from a DisplayPort format to a PCI Express format, so the transceiver can send the display information through a wireless network, such as a personal area network, to the display. A display module located at the transceiver coordinates initiation of communication of display information from the graphics system to the display.

Owner:DELL PROD LP

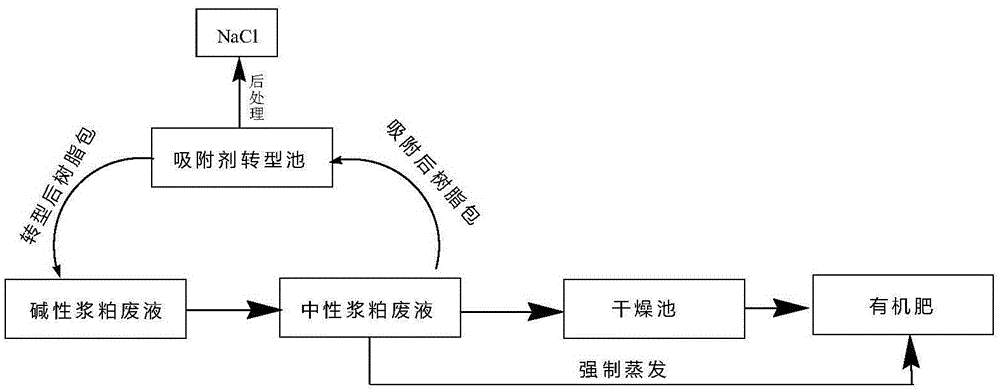

Treatment method of alkaline pulp waste liquid

InactiveCN105152268AFacilitate solid-liquid separationFast transitionWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentHydrogenIon-exchange resin

The invention discloses a treatment method of alkaline pulp waste liquid. The method comprises the steps that hydrogen type ion exchange resin or chelating resin package makes full contact with pulp waste liquid, the hydrogen type ion exchange resin or chelating resin package is taken out, washed and immersed through acid, and the hydrogen type ion exchange resin or the chelating resin is obtained by washing resin through water; the steps are repeated till the treated pulp waste liquid is neutral. According to the treatment method of the alkaline pulp waste liquid, the whole process route can make harmless treatment and comprehensive utilization of the alkaline pulp waste liquid truly achieved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

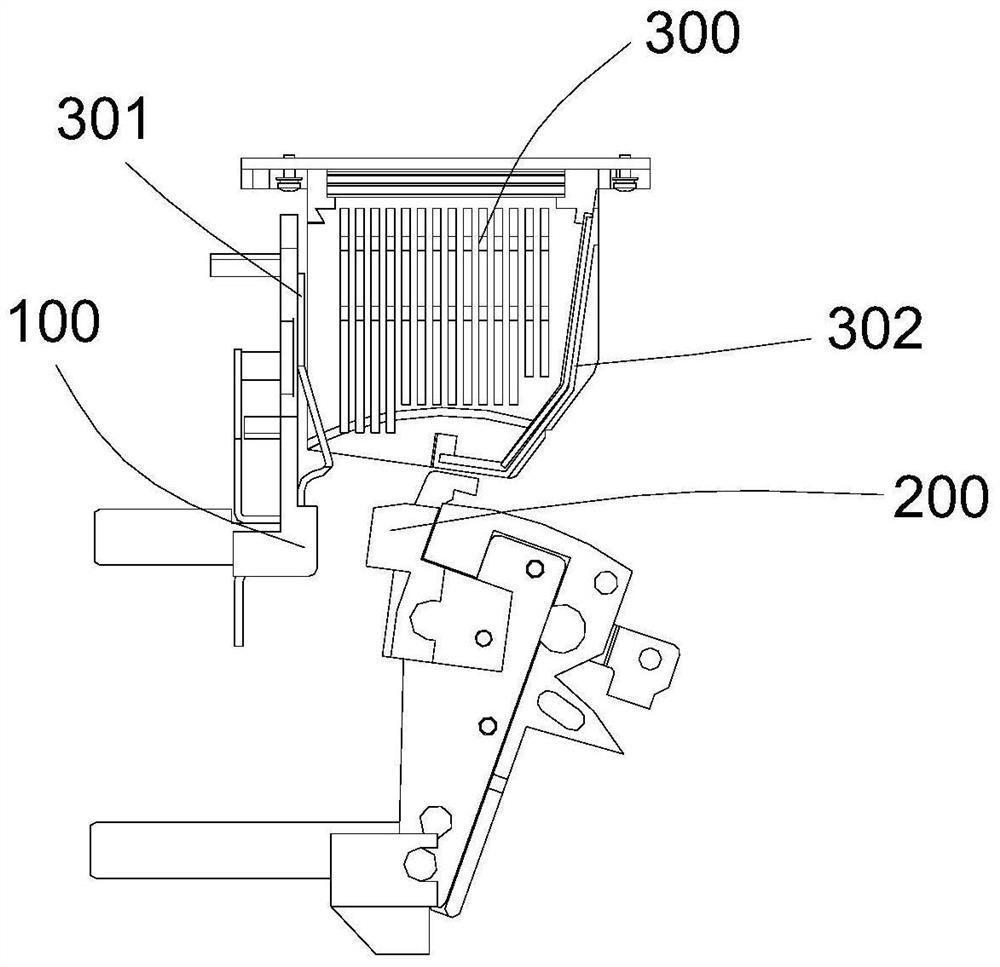

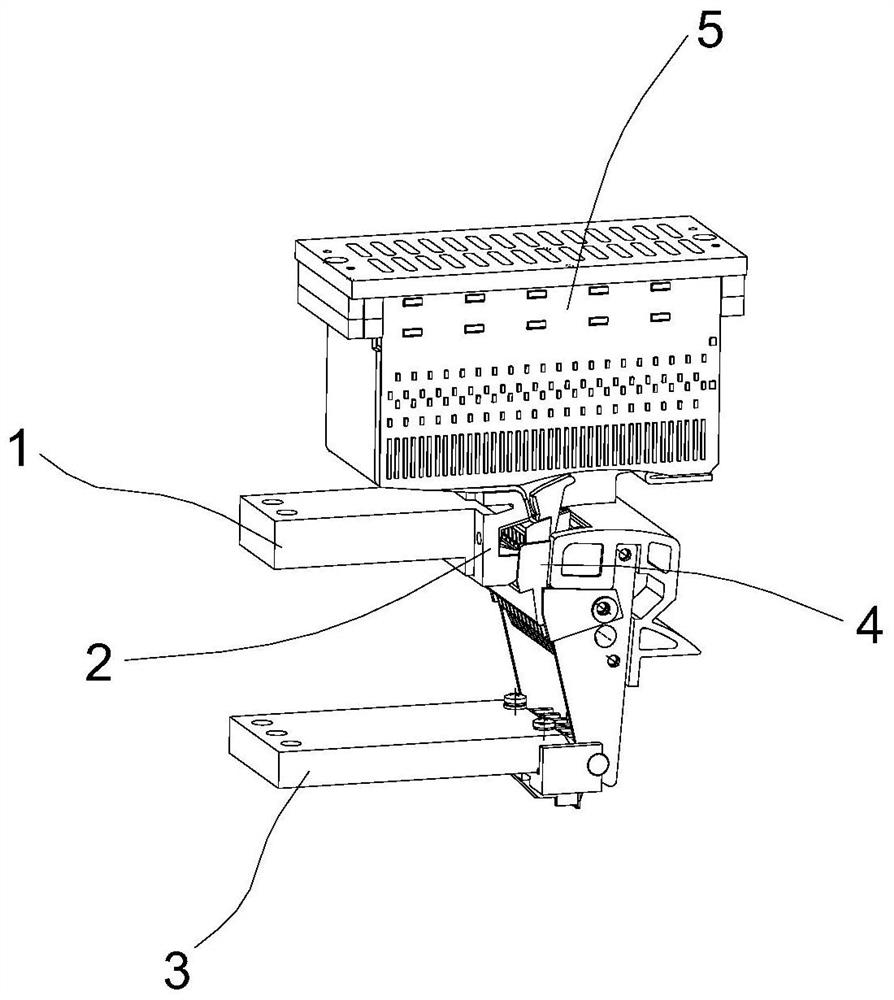

Circuit breaker

PendingCN112017881AFast transitionImprove arc extinguishing efficiencyElectric switchesCircuit-breaking switch contactsBreaking capacityContact group

The invention relates to a circuit breaker, which is characterized in that corresponding upper and lower rows of contact groups are respectively arranged on a moving contact and a static contact, thecontact group close to an arc extinguishing chamber is used as an arcing contact, the other contact group is used as a current-carrying contact, and the contact groups are separated by gas generationinsulating pieces to protect the current-carrying contact from being ablated by an electric arc; the gas generation insulating piece is installed on the contact, and a large amount of gas can be generated to push the arc to move towards the arc extinguishing chamber when the arc is generated, so that arc extinguishing efficiency is improved, and breaking capacity is improved; and an insulating flash barrier for dividing the arc is arranged in the arc extinguishing chamber to assist in arc extinguishing and cooling of the arc, and the arc can jump from the moving contact to an arc striking sheet quickly to run out of the arc by arranging the moving contact and the arc striking sheet close to each other. According to the invention, contacts are saved on the whole, and the arc extinguishing efficiency is improved.

Owner:XIAMEN HONGFA ELECTRICAL SAFETY & CONTROLS CO LTD

Method for improving weather resistance of decorative base paper titanium dioxide

ActiveCN107500348AReduce concentrationIncrease concentrationTitanium dioxideWeather resistancePotassium

The invention provides a method for improving weather resistance of decorative base paper titanium dioxide, and belongs to the technical field of decorative base paper titanium dioxide. The control is performed through salt treatment and calcination. The method comprises the following steps of A, using bleached slurry as raw materials; adding titanium dioxide sol into the raw materials; controlling the addition to meet the requirement that the proportion of TiO2 in the titanium dioxide sol to TiO2 in metatitanic acid is 2 to 6 percent; performing water washing; diluting the slurry subjected to water washing into 300 to 400g / L TiO2 slurry; B, adding potassium and phosphorus solution with the K2O / P2O5 ratio being 1.3 to 4.0 into the diluted slurry; performing stirring; adding aluminum-containing compound solution according to the Al2O3 to TiO2 proportion being 0.3 to 0.9 percent; performing stirring; C, performing pressurized filtering on the slurry material treated by the step B until the filter cake solid content is 45 to 55 percent; C, roasting the filter cake in the step C for 8 to 10h at the roasting temperature of 200 to 950 DEG C. Through the control on the salt treatment and roasting processes, the primary product weather resistance of the decorative base paper titanium dioxide is improved; the weather resistance of the decorative base paper titanium dioxide is further improved.

Owner:HEBEI MILSON TITANIUM DIOXIDE

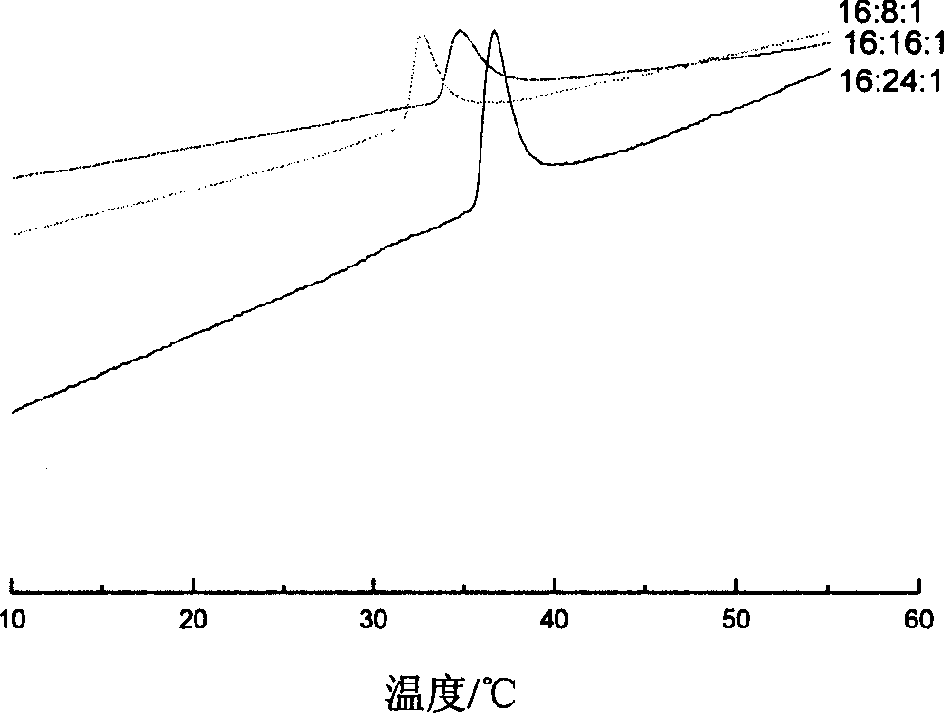

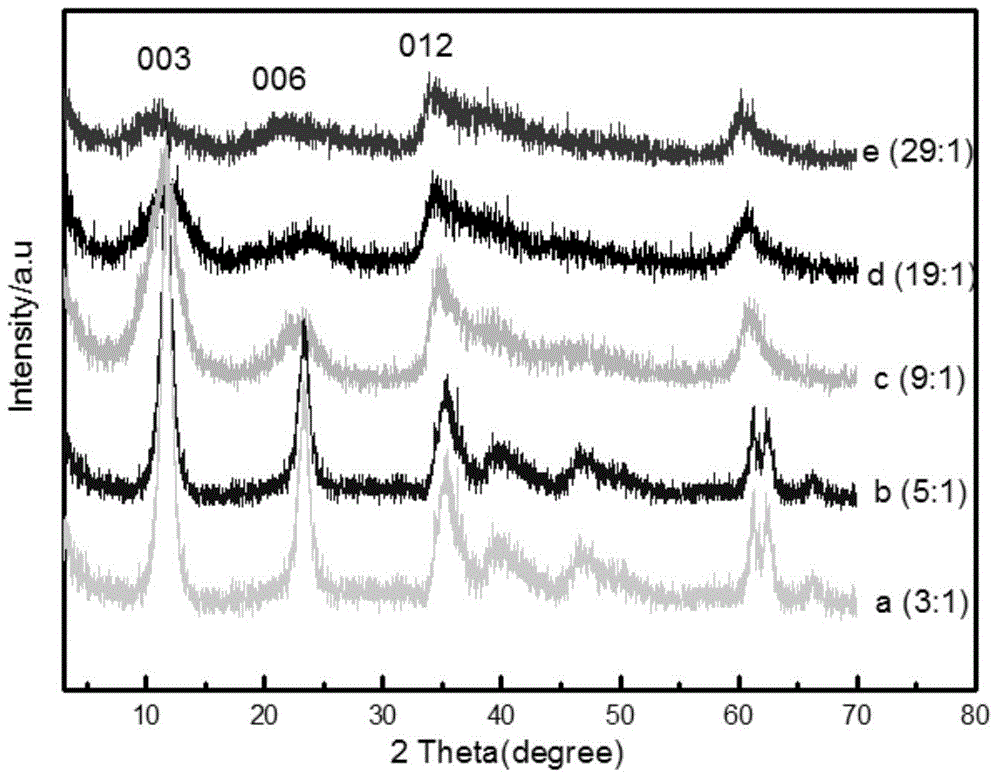

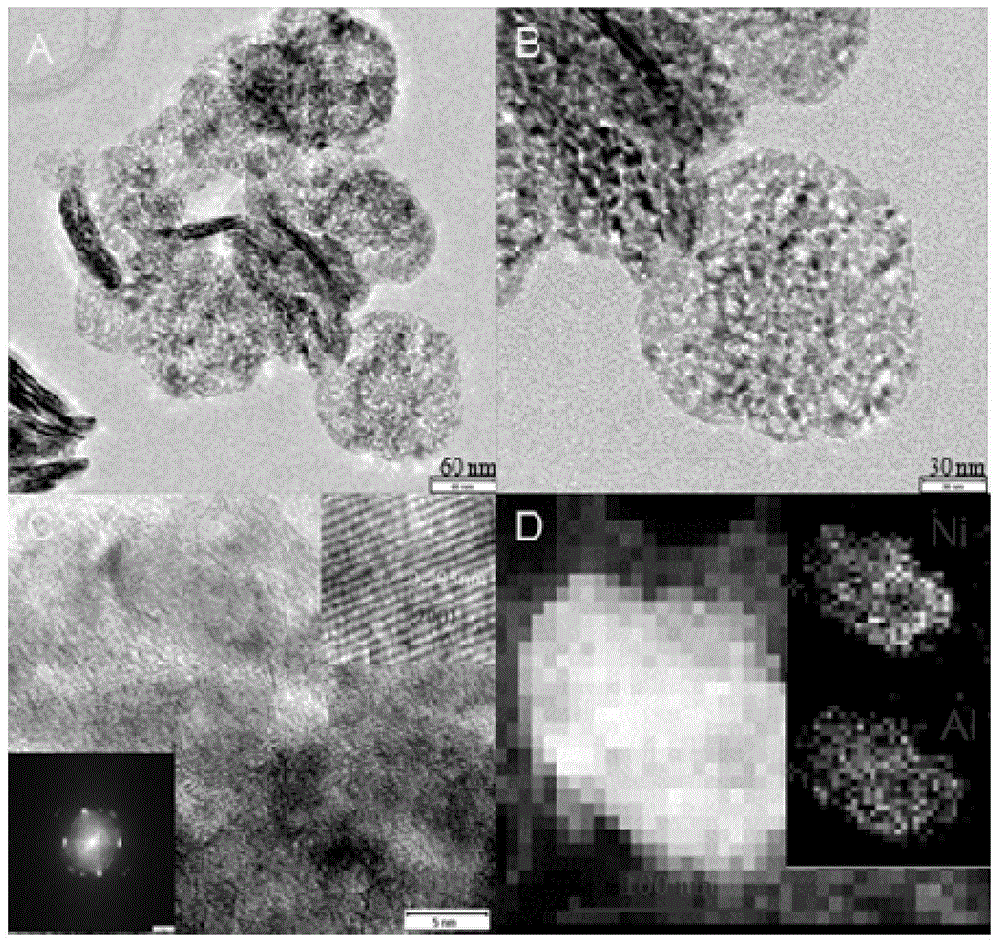

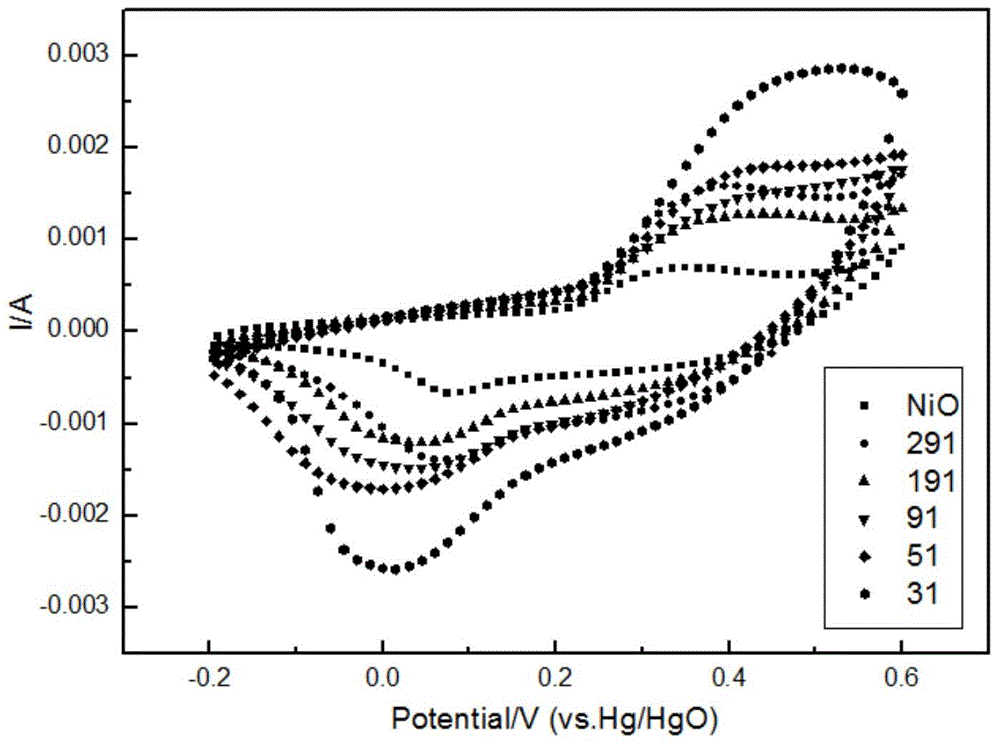

Method for preparing aluminum-doped nickel oxide electrochromic film by virtue of hydrotalcite precursor pyrolysis

The invention discloses a method for preparing an aluminum-doped nickel oxide electrochromic film by virtue of hydrotalcite precursor pyrolysis. The method comprises the following steps: firstly, synthesizing Ni-Al LDHs differing in cationic proportion by virtue of a conventional coprecipitation method, dispersing the Ni-Al LDHs in ethanol so as to obtain a colloidal solution, spin-coating the colloidal solution by virtue of a film coating machine and pyrolyzing in a muffle furnace so as to obtain the aluminum-doped nickel oxide electrochromic film. The electrochromic film prepared by the method disclosed by the invention is a novel uniform aluminum-doped nickel oxide electrochromic film. The film is wide in optical modulating range (58%), high in transformation rate (bleaching time is 1.8s and coloring time is 4.2s) and good in cycling stability (15% of electrochromic performance is reduced by cycling for 200 times). The film can be also used for changing the performance of the aluminum-doped nickel oxide electrochromic film by regulating and controlling the cationic proportion.

Owner:BEIJING UNIV OF CHEM TECH

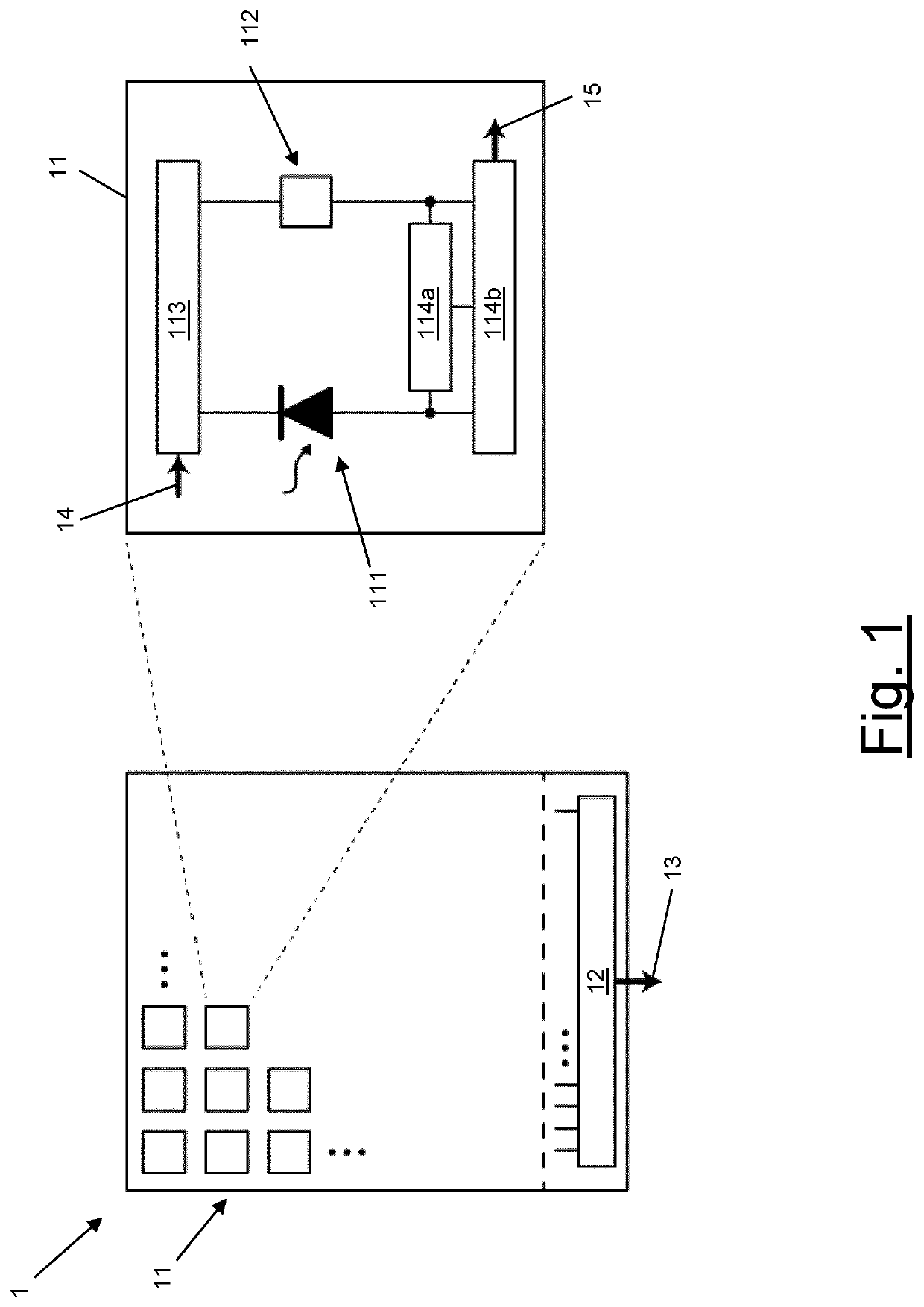

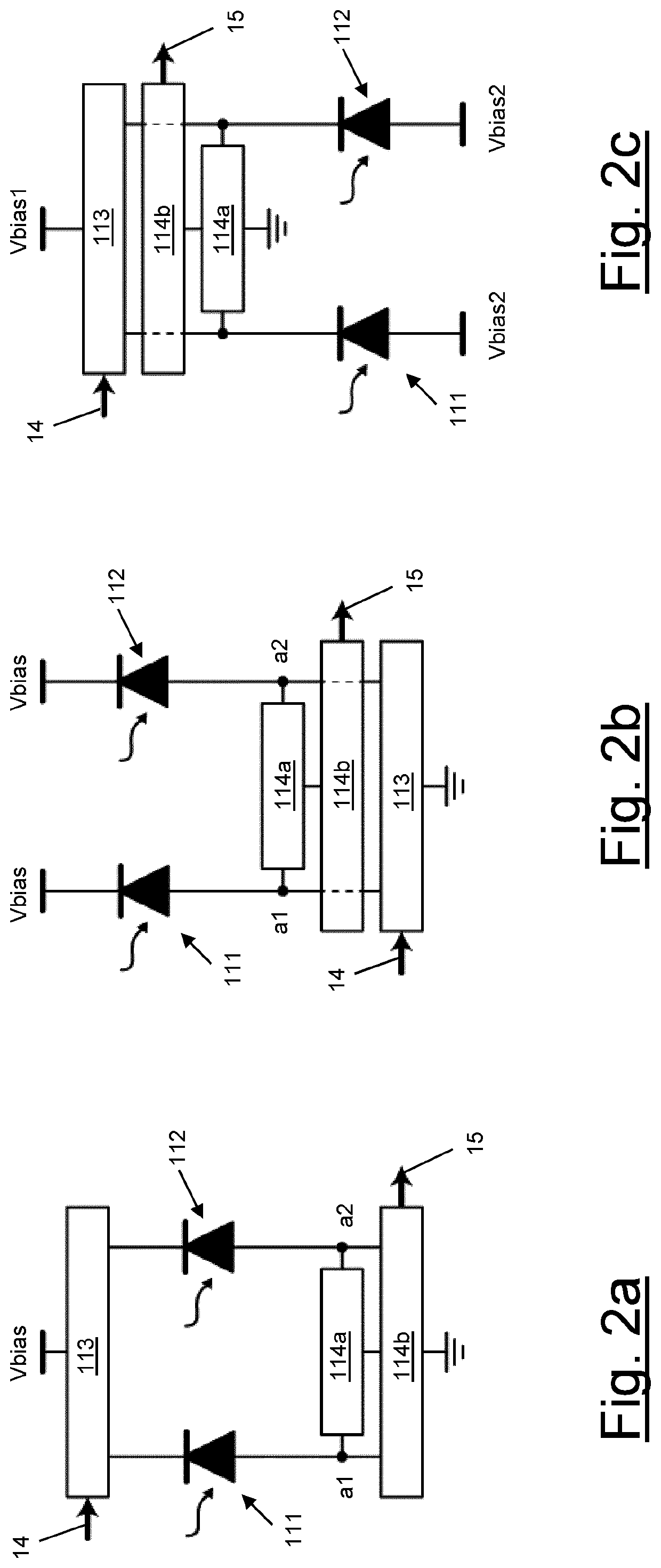

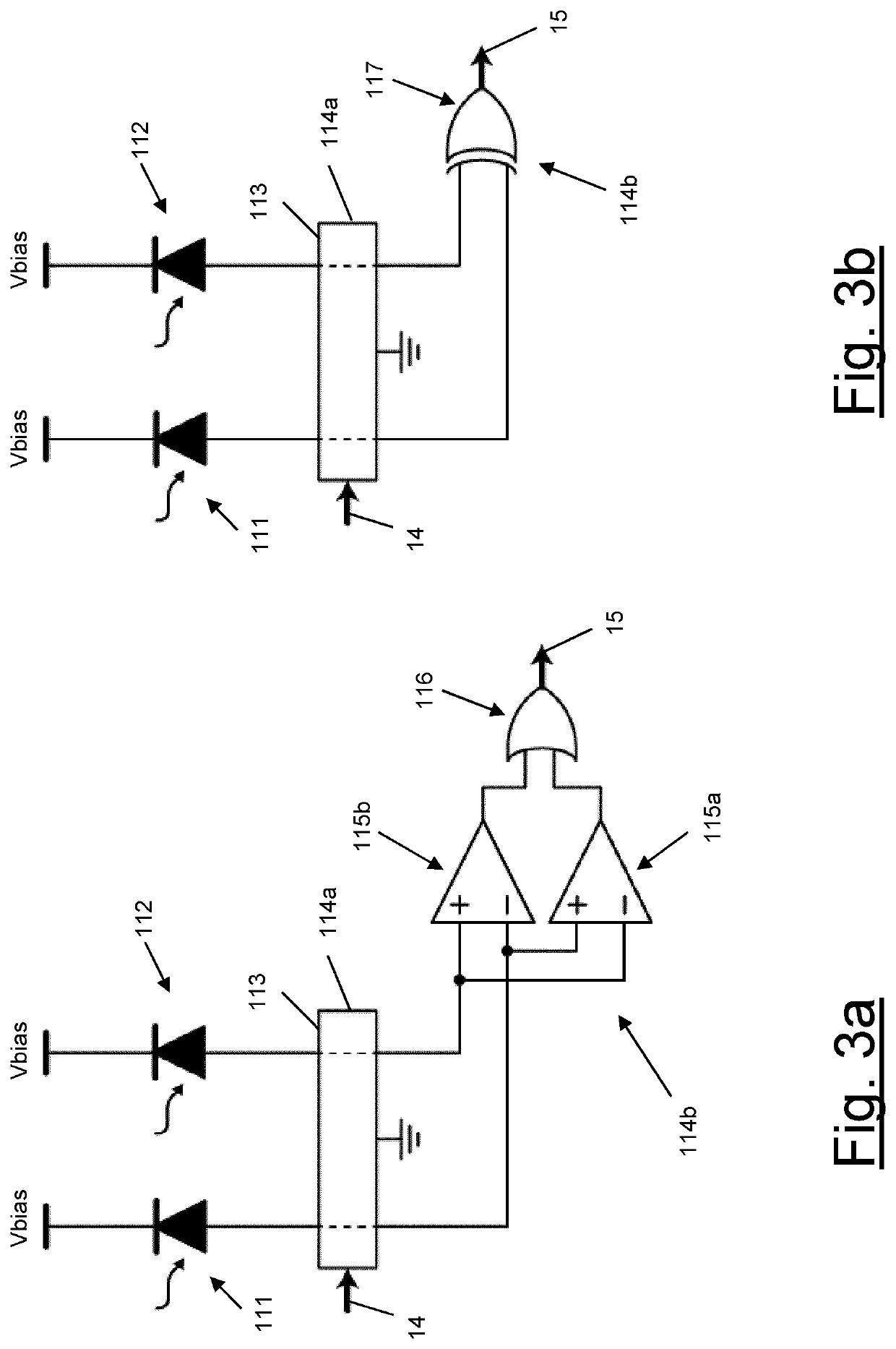

Wide-area single-photon detector with time-gating capability

PendingUS20220069152A1Wide active areaEnhanced signalDiodeRadiation controlled devicesTime gatingPhotovoltaic detectors

A photodetector may include an array of microcells and an output module configured to collect, from each microcell, an output signal indicative of a photon detection and to combine the collected output signals in at least one output line. Each microcell comprises a first device and a second device, wherein at least one of the devices is a photosensitive device capable of detecting the photon; a time-gating module connected to said at least one photosensitive device and configured to provide a gate signal to the at least one photosensitive device to activate it; and a readout module configured to receive, upon arrival of the photon on the at least one activated photosensitive device, a corresponding signal from the at least one activated photosensitive device and, on the basis of the received signal, to provide the output signal to the output module.

Owner:POLITECNICO DI MILANO +1

Electric circuit

InactiveUS8508902B2Fast transitionAvoid sudden changesElectroluminescent light sourcesSemiconductor lamp usageCapacitanceElectricity

A functional element is prevented from breakdown and deterioration because of mounting and demounting of the functional element immediately after cut-off of driving power from a constant-current power supply or during supply of the driving power.An electric circuit is configured to electrically connect a constant-current power supply 1 having a capacitance between an output terminal and a reference potential terminal and a detachable functional element 2 to each other. The electric circuit has an element breakdown prevention circuit 10 having a first circuit terminal connected to an output terminal of the constant-current power supply 1 through the functional element 2, and a second circuit terminal connected to the reference potential terminal of the constant-current power supply 1 through the functional element 2. The element breakdown prevention circuit 10 increases an impedance between the circuit terminals to a disconnected state impedance in response to a transition from a connected state, in which the functional element 2 is mounted, to a disconnected state, in which the functional element 2 is removed. The element breakdown prevention circuit 10 decreases the impedance between the circuit terminals to a connected-state impedance in response to a connection state transition.

Owner:IDEC CORPORATION

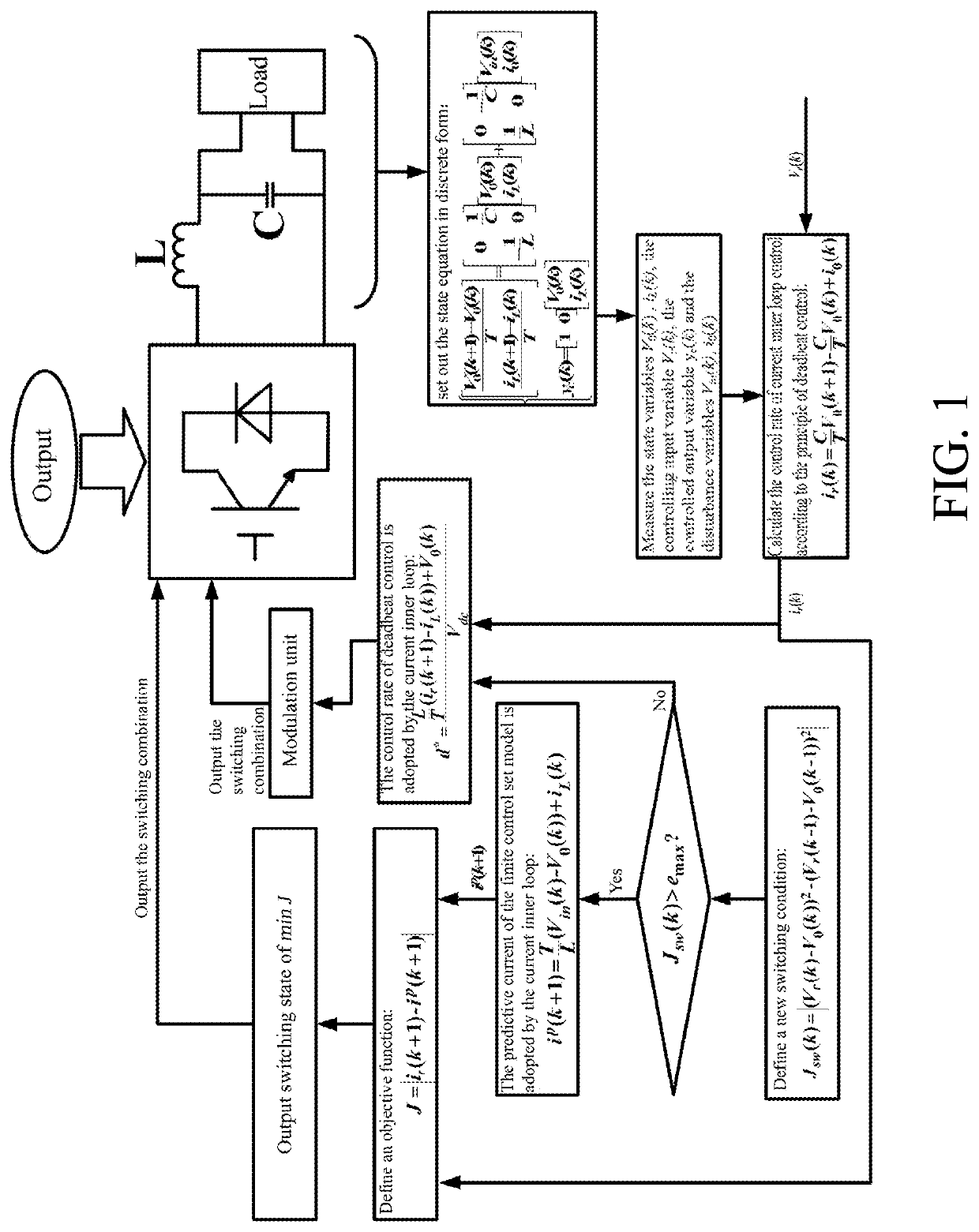

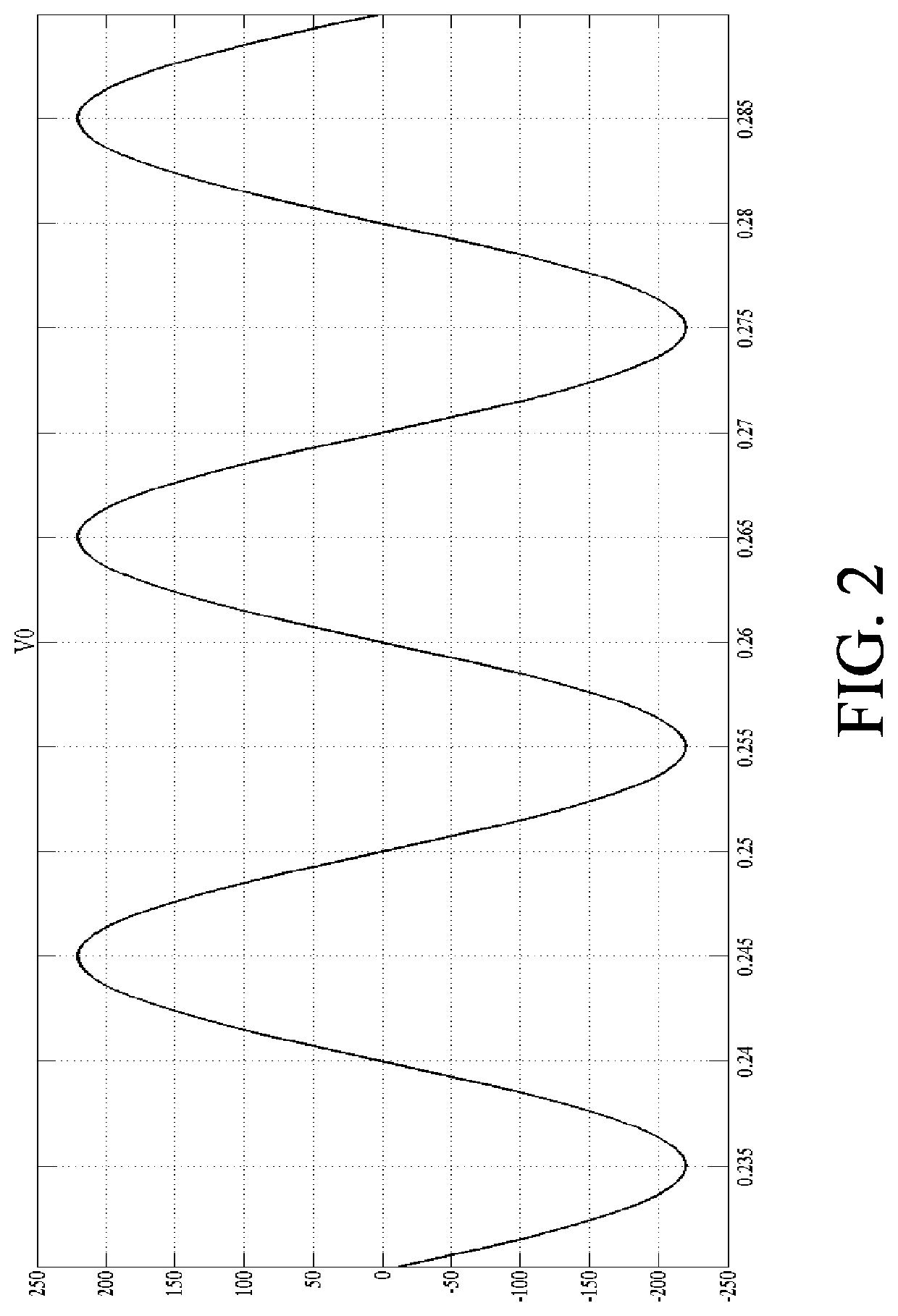

Switching type control method based on double loop predictive control

ActiveUS20200304040A1Improve performanceSteady-state errorDc-ac conversion without reversalTransient stateLoop control

The present invention discloses a switching type control method based on double loop predictive control, which belongs to the field of power electronic converter technology and industrial control. The invention is based on double loop predictive control, and the deadbeat control is adopted by the outer loop control to improve the overall performance of the system (the system refers to the implementation object of the control method, and generally refers the power electronic converter); a switching type control method is adopted by the inner loop control: when the system is in the steady state, the deadbeat control is adopted to ensure the steady state accuracy of the system and to achieve the fixed switching frequency; when the system is in the transient state, it is switched to the finite control set model predictive control to ensure the rapid transition of the system to the steady state. The switching type control method based on double loop predictive control disclosed by the invention has the respective advantages of both kinds of predictive control, and the deadbeat control is adopted by the inner loop to greatly improve the overall performance of the system, which can well meet the working requirements of the power electronic system.

Owner:SOUTH CHINA UNIV OF TECH

Method and apparatus for controlling SCell state

ActiveUS11019674B2Fast transitionFast operationPower managementTransmission path divisionChannel state informationCarrier signal

Provided is a method and an apparatus for changing or controlling a state of a secondary cell in carrier aggregation. The method includes receiving secondary cell (SCell) state indication information indicating a state for a SCell from a base station through an RRC message or an MAC control element, causing a state of the SCell to transition into a dormant state when the SCell state indication information indicates the dormant state, and transmitting channel state information reporting for the SCell in the dormant state according to an dormant state CQI report period parameter set separately from an activation state CQI report period parameter.

Owner:KT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com