Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Raise the phase transition temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special flux-cored wire for carrying out preheating-free and heat treatment-free surfacing repair and reproducing on shaft and gear parts

InactiveCN102019520AImprove wear resistanceImprove thermal fatigue resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

The invention belongs to the field of material science and engineering and relates to a special flux-cored wire for carrying out preheating-free and heat treatment-free surfacing repair and reproducing on shaft and gear parts. The special flux-cored wire comprises the following chemical compositions in percentage by weight: 5 to 10 percent of fluorite, 20 to 40 percent of high-carbon ferrochrome, 5 to 10 percent of high carbon ferromanganese, 5 to 10 percent of ferrosilicon, 5 to 10 percent of ferromolybdenum, 10 to 15 percent of rare earth oxide, 15 to 20 percent of metallic nickel, 2 to 5 percent of ferrovanadium, 2 to 5 percent of ferrocolumbium, 2 to 5 percent of ferrotitanium, 0.1 to 0.5 percent of graphite, 5 to 15 percent of iron powder, 0.5 to 2 percent of nitride and 1 to 3 percent of aluminum magnesium alloy. A sheath of the special flux-cored wire is a low-carbon steel strip. The special flux-cored wire can be suitable for open arc welding or submerged arc welding. The series flux-core wire for surfacing can carry out surfacing repair and reproducing on the shaft and gear parts under the conditions that preheating is free before surfacing and heat treatment is free after surfacing. The surfacing metal has high crack resistance. The performance of the repaired parts is equal to or even superior to that of the original parts. The special flux-cored wire is convenient to use on site. The hardness range is between HRC20 and HRC45. The service life of the repaired parts is about 3 times longer than that of the original parts.

Owner:YANSHAN UNIV

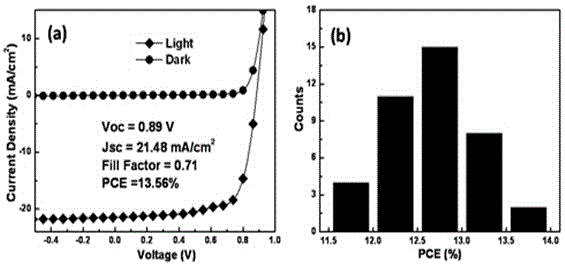

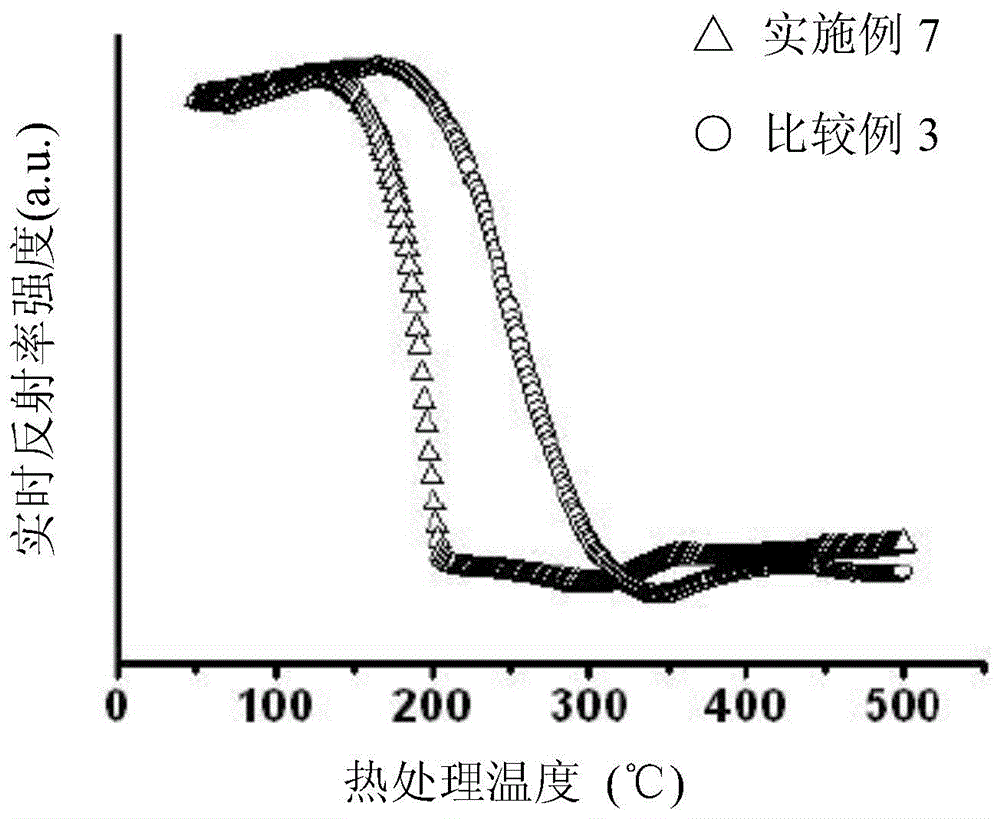

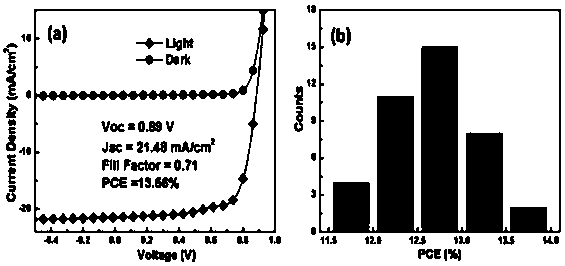

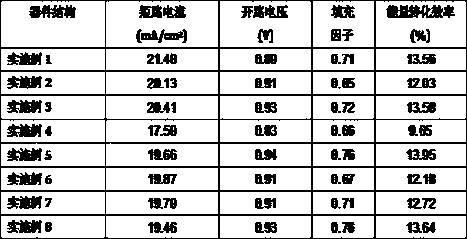

Perovskite-based inverted thin film solar cell and preparation method thereof

ActiveCN105006522AWide absorption rangeRaise the phase transition temperatureSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringRepeatability

The invention belongs to the field of thin film solar cells and relates to a perovskite-based inverted thin film solar cell and a preparation method thereof. The inverted thin film solar cell is based on an inverted planar structure, uses a FAPbI3 perovskite system as a light absorption layer, and is prepared by a solution method under a low temperature condition. The inverted thin film solar cell uses the novel FAPbI3 perovskite system as the light absorption layer. Compared with a conventional MAPbI3 perovskite system, the FAPbI3 perovskite system has a wider absorption range, higher phase inversion temperature, and better stability, prevents a high-temperature sintering defect in a conventional inverted structure, and may greatly decrease cost in industrialized production. The preparation method of theinverted thin film solar cell is simple, low in cost, good in repeatability, achieves a low-cost reel-to-reel mode, and has potential application value in the future industrialized production.

Owner:SUZHOU UNIV

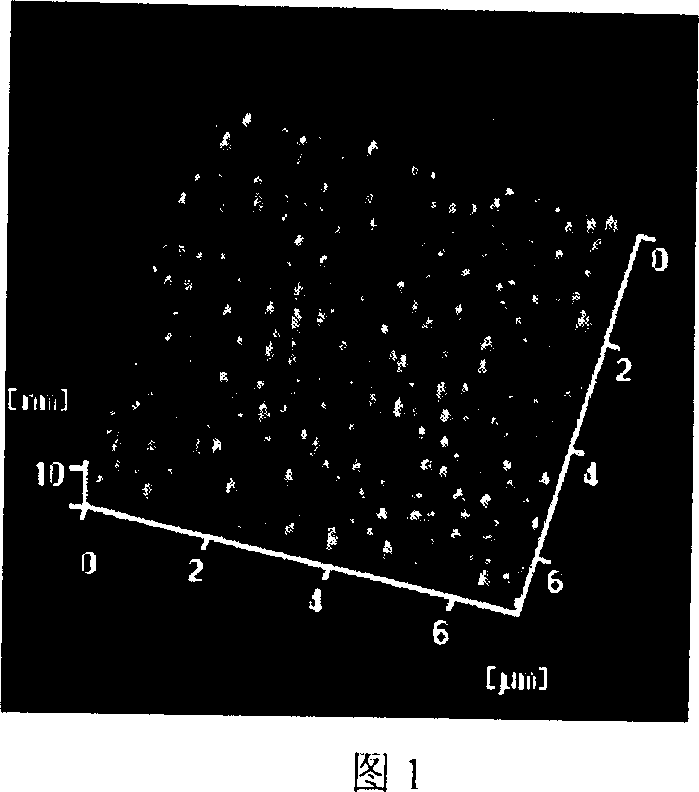

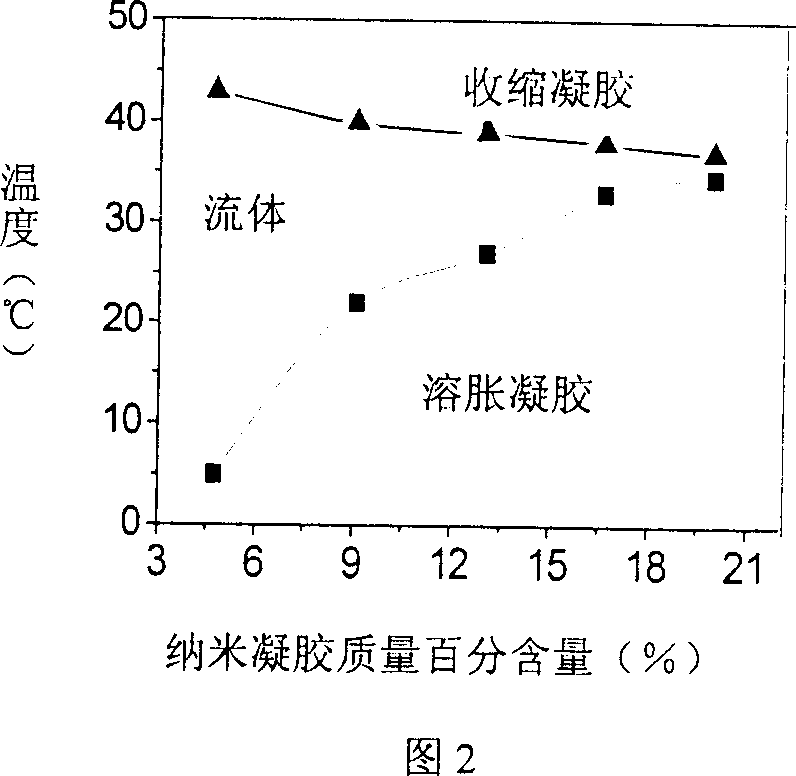

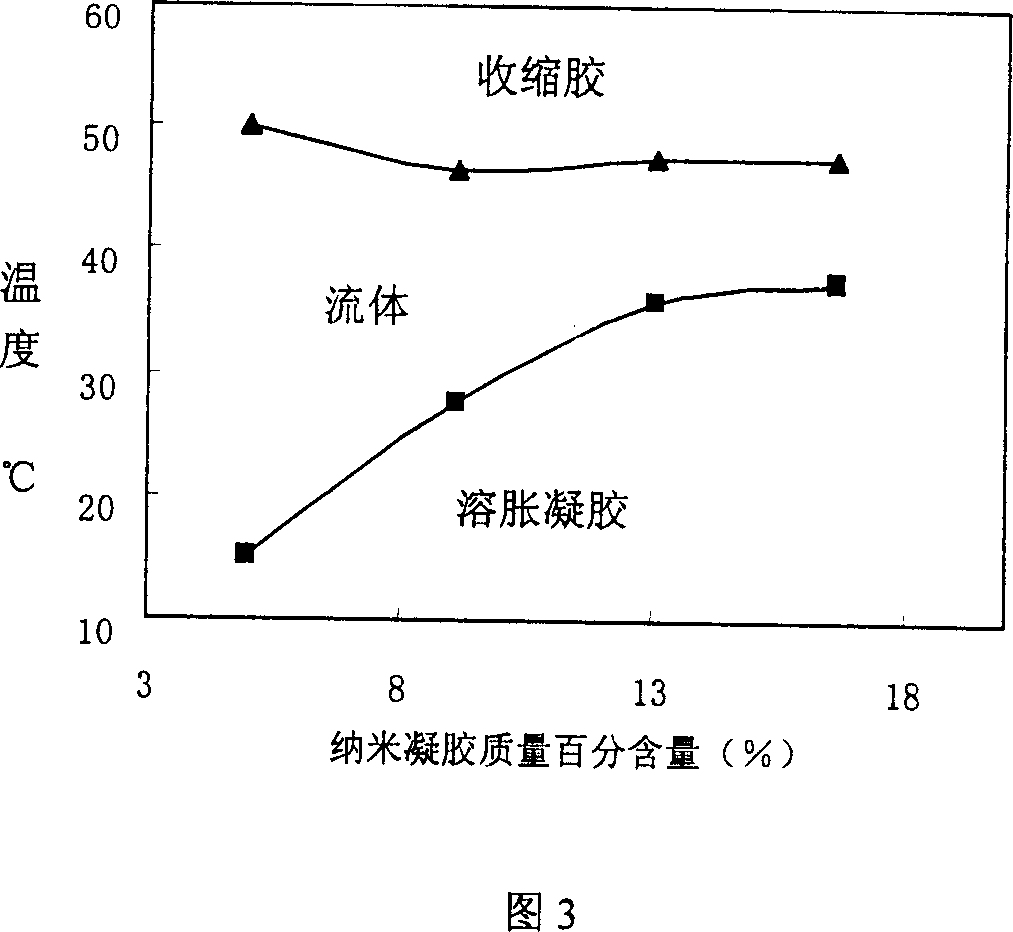

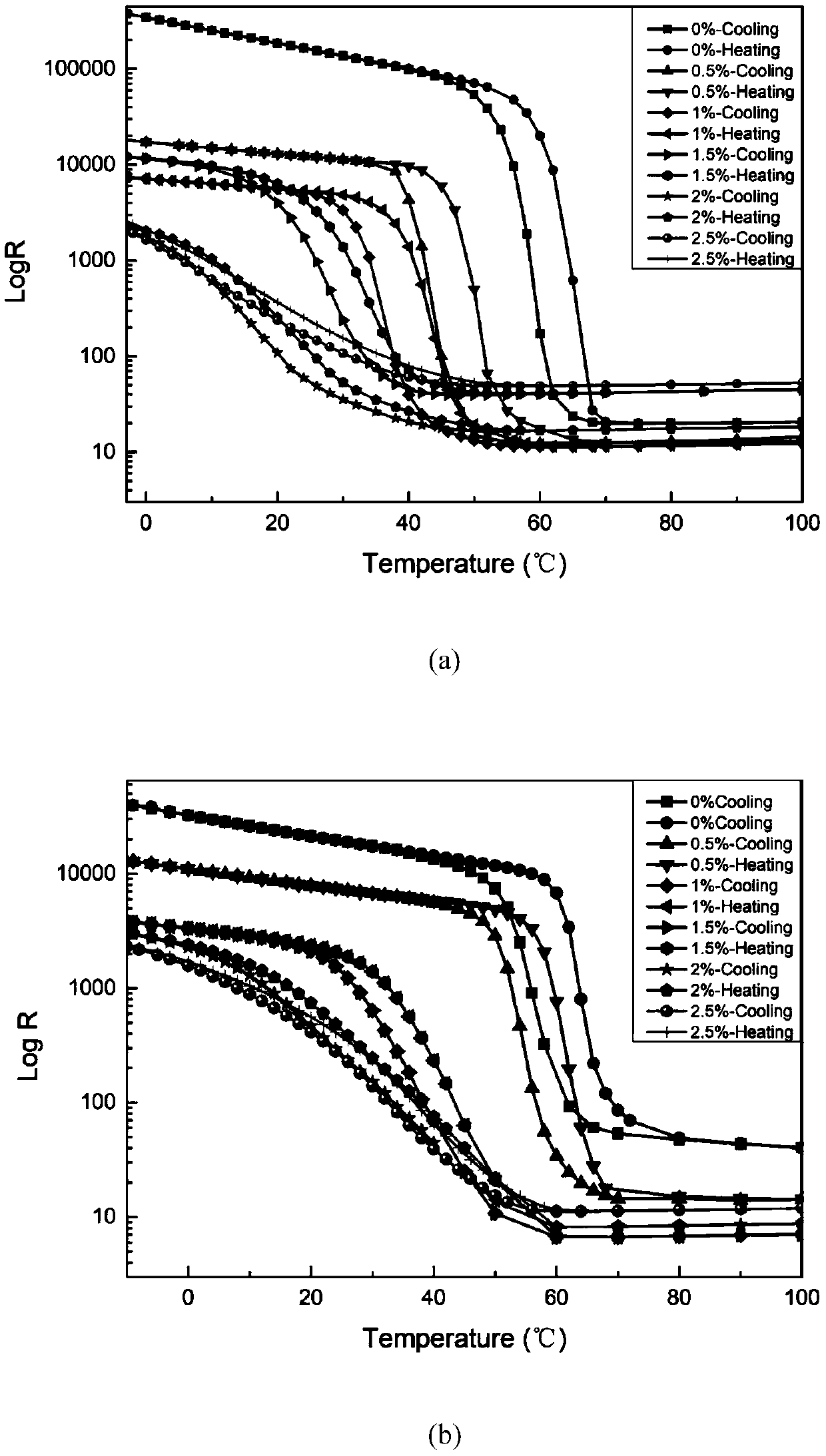

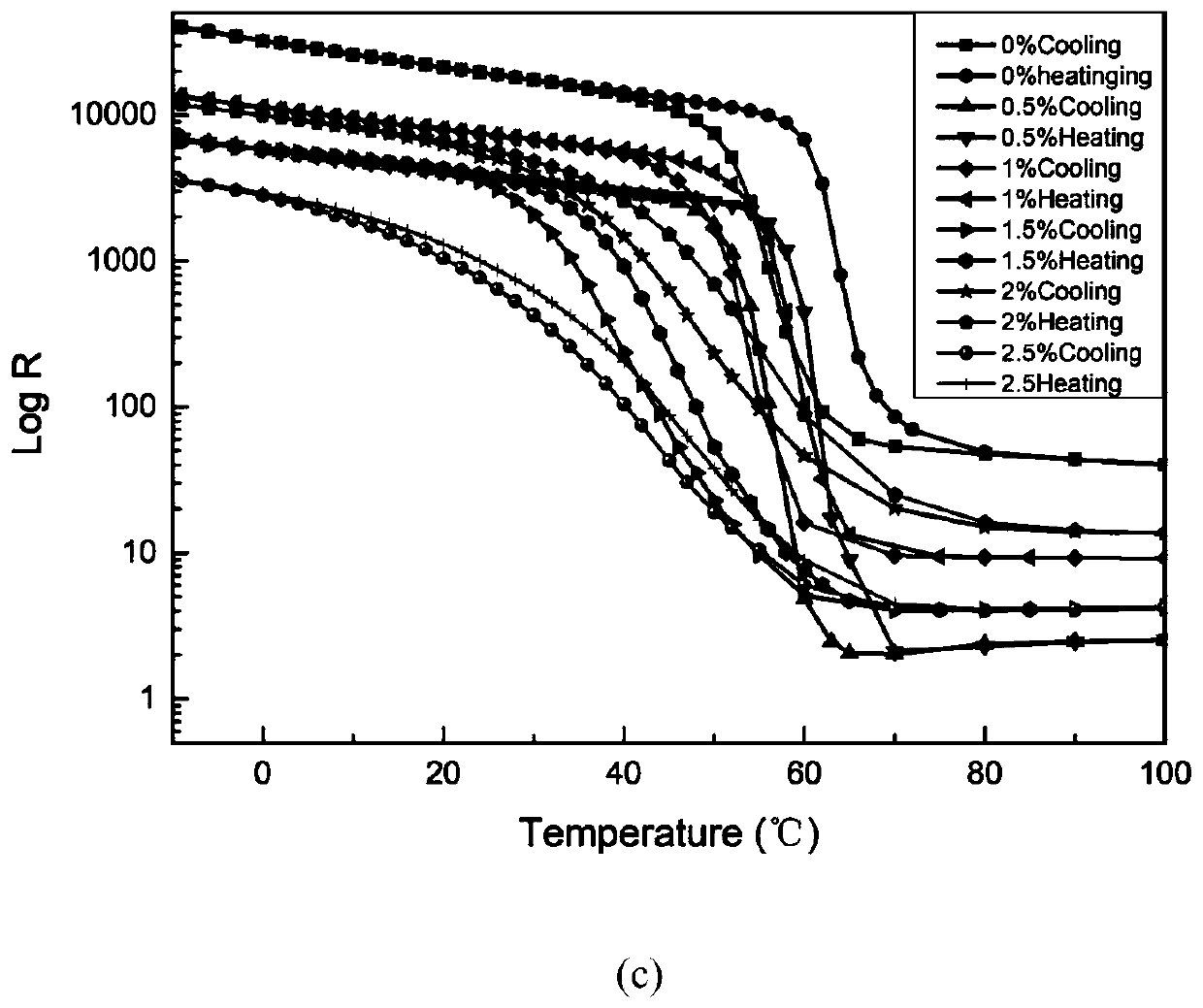

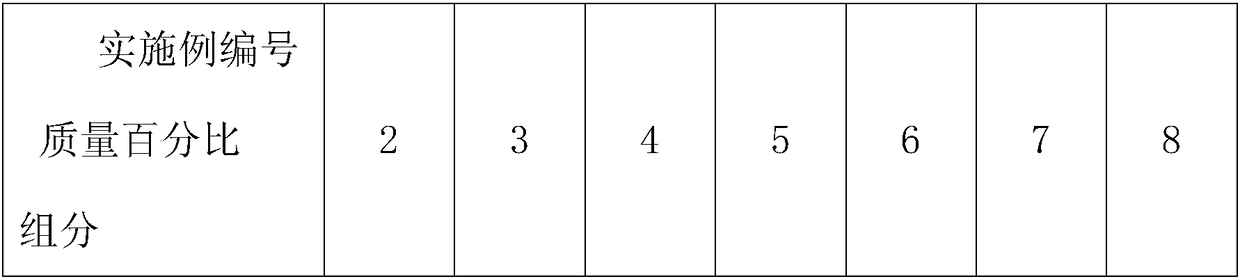

Temperature sensing nano gel system for blood vessel embolism material

ActiveCN1923303AAdjustable transition temperatureBlock blood vesselsSurgeryDiseaseArteriovenous malformation

The invention relates to a vessel plug material used in intervene treatment. Wherein, said material is temperature-sensitive nanometer gel system based on polymer N-isopropyl acrylamide (PNIPAAm), which comprises polymer N-isopropyl acrylamide nanometer gel and dispersed medium, while the gel mass percentages is 3-20% and the particle diameter of temperature-sensitive nanometer gel is 50-1000nm. The inventive temperature-sensitive nanometer gel system also can contain developer, soluble antineoplastic. The invention can control the polymer monomer kinds and ratios, the crosslinker amount and the density of temperature-sensitive nanometer gel, to control the sol-gel transformation temperature of said system, and the inventive product has better external flow property and high sol-gel transformation speed, to be used to treat vessel plug, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

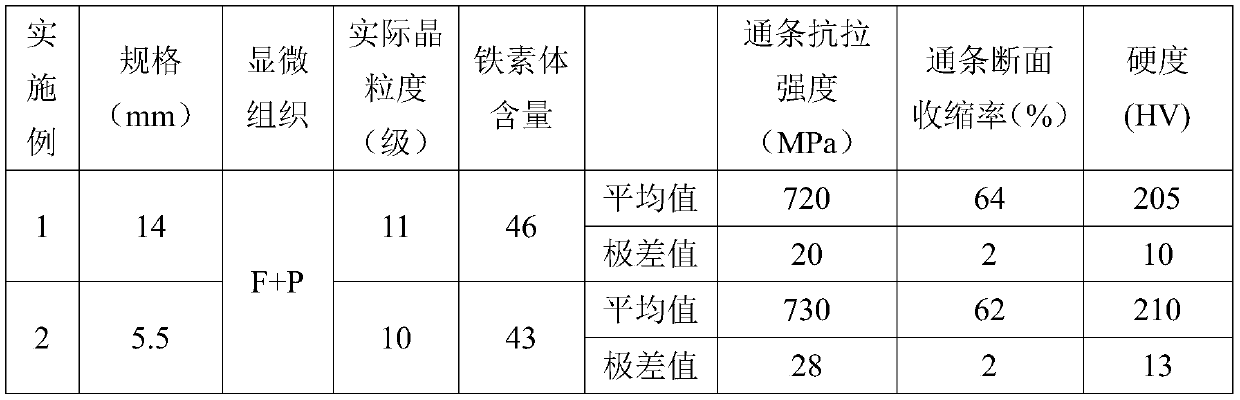

Manufacturing method of medium-carbon CrMo steel wire rod free of annealing and drawing

ActiveCN110004376AImprove purityImprove internal qualityTemperature control deviceMetal rolling arrangementsHigh pressure waterHigh pressure

The invention relates to a manufacturing method of a medium-carbon CrMo steel wire rod free of annealing and drawing, and belongs to the field of wire rod production. Raw materials are prepared and smelted according to chemical compositions, and KR hot metal pretreatment, converter smelting, LF and RH refining, steel blank machining, warm supply or heat supply, steel blank heating and cogging, middle blank surface clearing, reheating, high-pressure water descaling, rolling control and temperature control, cooling control and wire rod forming are carried out in sequence. Rolling comprises roughrolling, medium finish rolling and reducing and sizing. In the medium finish rolling process, in the later period, rolled parts are subjected to water cooling to be below phase change temperature, and the compression ratio of the last two passes is set to be larger than or equal to 35%; coils are slowly cooled online; and the roller speed is constant, a heat preservation cover is closed for heatpreservation, and the rolled parts are discharged out of the cover to be subjected to air cooling to room temperature. The wire rod needs no annealing before drawing, large-draft drawing can be directly carried out, the production cost is reduced, and energy saving and environment protection are achieved.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD +1

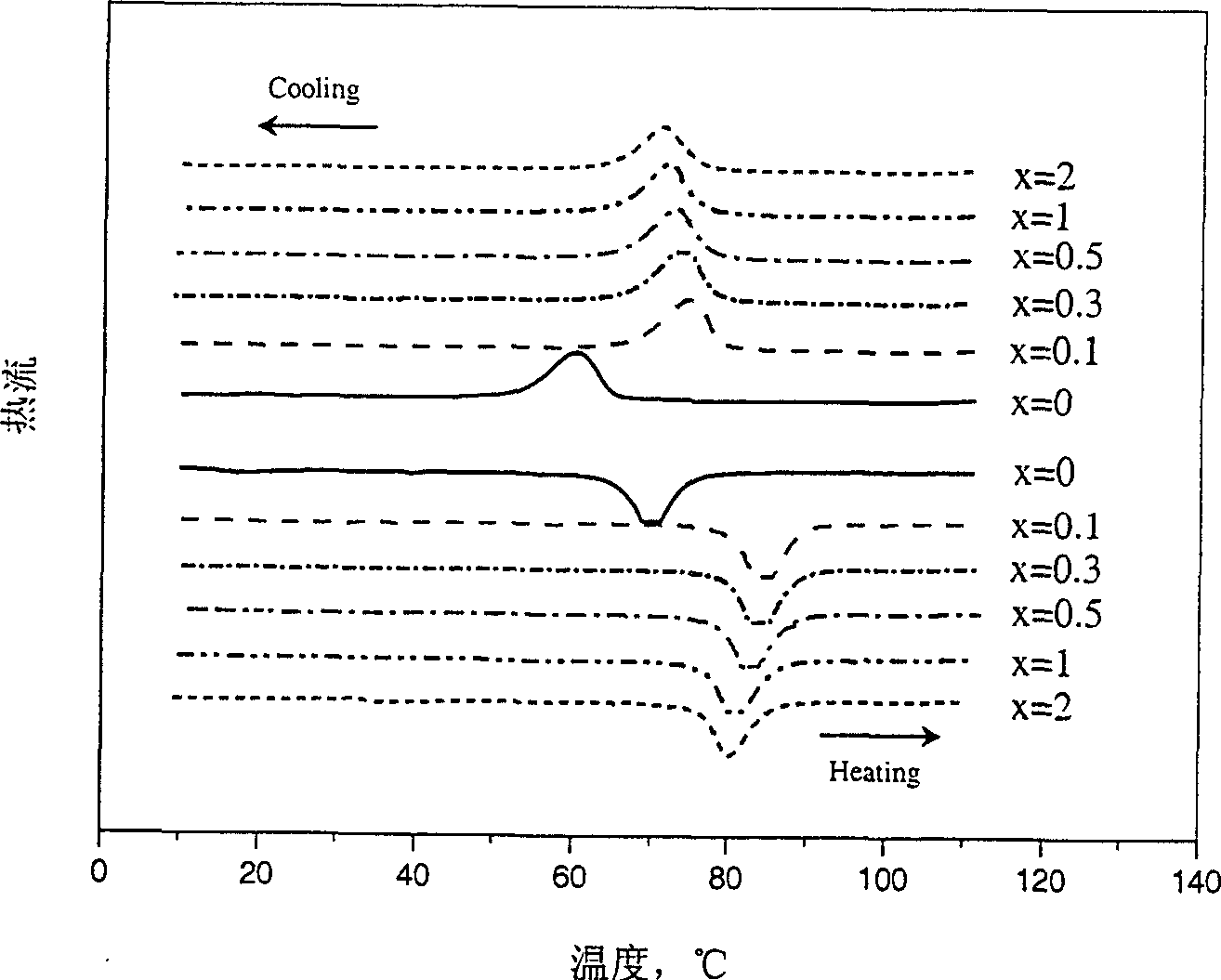

Prepn process of dispersed polymer liquid crystal material

InactiveCN1421506ARaise the phase transition temperatureImprove stabilityLiquid crystal compositionsPolymer scienceIndium tin oxide

The preparation process of dispersed polymer liquid-crystal material includes the main steps of: mixing the substrate material and liquid crystal material in the weight ratio of 0.25-1 in a containerthrough stirring, painting the mixture between two conductive glass plates with coated indium tin oxide film, applying DC voltage of 45-65 V across the glass plates to cure the mixture as dispersed polymer liquid crystal material. The dispersed polymer liquid crystal material thus prepared has high phase transferring temperature and high stability. The preparation process is simple, environment friendly, short in preparation period and suitable for industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

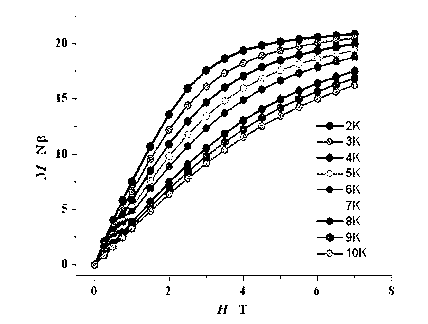

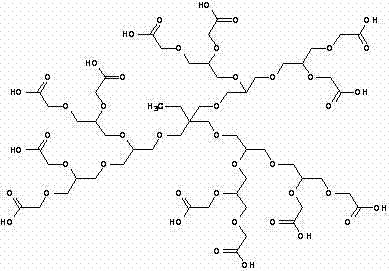

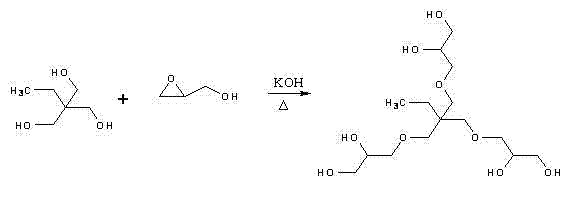

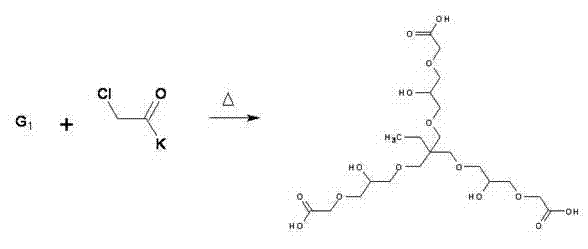

Gadolinium compound with dual functions of magnetic refrigeration function and ferroelectric function and preparation method thereof

InactiveCN103012450AImprove ferroelectric propertiesRaise the phase transition temperatureGroup 3/13 element organic compoundsHeat-exchange elementsEthylene diamineNitrate

The invention discloses a gadolinium compound with dual functions of a magnetic refrigeration function and a ferroelectric function. The chemical formula of the gadolinium compound is shown as follows: [Gd3(HL)(H2L)(NO3)4].C2H5OH, wherein H4L is N, N, N', N'-tetrahydroxyethyl-ethylene diamine; the EtOH is ethanol; and the gadolinium compound has three Gd atoms with different coordination environments, so that an isosceles triangle structure is formed. The preparation method for the gadolinium compound comprises the following steps of: using hexahydrate gadolinium nitrate as metal salt; using H4L as ligand; using LiOH alkali substance to regulate the pH of the mixed solution to 7; and stirring and baking the mixed solution, and separating out the solid and washing the separated solid to obtain the gadolinium compound. The invention has the advantages that the gadolinium compound has excellent magnetic refrigeration and excellent ferroelectric properties, and so that the gadolinium compound has a giant potential value in low-temperature magnetic refrigeration and solid apparatuses such as a ferroelectric memory and the like.

Owner:NANKAI UNIV

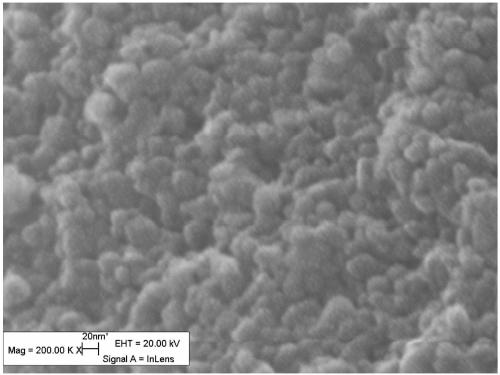

Rare-earth cerium doped alumina nano fiber catalyst carrier material and preparation method thereof

InactiveCN101590434ALarge specific surface areaImprove thermal stabilityCatalyst carriersCatalytic crackingFiberHeat stability

The invention relates to a rare-earth cerium doped alumina nano fiber membrane catalyst carrier material and preparation technology thereof. The nano fiber membrane catalyst carrier material consists of gamma-type alumina nano fiber with the diameter ranging from 50 to 200 nm, and the mass percentage formula of the fiber comprises 80 to 95 weight percent of alumina and 5 to 20 weight percent of cerium oxide. The preparation method of the catalyst carrier material adopts the mass percentage formula and following process steps: (1) preparing sol-gel electrostatic spinning solution; (2) preparing an organic / inorganic hybrid nano fiber material by the prepared sol-gel spinning solution by electrostatic spinning; and (3) putting the prepared nano fiber membrane in a muffle furnace, and calcining the nano fiber membrane at a high temperature to obtain the alumina nano fiber membrane catalyst carrier material. The prepared rare-earth cerium doped alumina nano fiber membrane is a catalyst and a carrier material with high specific surface area, good heat stability and excellent mechanical property, greatly improves the phase transition temperature of the gamma-Al2O3 nano fiber carrier material through doping the rare-earth cerium, and simultaneously endows the material with excellent oxygen storage and release function.

Owner:TIANJIN POLYTECHNIC UNIV

High-temperature phase-transitional temperature-sensitive fire-extinguishing gel and preparation method thereof

InactiveCN102188781ARaise the phase transition temperatureFast transitionFire extinguisherChemistryWater soluble

The invention relates to a high-temperature phase-transitional temperature-sensitive fire-extinguishing gel and a preparation method thereof. Through the physical crosslinking between polyacid with a hydrophilic backbone structure and polyamine with a hydrophobic backbone structure, the fire-extinguishing gel is in a soluble state at a low temperature and in a gel state at a high temperature. The fire-extinguishing agent is a low-viscosity aqueous solution at normal temperature; the viscosity is gradually increased as the temperature rises, and then the aquagel is formed and adhered on the surface of burning objects, thus the effect of fire-extinguishing is achieved and the fire behavior is blocked from spreading; after the temperature of the gel is lowered to a certain temperature, the gel is returned to the state of liquid, the residue can be cleaned by using water for flushing, thereby being efficient and environment-friendly. The fire-extinguishing agent provided by the invention has low viscosity, can be spouted by using the traditional squirt gun; meanwhile, other elements, such as fire-proofing agent, flame retardant, and the like, can be added to improve the fire-extinguishing performance of the fire-extinguishing agent.

Owner:SHANGHAI UNIV +1

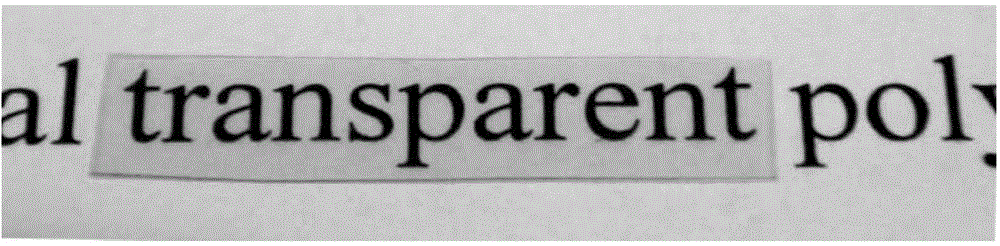

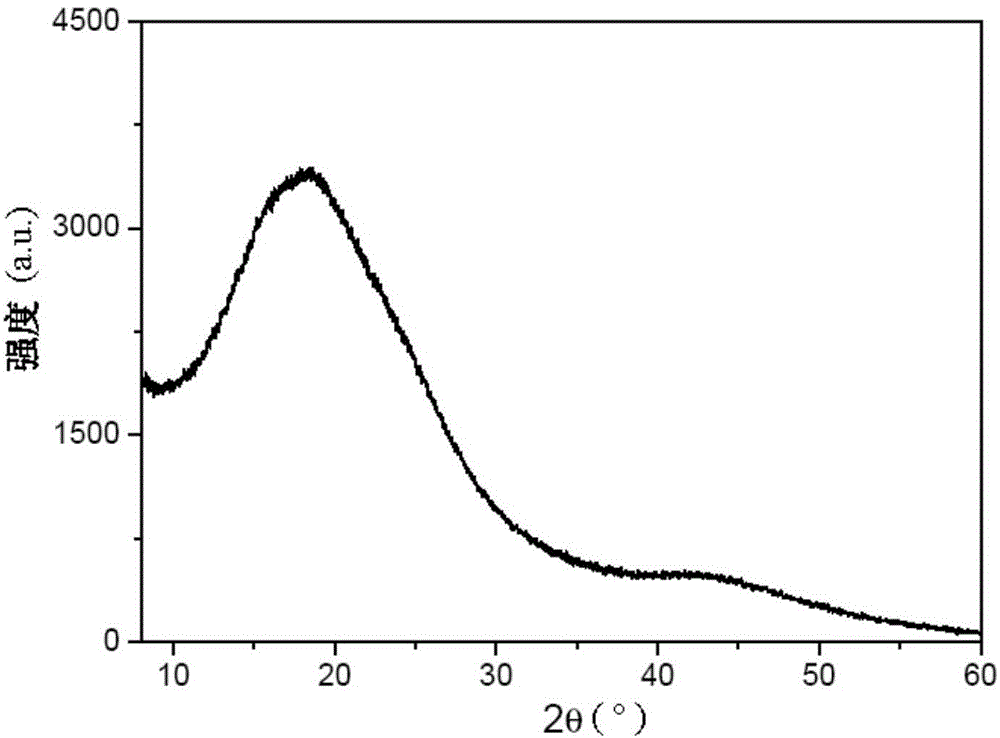

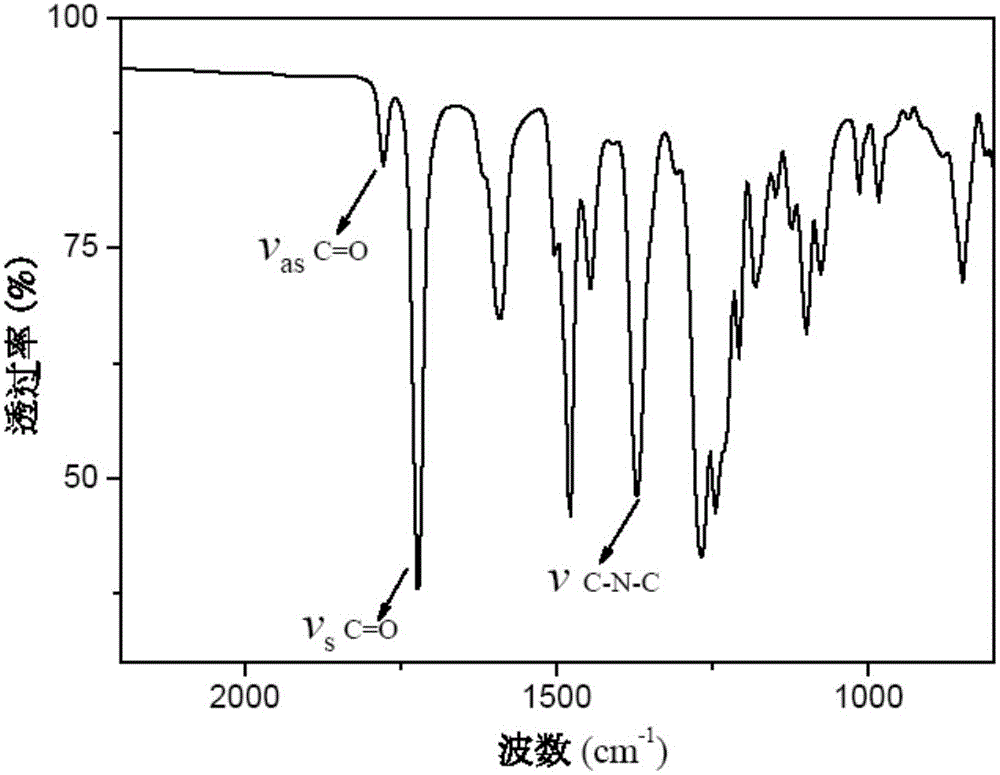

Optical transparent light-colored high temperature-resisting shape memory polymer and preparation method thereof

ActiveCN104788675ARaise the phase transition temperatureAchieving the shape memory effectChemical recyclingPolymer sciencePolyamide

The invention relates to an optical transparent light-colored polymer and a preparation method thereof, in particular to an optical transparent light-colored high temperature-resisting shape memory polymer and a preparation method thereof, and aims to solve the problems, in the prior art, that an optical transparent shape memory polymer is relatively low in phase inversion temperature and existing transparent polyimide is difficult to generate a shape memory effect due to relatively small thickness, so that the use requirement of a photoelectronic device cannot be met in a high temperature environment. The optical transparent light-colored high temperature-resisting shape memory polymer is prepared from 1,3-Bis(3-aminophenoxy)benzene and 4,4'- Bisphenol A dianhydride as reactive monomers, and has the structural formula shown in the specification. The preparation method comprises the following steps: firstly, dissolving 1,3-Bis(3-aminophenoxy)benzene; secondly, preparing a sol-gel polyamide acid; thirdly, removing residual bubbles; fourthly, performing thermal imidization; fifthly, stripping to obtain the optical transparent light-colored high temperature-resisting shape memory polymer. Through the invention, the optical transparent light-colored high temperature-resisting shape memory polymer can be obtained.

Owner:HARBIN INST OF TECH

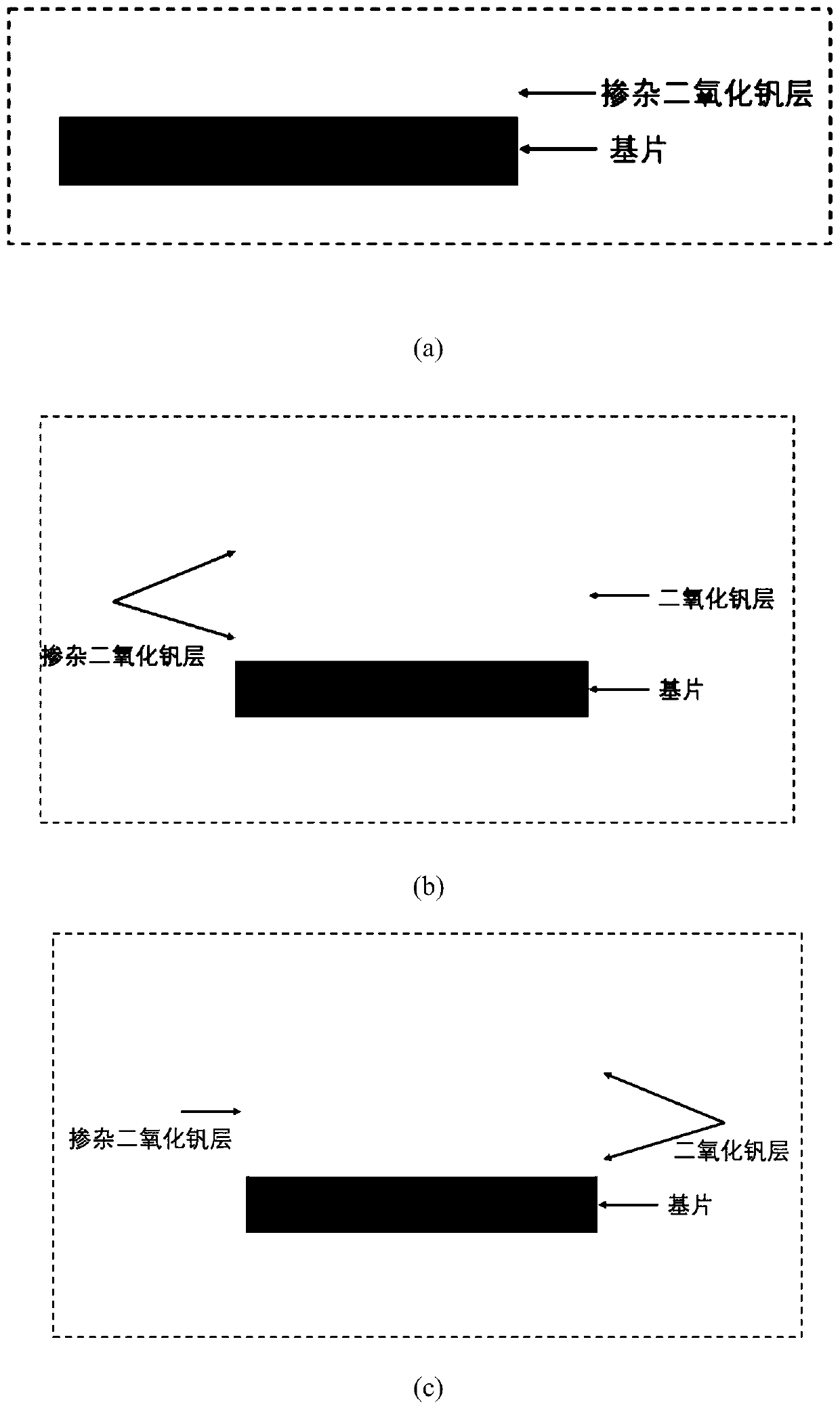

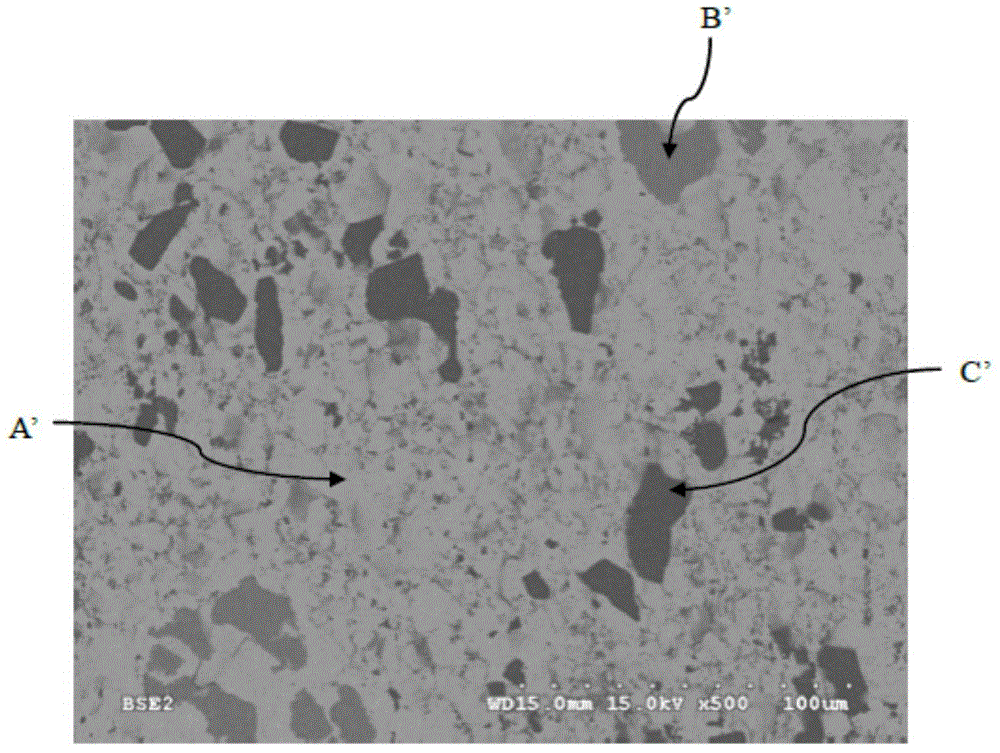

Vanadium dioxide composite thin film with adjustable transmissivity, and preparation method thereof

InactiveCN110284125AHigh refractive indexLarge adjustment rangeLiquid/solution decomposition chemical coatingVanadium dioxideMaterials preparation

The invention provides a vanadium dioxide composite thin film with adjustable transmissivity, and a preparation method thereof, and belongs to the technical field of thin film material preparation. The vanadium dioxide composite thin film provided by the invention is prepared by alternately growing a thin film doped with vanadium dioxide and a thin film non-doped with vanadium dioxide, no extra adding layer is needed, and favorable growth can be realized between layers, so that a good thin film system is obtained. Meanwhile, according to the system, by utilizing the difference of phase-transition temperatures of the thin film layer doped with the vanadium dioxide and the thin film layer non-doped with the vanadium dioxide, the coexistence of a metal state and an insulation state of the thin film can be realized at one same temperature, the refractive index of the vanadium dioxide between a metal-state interface and a non-metal-state interface is large, back-and-forth multi-time reflection is carried out between the interfaces, destructive interference is produced, and reflection is reduced, so that the aims of increasing permeability and reducing reflectivity are achieved, and the composite thin film can adjust the transmissivity of a visible light wave band and a near-infrared light wave and.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

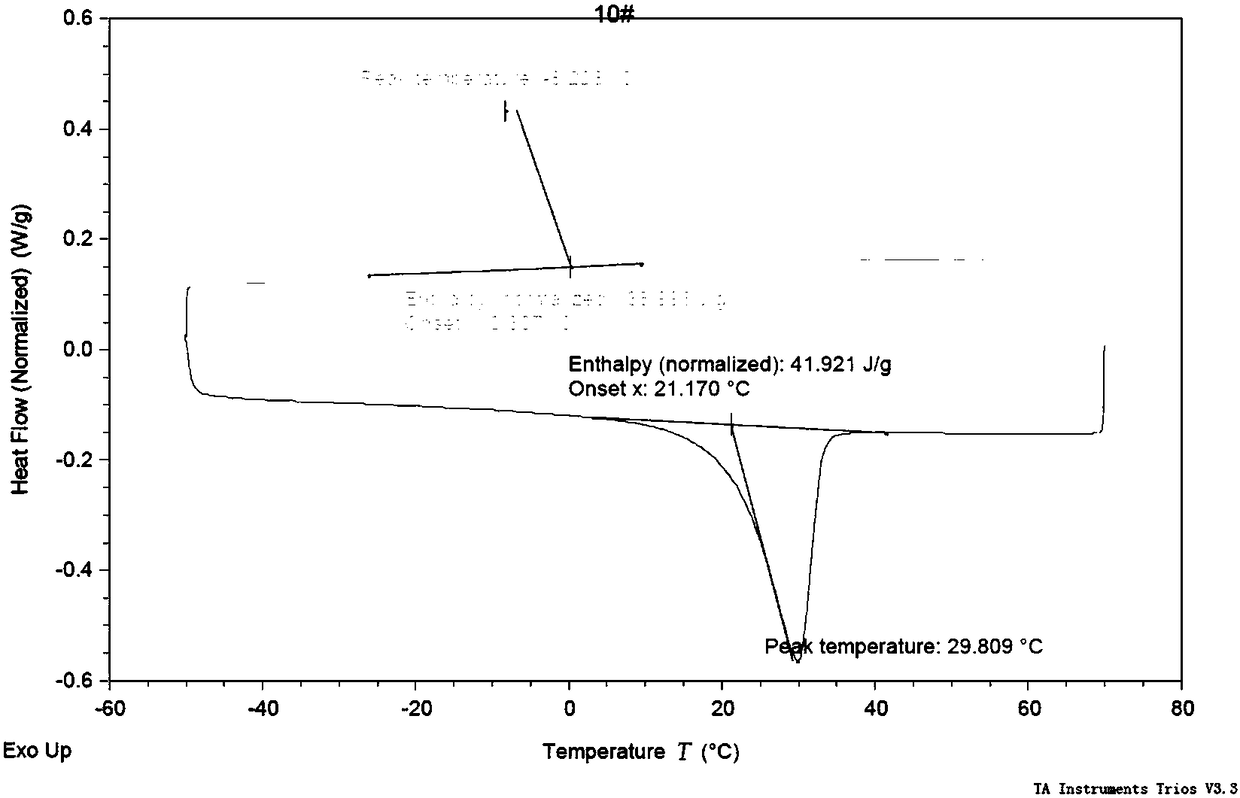

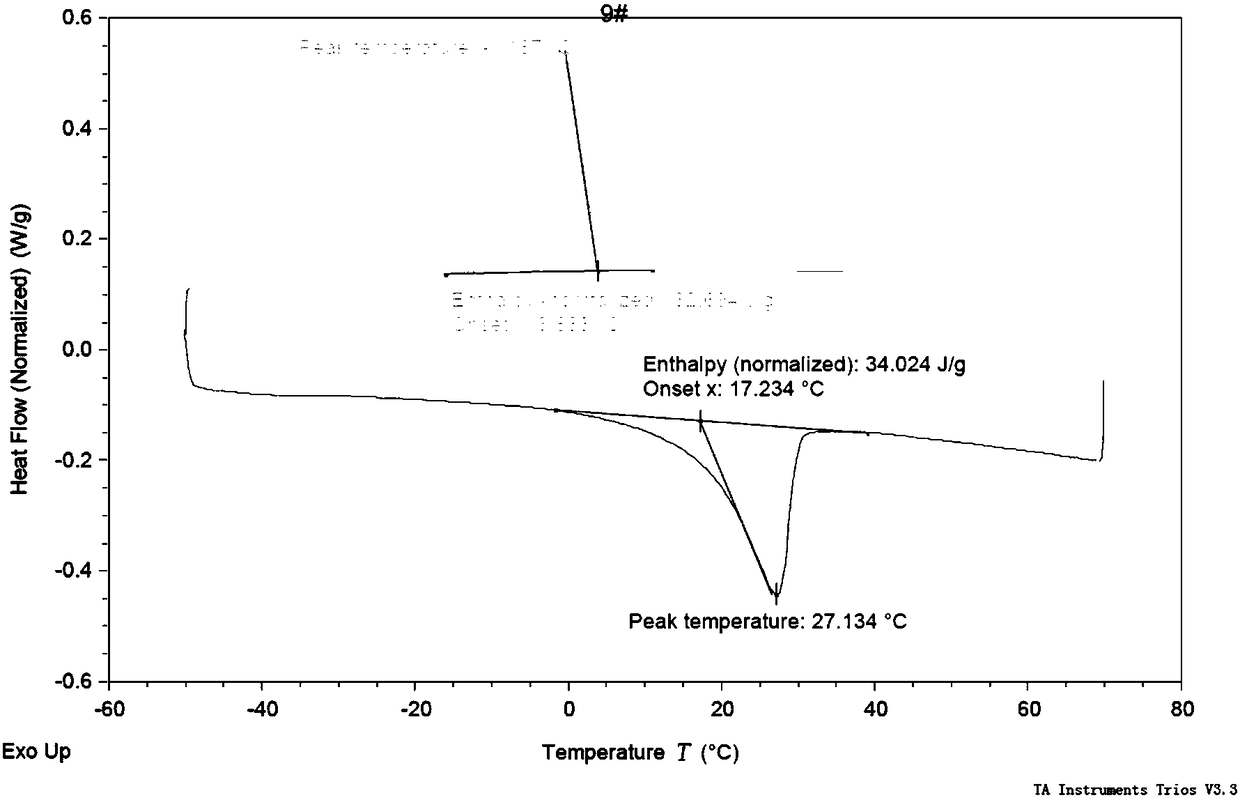

Inorganic phase-change energy storing particles, floor heating mortar and preparation method thereof

The invention provides inorganic phase-change energy storing particles, floor heating mortar and a preparation method thereof. The inorganic phase-change energy storing particles comprise the following components in percentage by mass: 20-50% of inorganic phase-change material, 10-25% of water, 0.1-1.5% of phosphorylated starch gum, 0.1-1.5% of water-absorbent resin, 10-35% of gypsum, and 15-35% of cement. The inorganic phase-change energy storing particles are prepared by the steps of preparing phosphorylated starch gum, preparing materials, mixing, pelletizing, coating, and covering with films. The floor heating mortar comprises 15-35% of cement, 10-25% of sand, 20-50% of inorganic phase-change energy storing particles, and 20-30% of water. The floor heating mortar is prepared by preparing materials, and mixing. According to the inorganic phase-change energy storing particles, the floor heating mortar and the preparation method thereof, the raw materials are wide in source; the chemical stability is high; the phase change temperature is low; leakage is avoided; the energy storing particles are good in energy storing effect, and high in stability; the floor heating mortar is highin strength, and the indoor temperature can be effectively conditioned, and the energy saving effect is good; and various buildings such as a house, a school and a hospital widely apply.

Owner:SOUTHWEAT UNIV OF SCI & TECH

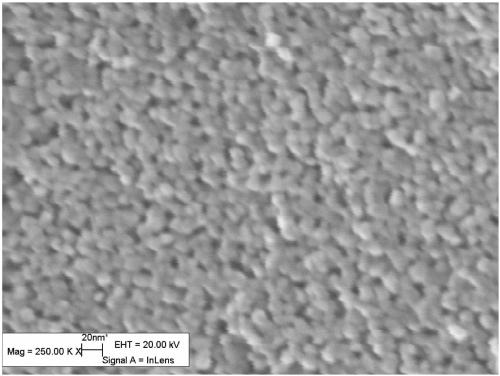

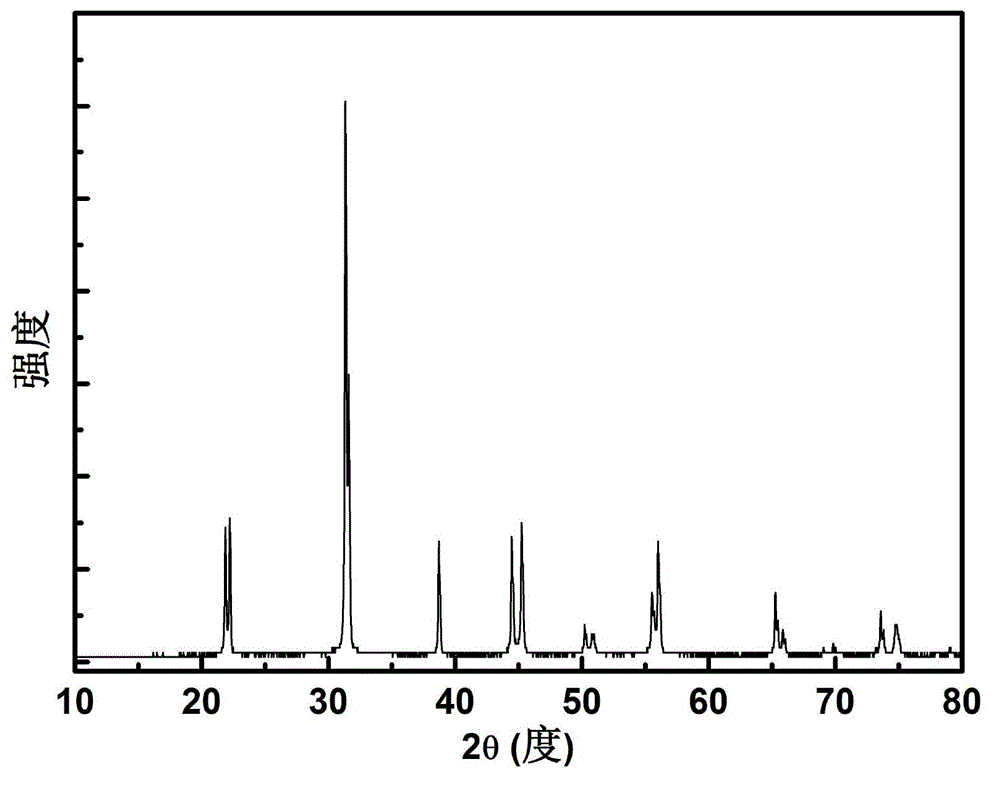

Preparation method of rare-earth-doped modified nano titanium oxide photocatalyst capable of degrading methyl orange organic dye

InactiveCN109603803AUniform particlesGrowth inhibitionMaterial nanotechnologyWater/sewage treatment by irradiationOrganic dyeElectronic band structure

The invention discloses a preparation method of a rare-earth-doped modified nano titanium oxide photocatalyst capable of degrading methyl orange organic dye. In the preparation method of the rare-earth-doped modified nano titanium oxide photocatalyst capable of degrading methyl orange organic dye, a sol-gel method is used to introduce a rare earth ion into a TiO2 lattice so as to introduce new charges into the lattice, further form defects or change the lattice type, affect the movement state of photogenerated electron-hole pairs, adjust the distribution state of the photogenerated electron-hole pairs or change the energy band of TiO2, and finally lead to a change in the photocatalytic activity of TiO2. An obtained rare-earth-doped modified nano-TiO2 powder has uniform particles, has a crystal grain size in a range of 10 to 35 nm. The photocatalytic performance is obviously improved after doping, and the absorption spectrum is shifted to the visible light. Doping of the rare earth ioncan inhibit the transformation of a TiO2 anatase phase to a rutile phase and increase the phase transition temperature. Also, the growth of nanocrystals is inhibited, and effect of refining crystal grains is exerted.

Owner:WUYI UNIV

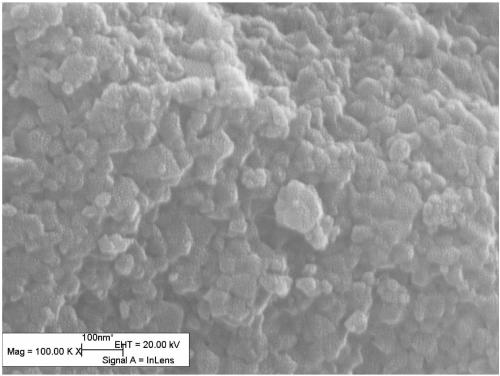

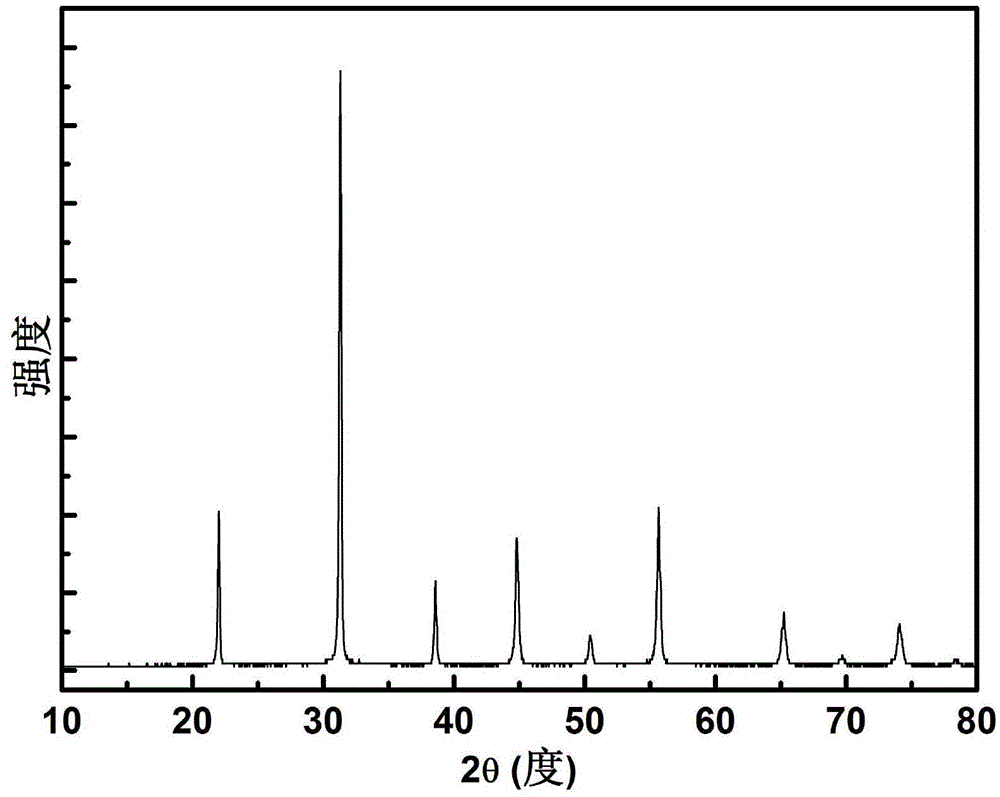

Quaternary relaxation piezoelectric single crystal material and growing method thereof

ActiveCN104152997AElectromechanical coupling performance is smallSuperior piezoelectricPolycrystalline material growthFrom frozen solutionsChemistryOxide

The invention discloses a quaternary relaxation piezoelectric single crystal material and a growing method thereof. The chemical formula of the single crystal material is xPb(Mg1 / 3Nb2 / 3)O3-yPb(In1 / 2Nb1 / 2)O3-zBiAlO3-(1-x-y-z)PbTiO3, wherein x is more than 0 and less than 1; y is more than 0 and less than 1; z is more than 0 and less than 1; x+y+z is less than 1. The growing method comprises the following steps: weighing the oxide raw materials except lead and presintering the oxide raw materials under high temperature; mixing the presintered materials with the oxide of lead and briquetting the mixture; then carrying out insulation at 500-1250 DEG C for 3-20 hours, continuously raising the temperature to 1340-1410 DEG C, carrying out insulation for 3-15 hours to melt all the starting materials and cooling at a speed of 0.1-1.2mm / h to gradually carry out crystallization, wherein the interface temperature gradient is 20-100 DEG C / cm; after growth is completed, cooling the crystals to the room temperature at a speed of 10-300 DEG C / h. The method can be adopted to grow piezoelectric crystals with different orientations, shapes and dimensions according to the requirements, has the advantages of simple process equipment, convenience in operation, productivity with one furnace and the like and is suitable for large-scale industrial growth or production of crystals.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

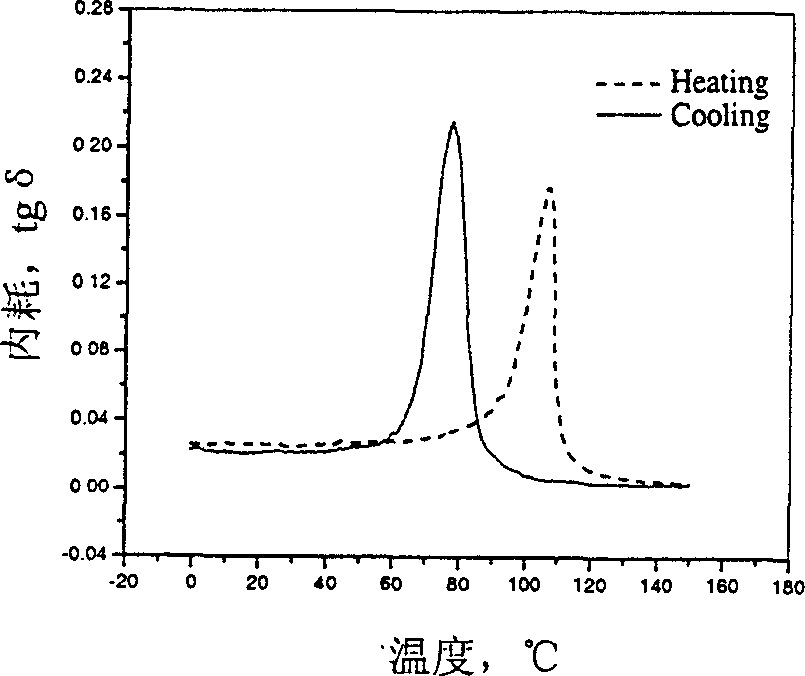

High-damping shape memory alloy

The present invention relates to a high-damping marmem. In the original marmem Ti-Ni-Cu the trace rare earth element Y is contained, the content of Y is 0.01-5 at%. Said invented high-damping alloy utilizes the regulation of content of constituent element Cu and Y can raise and control martensific phase transformation temperature of the alloy so as to obtain high-damping alloy with wider working temperature range. Said invented high-damping alloy can be smelted by adopting vacuum induction smelting process or electric arc process, can be directly prepared into the antivibration component product. Said invented high-damping marmem has excellent damping performance, wider application range, lower cost and excellent antifriction, wear-resisting and corrosion-proofing properties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Phosphate type epoxy resin-nano clay hydrogel and preparation method thereof

The invention relates to the technical field of hydrogel composite materials, and discloses the phosphate type epoxy resin-nano clay hydrogel and a preparation method thereof. The phosphate type epoxyresin-nano clay hydrogel comprise the following formula raw materials of hydrogenated bisphenol A, epoxy chloropropane, an alkalizing agent, 1-naphthyl phosphate, an esterification catalyst, the ultrapure water, an end-capping reagent, a functional additive, an initiator and 8-11 parts of nano clay. The preparation method of the phosphate type epoxy resin-nano clay hydrogel comprises the following steps of adding the 1-naphthyl phosphate,carrying out the esterification reaction on the phosphate group and the hydroxyl of the epoxy resin to generate the phosphate-generating epoxy resin, whereinthe phosphate ester contains a large amount of hydrophilic hydroxyl-OH, so that the epoxy resin has better hydrophilicity, and the water absorption property and the water retention property of the hydrogel are improved. Meanwhile, the -OH groups and the ether bonds in the epoxy resin form the hydrogen bonds with high chemical energy, so that the chemical stability of the epoxy resin is better, the phase transition temperature of the hydrogel is greatly increased, and the thermal stability of the hydrogel material is enhanced.

Owner:广州思奇高分子材料技术有限公司

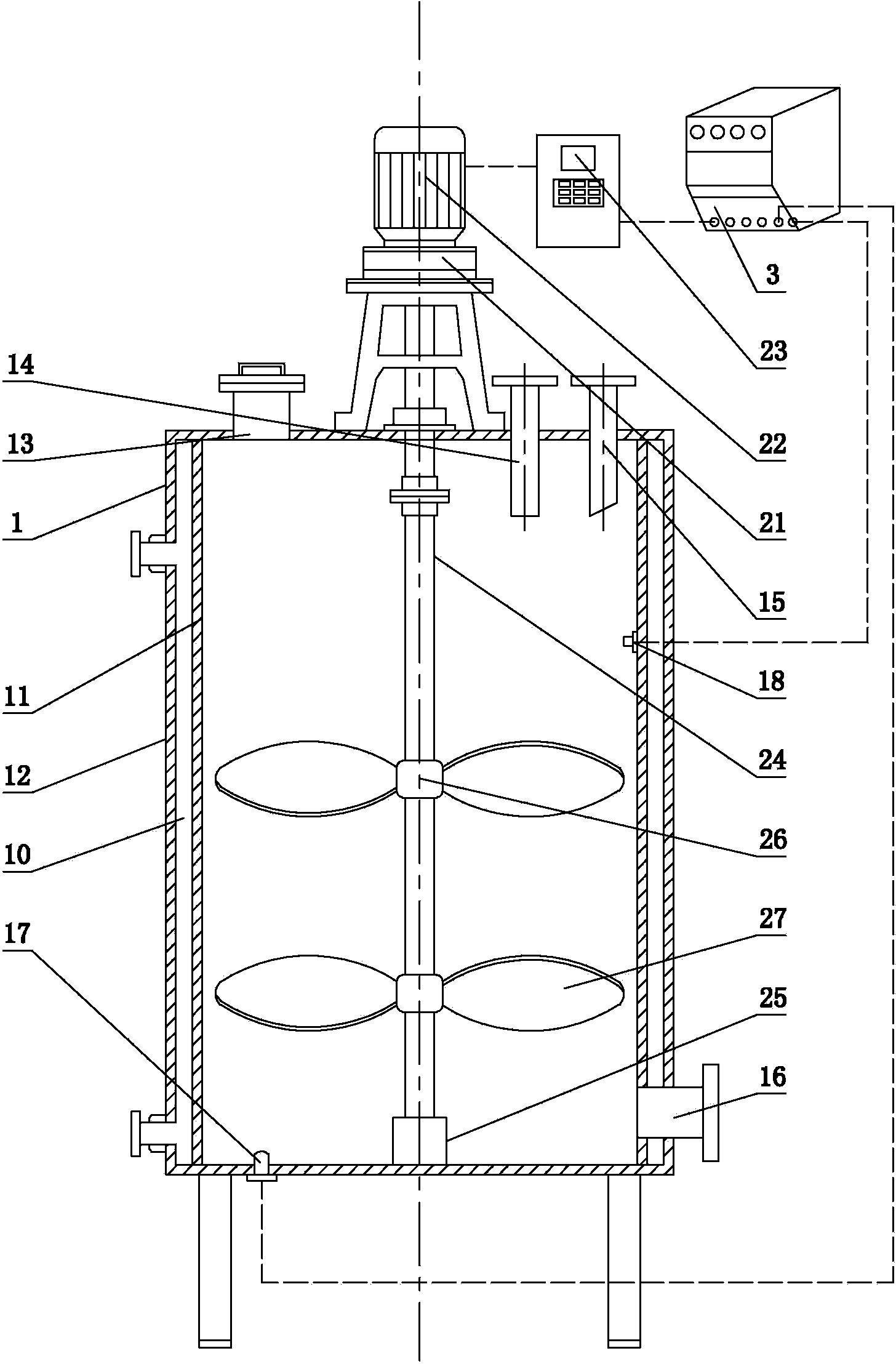

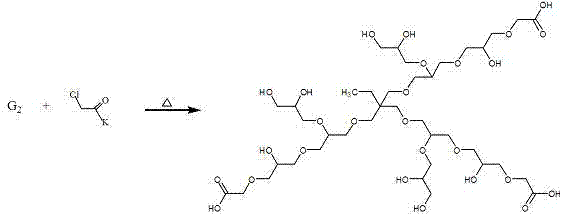

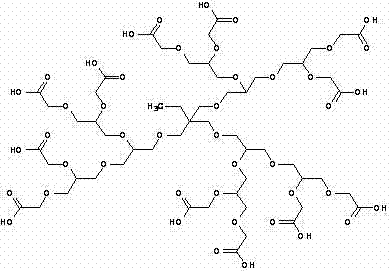

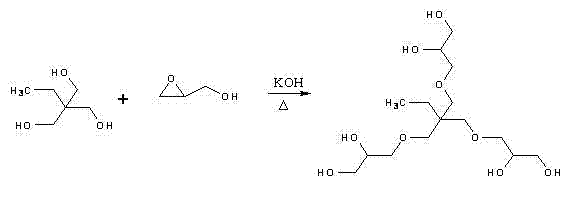

Beta-hydroxyalkyl amide synthesis process

InactiveCN103664676AHas anti-yellowing effectReasonable workmanshipOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsTemperature controlSulfite salt

The invention relates to a beta-hydroxyalkyl amide synthesis process, which comprises the steps of inputting diethanol amine and silica into a reaction kettle, adding a multi-component composite catalyst into the reaction kettle, introducing argon gas for three times for gas replacement, extracting gas in the reaction kettle until the pressure reaches negative pressure, stirring and dripping dimethyl adipate into the reaction kettle, heating for two times and constantly stirring and introducing argon gas at the same time, and obtaining the finished product beta-hydroxyalkyl amide after the product cools down naturally. The beta-hydroxyalkyl amide synthesis process has the advantages of reasonable process, reliable performance and the like; under the catalytic action of the multi-component composite catalyst, ammonolysis of dimethyl adipate is realized through diethanol amine, ,and the beta-hydroxyalkyl amide is obtained, besides, sodium carbonate can accelerate the reaction, and sodium sulfite and sodium citrate have efficacy of xanthochromia resistance. The structure of the reaction kettle body for beta-hydroxyalkyl amide synthesis is reasonable, and temperature control and stirring effect are good; as reaction is performed under segmented temperature in the reaction kettle, mass production requirement can be satisfied.

Owner:HUBEI JIANGDA CHEM

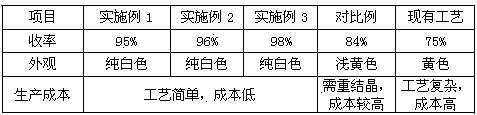

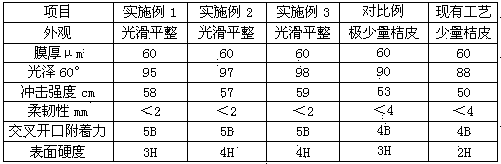

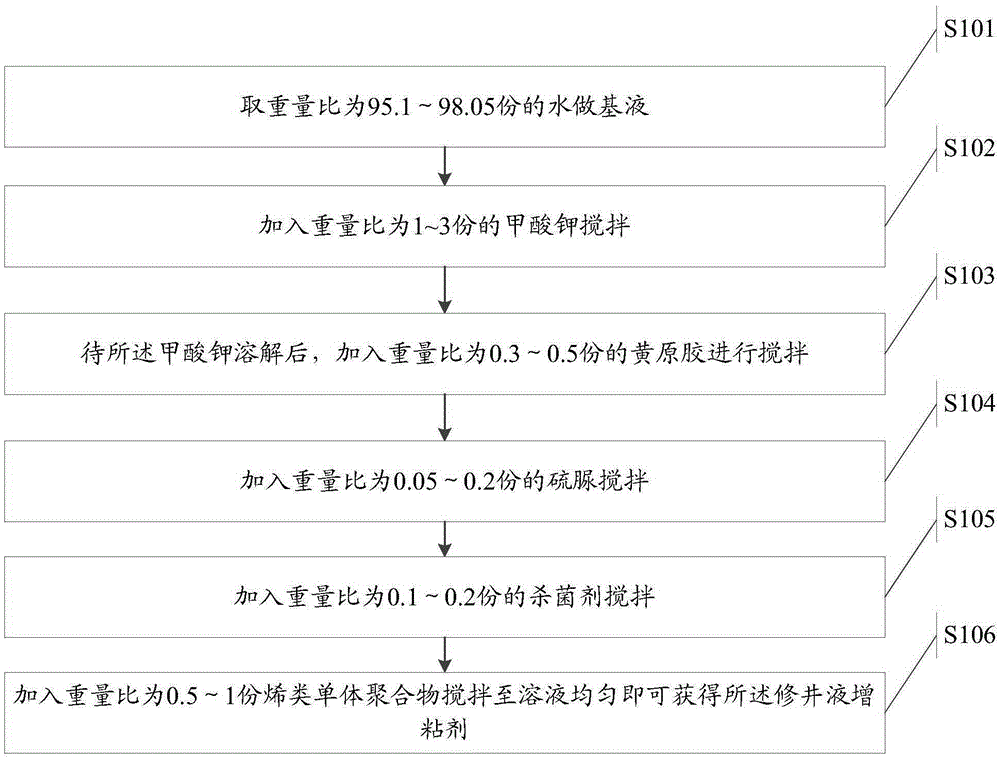

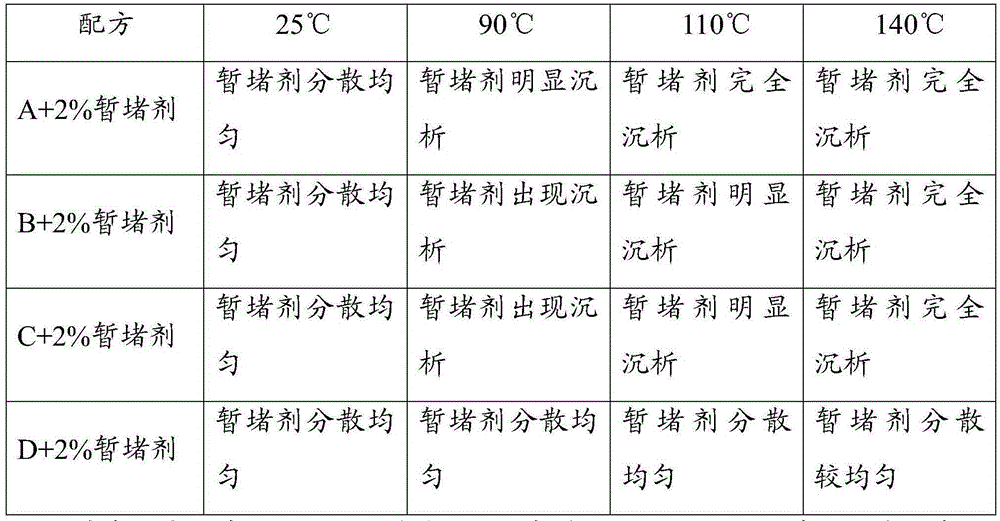

Workover fluid tackifier and preparation method of same

InactiveCN105238369ARaise the phase transition temperatureImprove high temperature stabilityDrilling compositionChemistryWorkover

The invention relates to the field of oil field workover and discloses a workover fluid tackifier and a preparation method of same. The invention solves the technical problem that when xanthan gum is employed as the tackifier in the prior art, the anti-high-temperature capability is poor. The workover fluid tackifier includes, by weight, 95.1-98.05 parts of water, 0.3-0.5 parts of xanthan gum, 1-3 parts of potassium formate, 0.05-0.2 parts of thiourea, 0.1-0.2 parts of a sterilizing agent and 0.5-1 part of an olefin monomer polymer. The workover fluid tackifier is enhanced in high-temperature stability of the xanthan gum.

Owner:PETROCHINA CO LTD

MPP pipe for electric power engineering and production process of MPP pipe

PendingCN113980394AHigh low temperature impact resistanceImprove impact resistanceCrazingPower engineering

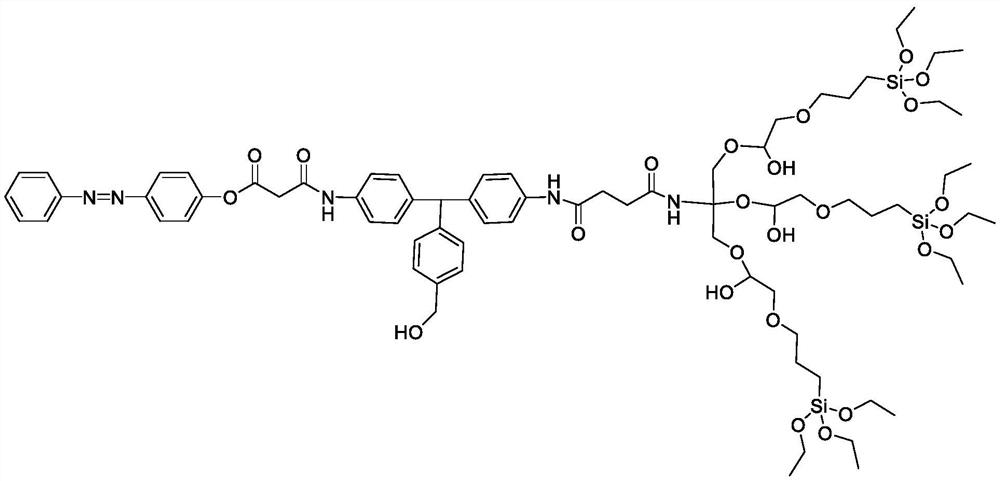

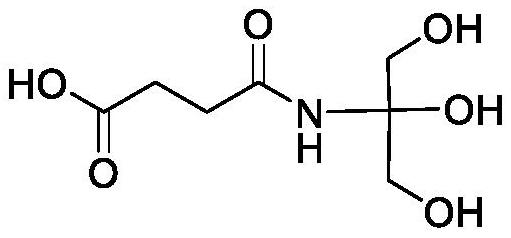

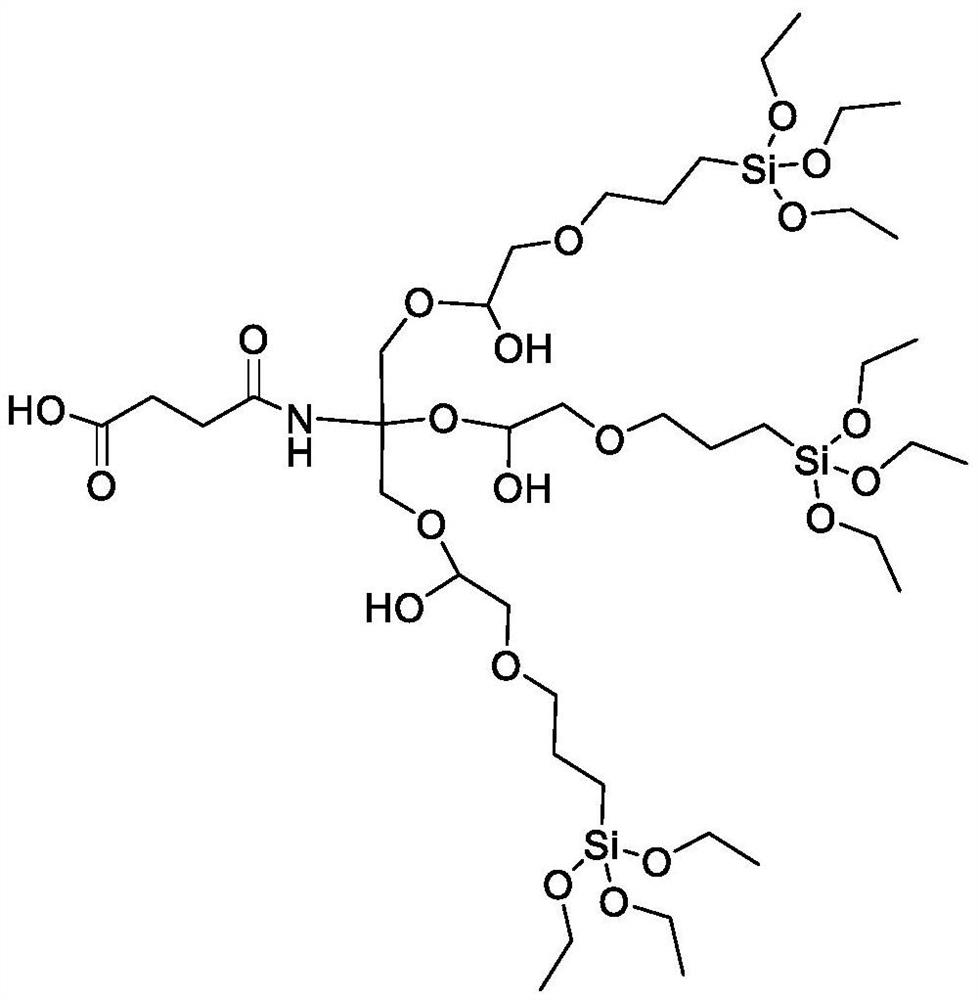

The invention relates to an MPP pipe for electric power engineering and a production process thereof, and belongs to the technical field of pipes. The MPP pipe comprises the following raw materials: modified PP resin, modified hyperbranched polysiloxane, an antioxidant, a solubilizer, a nucleating agent, a filler, a coupling agent and a master batch. The modified hyperbranched polysiloxane has the characteristics of high branched structure, low melting point, low viscosity and easiness in processing, molecules of the modified hyperbranched polysiloxane consist of hard chains and soft chains, and a long chain segment consisting of an azobenzene chain and a benzamide chain is a crystalline phase at low temperature, so that expansion and extension of cracks in a modified PP resin base material can be prevented, and the low-temperature impact resistance of the MPP pipe is further improved; and a molecular chain of the modified hyperbranched polysiloxane contains a benzotriazole structure, and the benzotriazole structure is connected into hyperbranched polysiloxane molecules in a chemical bond mode, so that the weather resistance and the stability of the weather resistance of the MPP pipe are improved.

Owner:HANGZHOU XINLU IND CO LTD

Liposome adjuvant, temperature-sensitive gel and temperature-sensitive gel preparation

PendingCN114306591AMedication is stableImprove efficacyAerosol deliveryOintment deliveryGel preparationCholesterol

The invention specifically discloses a liposome adjuvant, a temperature-sensitive gel and a temperature-sensitive gel preparation. The liposome adjuvant is prepared from the following components in parts by weight: 1 to 4 parts of DOTAP, 280 to 320 parts of soybean lecithin and 40 to 60 parts of cholesterol. The preparation method comprises the following steps: S1, dissolving DOTAP, soybean lecithin and cholesterol in a solvent; rotating and evaporating the solvent to dryness to obtain a film; s2, adding PBS (Phosphate Buffer Solution) into the film obtained in S1, stirring at 45-55 DEG C for 0.5-1.5 hours, and dissolving the film to obtain a liposome stock solution; s3, enabling the liposome stock solution to pass through a polycarbonate film, and extruding for 20-80 times to obtain the liposome adjuvant. The temperature-sensitive gel is prepared from poloxamer gel and a liposome adjuvant; the temperature-sensitive gel can be used for preparing a temperature-sensitive gel adjuvant. The liposome adjuvant has the advantages that the phase change temperature and viscosity of the temperature-sensitive gel can be adjusted, and the administration efficiency of the temperature-sensitive gel preparation can be improved.

Owner:LIAONING CHENGDA BIOTECH

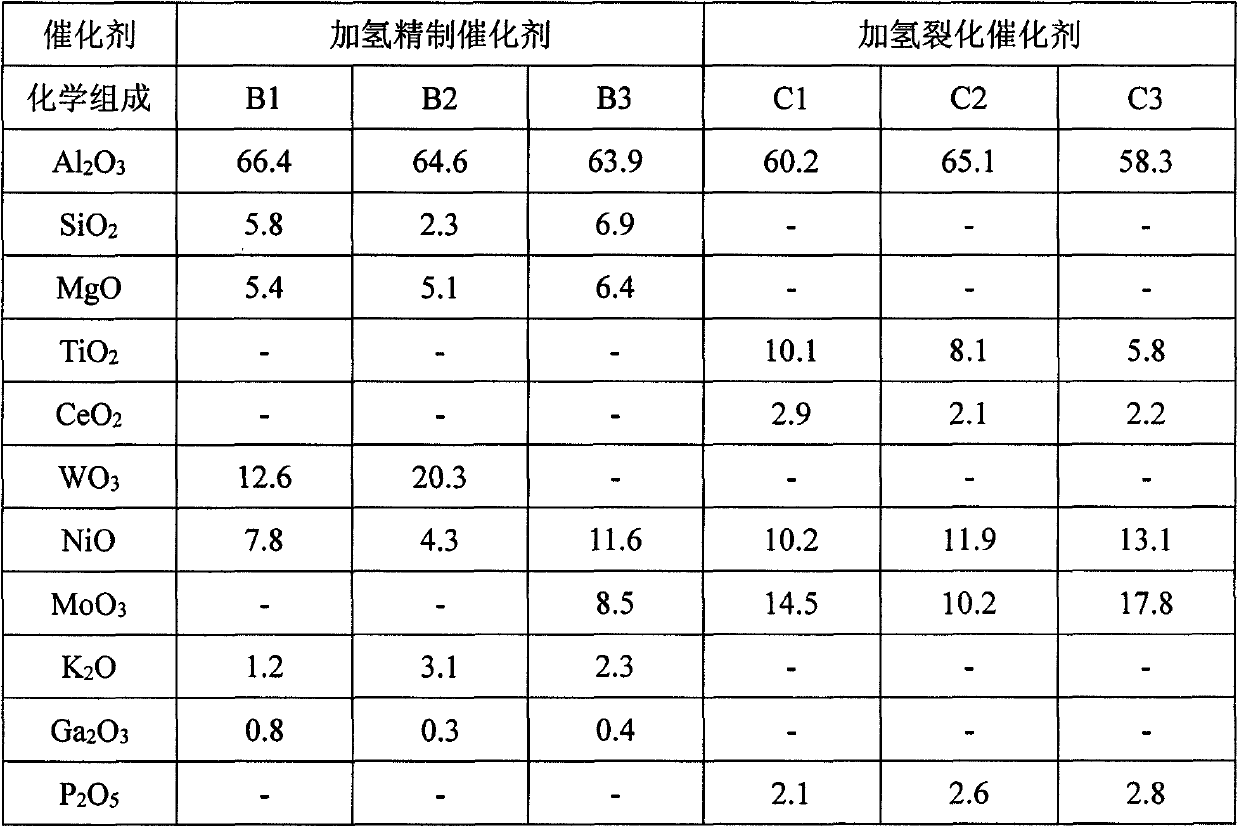

Method for preparing diesel by hydrogenating anthracene oil of coal tar

ActiveCN103695030AImprove stabilityInhibit coke cloggingTreatment with hydrotreatment processesPotassiumCerium

The invention relates to a method for preparing diesel by hydrogenating anthracene oil. The method comprises the following steps: reacting anthracene oil in hydrogenation reaction region containing a first catalyst; allowing the product oil obtained in the hydrogenation reaction region to enter a hydrocracking reaction region containing a second catalyst to react to prepare a diesel component finished product. The method has the advantages that hydrofining catalysts can realize hydrodesulfurization, hydrodenitrification and hydrodeoxygenation of coal tar and can improve activity, so that aromatic hydrocarbon is saturated and subjected to ring opening; an aid potassium is added into the catalysts, so easy-to-coke substances of the coal tar can be inhibited from coking and blocking reactors and the stability of the catalysts is improved; the acidity of a carrier is effectively controlled by adjusting the adding ratio of titanium dioxide and cerium dioxide of the carrier, so that hydrocracking activity and selectivity are improved; the titanium dioxide has strong adsorption capability on sulfur, so desulfuration is promoted; the cerium dioxide has high melting point, so the stability of the carrier is improved and the service life of the catalysts is prolonged.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH +1

High-temperature phase-transitional temperature-sensitive fire-extinguishing gel and preparation method thereof

InactiveCN102188781BRaise the phase transition temperatureFast transitionFire extinguisherBackbone chainEnvironmental engineering

The invention relates to a high-temperature phase-transitional temperature-sensitive fire-extinguishing gel and a preparation method thereof. Through the physical crosslinking between polyacid with a hydrophilic backbone structure and polyamine with a hydrophobic backbone structure, the fire-extinguishing gel is in a soluble state at a low temperature and in a gel state at a high temperature. Thefire-extinguishing agent is a low-viscosity aqueous solution at normal temperature; the viscosity is gradually increased as the temperature rises, and then the aquagel is formed and adhered on the surface of burning objects, thus the effect of fire-extinguishing is achieved and the fire behavior is blocked from spreading; after the temperature of the gel is lowered to a certain temperature, the gel is returned to the state of liquid, the residue can be cleaned by using water for flushing, thereby being efficient and environment-friendly. The fire-extinguishing agent provided by the invention has low viscosity, can be spouted by using the traditional squirt gun; meanwhile, other elements, such as fire-proofing agent, flame retardant, and the like, can be added to improve the fire-extinguishing performance of the fire-extinguishing agent.

Owner:SHANGHAI UNIV +1

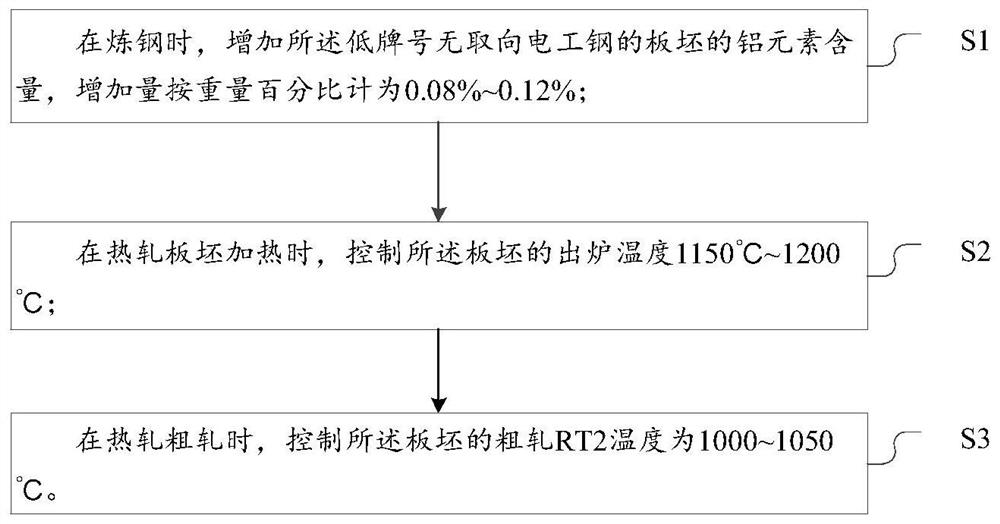

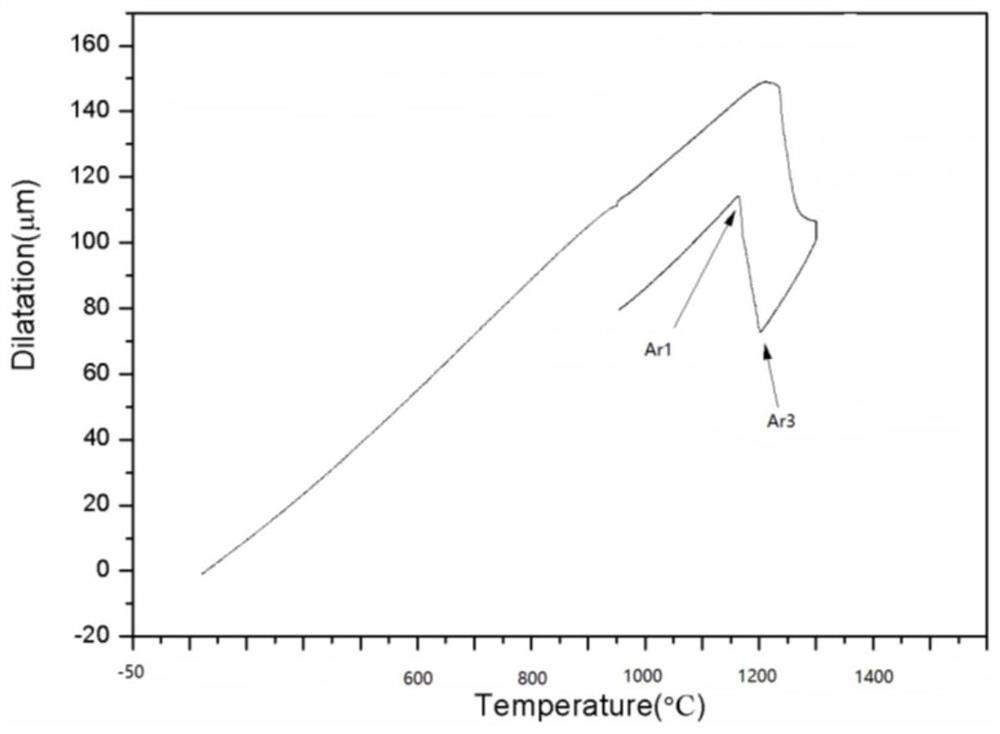

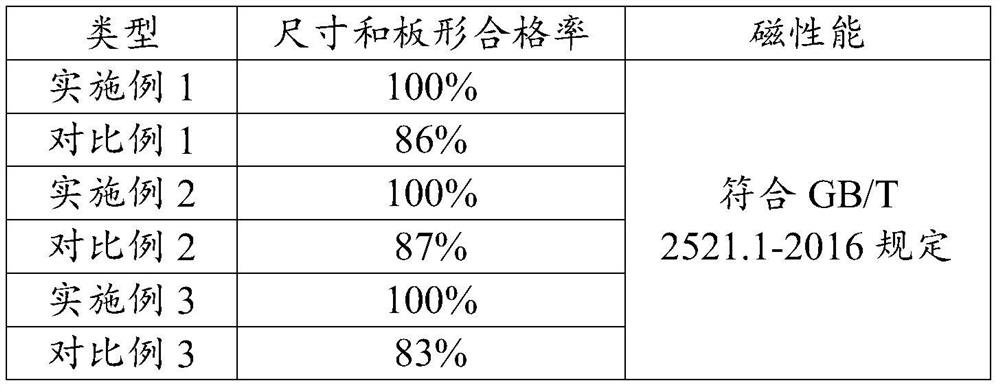

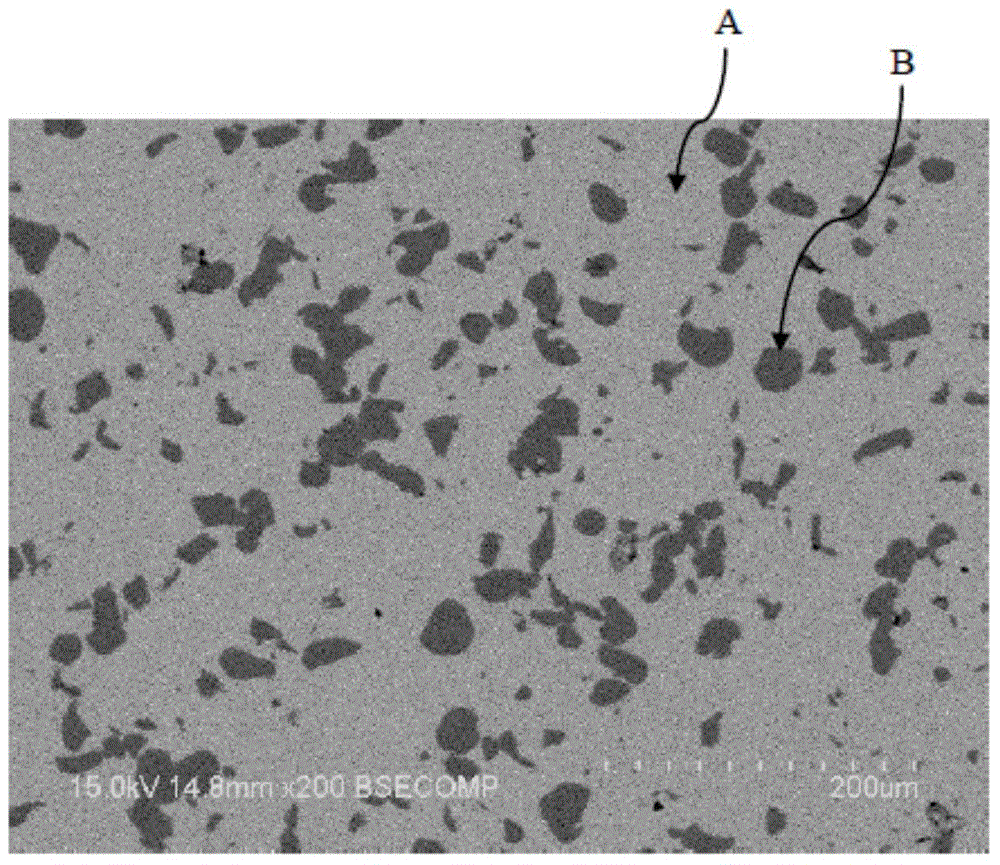

Low-grade non-oriented electrical steel and manufacturing method thereof

ActiveCN113564489AIncrease the content of aluminum elementRaise the phase transition temperatureTemperature control deviceSteelmakingTemperature control

The invention discloses a manufacturing method of low-grade non-oriented electrical steel. The method comprises the following steps of during steelmaking, increasing the content of an aluminum element in a plate blank of the low-grade non-oriented electrical steel by 0.08 to 0.12 weight percent; during the hot-rolled plate blank heating, controlling the tapping temperature of the plate blank to be 1150-1200 DEG C; and during hot rolling and rough rolling, controlling the rough rolling RT2 temperature of the plate blank to be 1000 to 1050 DEG C. According to the method, the phase transition temperature of the low-grade non-oriented electrical steel is increased by increasing the aluminum content; and the low-grade non-oriented electrical steel is enabled not to generate rolling force fluctuation due to rolling of a phase transition region in the finish rolling process by combining the tapping temperature control and the rough rolling RT2 temperature control of the plate blank, so that the finish rolling process is stabilized, and the size and plate shape precision of a low-grade non-oriented electrical steel plate coil after finish rolling are improved.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

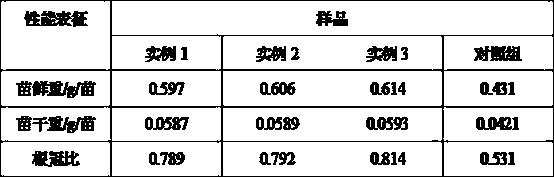

Preparation method for low-temperature-resistant seed coating agent material

InactiveCN108192426AImprove low temperature resistanceRaise the phase transition temperatureSeed coating/dressingHyaluronic acid coatingsSurface layerCuticle

The invention relates to a preparation method for a low-temperature-resistant seed coating agent material, belonging to the technical field of agricultural materials. According to the invention, cholesterol and lecithin are used as wall materials for wrapping of a paraffin material, so a microcapsule particle is prepared; prepared paraffin condenses and releases a great amount of heat when encountering with cold, so the low-temperature resistance of the seed coating agent material is effectively improved; meanwhile, since the surface layer of a prepared seed coating agent has a gel with a hydrophilic structure, the seed coating agent can effectively bond with interior moisture in the epidermal cells of seeds, so partial dehydration of the cells before freezing of the seeds is avoided, thephase transition temperature of cell membranes is improved, and the low-temperature resistance of the seed coating agent material is effectively improved; and an internal structure with the hydrophobic structure is adopted to effectively prevent water from sufficiently penetrating the surface of the seed coating agent, so the internal structure serves as a protective layer to effectively protect internal seed coats from damage by ice crystals formed by freezing and reduce damage to seed coats caused by a low temperature environment, and thus, the low-temperature resistance of the seed coatingagent is effectively improved.

Owner:俞小峰

Copper silicon alloy sputtering target material and copper silicon alloy recording layer

InactiveCN104575532AHigh modulation valueRaise the contrast valueRecord information storageOptical record carrier manufactureSilicon alloyTitanium

The invention provides a copper silicon alloy sputtering target material and a copper silicon alloy recording layer. The copper silicon alloy sputtering target material and the copper silicon alloy recording layer both consist of CuaSibMc alloy, wherein M is nickel, chromium, molybdenum or titanium, a is 0.55-0.93, b is 0.05-0.25, c is 0.02-0.20, and the sum of a, b and c is 1. The copper silicon alloy recording layer contains copper, silicon, nickel, chromium, molybdenum or titanium with appropriate contents, so that a phase transition temperature is higher than 150 DEG C and is lower than 500 DEG C, and when being applied to optical recording media, the copper silicon alloy recording layer can obtain favorable recording quality, favorable stability and higher programming speed.

Owner:SOLAR APPLIED MATERIALS TECHNOLOGY CORPORATION

High-damping high-thermal-conductivity gold alloy for bonding wires in electronic fields and technic thereof

InactiveCN109881037AImprove damping performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesThermal conductivitySocial benefits

The invention discloses a high-damping high-thermal-conductivity gold alloy for bonding wires in electronic fields and a technic thereof. The alloy comprises the following components of, in percentageby weight, 20.0-25.0wt.% of Mn, 4.0-5.0wt.% of Fe, 1.0-2.0wt.% of Ni, 0.4-0.6wt.% of Ge, 0.1-0.2wt.% of Sc, 0.2-0.4wt.% of Ru, 2.0-3.0wt.% of Sn, 0.1-0.2wt.% of Be and the balance Au. The gold alloyprovides a solution which is different from that of a traditional material for gold alloy bonding wires which work in electronic devices with obvious vibration, so that the current situation that existing gold bonding wires do not have damping performance can be effectively overcome. It is predicted that implementation and industrialization of the gold alloy not only can effectively avoid fatiguedamage to the gold bonding wires caused by vibration, but also can obtain great social benefits and economic benefits.

Owner:杭州辰卓科技有限公司

Fabric with bidirectional temperature adjusting performance and preparation method thereof

InactiveCN108560125AImproved phase transition temperature and thermoregulation performanceIncrease thermal activityWeft knittingDyeingEngineering

The invention discloses a fabric with bidirectional temperature adjusting performance and a preparation method thereof. The method comprises the following steps: (1) mixing PEG compound, a cross-linking agent and a catalyst and evenly stirring to obtain a temperature adjusting work solution; (2) utilizing a twice-soaking twice-rolling mode to mix and dip dye the temperature adjusting work solutionand fiber fabric according to a material-liquid ratio of (0.5 to 1) to (0.8 to 1.5), wherein each time of dip dyeing is for 3 to 5h; (3) pre-drying a product obtained in the step (2) for 30 to 40minunder the condition of 50 to 60 DEG C and then continuing drying for 4 to 8 min under 130 to 150 DEG C to obtain the fabric with the bidirectional temperature adjusting performance. The prepared fabric disclosed by the invention has the excellent bidirectional temperature adjusting performance and greatly improves clothes comfortableness and environmental temperature adaptability.

Owner:CHENGDU AERONAUTIC POLYTECHNIC

Copper-silicon alloy sputtering target and copper-silicon alloy recording layer

InactiveCN104575532BAppropriate phase transition temperature rangeReduce contentRecord information storageOptical record carrier manufactureSilicon alloyOptical recording

Owner:SOLAR APPLIED MATERIALS TECHNOLOGY CORPORATION

Inorganic phase change energy storage particles, floor heating mortar and preparation method thereof

An inorganic phase change energy storage particle, floor heating mortar and a preparation method thereof, wherein the mass percentage composition of the inorganic phase change energy storage particle includes: 20%-50% inorganic phase change material, 10%-25% water, 0.1%-1.5% Phosphated starch glue, 0.1%-1.5% water-absorbing resin, 10%-35% gypsum and 15%-35% cement; prepared phosphated starch glue, ingredients, mixing, granulation and coating, and coating The ground heating mortar is composed of 15% to 35% cement, 10% to 25% sand, 20% to 50% inorganic phase change energy storage particles, and 20% to 30% water; it is prepared by batching and mixing. The invention has wide sources of raw materials, good chemical stability, low phase transition temperature, no leakage, good energy storage effect of energy storage particles, high stability, high strength of floor heating mortar, can effectively adjust indoor temperature, good energy saving effect, and can be widely used It is widely used in residential buildings, schools, hospitals and other buildings.

Owner:SOUTHWEAT UNIV OF SCI & TECH

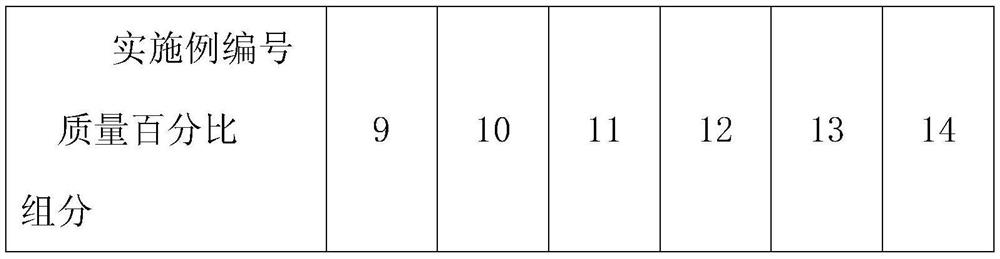

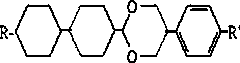

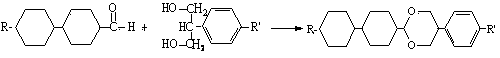

Liquid crystal monomer bicyclohexyl-containing epoxyethane compound and synthetic method thereof

ActiveCN102838584BThe synthetic route is simpleReduce molecular viscosityLiquid crystal compositionsOrganic chemistryCrystallographyDielectric anisotropy

The invention discloses a liquid crystal monomer bicyclohexyl-containing epoxyethane compound and a synthetic method thereof. The liquid crystal monomer bicyclohexyl-containing epoxyethane compound has such structure, wherein R is one of fluorine, chlorine, H, C1-C5 linear chain alkyl and C1-C5 linear chain alkoxy; R' is one of fluorine, chlorine, H, C1-C5 linear chain alkyl, C1-C5 linear chain alkoxy, and cyan; and such compound can be independently or mixed to be used for liquid crystal display in various forms. The liquid crystal monomer bicyclohexyl-containing epoxyethane compound and the synthetic method provided by the invention have the characteristics that the liquid crystal display is achieved, the demands on 3D (three-dimensional) display technology are met, the rotating viscosity of a liquid crystal material is reduced, and the dielectric anisotropy coefficient of the liquid crystal material is improved.

Owner:山东盛华电子新材料有限公司

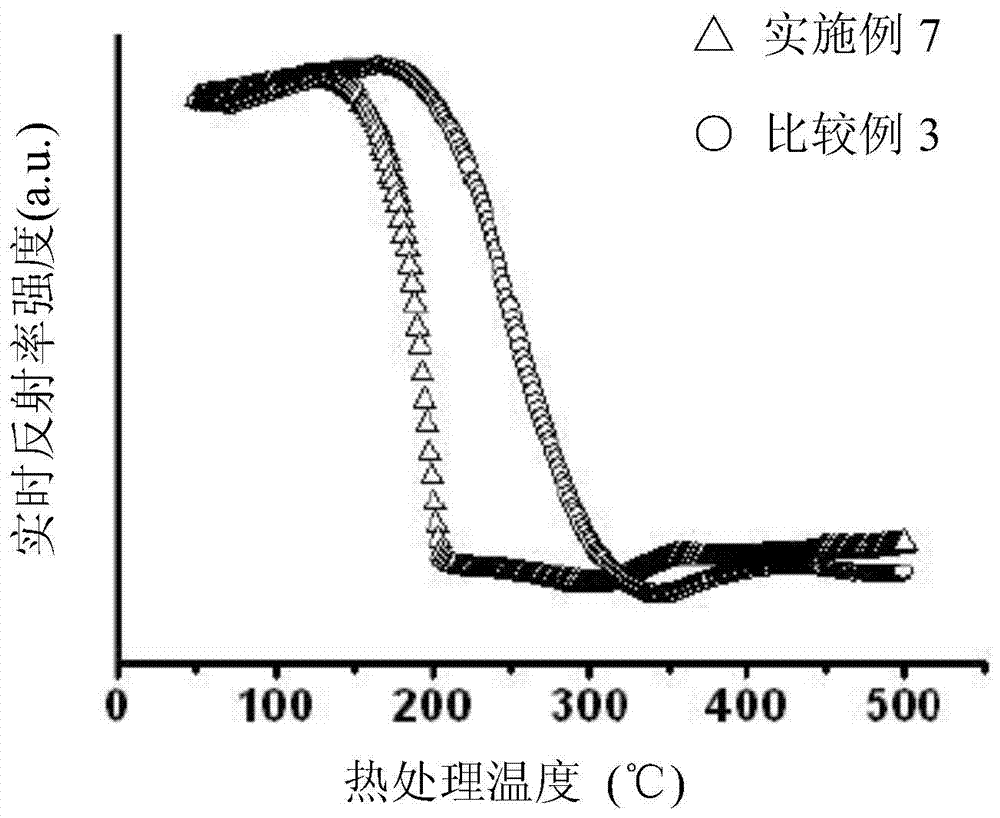

A perovskite-based inverted thin-film solar cell and its preparation method

ActiveCN105006522BWide absorption rangeRaise the phase transition temperatureSolid-state devicesSemiconductor/solid-state device manufacturingElectrical batteryPerovskite (structure)

The invention belongs to the field of thin-film solar cells, and relates to a perovskite-based inverted thin-film solar cell and a preparation method thereof. The thin-film solar cell is based on an inverted planar structure and uses a FAPbI3 perovskite system as a light-absorbing layer. Prepared under low temperature conditions by solution method. This thin film battery uses a new type of FAPbI3 perovskite system as the light absorbing layer, which has a wider absorption range, higher phase transition temperature and better stability than the traditional MAPbI3 perovskite system; avoid Based on the disadvantages of high-temperature sintering in the traditional inverted structure, the cost can be greatly reduced in industrial production; the thin-film solar cell is not only simple in preparation method, low in cost, but also has good repeatability, and can realize low-cost roll-to-roll mode. It has very potential application value in future industrialized production.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com