Quaternary relaxation piezoelectric single crystal material and growing method thereof

A piezoelectric single crystal, quaternary system technology, applied in the direction of polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the limited application range, only 75 ℃ and 70 ℃, PMN-PT and PZN-PT Low phase transition temperature and other issues, to achieve the effect of wide application prospects, small electromechanical coupling performance, and superior piezoelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

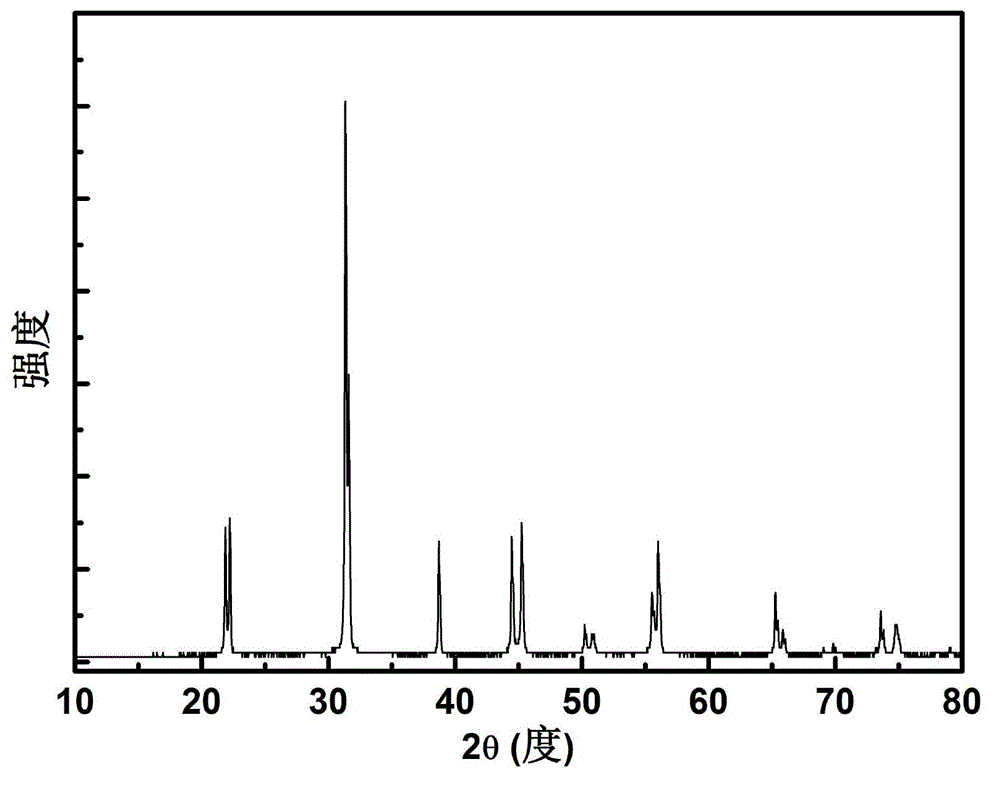

[0024] The high-purity raw material Bi 2 O 3 , MgO, Nb 2 O 5 , In 2 O 3 , TiO 2 and Al 2 O 3 According to the chemical formula 0.36Pb (Mg 1 / 3 Nb 2 / 3 )O 3 -0.25Pb(In 1 / 2 Nb 1 / 2 )O 3 -0.07BiAlO 3 -0.32PbTiO 3 After the stoichiometric ratio of the ingredients is mixed uniformly, it is kept at a temperature of 1100 ° C for 10 hours, and then mixed with the PbO weighed according to the stoichiometric ratio, and then pre-fired again at a temperature of 900 ° C for 2 hours under the condition of holding the temperature. The mixing is briqueted by cold isostatic pressing. The briquette is placed in a cylindrical platinum crucible together with the selected seed crystal with an orientation of (111). The crucible is sealed and placed in the crucible descending furnace for crystal growth. Continue to heat up to 1350 °C for 10 h to melt the starting material, and adjust the crucible position to melt the top of the seed crystal. The temperature gradient of the growth interf...

Embodiment 2

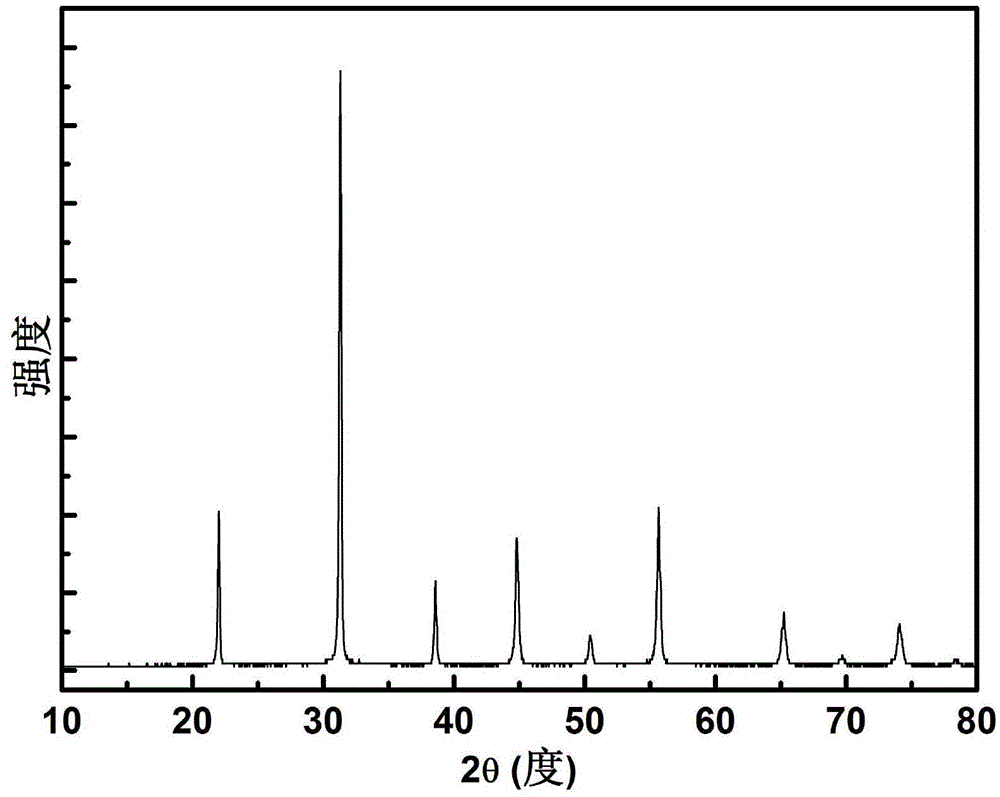

[0026] The high-purity raw material Bi 2 O 3 , MgO, Nb 2 O 5 , In 2 O 3 , TiO 2 and Al 2 O 3 According to the chemical formula 0.20Pb (Mg 1 / 3 Nb 2 / 3 )O 3 -0.39Pb(In 1 / 2 Nb 1 / 2 )O 3 -0.12BiAlO 3 -0.29PbTiO 3 After the stoichiometric ratio ingredients are evenly mixed, they are kept at a temperature of 1000 ° C for 12 hours, and then mixed with the Pb weighed in stoichiometric ratio. 3 O 4 After mixing, briquetting was performed by cold isostatic pressing. The briquette is placed in a rectangular platinum crucible together with the selected seed crystal with an orientation of (110). The crucible is sealed and placed in the crucible descending furnace for crystal growth. The temperature is kept at 1200 ° C for 8 hours, and then the temperature is continued. Keep the temperature at 1370 °C for 6 h to melt the starting material, and adjust the position of the crucible to melt the top of the seed crystal. The temperature gradient of the growth interface is 30 °C / cm,...

Embodiment 3

[0028] The high-purity raw material Bi 2 O 3 , MgO, Nb 2 O 5 , In 2 O 3 , TiO 2 and Al 2 O 3 According to the chemical formula 0.30Pb (Mg 1 / 3 Nb 2 / 3 )O 3 -0.21Pb(In 1 / 2 Nb 1 / 2 )O 3 -0.28BiAlO 3 -0.21PbTiO 3 After the stoichiometric ratio ingredients are evenly mixed, keep at a temperature of 1100 ° C for 9 hours, and then mix with PbO and Pb in a 1:1 molar ratio weighed according to the stoichiometric ratio. 3 O 4 After mixing, it is pressed and formed by a powder tablet machine, and the briquette is placed in a cylindrical iridium crucible together with the selected seed crystal with an orientation of (100), and the crucible is sealed and placed in a crucible descending furnace for crystal growth. , pass argon into the furnace for protection, first raise the furnace temperature to 1200 °C for 3 hours, and then continue to heat up to 1400 °C for 6 hours to melt the starting material, and adjust the crucible position to melt the top of the seed crystal. The temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric constant | aaaaa | aaaaa |

| Loss tangent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com