High-damping shape memory alloy

A memory alloy and high damping technology, applied in the field of damping materials, can solve the problems of Cu-Zn-Al shape memory alloys with inferior mechanical properties, processability and corrosion resistance, high cost of TiNi shape memory alloys, and limited application of damping alloys, etc. , to achieve the effect of remarkable economy, excellent comprehensive performance and lower application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Ti50Ni24Cu25Y and Ti50Ni25Cu25 alloys were prepared by vacuum induction melting.

[0029] 1. Put the sponge titanium, electrolytic nickel and oxygen-free copper prepared according to the atomic ratio into a vacuum induction furnace for melting;

[0030] 2. For Ti50Ni24Cu25Y alloy, add element Y into the molten pool 1 minute before it comes out of the furnace;

[0031] 3. Pouring at 1420-1450°C, pouring the molten Ti50Ni24Cu25Y and Ti50Ni25Cu25 alloys into the mold shell or crucible;

[0032] 4. After the mold shell or crucible is cooled, the alloy can be taken out;

[0033] 5. According to the needs, carry out necessary heat treatment and machining on the alloy, and prepare Ti50Ni24Cu25Y and Ti50Ni25Cu25 alloy products or experimental samples;

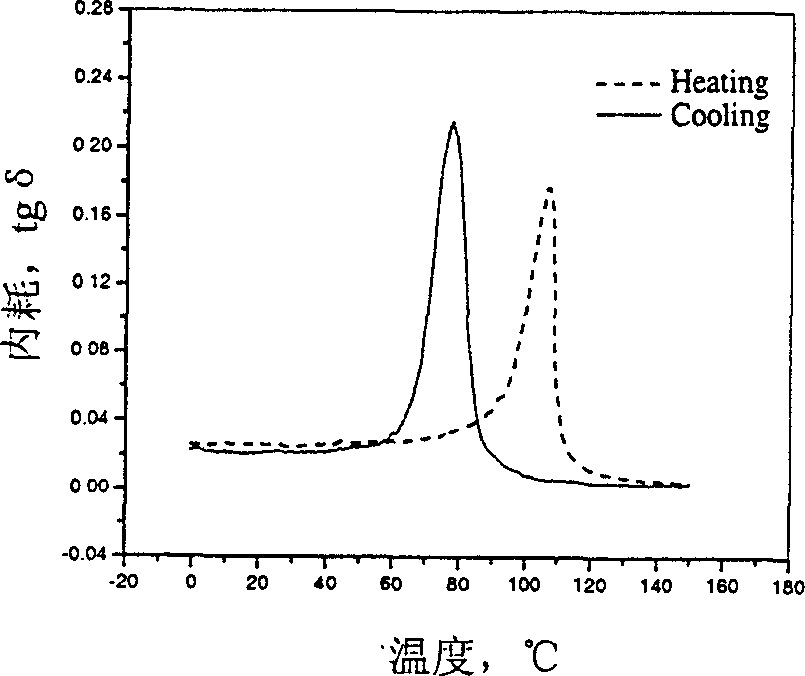

[0034] 6. The thermoelastic martensitic phase transition temperature of Ti50Ni24Cu25Y and Ti50Ni25Cu25 alloys was measured on a Rheometric Scientific DSC SP instrument. DSC experimental conditions: heating and cooling rate is ...

Embodiment 2

[0040] Ti50Ni(25-x)Cu25Yx(x=0, 0.1, 0.3, 0.5, 1 and 2) alloys were prepared by magnetron tungsten casting (non-consumable) electric arc furnace protected by argon.

[0041] 1. Put the industrially pure titanium, electrolytic nickel, oxygen-free copper and element Y prepared according to the atomic ratio into the water-cooled copper crucible of the argon-protected magnetron tungsten casting (non-consumable) electric arc furnace;

[0042]2. Heating and magnetic stirring to smelt the alloy;

[0043] 3. Melt the alloy repeatedly for 3 times (or more) to ensure the uniformity of the alloy composition;

[0044] 4. After the crucible is cooled, the alloy ingot can be taken out;

[0045] 5. According to the needs, carry out necessary heat treatment and machining on the alloy to prepare Ti50Ni(25-x)Cu25Yx alloy products or experimental samples;

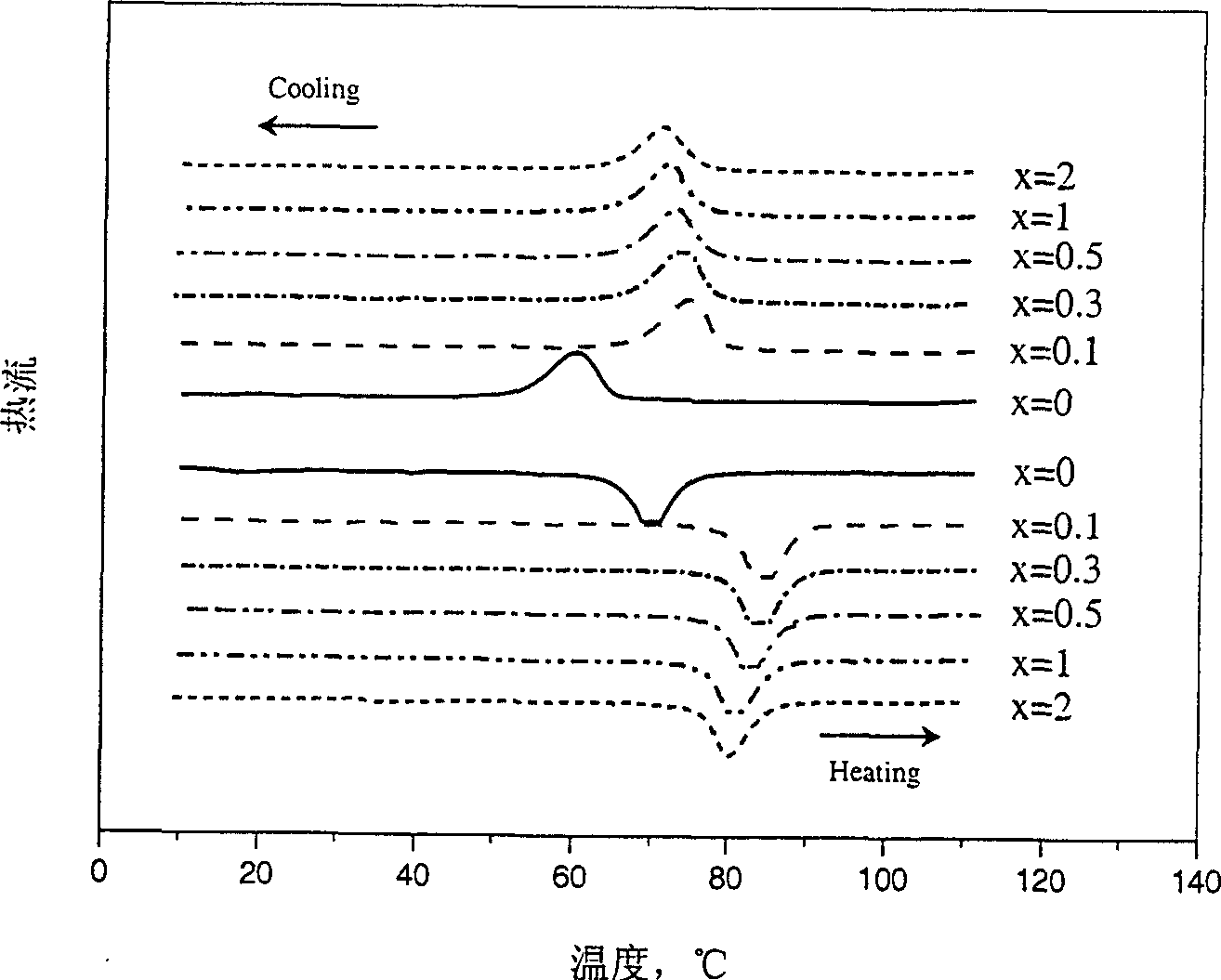

[0046] 6. The thermoelastic martensitic phase transition temperature of Ti50Ni(25-x)Cu25Yx alloy was measured on Rheometric Scientific DSC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com