Convenient method for preparing binder-free stannic oxide/carbon fibrofelt for negative pole of high-performance lithium ion battery

A lithium-ion battery, carbon fiber felt technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of limited laboratory conditions, unfavorable large-scale production, cumbersome synthesis steps, etc., to suppress volume changes, improve electrical conductivity and Catalytic ability, effect of improving mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

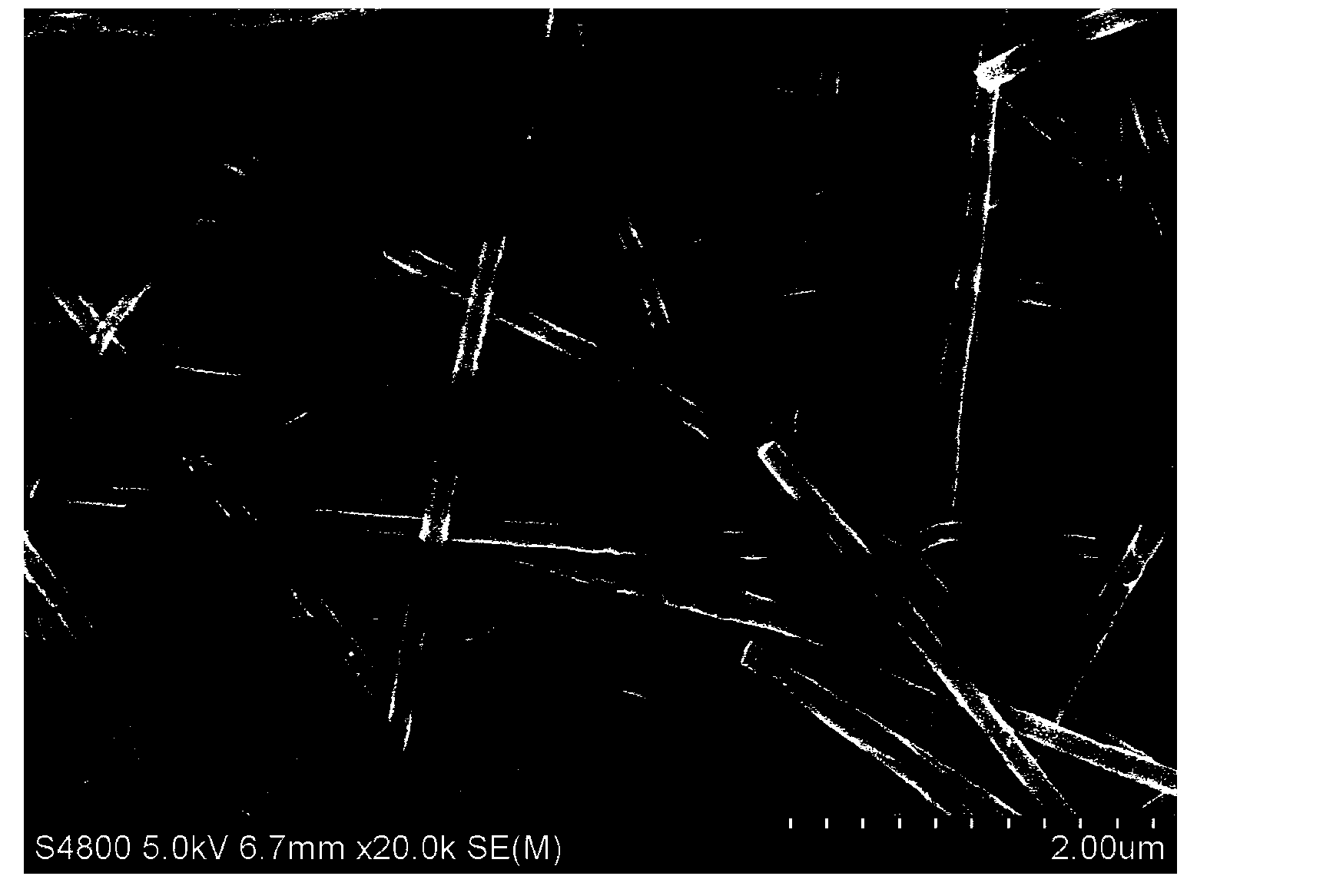

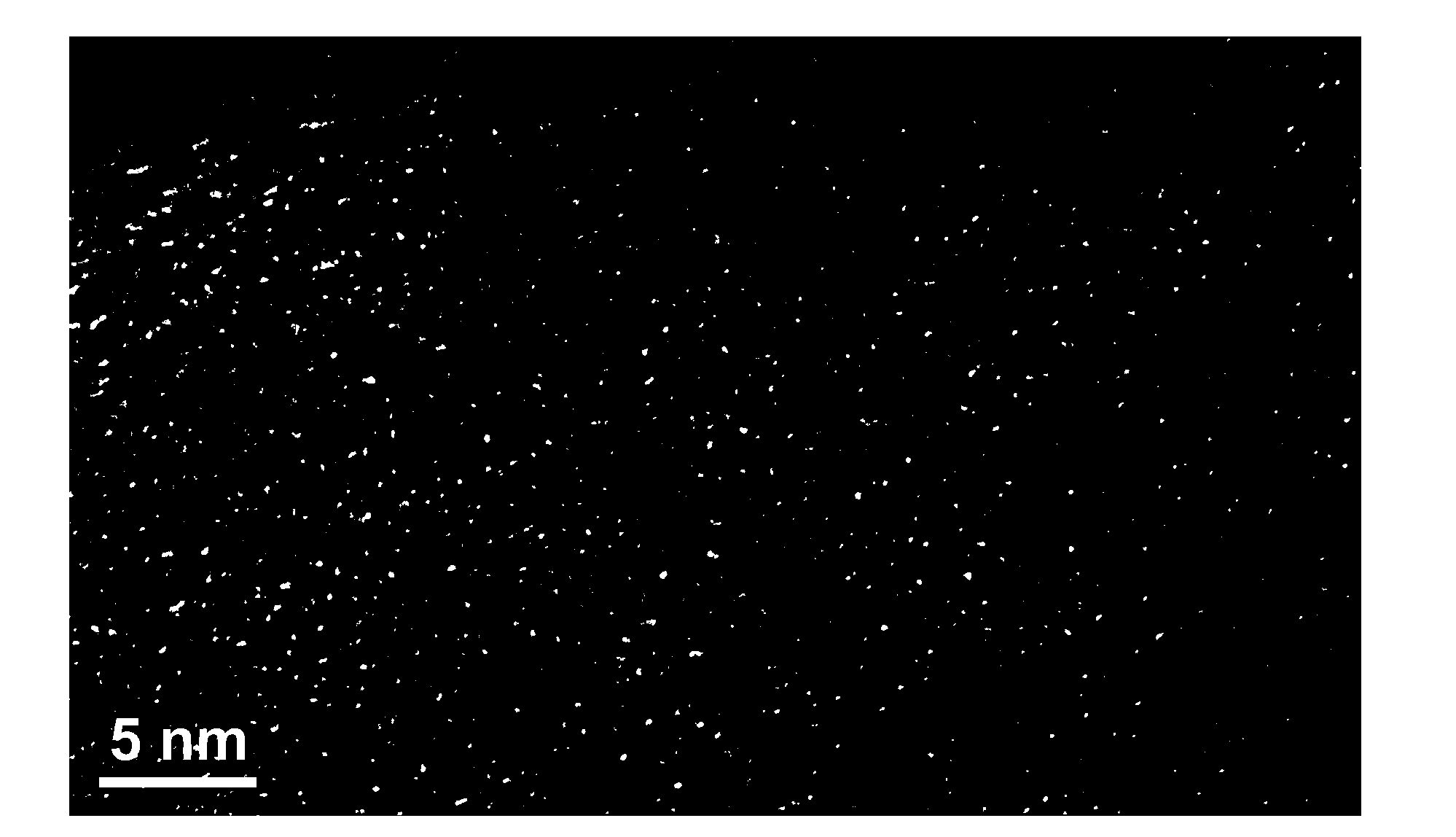

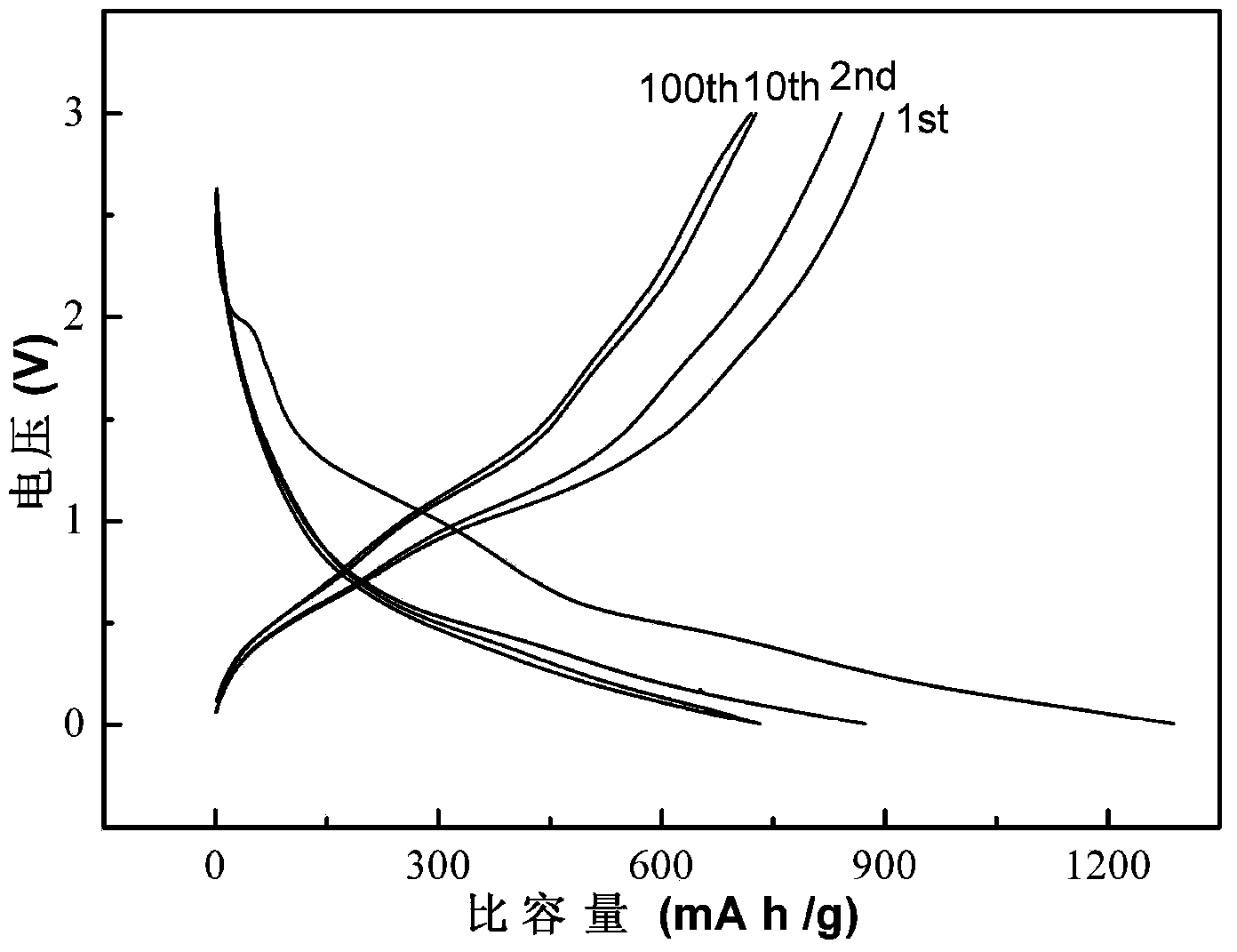

[0022] First take the GO suspension; then take PAN (polyacrylonitrile), dihydrate tin dichloride dissolved in DMF, the concentration is 6.5% and 2.5% respectively, and mix the graphene oxide suspension as the precursor solution; the precursor solution At 60°C, stir magnetically until the mixture turns into a clear solution, and the color changes from transparent light brown to black (graphene color); the precursor solution is transferred to a 10ml syringe with a 0.7mm inner diameter stainless steel needle, and the syringe pump Control the flow rate of the precursor solution, which is about 0.1-0.8ML / h; the aluminum foil heat sink is used as the collecting plate, the needle is perpendicular to the collecting plate, and the distance is 8-15cm, and the DC high voltage source is selected as a high voltage of 8-15KV; Dry in a vacuum oven at 80°C overnight, pre-oxidize in air at 230°C for 4 hours (1°C / min), then cut into pieces, and then carbonize in argon at 700°C (5°C / min) for 2 ho...

Embodiment 2

[0025] First take the GO suspension; then take PAN (polyacrylonitrile), dihydrate tin dichloride dissolved in DMF, the concentration is 5.5% and 1.5% respectively, and mix the graphene oxide suspension as the precursor solution; the precursor solution At 60°C, stir magnetically until the mixture turns into a clear solution, and the color changes from transparent light brown to black (graphene color); the precursor solution is transferred to a 10ml syringe with a 0.7mm inner diameter stainless steel needle, and the syringe pump Control the flow rate of the precursor solution, which is about 0.1-0.8mL / h; the aluminum foil heat sink is used as the collecting plate, the needle is perpendicular to the collecting plate, and the distance is 8-15cm, and the DC high voltage source is selected as a high voltage of 8-15KV; Dry in a vacuum oven at 80°C overnight, pre-oxidize in air at 220°C for 4 hours (1°C / min), then cut into pieces, and then carbonize at 600°C (5°C / min) in argon for 2 ho...

Embodiment 3

[0028] First take the GO suspension; then take PAN (polyacrylonitrile), dihydrate tin dichloride dissolved in DMF, the concentration is 7.5% and 1.5%, respectively, mixed graphene oxide suspension, as the precursor solution; the precursor solution At 60°C, stir magnetically until the mixture turns into a clear solution, and the color changes from transparent light brown to black (graphene color); the precursor solution is transferred to a 10ml syringe with a 0.7mm inner diameter stainless steel needle, and the syringe pump Control the flow rate of the precursor solution, which is about 0.1-0.8mL / h; the aluminum foil heat sink is used as the collecting plate, the needle is perpendicular to the collecting plate, and the distance is 8-15cm, and the DC high voltage source is selected as a high voltage of 8-15KV; Dry in a vacuum oven at 80°C overnight, pre-oxidize in air at 210°C for 4 hours (1°C / min), then cut into pieces, and then carbonize at 500°C (5°C / min) in argon for 2 hours....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com