Heat-resistant electronic membrane and preparation method thereof

An electronic film, heat-resistant technology, applied in the direction of coating, can solve the problems of difficult to meet engineering technology, high cross-linking density, poor weather resistance and heat and humidity resistance, etc., to achieve good curing effect, good compatibility, compatibility Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

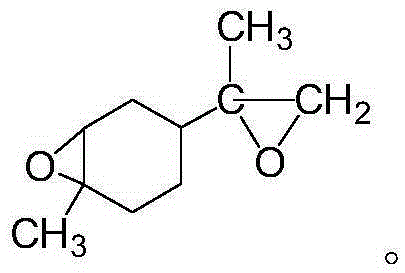

[0024] Mix 9g of di-n-hexylamine and 13g of filler for 1 hour, then add 1.2g of N-formylmorpholine, 10g of N,N-dimethylaniline and 1.8g of sodium iodide, and mix for 2 hours to obtain a mixture; Diepoxide and 6g of 2,6-bis(4-aminophenoxy)benzonitrile were added to the mixture and stirred at 170°C for 5 minutes to obtain a compound; the compound was added to the extruder; then the surface was The polyimide film (thickness is 0.2mm) after the corona treatment passes through the extruder at a speed of 1m / min, and the compound is coated on the treated polyimide film by the extrusion die to prepare the composite polyimide film. Imide film; heat-resistant electronic film obtained after composite polyimide film is formed; thickness is 0.22mm.

Embodiment 2

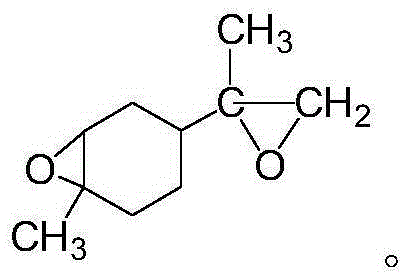

[0026] Mix 9g of di-n-hexylamine and 14g of filler for 1 hour, then add 1.3g of N-formylmorpholine, 9g of N,N-dimethylaniline and 1.6g of sodium iodide, and mix for 2 hours to obtain a mixture; Diepoxide and 8g of 2,6-bis(4-aminophenoxy)benzonitrile were added to the mixture and stirred at 170°C for 5 minutes to obtain a compound; the compound was added to the extruder; then the surface was The polyimide film after corona treatment passes through the extruder at a speed of 1m / min, and the compound is coated on the treated polyimide film by the extrusion die to prepare a composite polyimide film; The polyimide film is processed to obtain a heat-resistant electronic film.

Embodiment 3

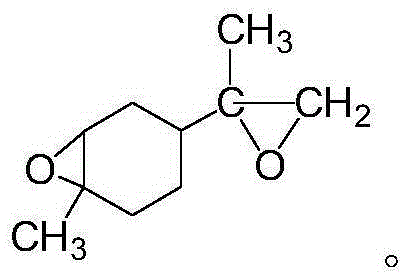

[0028] Mix 9g of di-n-hexylamine and 13g of filler for 1 hour, then add 1.3g of N-formylmorpholine, 9g of N,N-dimethylaniline and 1.8g of sodium iodide, and mix for 2 hours to obtain a mixture; Diepoxide and 8g of 2,6-bis(4-aminophenoxy)benzonitrile were added to the mixture and stirred at 170°C for 5 minutes to obtain a compound; the compound was added to the extruder; then the surface was The polyimide film after corona treatment passes through the extruder at a speed of 1m / min, and the compound is coated on the treated polyimide film by the extrusion die to prepare a composite polyimide film; The polyimide film is processed to obtain a heat-resistant electronic film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com